Introduction

The Agras MG-1P series (MG-1P / MG-1P RTK) from SZ DJI TECHNOLOGY CO., LTD. represents a new frontier in precision agriculture. Engineered for rigorous field operations, these advanced agricultural drones are purpose-built for efficient crop spraying, intelligent route planning, and real-time environmental awareness. Both the MG-1P and its RTK variant are tailored to meet the demands of modern large-scale farming, offering robust obstacle avoidance, multi-drone control, and high-precision navigation.

Crucially, the Agras MG-1P series is certified under FCC ID SS3-MG1P1801, confirming its adherence to stringent US radio frequency emission standards. This certification is more than a regulatory checkbox—it’s a guarantee of legal marketability, electromagnetic compatibility, and safe operation within US airspace. While the FCC grant date is listed as none, the device’s registration at FCC.gov ensures its compliance and underscores DJI’s commitment to reliability and safety.

In this article, we’ll explore the Agras MG-1P series’ key features, technical specifications, wireless technologies, and internal hardware. We’ll also analyze its regulatory standing and real-world use cases, providing an expert teardown perspective for engineers, drone operators, and tech enthusiasts alike.

Key Features & Specifications

The Agras MG-1P series is a sophisticated agricultural drone platform, blending advanced flight control, rugged design, and state-of-the-art wireless communication. Below are the standout features and technical specifications that define its performance and utility.

Key Features

-

Remote Controller with OcuSync Dual-Band Video Downlink:

The second-generation DJI OcuSync system supports both 2.4 GHz and 5.8 GHz bands, enabling stable, low-latency video transmission over long distances. This ensures real-time situational awareness for operators in dynamic environments. -

Intelligent Obstacle Sensing and Avoidance:

Equipped with high-precision radar, the MG-1P detects and automatically avoids obstacles up to 30 meters away. This is vital for safe, autonomous operation in complex agricultural landscapes. -

Rugged, Field-Ready Design:

The drone’s IP43-rated body is dust-proof, water-resistant, and anti-corrosive, making it ideal for harsh outdoor conditions and prolonged use in agricultural settings. -

A3 Redundancy System & Eight-Rotor Propulsion:

With the DJI A3 flight controller and eight-rotor redundancy, the MG-1P series offers exceptional reliability and stability, even in the event of single-rotor failure. -

Advanced Radar Module:

The integrated radar supports both terrain following and obstacle avoidance, providing centimeter-level altitude control for consistent spraying results. -

Intelligent Operation Planning:

The system features waypoint and route planning, allowing operators to predefine missions for efficient, repeatable field coverage. -

MG-1P RTK with DJI Onboard D-RTK:

The RTK variant includes a built-in DJI Onboard D-RTK module, delivering centimeter-level positioning accuracy—a game-changer for precision agriculture. -

Wide-Angle FPV Camera:

A front-mounted, wide-angle FPV camera supports real-time field monitoring and enhances operational safety.

Technical Specifications

- Charging Hub Operating Temperature: 41° to 104° F (5° to 40° C)

- Remote Controller Battery Energy: 37.39 Wh

- AC Power Adapter Rated Power: 57 W

- Operating Frequency: 2.400 GHz to 2.483 GHz, 5.725 GHz to 5.850 GHz (not supported in Japan)

- Charging Hub Input Voltage: 17.3 – 26.2 V

- MG-1P RTK Dimensions (Arms Unfolded, Propellers Removed): 1460 mm × 1460 mm × 616 mm

- Radar EIRP:

- SRRC: 13 dBm

- FCC/CE/MIC/KCC: 20 dBm

- Diagonal Wheelbase: 1500 mm

- Wi-Fi: 2.400 GHz – 2.483 GHz, 5.725 GHz – 5.850 GHz (not supported in Japan)

- Bluetooth: Present (details not specified)

- Battery & Flight Time:

- Hovering Time: 9 min (23.7 kg takeoff weight, 12000 mAh battery)

- 22 min (14 kg takeoff weight)

- 20 min (13.7 kg takeoff weight, 12000 mAh battery)

- Battery Model: MG-12000P

These features and specs empower operators to conduct large-scale, precise spraying missions with confidence, maximizing efficiency while minimizing operational risk.

