Introduction

The DJI Mavic 2 Pro stands as a flagship in DJI’s celebrated drone lineup, engineered for aerial photography enthusiasts and professional content creators alike. With its robust flight capabilities, advanced imaging system, and intelligent obstacle sensing, the Mavic 2 Pro is designed to deliver stunning results in a compact, foldable form. At the heart of its appeal is a 1-inch CMOS sensor camera co-developed with Hasselblad, promising exceptional image quality and dynamic range.

Crucially, the Mavic 2 Pro (Model: Mavic 2 Pro) is certified under FCC ID SS3-RC1B1809, ensuring compliance with stringent US regulatory standards for radio frequency (RF) emissions and electromagnetic compatibility. This certification is not just a legal prerequisite for sale and operation in the United States; it also signals that the device has passed rigorous testing for wireless performance and safety.

In this article, we’ll explore the Mavic 2 Pro’s key features, technical specifications, wireless technologies, and internal hardware through expert teardown analysis. We’ll also unpack the regulatory insights gleaned from its FCC filing, providing a comprehensive view of what makes this drone a standout in its class.

Key Features & Specifications

The DJI Mavic 2 Pro is packed with a suite of cutting-edge features and robust technical specifications that cater to both advanced users and demanding shooting scenarios. Here’s a detailed breakdown:

Key Features

-

Fully Stabilized 3-Axis Gimbal:

Delivers buttery-smooth footage and sharp stills by compensating for drone movement, essential for cinematic aerial photography. -

Omnidirectional Vision Systems:

Equipped with sensors on all sides for comprehensive obstacle detection, significantly minimizing collision risk during complex flights. -

Obstacle Sensing:

Integrates both vision and infrared sensing systems to deliver reliable obstacle avoidance in diverse environments. -

Detachable Control Sticks for Remote Controller:

Enhances portability and convenience, allowing the controller to be easily stored and transported. -

On-board LCD Screen on Remote Controller:

Provides real-time telemetry and system status, enabling pilots to monitor critical information without relying solely on a mobile device. -

microSD Card Slot (Max Capacity: 128 GB, UHS-I Speed Grade 3 required):

Supports high-speed data storage for large 4K video files and high-resolution images. -

Infrared Sensing Systems:

Enables precise hovering and improved obstacle detection, especially in low-light scenarios. -

Maximum Service Ceiling Above Sea Level: 19,685 ft (6,000 m):

Allows for high-altitude operation, expanding creative possibilities in mountainous or elevated locations.

Technical Specifications

- Intelligent Flight Battery:

- Capacity: 3850 mAh

- Energy: 59.29 Wh

- Voltage: 17.6 V (max), 15.4 V (typical)

- Battery Type: LiPo 4S

- Maximum Charging Power: 80 W

- Charging Temperature Range: 41°F to 104°F (5°C to 40°C)

- Maximum Flight Time: 31 minutes

-

Battery Net Weight: Approx. 297 g

-

Charger:

- Output Voltage: 17.6±0.1 V

-

Maximum Charging Power: 80 W

-

Camera:

- Sensor: 1″ CMOS; Effective pixels: 20 MP

- Video Recording Modes:

- 4K Ultra HD: 3840×2160 @ 24/25/30p

- 2.7K: 2688×1512 @ 24/25/30/48/50/60p

- FHD: 1920×1080 @ 24/25/30/48/50/60/120p

-

Max Image Size: 5472×3648

-

Still Photography Modes:

- Single Shot

- Burst Shooting: 3/5 frames

- Auto Exposure Bracketing (AEB): 3/5 bracketed frames at 0.7 EV Bias

-

Interval Shooting

-

Remote Controller:

- Operating Temperature: 32°F to 104°F (0°C to 40°C)

-

Detachable sticks and integrated LCD for enhanced usability

-

Wireless Specs:

- Wi-Fi: 2.4–2.4835 GHz; 5.725–5.850 GHz

- Bluetooth: Present (details not specified)

These features and specifications ensure that the Mavic 2 Pro delivers a balance of professional-grade imaging, intelligent flight modes, and robust wireless communication, making it a top choice for aerial imaging professionals and demanding hobbyists.

