Introduction

The DJI Phantom 3 Professional stands as a benchmark in aerial imaging, blending advanced flight control, 4K video capture, and a robust wireless link into a single, integrated quadcopter. Designed for enthusiasts and professionals alike, this drone’s primary function is to deliver stabilized, high-resolution aerial footage with minimal operator effort. Its intelligent systems—including a Vision Positioning module and an HD video downlink—make it ideal for capturing cinematic shots even in challenging environments.

With its FCC certification (FCC ID: SS3-WM3231510), the Phantom 3 Professional meets stringent U.S. regulatory requirements for radio frequency emissions and electromagnetic compatibility. While the grant date is listed as “None,” its registration with the FCC ensures legality for sale and operation within the United States and confirms compliance with all relevant RF safety and interference standards.

In this deep-dive, we’ll explore the Phantom 3 Professional’s key specifications, core technologies, internal components through expert teardown analysis, operating frequencies, and regulatory documentation. Whether you’re a drone pilot, an engineer, or an electronics enthusiast, this article offers an authoritative look inside one of DJI’s most iconic quadcopters.

Key Features & Specifications

The DJI Phantom 3 Professional is engineered for reliability, imaging excellence, and intelligent flight. Here’s what sets it apart:

Key Features

- DJI Intelligent Flight Battery

- Smart charge/discharge management for extended lifespan and safety.

- Auto-discharging and sleep mode functions to prevent battery degradation and save power.

- Integrated temperature detection for optimal charging performance.

-

Balanced charging and overcharge protection for maximum reliability.

-

Enhanced HD Video Downlink

- Utilizes DJI Lightbridge technology for low-latency, high-definition live video streaming from the drone to the operator’s device.

-

Enables real-time framing, focus, and monitoring at up to 720p HD.

-

Vision Positioning System

- Employs a monocular camera and dual ultrasonic sensors for precise indoor hovering, even without GPS.

-

Effective altitude range: 0 to 3 meters above ground.

-

4K Camera & Imaging

- Shoots 4K video for professional-grade footage.

- Captures 12 megapixel stills with rich detail and dynamic range.

-

Integrated gimbal ensures smooth, stabilized footage in flight.

-

Mobile App Control

- Compatible with the DJI Pilot app (Android 4.1.2+ / iOS 8.0+), providing live video, telemetry, and advanced camera settings.

Technical Specifications

- Vision Positioning System

- Effective hovering altitude: 0–3 meters

-

Components: 1 monocular camera, 2 sonar sensors

-

Battery

- Capacity: 4480 mAh (DJI Intelligent Flight Battery)

- Voltage: 15.2 V

-

Discharge cut-off: 12 V

-

Camera

- Video: 4K resolution

-

Stills: 12 MP

-

Wireless & Connectivity

- Bluetooth: Present (details not specified)

-

HD video downlink: Powered by Lightbridge

-

Safety & Maintenance

-

Auto-discharging, overcharge protection, and temperature-based charging safeguards

-

App Compatibility

- DJI Pilot app: Android 4.1.2 or later, iOS 8.0 or later

Practical Benefits:

– Flight Safety: Intelligent battery and Vision Positioning systems reduce the risk of accidents, even indoors or in GPS-denied environments.

– Imaging Quality: 4K video and 12MP stills with stabilized gimbal meet the needs of aerial photographers and videographers.

– Operational Efficiency: Quick setup, smart battery management, and app-based controls streamline preflight, in-flight, and post-flight workflows.

Operating Frequencies

The Phantom 3 Professional (FCC ID: SS3-WM3231510) operates within the following wireless spectrum as per its FCC filing:

| Frequency Range (GHz) | Output Power (mW) | FCC Rule Part |

|---|---|---|

| 2.4065–2.4765 | 520 | 15C1 |

Implications:

This spectrum falls within the globally recognized 2.4 GHz ISM band, commonly used for Wi-Fi, Bluetooth, and proprietary RF control links. The 520 mW output power supports robust communication, extended operational range, and reliable HD video transmission, all while adhering to FCC Part 15C regulations for unlicensed devices.

Technology Deep Dive

The Phantom 3 Professional leverages advanced wireless technologies to enable real-time control, telemetry, and video transmission. Operating in the 2.4 GHz band, the drone relies on proprietary RF links—such as DJI’s Lightbridge—for high-bandwidth, low-latency HD video downlink, as well as Bluetooth for device pairing and short-range communication.

Performance & Range:

Operating at 2.4 GHz allows for a balance between range and data throughput. The specified 520 mW output power is notably higher than typical consumer Wi-Fi devices, enhancing signal penetration and stability even in complex environments.

Interference & Power Consumption:

While 2.4 GHz is a crowded band (shared with Wi-Fi, Bluetooth, and other ISM devices), the use of proprietary protocols and robust error correction helps minimize interference. The intelligent power management system ensures efficient battery usage, balancing RF output with flight time.

