Introduction

The Matrice 30 Series Dock Version by SZ DJI TECHNOLOGY CO., LTD. represents a leap forward in enterprise drone automation, designed to enable fully remote, automated aerial operations. Built for integration with the DJI Dock ecosystem and managed via DJI FlightHub 2, this advanced drone system is engineered for reliability, seamless connectivity, and robust performance in challenging environments. Its primary purpose is to facilitate persistent, unattended drone operations—ideal for industrial monitoring, infrastructure inspection, emergency response, and more.

A critical milestone in its commercial deployment is its FCC certification under FCC ID SS3-M302110. This certification is not just a regulatory checkbox; it confirms that the Matrice 30 Series Dock Version complies with stringent US radio frequency (RF) emission standards, ensuring it is legal to sell and operate in the United States. The FCC process validates the device’s electromagnetic compatibility, protecting users and nearby equipment from interference.

In this article, we’ll dissect the Matrice 30 Series Dock Version’s key features, wireless specifications, operating frequencies, and the advanced technology underpinning its performance. We’ll also offer a detailed teardown analysis of its internal hardware and explore the regulatory insights from its FCC filings. Whether you’re an engineer, tech enthusiast, or enterprise drone operator, this in-depth analysis will provide a comprehensive understanding of this cutting-edge drone platform.

Key Features & Specifications

The Matrice 30 Series Dock Version is purpose-built for demanding, automated drone missions. Let’s break down its standout features and technical specs that set it apart:

Key Features

- O3 Enterprise Video Transmission System

- Offers robust, low-latency, high-definition video links for superior situational awareness and mission control.

- Seamless Integration with DJI Dock Version

- The aircraft is engineered to dock and charge autonomously, supporting persistent, remote operations.

- Automated Operations via DJI FlightHub 2

- Enables fully remote mission planning, execution, health monitoring, and data management—ideal for industrial and critical infrastructure use.

- Wide Operating Temperature Range

- Functions reliably from -20° to 50° C (-4° to 122° F), ensuring dependable performance in harsh environments.

- Supports TB30 Intelligent Flight Battery

- Leverages intelligent power management for extended flight endurance and safe, efficient charging cycles.

- Modular Camera Options

- The M30 Dock Version and M30T Dock Version support different camera payloads, catering to diverse operational needs such as visual inspection, thermal imaging, and situational awareness.

- Industrial-Grade Build Quality

- Robust construction and advanced EMI shielding for high reliability in mission-critical deployments.

Technical Specifications

- Transmitter Power (EIRP):

- 2.4 GHz: < 23 dBm (FCC), < 20 dBm (CE/SRRC/MIC)

- 5.1 GHz: < 23 dBm (FCC/CE/SRRC/MIC)

- 5.8 GHz: < 23 dBm (FCC/SRRC), < 14 dBm (CE)

- Operating Frequency Bands:

- 2.4000–2.4835 GHz, 5.170–5.250 GHz, 5.725–5.850 GHz

- Max Transmission Distance:

- Up to 15 km (FCC), 8 km (CE/SRRC/MIC)

- Wireless Connectivity:

- Wi-Fi: Operates across standard 2.4 GHz and 5 GHz bands

- Bluetooth: Present (specific details not provided)

- Battery Compatibility:

- TB30 Intelligent Flight Battery for safe, reliable power and optimal charging cycles

- Power Supply:

- Operates using external battery, designed for integration with dock charging systems

- Camera Payload:

- M30T version includes advanced thermal and visual cameras; selection depends on the variant purchased

Benefits in Practice

- Unattended Operations: The integration with DJI Dock and FlightHub 2 allows for scheduled, repeatable missions without human intervention, maximizing efficiency.

- Resilience: The wide temperature range and robust construction ensure the drone can be deployed in diverse environments, from arctic cold to desert heat.

- Reliable Connectivity: The O3 Enterprise transmission system and multi-band Wi-Fi support ensure solid command-and-control links, critical for safe, remote operation.