Operating Frequencies

The Mavic 2 Pro, as detailed in its FCC filing under FCC ID SS3-RC1B1809, operates across a range of frequencies vital to its wireless communication and control systems:

| Frequency Range (GHz) | Output Power (mW) | FCC Rule Part |

|---|---|---|

| 2.4655 | 582 | 15CCC1.12.4105 |

| 2.4715 | 57 | 15CCC1.35.7285 |

| 5.8395 | 14 | 15ECC2.3 |

| 5.8445 | 15 | 15ECC2.25.7355 |

| 5.8465 | 140 | 15ECC2.15.7305 |

| 12.4055–2.4775 | 46 | 15CCC1.22.4075 |

These bands support the device’s high-bandwidth video transmission, remote control, and possibly telemetry, ensuring reliable performance and compliance with regulatory limits on RF emissions.

Technology Deep Dive

The DJI Mavic 2 Pro leverages a sophisticated blend of wireless technologies to facilitate seamless control, real-time video streaming, and robust connectivity. Primarily, the drone utilizes Wi-Fi in both the 2.4 GHz and 5.8 GHz ISM bands, which are standard for high-throughput, low-latency communication between the drone and its controller. Bluetooth is also included for auxiliary connectivity, likely used for device pairing or low-bandwidth data exchange.

The selected frequency bands ensure optimal balance between range and interference resistance. The 2.4 GHz band offers superior penetration and longer range, while the 5.8 GHz band provides higher data rates with less congestion in urban environments. Output power levels, as documented in the FCC filing, are carefully regulated to maximize range while adhering to safety and interference standards.

This multi-band approach not only enhances flight stability and responsiveness but also supports high-definition video downlink, critical for professional aerial imaging. The internal documentation and test reports further confirm that the device’s RF systems are engineered for minimal interference and efficient power consumption, contributing to extended flight times and reliable operation in diverse environments.

In-Depth Internal Component Analysis / Teardown

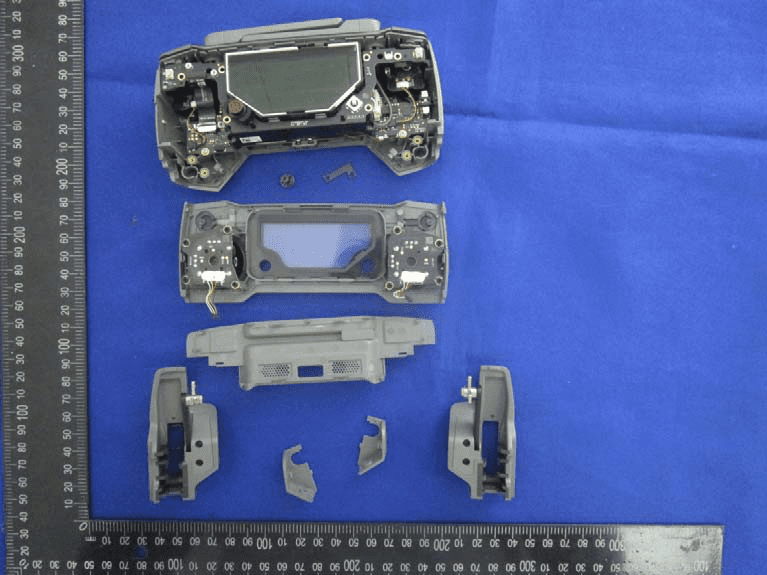

Remote Controller Mainboard and LCD Subassembly

A close examination of the remote controller’s internal structure reveals a meticulously organized main PCB, partially obscured by the LCD and mechanical controls. The board is a multi-layer FR4 construction, likely 4-6 layers, optimized for RF and power signal integrity. Although most major ICs are not visible due to the assembly, one can infer the presence of a high-performance MCU, RF transceivers for dual-band communication, and power management circuits. Several FPC/FFC connectors are observed, facilitating modular connections for the LCD, button arrays, and external antennas via coaxial cables. The absence of visible RF shielding suggests it may reside on the reverse side or was removed for inspection. Notably, the modular design promotes ease of repair and robust EMI management, reflecting DJI’s commitment to quality and serviceability.