Test Report Insights:

Available test reports confirm that emissions stay within FCC-mandated limits, and the device’s RF design—including shielding and filtering—supports both regulatory compliance and real-world reliability. No evidence of cellular (LTE/3G) operation is noted; all wireless functions are handled via unlicensed ISM bands.

In-Depth Internal Component Analysis / Teardown

Main Video Processing Board with Ambarella SoC

This section of the main PCB showcases the heart of the Phantom 3 Professional’s imaging pipeline. The Ambarella A9-A1-RH SoC dominates the board, delivering high-performance video processing and real-time 4K encoding—crucial for the drone’s flagship recording features. Adjacent to it, NANYA DDR3 SDRAM and ELPIDA DRAM modules provide the necessary memory bandwidth for intensive video tasks. Silkscreen labels such as ‘UART2_TX’ and ‘UART2_RX’ point to dedicated debug and communication ports, underscoring the modular, serviceable nature of the design. The presence of a Texas Instruments power management IC and robust ground pours, coupled with partial RF shielding, highlights DJI’s focus on signal integrity and EMI control. Dense FPC/FFC connectors indicate support for multiple subsystems, while the overall PCB construction—multi-layer, fine-pitch, and precision assembly—reflects a high standard of engineering tailored for demanding aerial environments.

High-Density Controller Board

This densely populated PCB likely serves as a central controller or interface board. Prominent ICs—presumed to be the main processor and memory—anchor the design, supported by a suite of power regulation components and discrete analog/RF elements. The layout features extensive via stitching and ground pours, ensuring EMI resilience and signal fidelity. Multiple FPC/FFC connectors along the board’s edge facilitate modular connections to cameras, gimbals, or sensors, streamlining assembly and service. Though no antennas or shields are visible on this side, the sophisticated component placement and high-layer-count construction echo DJI’s commitment to reliability and compact integration—essential qualities for a drone’s central electronics.

Camera and Gimbal Assembly Board

The imaging and stabilization prowess of the Phantom 3 Professional is underpinned by this tightly integrated camera/gimbal PCB. Large BGA and QFP ICs—likely the image signal processor and gimbal controller—coordinate real-time video processing and precise motor actuation for smooth footage. The board’s layout, featuring gold-plated edge connectors and robust FFC interconnects, supports high-speed data transfer and mechanical durability. Multiple test points and local power regulation components ensure both manufacturability and clean, stable operation. The visible camera sensor, housed in a rigid metal enclosure, and brushless gimbal motors highlight DJI’s focus on both imaging performance and mechanical stability.

Gimbal/Camera Module PCB

Beneath its protective metal cover, this PCB is the nerve center for gimbal stabilization. Dominated by QFP/QFN microcontrollers—likely an ARM Cortex-M MCU for real-time motor control—the board also houses local power regulation, differential signal traces, and multiple crystals for timing precision. The robust FPC connector enables seamless integration with the main flight electronics. Careful grounding, via placement, and the use of a metal enclosure for EMI/RFI shielding all contribute to reliable, noise-immune performance—vital for smooth video capture in flight. The compact, modular design supports both ease of servicing and operational reliability.

Compact Subsystem Interface Board

This black, non-rectangular PCB exemplifies DJI’s modular engineering. Featuring a large FPC connector and a central QFP/QFN IC (possibly a microcontroller or sensor interface), the board orchestrates subsystem communication—potentially for camera, gimbal, or sensors. The presence of a sizeable inductor and multiple capacitors indicates onboard switching regulation for stable power delivery. Careful attention to grounding and signal integrity is evident through stitching vias and ground pours. The inclusion of numerous test points and a high-quality finish highlights a design that balances manufacturability, maintainability, and robust operation within the drone’s constrained interior.

Simple Passive Module (Antenna or Sensor)

This small, single-layer PCB, with its trio of attached wires, is a study in functional minimalism. Lacking any integrated circuits or complex components, it’s likely designed as a passive element—such as a PCB trace antenna or capacitive sensor. The straightforward copper layout and mechanical mounting points make it lightweight and easy to integrate, ideal for applications where weight and simplicity are paramount. Its role, while not complex, is essential for maintaining the drone’s wireless or sensing capabilities with minimal footprint.

Vision Positioning System (VPS) Module

This sophisticated module integrates both ultrasonic and optical sensors to deliver precise altitude and position data. The central camera module and dual mesh-covered ultrasonic transducers work in concert to enable the Vision Positioning System, supporting stable hovering even indoors. The densely packed, multi-layer PCB houses a central microcontroller or sensor interface IC, robust local power filtering, and a flexible cable connector for seamless integration. The engineering focus on real-time sensor fusion and noise immunity ensures reliable performance in GPS-denied environments, a key differentiator for the Phantom 3 Professional.