- Enterprise-Grade Power: Intelligent battery integration means longer missions, safer charging, and reduced downtime.

Operating Frequencies

The Matrice 30 Series Dock Version (FCC ID SS3-M302110) operates across a variety of RF bands, as rigorously tested and documented in its FCC filing. The table below summarizes the frequency ranges and corresponding output power levels:

| Frequency Range (GHz) | Output Power (mW) | FCC Rule Part |

|---|---|---|

| 2.4035-2.4695 | 57 | 15CCC |

| 2.40512-2.47112 | 52.4 | 15CCC |

| 5.7285-5.8465 | 40.1 | 15ECC |

| 2.4055-2.4685 | 55.2 | 15CCC |

| 5.17-5.23 | 49.8 | 15ECC |

| 5.73012-5.84812 | 40.5 | 15ECC |

| 2.4075-2.4675 | 837.5 | 15CCC |

| 5.7275-5.8445 | 41.2 | 15ECC |

| 2.4125-2.4625 | 561 | 15CCC |

| 5.73012-5.84812 | 40.5 | 15ECC |

| 5.7302-5.8472 | 47.3 | 15ECC |

| 2.4082-2.4712 | 53.5 | 15CCC |

| 5.7302-5.8472 | 47.3 | 15ECC |

| 5.7305-5.8445 | 202.8 | 15ECC |

| 5.161-5.24 | 50 | 15ECC |

| 5.7285-5.8465 | 40.1 | 15ECC |

| 5.7355-5.8395 | 200 | 15ECC |

| 2.4225-2.4525 | 498.9 | 15CCC |

| 5.7305-5.8445 | 202.8 | 15ECC |

| 5.7455-5.8295 | 141.6 | 15ECC |

| 5.7355-5.8395 | 200 | 15ECC |

| 5.7455-5.8295 | 141.6 | 15ECC |

These bands and power levels form the backbone of the device’s wireless connectivity, ensuring robust command, control, and data transmission, while adhering to regulatory requirements for RF emissions and spectrum use.

Technology Deep Dive

The Matrice 30 Series Dock Version leverages a sophisticated blend of wireless technologies to deliver uncompromising performance and reliability. Its primary communication systems operate over the 2.4 GHz and 5 GHz ISM bands, supporting Wi-Fi and proprietary O3 Enterprise video transmission for real-time HD video and telemetry. Bluetooth is also present, likely serving roles in device provisioning, short-range diagnostics, or peripheral connectivity.

The device’s use of multiple frequency bands enhances operational flexibility, allowing for optimal link quality even in congested RF environments. High transmitter power (up to 23 dBm EIRP per FCC limits) and advanced modulation schemes ensure long-range, interference-resistant communications—vital for autonomous, remote missions.

These technologies are tightly integrated with intelligent power management to balance range, throughput, and battery life. The multi-band support also allows for robust fallback and redundancy, minimizing the risk of lost connections. The presence of extensive EMI shielding and careful PCB layout (as seen in the internal component analysis) underscores a design philosophy centered on maximizing RF performance while minimizing interference, both internally and with external systems.

The FCC test reports further confirm that the device meets or exceeds all regulatory thresholds for RF emissions and susceptibility, ensuring safe operation in both urban and industrial settings.

In-Depth Internal Component Analysis / Teardown

A close examination of the Matrice 30 Series Dock Version’s internal hardware reveals a meticulously engineered system, optimized for reliability, modularity, and high performance. Below, we analyze ten key internal subsystems based on detailed component photographs:

