Introduction

The DJI RoboMaster S1 is a groundbreaking educational robot designed to ignite curiosity and technical skills in students, families, and science and technology enthusiasts. Blending interactive learning with hands-on robotics, the S1 offers a dynamic platform for exploring artificial intelligence, programming, and engineering concepts through real-world application. At its core, the RoboMaster S1 boasts an impressive array of features—including computer vision, speech recognition, and agile omnidirectional movement—making it both an engaging educational tool and a robust robotics platform.

A critical milestone in its journey to market is its FCC certification, identified by FCC ID SS3-RMS11902. This certification is more than a regulatory checkbox; it guarantees the RoboMaster S1 meets stringent US standards for radio frequency (RF) emissions and electromagnetic compatibility, ensuring it is legal to sell and operate within the United States. In this article, we’ll explore the RoboMaster S1’s key specifications, innovative technologies, wireless capabilities, and internal hardware design. We’ll also provide expert regulatory insights based on its FCC filing, giving you a complete picture of this sophisticated robotics solution.

Key Features & Specifications

The DJI RoboMaster S1 stands out in the educational robotics market with a rich suite of features and robust technical specifications designed to foster learning and creativity. Here’s an in-depth look at what sets it apart:

Key Features

- Speech Recognition: Enables intuitive voice command control, making programming and operation more engaging and accessible, especially for younger users.

- FPV Camera: The integrated first-person view camera delivers real-time, low-latency video streaming, perfect for both immersive piloting and advanced computer vision projects.

- Hit Detector Armor: Embedded sensors in the armor detect impacts from gel bead projectiles, supporting interactive, competitive play and coding challenges.

- Programming Learning Platform: Accompanied by a comprehensive suite of interactive courses, video tutorials, and a user-friendly programming environment (supporting Scratch and Python), it offers a hands-on path from beginner to advanced coding.

- Stable Image Transmission: The high-quality, low-latency video feed ensures lag-free FPV control and reliable image data for AI applications.

- Speaker Integration: Built-in audio output allows for custom sounds, alerts, and interactive scenarios, enhancing the learning experience.

- Omnidirectional Mecanum Wheels: Four-wheel drive with Mecanum wheels delivers agile, omnidirectional movement, enabling complex maneuvers and precise navigation.

Technical Specifications

- Battery & Power

- Battery Charging Temperature: 32° to 104° F (0° to 40° C)

- Battery Operating Temperature: -4° to 140° F (-20° to 60° C)

- Battery Capacity: 2400 mAh (LiPo 3S)

- Net Weight: ~169 g

- Energy: 25.92 Wh

- Charging Voltage: 12.6 V

- Chassis Performance

- Max Rotating Speed: 600°/s (chassis)

- Max Movement Speed: 3.5 m/s (forward), 2.5 m/s (backward)

- Launcher

- Initial Velocity of Gel Beads: Approx. 26 m/s

- Camera

- Operating Temperature: -4° to 140° F (-20° to 60° C)

- Image Transmission Resolution: 720p @ 30fps

- Sensor: 1/4” CMOS, 5 MP effective pixels

- Wireless Connectivity

- Wi-Fi: IEEE802.11a/b/g/n, 2.4 GHz, 5.2 GHz (indoor only), 5.8 GHz

- Bluetooth: Present (details not specified)

- Other

- Speaker: Integrated

- Chassis: Omnidirectional Mecanum wheels for agile, precise movement

These features combine to create a robot that is not only fun and interactive but also a serious platform for learning about robotics, AI, and programming. The robust wireless connectivity supports real-time control and data transmission, while the modular design and high-quality components ensure durability and ease of maintenance—a hallmark of DJI engineering.

Operating Frequencies

The DJI RoboMaster S1 (FCC ID SS3-RMS11902) operates on multiple frequency bands, as documented in its FCC filing. These frequencies are essential for understanding its wireless communication capabilities, range, and compliance with regulatory standards:

| Frequency Range (GHz) | Output Power (mW) | FCC Rule Part |

|---|---|---|

| 2.412-2.462 | 219 | 15C |

| 5.18-5.24 | 294 | 15E |

| 5.745-5.825 | 288 | 15E |

These bands are typically associated with Wi-Fi communications, supporting both 2.4 GHz and 5 GHz operation for flexible, high-speed, and low-latency control and video transmission. The specified output power levels ensure robust connectivity while adhering to safe and legal RF emission limits.

Technology Deep Dive

The RoboMaster S1 leverages a combination of advanced wireless technologies to deliver seamless control and immersive experiences. Its primary wireless communication is based on dual-band Wi-Fi (2.4 GHz and 5 GHz), enabling high-speed, low-latency data transfer essential for real-time video streaming and responsive robot control. The inclusion of Bluetooth, while not detailed in the documentation, likely supports device pairing and auxiliary functions.

Operating across multiple Wi-Fi bands provides flexibility, allowing the S1 to avoid interference from congested networks and maintain stable connections in diverse environments. The 2.4 GHz band offers longer range and better penetration through obstacles, while the 5 GHz bands deliver higher throughput and reduced interference—ideal for FPV video and responsive command input. The output power levels, carefully regulated as per FCC guidelines, ensure effective range without exceeding RF emission limits.