Operating Frequencies

The Agras MG-1P series (FCC ID SS3-MG1P1801) utilizes multiple frequency bands for its wireless communications, as detailed in its FCC filings:

| Frequency Range (GHz) | Output Power (mW) | FCC Rule Part |

|---|---|---|

| 2.4035–2.4775 | 203 | 15CCC2.12.4055 |

| 2.4775 | 87 | 15CCC2.25.7285 |

| 5.8465 | 220 | 15E38 |

| 15.7305–5.8445 | 229 | 15E38 |

These operating bands are critical for robust, interference-resistant wireless video downlink, remote control, and data telemetry. The specified output powers and regulatory rule parts confirm the device’s alignment with FCC Part 15 requirements for unlicensed wireless operation.

Technology Deep Dive

The Agras MG-1P series leverages a suite of wireless technologies to deliver seamless, reliable connectivity in the field. Its primary wireless interfaces include dual-band Wi-Fi (2.4 GHz and 5.8 GHz), as well as Bluetooth for short-range device pairing or maintenance tasks. The OcuSync video downlink system, operating across these bands, ensures real-time, high-definition video transmission with low latency—essential for FPV piloting and mission oversight.

The use of multiple frequency bands bolsters communication reliability, allowing the system to dynamically select the optimal channel for minimal interference. This is particularly valuable in rural environments, where agricultural machinery and other RF sources may coexist. The specified output powers (up to 229 mW) provide a balance of extended range and regulatory compliance, while the adoption of advanced modulation and error correction techniques helps maintain signal integrity.

From a performance perspective, these wireless technologies support long-range operation, multi-drone control, and robust data links even in challenging RF environments. The integration of Bluetooth, though less detailed in the documentation, likely facilitates device setup, diagnostics, or accessory connectivity. Overall, the MG-1P series’ RF architecture is designed for reliability, scalability, and safety—meeting the demands of professional agricultural drone fleets.

In-Depth Internal Component Analysis / Teardown

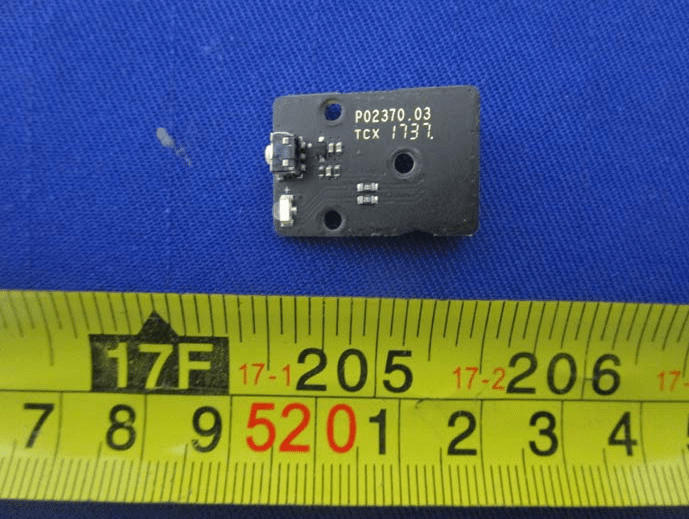

Compact Sensor or Interface Board

A compact black PCB, labeled ‘P02370.03 TCX 1737’, is meticulously constructed with a minimal selection of surface-mount components. Measuring approximately 25mm x 15mm, the board features a single small IC—likely a transistor or op-amp—alongside various passive elements such as resistors and capacitors. The wide traces, single-sided layout, and absence of high-speed or RF features suggest this board serves as a sensor interface or simple status indicator within the drone. Its design prioritizes reliability and manufacturability, with clean solder joints and clear silkscreen labeling, ensuring robust performance as a dedicated subsystem.