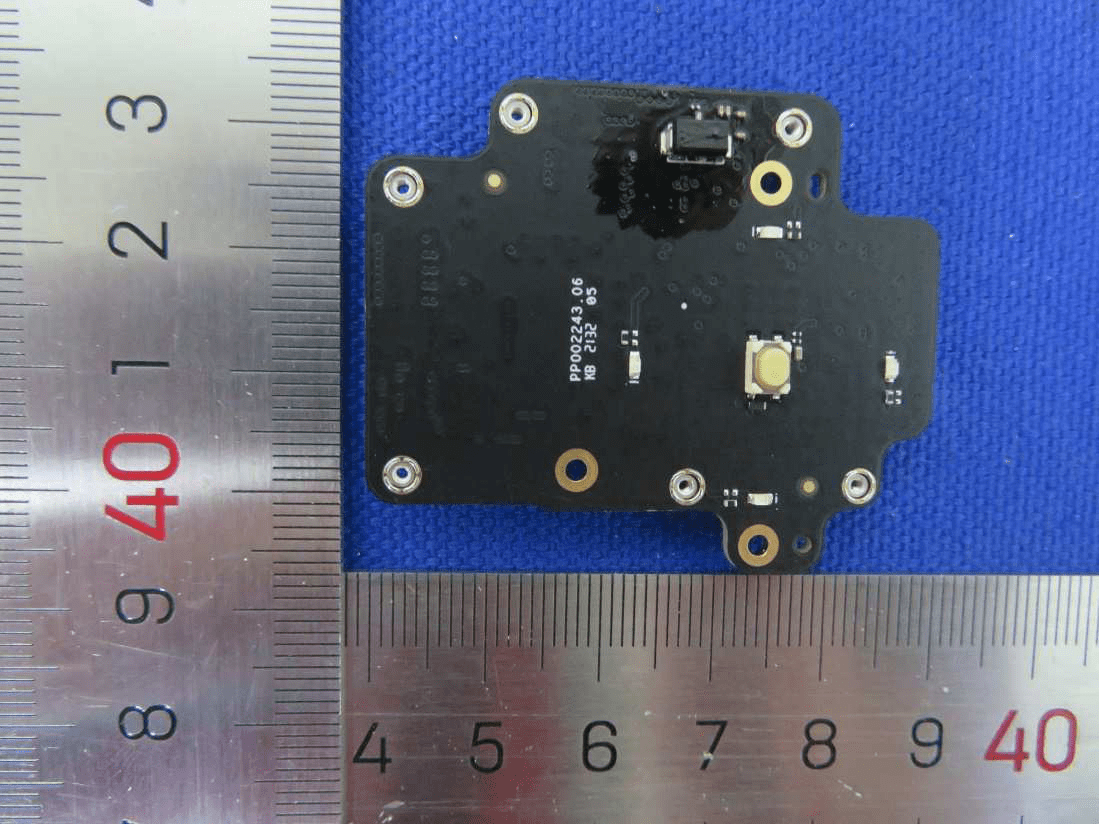

The small black PCB, measuring roughly 40mm square, exemplifies DJI’s focus on modularity and robust mechanical integration. Dominated by a tactile pushbutton switch and a compact surface-mount connector, this board is clearly designed for low-power interfacing—likely serving as a user input or status interface within the larger system. The absence of significant ICs, RF components, or antennas on this side suggests it is not a processing or radio module, but its clean soldering, unpopulated pads, and solid mounting holes reflect high build quality and attention to durability. This board plays a supporting role, enabling reliable user or system interaction while maintaining mechanical and electrical integrity within the drone or dock enclosure.