The absence of cellular connectivity, as indicated by the equipment class, means all communications occur over local wireless networks. This design choice prioritizes low latency, privacy, and ease of setup in educational and home environments. Test reports from the FCC filing confirm that the S1 meets all relevant standards for RF emissions and electromagnetic compatibility, validating its safe operation in a variety of settings.

In-Depth Internal Component Analysis / Teardown

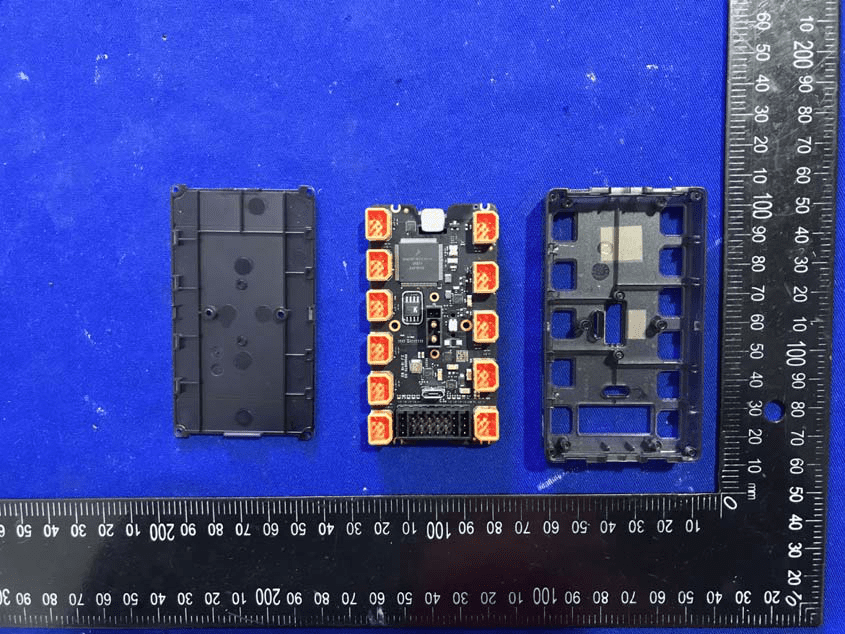

Main Robotics Control Board

A detailed view of the primary internal module reveals a meticulously engineered PCB, measuring approximately 90mm x 45mm. At its heart lies a large, centrally positioned microcontroller or SoC—most likely an ARM Cortex-based MCU—responsible for real-time control of the S1’s complex systems. Surrounding this are several power management ICs, potential motor drivers, and a precision crystal oscillator for accurate timing. The board’s black ENIG finish, dense component layout, and multi-layer construction underscore its high quality and signal integrity. Robust orange connectors, likely for motor and sensor interfacing, and a substantial power/data connector, highlight its role as the central nervous system of the robot. The presence of significant capacitors and inductors confirms onboard power regulation, essential for driving motors and sensors. Overall, this board exemplifies DJI’s focus on modularity, reliability, and serviceability, with a design tailored for demanding robotics applications.

Compact Optical Sensor Module

The compact sensor board, approximately 60mm x 25mm, demonstrates DJI’s expertise in miniaturized, high-performance electronics. Its central IC, likely a dedicated microcontroller or sensor interface, orchestrates the board’s functions. Notably, the symmetrical arrangement of white components—probably LEDs or photodiodes—around a central optical element suggests an advanced optical or vision sensor, potentially for line tracking, object detection, or distance measurement. High component density, multi-layer construction, and careful grounding practices ensure signal integrity and noise immunity. Dual multi-pin connectors facilitate integration with the main system, while local power regulation components provide clean, stable voltage for sensitive electronics. This board’s design balances precision, robustness, and modularity, supporting the S1’s sophisticated navigation and sensing capabilities.

Sensor/Interface Board with FPC Connector

This high-density, 60mm x 30mm PCB exemplifies thoughtful engineering for sensor integration and control. A centrally located IC—likely handling either power management or sensor interfacing—anchors the board, surrounded by several smaller ICs and substantial passive components for local power regulation. The inclusion of an FPC/FFC connector suggests modular interfacing with other subsystems, such as cameras or additional sensors. Numerous gold-plated test points facilitate manufacturing and diagnostics, while the robust black soldermask and multi-layer construction highlight the emphasis on durability and signal quality. The presence of multiple LEDs and mounting holes further indicate its role as a versatile, easily serviced module within the S1’s architecture.