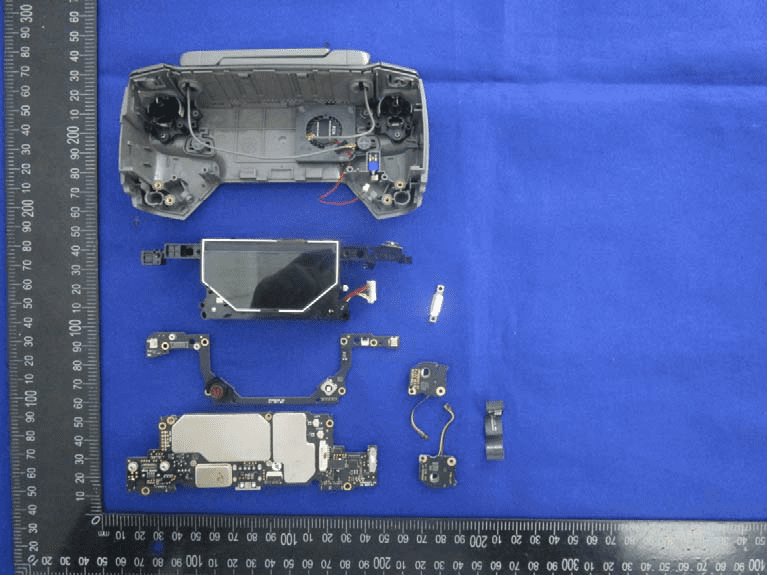

Remote Controller PCB with Shielded RF and SoC Sections

A detailed teardown of the remote controller reveals a densely populated main PCB with both surface-mount and through-hole components. Prominent metal shields protect the RF and main processing sections, underscoring the importance of EMI/RFI control in this device. Key ICs likely include a central SoC, memory modules, and RF transceivers, complemented by dedicated power management and sensor interface chips. The use of a multi-layer PCB, extensive ground pours, and controlled impedance traces highlights a sophisticated approach to high-speed RF and digital design. Multiple FPC/FFC connectors, board-to-board links, and antenna harnesses ensure robust connectivity, while the modular layout supports serviceability and future upgrades. This assembly exemplifies DJI’s high standards in integrating wireless, user interface, and power systems within a compact form factor.