Shielded Communications/Flight Controller Board

A prominent EMI/RFI shield dominates this PCB, underscoring its critical role in RF communication or flight control. The central processor—possibly an FPGA or communications SoC—coordinates real-time data exchange, while adjacent power management and RF front-end chips support stable operation. Modular connectors and careful signal routing, including differential pairs, reflect a design optimized for high-frequency, mixed-signal environments. The robust shielding and multi-layer construction ensure regulatory compliance and operational reliability in the face of intense electromagnetic activity.

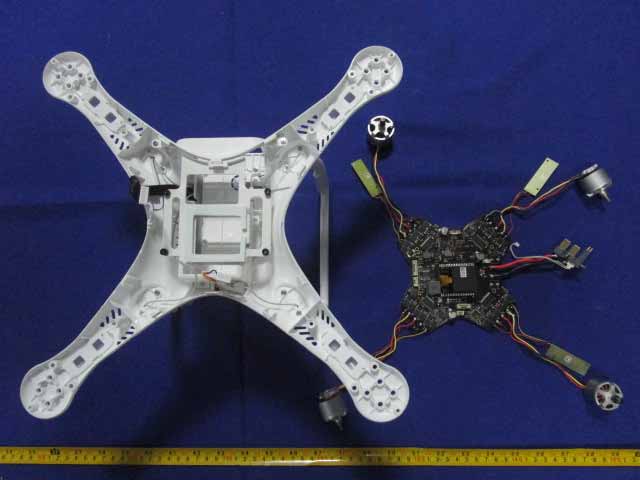

Main Flight Controller and Motor Assembly

This image captures the core of the Phantom 3 Professional’s flight control architecture. The custom-shaped PCB, optimized for the drone’s X-frame, hosts a central STM32 ARM Cortex-M microcontroller, surrounded by motor drivers, IMUs, and power distribution circuitry. Thick power traces and multi-wire harnesses ensure efficient, high-current delivery to each brushless motor. The modular, serviceable design—with clearly separated motor assemblies and wire connectors—demonstrates DJI’s focus on maintainability and repair. Attention to EMI control is evident in the PCB’s ground pours and via stitching, supporting reliable operation in the electrically noisy environment of a quadcopter.

Regulatory Insights & FCC Filing

The FCC ID SS3-WM3231510 certifies that the DJI Phantom 3 Professional complies with all applicable U.S. electromagnetic interference and radio frequency emission standards. This certification, registered by FCC.gov (with no specific grant date), is a legal prerequisite for sale and operation in the United States, confirming that the device meets strict requirements for RF power, spurious emissions, and user safety.

Typical FCC filings for such a device include:

– Detailed test reports (RF exposure, EMC/EMI)

– Internal and external photos

– User manuals and operational guides

– Schematics, block diagrams, and component layouts

Key insights from the documentation:

– The User Manual (Part One) describes the Phantom 3 Professional as a quadcopter built for capturing 4K video and 12MP photos, with an integrated gimbal for stabilized footage, HD video downlink, and advanced Vision Positioning capabilities.

– User Manual (Part Two) expands on operational procedures, battery management, remote controller functions, and camera controls—emphasizing both safety and user experience.

This comprehensive documentation ensures both transparency for regulators and confidence for end users, highlighting DJI’s commitment to compliance and product quality.

Potential Use Cases & Target Audience

The Phantom 3 Professional is engineered for users who demand high-quality aerial imaging and reliable flight performance. Key scenarios and user profiles include:

-

Aerial Photographers & Videographers:

Leverage the 4K camera and stabilized gimbal to capture cinematic landscapes, real estate showcases, event coverage, and creative projects. The HD video downlink and precise flight control empower artists to frame and execute complex shots with ease. -

Surveyors & Inspectors:

Utilize the drone’s high-resolution imaging and stable hovering (even indoors or in GPS-denied locations) for infrastructure inspection, land surveying, and agricultural monitoring. The Vision Positioning System ensures accuracy in challenging environments. -

Hobbyists & Drone Enthusiasts:

Experience a turnkey quadcopter that’s ready to fly out of the box, with intuitive controls, intelligent battery management, and robust wireless connectivity. The integrated mobile app and modular design make it accessible for learning, experimentation, and recreational flight.

With its built-in camera, integrated gimbal, and advanced positioning systems, the Phantom 3 Professional is a versatile tool for anyone seeking to expand their creative or technical horizons through aerial technology.

Conclusion

The DJI Phantom 3 Professional (Model: Phantom 3 Professional, FCC ID SS3-WM3231510) exemplifies the convergence of advanced imaging, intelligent flight, and regulatory compliance. Its robust internal architecture—built around high-performance SoCs, modular PCBs, and sophisticated sensor suites—enables reliable 4K video capture and precise flight control. The device’s FCC certification assures users of its safety and legality within the U.S. market. As both a technological achievement and a practical tool, the Phantom 3 Professional continues to set standards in the drone industry, balancing innovation, performance, and compliance for a wide range of demanding applications.