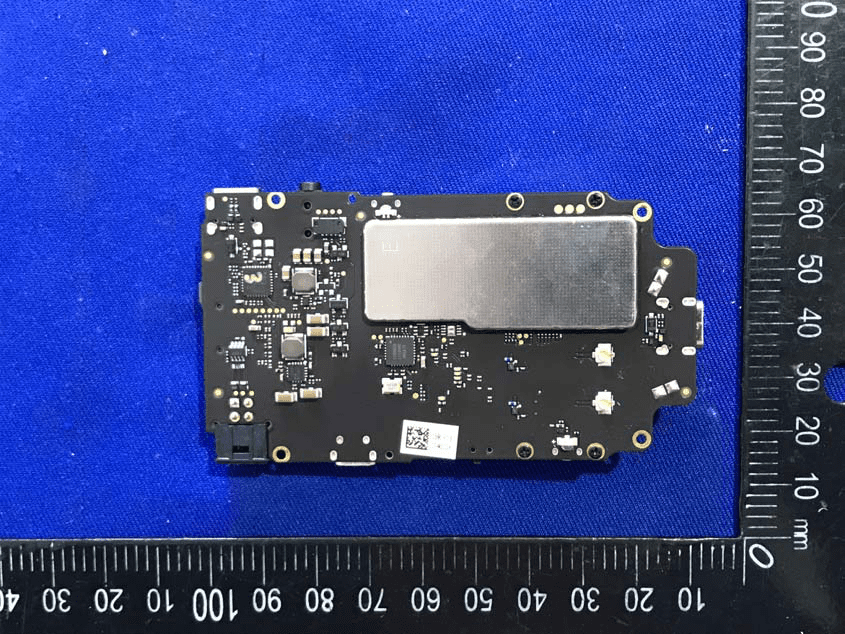

Shielded High-Speed/RF Subsystem

A densely populated PCB features a prominent metal EMI shield, indicative of high-speed digital or RF circuitry beneath—likely supporting Wi-Fi/Bluetooth communications or high-fidelity video processing. The board’s multi-layer construction, tight routing, and controlled impedance traces support high-frequency signal integrity, while numerous capacitors and inductors ensure robust power delivery and decoupling. Connectors at the board’s edge provide interfaces for power, data, or peripheral modules. The presence of extensive shielding and grounding underscores DJI’s commitment to electromagnetic compatibility and reliable wireless performance in complex environments. This assembly is a testament to the sophisticated integration of RF and digital systems required for seamless FPV streaming and remote control.

Modular Sensor and Motor Control Assemblies

A collection of custom-shaped PCBs, including round, semi-circular, and small rectangular boards, reflects the S1’s modular and highly integrated approach to motor control and sensing. The round board, featuring a major microcontroller or motor driver IC, likely manages brushless motor operations or gimbal functions. The semi-circular and smaller boards, populated with SMD LEDs and photodiodes, suggest roles in optical sensing—potentially for wheel encoders or line-following applications. The use of robust FPC/FFC connectors, test points, and local power regulation components ensures reliability and ease of maintenance. The overall build quality is exemplary, with careful attention to grounding, signal routing, and mechanical fit, supporting precise motion control and feedback essential for robotics education and competition.

Regulatory Insights & FCC Filing

The FCC ID SS3-RMS11902, assigned to the DJI RoboMaster S1, confirms its compliance with US regulatory standards for electromagnetic interference and RF emissions. This certification, overseen by FCC.gov, is a prerequisite for legal sale and operation of wireless devices in the United States. The FCC filing encompasses a comprehensive suite of documentation, including RF exposure and EMC test reports, internal and external photographs, user manuals, schematics, and block diagrams.

Review of the user manual and supporting documentation highlights that the RoboMaster S1 is engineered as an educational and entertainment platform, offering advanced movement, AI capabilities, and flexible control modes. The test reports validate that all wireless subsystems operate within permitted frequency bands and power limits, ensuring safe and interference-free use in home, classroom, and competitive environments. Internal documentation further details the modular, serviceable design and robust engineering practices that underpin the S1’s reliability. Collectively, these filings not only demonstrate regulatory compliance but also provide valuable transparency into the device’s safety and technical integrity.

Potential Use Cases & Target Audience

The RoboMaster S1’s unique blend of programmability, AI, and robust hardware makes it an ideal tool for a variety of users and scenarios:

- STEM Education and Robotics Clubs: Students and educators can leverage the S1’s programming platform, interactive courses, and real-world robotics challenges to foster hands-on learning in coding, engineering, and AI. Its modular design and comprehensive documentation make it suitable for classroom integration and extracurricular robotics competitions.

- Family Learning & Entertainment: Families can enjoy immersive, collaborative play—using speech recognition, FPV piloting, and interactive missions—to explore technology together. The hit detector armor and competitive game modes add a fun, engaging layer to learning.

- Science & Technology Enthusiasts: Hobbyists and tinkerers benefit from the S1’s powerful hardware, advanced computer vision, and open programming environment, enabling custom projects, AI experiments, and integration with other smart devices.

These scenarios illustrate the RoboMaster S1’s versatility as both an educational platform and a sophisticated robotics tool, catering to a broad spectrum of learners and creators.

Conclusion

The DJI RoboMaster S1, certified under FCC ID SS3-RMS11902, exemplifies the intersection of innovative robotics, educational value, and regulatory compliance. Its advanced features—ranging from AI-driven interactivity to robust wireless connectivity—are supported by meticulously engineered internal components, ensuring reliability and performance. The FCC certification not only validates its safety and legality for US markets but also reflects DJI’s commitment to quality and transparency. Whether in classrooms, homes, or robotics arenas, the RoboMaster S1 stands as a premier platform for exploring and mastering the technologies shaping our future.