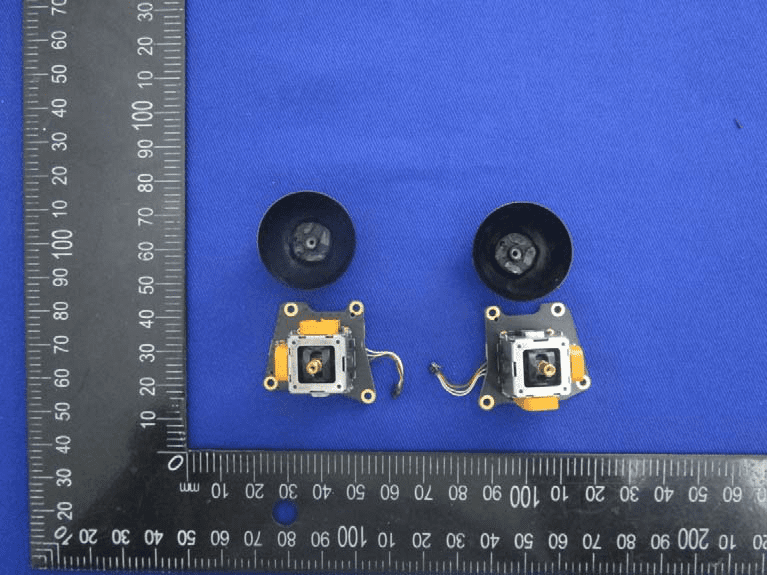

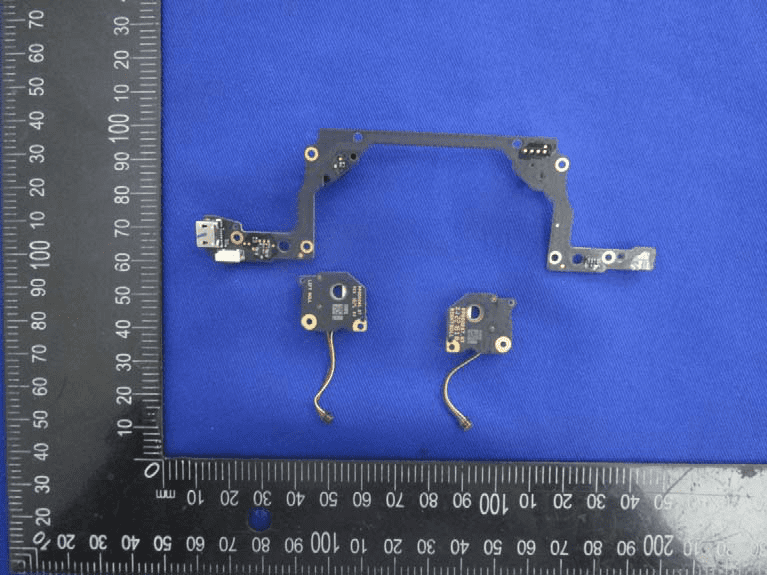

Precision Joystick Modules for Remote Controller

The joystick modules are engineered for precision and durability, featuring robust gimbal mechanisms with flex PCBs for signal transmission. Each joystick incorporates centering springs and modular shafts, with likely Hall effect sensors or potentiometers (though not externally visible) for accurate, contactless position sensing. The flex PCBs and wire harnesses are designed for repeated movement, ensuring longevity and minimal signal degradation. This modular construction allows for straightforward replacement or repair, a critical factor in high-use scenarios. The overall design underscores DJI’s focus on delivering responsive, reliable control essential for nuanced drone piloting.

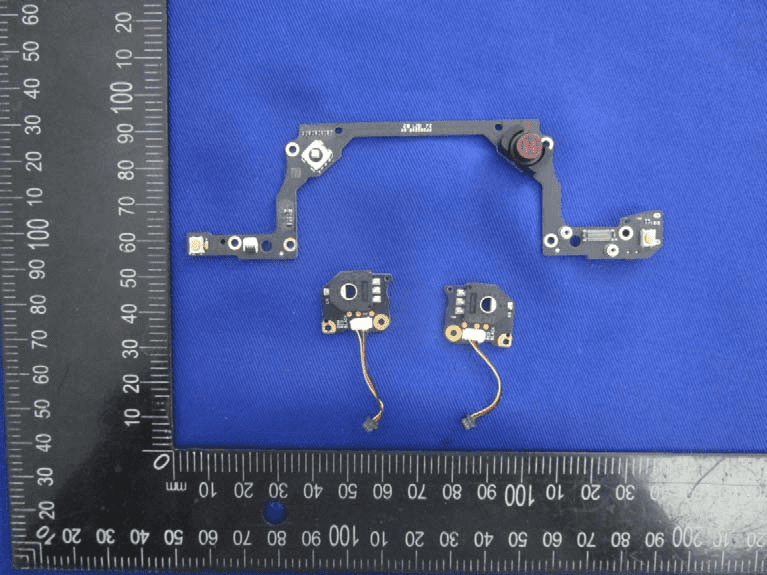

Drone Sensor and Interface PCBs

The internal sensor boards showcase DJI’s commitment to modularity and high-density design. The main PCB, finished in black ENIG, is compact with multiple layers for efficient signal routing and power distribution. Two smaller boards each feature a central sensor—likely optical or ToF—surrounded by passive components and minimal ICs. These are essential for the drone’s obstacle sensing and autonomous flight functions. Flex cable connectors enable seamless integration with the main flight controller, while test points and mounting holes facilitate assembly and maintenance. This arrangement allows for lightweight, easily replaceable sensor modules, contributing to the drone’s advanced vision and positioning systems.

Vision and Obstacle Avoidance Sensor Boards

The sensor boards are custom-shaped for optimal placement within the drone’s tight internal architecture. Two compact boards host what appear to be vision or proximity sensors, each with dedicated microcontrollers or sensor ICs for real-time data processing. These connect via short wire harnesses, likely using low-speed serial protocols for efficient communication with the main processor. The larger frame-shaped PCB features signal conditioning and power regulation components, as well as a small FPC/FFC connector and a possible service port. The absence of RF shielding is appropriate given their low EMI risk, and the modular design supports DJI’s strategy of maximizing sensor coverage while minimizing weight.