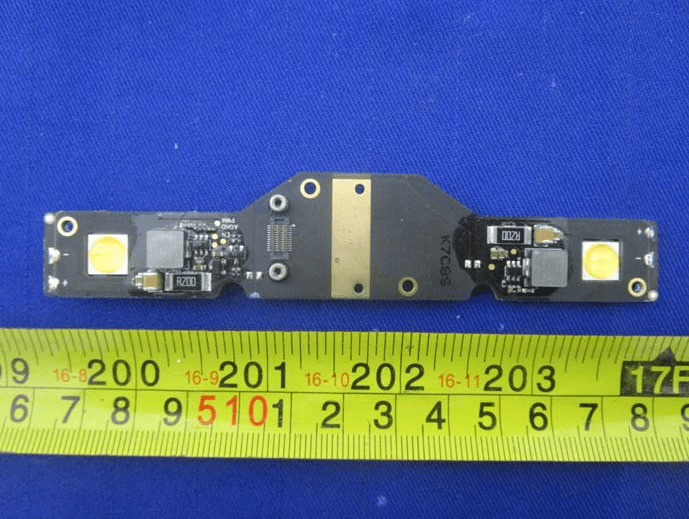

High-Power Dual-Channel LED Module

Spanning approximately 110mm, this black PCB exemplifies DJI’s attention to modular, serviceable design. The board is anchored by two high-intensity yellow LEDs at each end, each supported by its own power regulation circuitry—including large inductors, current sense resistors (R200), and power ICs. The sparse central area, featuring gold pads and a connector footprint, hints at a plug-and-play architecture for easy integration or replacement. This assembly is clearly engineered for robust illumination or signaling, likely serving as a navigation or status light within the Agras MG-1P system. The overall build quality, from ENIG finish to clean routing, reflects a high standard of manufacturing.

Flexible Printed Circuit for Dynamic Interconnect

A robust, gold-traced flexible printed circuit (FPC) is prominently wrapped around a cylindrical component—potentially a motor or sensor assembly. The FPC’s wide traces and polyimide substrate are optimized for mechanical flexibility and reliability, essential for transmitting power or low-frequency signals between moving parts. No integrated circuits or RF features are visible, indicating its primary function as a dynamic interconnect within the drone’s mechatronic systems. The professional finish and clean assembly underscore DJI’s focus on durability in high-vibration environments.

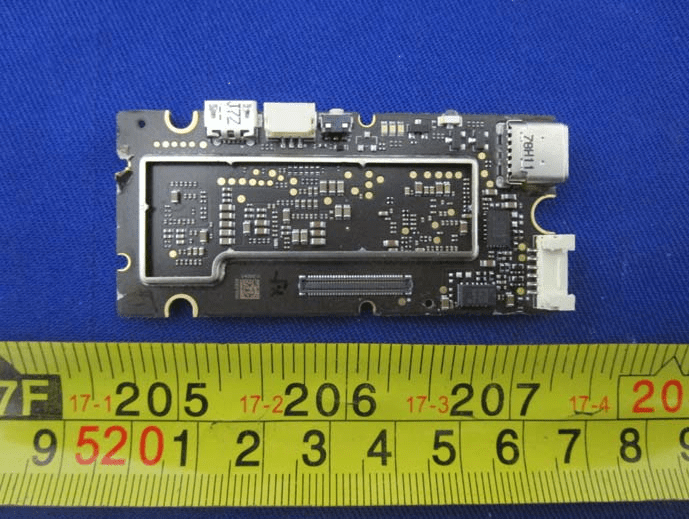

Main Communication and Navigation PCB

A densely populated, black-finished PCB showcases the core of the Agras MG-1P’s communication and navigation capabilities. The board features a prominent metal shield covering its central section—likely protecting a high-speed SoC or wireless/GNSS module. Multiple connectors, including a coaxial RF port and white multi-pin headers, facilitate modular integration with external antennas and peripheral devices. The extensive use of ground vias, high-density routing, and carefully placed crystals indicates a design focused on signal integrity, EMI/RFI robustness, and precise clocking. This board exemplifies DJI’s expertise in RF and digital system integration for mission-critical drone functions.

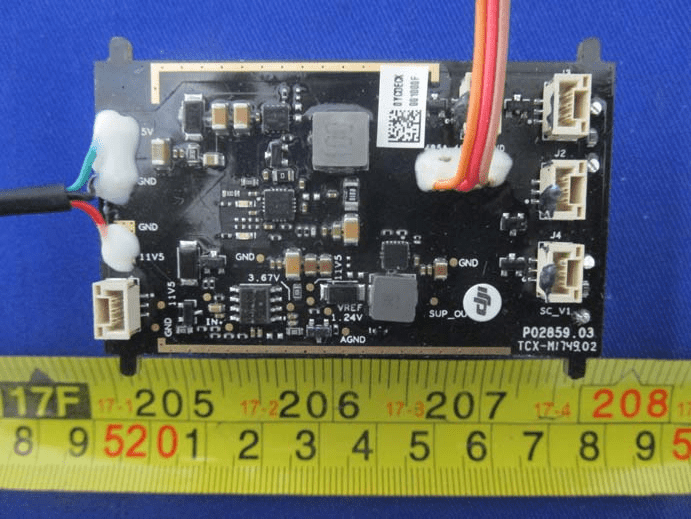

Power Management and Sensor Interface Board

This well-organized black PCB is equipped with multiple large inductors, capacitors, and several ICs—likely dedicated to advanced power management and subsystem interfacing. Four white JST-style connectors enable robust connections to other modules, while labeled power rails (5V, 11VS, 3.67V, 1.24V, 24V) and numerous test points facilitate both operation and diagnostics. The meticulous layout, use of via-in-pad technology, and clear silkscreen labeling reflect a design tailored for reliability and ease of service. This board likely serves as a central hub for distributing power and interfacing with various sensors within the Agras MG-1P drone.

Regulatory Insights & FCC Filing

The FCC ID SS3-MG1P1801 assigned to the Agras MG-1P series is a testament to its compliance with US electromagnetic interference (EMI) and radio frequency (RF) emission standards. This certification is essential for legal distribution and operation within the United States, ensuring the drone’s wireless systems do not interfere with other critical communications or devices.

Although the grant date is listed as none, the device’s presence in the FCC’s registry confirms that it has undergone rigorous testing and documentation as required by FCC.gov. Typical FCC filings for such devices include RF exposure assessments, electromagnetic compatibility (EMC) test reports, internal and external photographs, user manuals, schematics, and block diagrams. These documents collectively verify that the device operates within safe and legal RF limits, adheres to emissions guidelines, and is constructed according to best engineering practices.

Insights from the User Manual (User-Manual-3777061.pdf) highlight the MG-1P series’ advanced radar, robust controller system, and environmental resilience. The manual also details the drone’s intelligent operation planning, obstacle avoidance, and multi-drone control capabilities—further reinforcing the technical sophistication that underpins its regulatory compliance.

Potential Use Cases & Target Audience

The Agras MG-1P series (MG-1P / MG-1P RTK) is engineered for demanding agricultural applications, serving the following key user profiles and scenarios:

-

Precision Crop Spraying for Large-Scale Farms:

Professional farm operators can deploy the MG-1P RTK for high-precision, automated spraying missions. The onboard D-RTK ensures centimeter-level accuracy, reducing chemical waste and maximizing crop yield. -

Real-Time Field Mapping and Obstacle Avoidance:

Agronomists and agricultural service providers leverage the wide-angle FPV camera and advanced radar to conduct real-time field surveys, plan efficient spray routes, and safely navigate complex terrains—all from a single remote controller. -

Coordinated Multi-Drone Operations:

Large agricultural enterprises or cooperatives can utilize the MG-1P’s multi-drone control feature, managing up to five drones simultaneously. This enables rapid coverage of vast fields, streamlining operations and boosting productivity.

These scenarios demonstrate the Agras MG-1P series’ value for professional, high-efficiency agricultural workflows where reliability, precision, and safety are paramount.

Conclusion

The Agras MG-1P series (MG-1P / MG-1P RTK) by SZ DJI TECHNOLOGY CO., LTD. stands out as a technologically advanced and robust solution for modern agriculture. Its FCC certification (FCC ID SS3-MG1P1801) affirms its compliance with stringent US RF emission and safety standards, enabling legal and reliable operation. From intelligent flight control and rugged design to sophisticated internal architecture and wireless connectivity, the MG-1P series is engineered for demanding field applications. As precision agriculture continues to evolve, this platform sets a high bar for performance, safety, and regulatory integrity in aerial farm management.