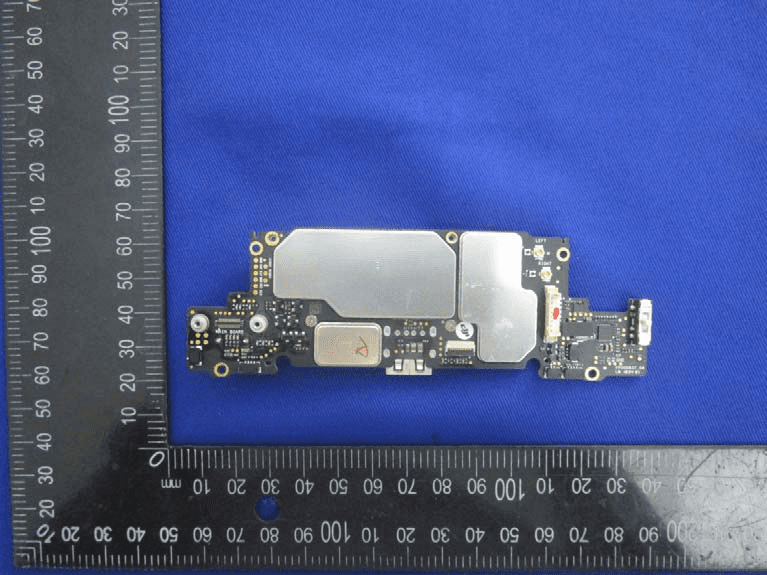

Drone Mainboard with Shielded Processing and RF Sections

The main flight controller PCB exemplifies high-density, high-complexity engineering. Major ICs—including the central processor, memory, and RF transceivers—are protected by extensive metal shields, ensuring robust EMI/RFI suppression. The multi-layer board (estimated 6-8 layers) features dense via patterns, ground stitching, and controlled impedance traces for reliable high-speed signal transmission. Multiple connectors support integration with camera modules, sensor arrays, and external antennas. Power regulation is handled by large inductors and capacitors strategically placed for efficient distribution. The compact, modular layout is optimized for both performance and manufacturability, embodying the technical sophistication required for advanced drone operation.

Regulatory Insights & FCC Filing

Certification under FCC ID SS3-RC1B1809 signifies that the DJI Mavic 2 Pro meets all US Federal Communications Commission requirements for RF emissions and electromagnetic compatibility. Registered through FCC.gov, this compliance is essential for legal sale and operation within the United States, confirming that the device poses no undue risk of interference with other wireless equipment.

FCC filings encompass a wide array of documentation, including test reports for RF exposure, electromagnetic compatibility (EMC), internal and external photographs, user manuals, block diagrams, and schematics. These materials provide transparency into the device’s design, performance, and safety measures.

Key insights from the official documentation highlight the Mavic 2 Pro’s integration of omnidirectional vision and infrared sensing systems, a highly stabilized 3-axis gimbal, and a 1-inch CMOS sensor camera co-developed with Hasselblad. The test reports confirm that the wireless systems operate within prescribed output power and frequency limits, ensuring safe and reliable use across various environments. Overall, the FCC documentation reflects DJI’s rigorous approach to regulatory compliance and product safety.

Potential Use Cases & Target Audience

With its advanced imaging system, intelligent flight features, and robust wireless capabilities, the DJI Mavic 2 Pro is tailored for a variety of demanding applications:

-

Professional Aerial Photography and Cinematography:

The combination of a stabilized 1″ CMOS sensor camera and omnidirectional obstacle sensing makes the Mavic 2 Pro ideal for capturing complex, high-quality shots in dynamic environments. Professionals in real estate, film, and surveying can rely on its image fidelity and flight precision. -

Content Creators and Enthusiasts:

Hobbyists and social media creators will appreciate the intuitive controls, detachable sticks for portability, and up to 31 minutes of flight time—enabling effortless capture of unique perspectives and dynamic footage. -

Industrial and Inspection Applications:

The drone’s high-altitude capability (up to 6,000 m above sea level) and obstacle avoidance systems make it suitable for infrastructure inspection, mapping, and search-and-rescue operations in challenging terrains.

With no specific user demographic, the Mavic 2 Pro appeals broadly to anyone seeking professional-grade aerial imaging with the reliability and flexibility that DJI is known for.

Conclusion

The DJI Mavic 2 Pro, certified under FCC ID SS3-RC1B1809, exemplifies the pinnacle of consumer drone technology—blending advanced imaging, intelligent flight, and robust wireless systems within a meticulously engineered platform. Its FCC certification guarantees legal compliance, safety, and reliability for users in the United States. Through sophisticated design and comprehensive regulatory adherence, the Mavic 2 Pro continues to set the standard for aerial creativity, performance, and innovation in the drone market.