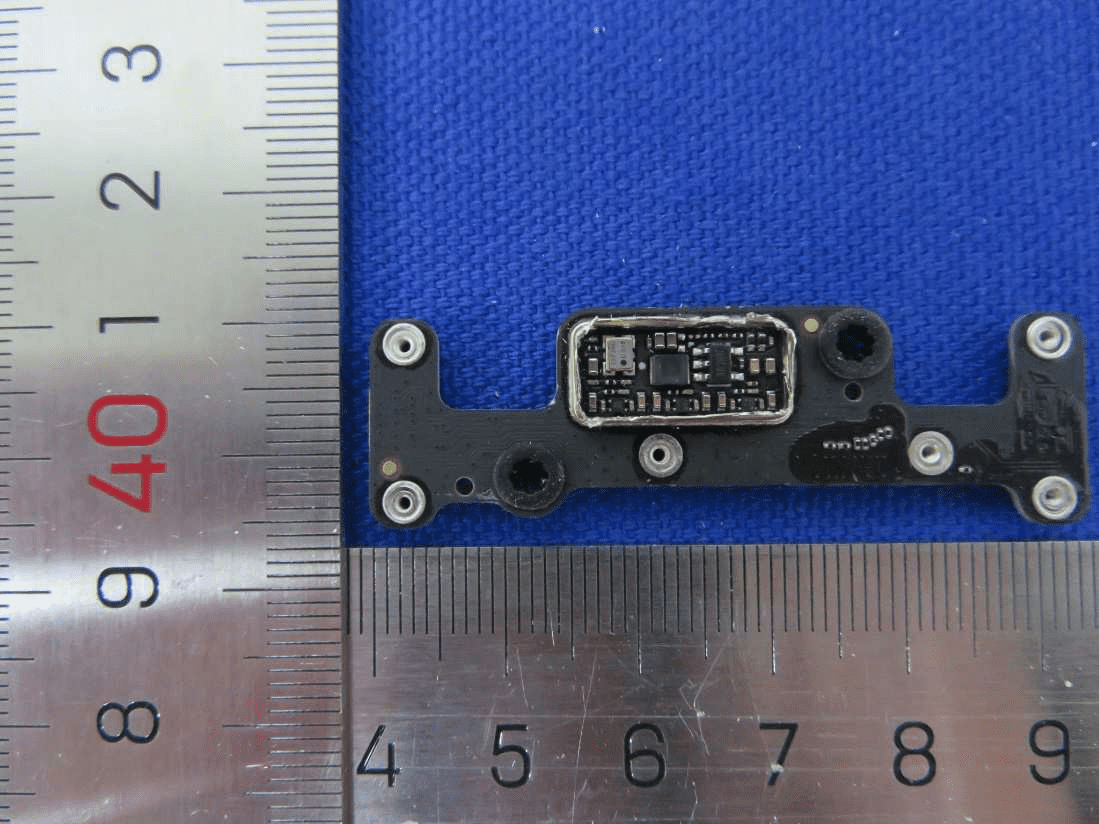

This compact black PCB, approximately 40mm in length, is densely populated with surface-mount components and features a prominent shielded area. The central, but unmarked, IC is likely a microcontroller or precision sensor, surrounded by supporting passives and possibly an EEPROM. The presence of a soldered metal shield can and numerous stitching vias highlights a strong focus on EMI suppression, suggesting this module is responsible for sensitive analog or sensor data handling—potentially an environmental or navigation sensor interface. The mechanical mounting points and high-quality assembly ensure the module’s resilience within the drone’s demanding operational environment. Its design underscores the importance of noise immunity and reliability for critical sensor or control subsystems.

Densely populated sensor/control PCB with shield can for EMI suppression and reliability.

The intricate camera/gimbal module PCB reveals a sophisticated mix of high-performance image processing and real-time stabilization hardware. Multiple BGA and QFN ICs, likely including image signal processors and microcontrollers, are shielded beneath metal cans and thermal pads, ensuring both EMI control and heat dissipation. The board’s multi-layer construction, high-density FPC/FFC connectors, and robust grounding strategy enable high-speed video data transfer and precise gimbal motor control. Visible gimbal motors and encoders indicate closed-loop stabilization, while extensive thermal management ensures sustained operation during demanding missions. This assembly is central to the drone’s ability to capture and transmit high-quality, stabilized imagery, a cornerstone of its automated inspection and monitoring capabilities.

High-density camera/gimbal PCB with ISPs, thermal pads, and gimbal motor integration.

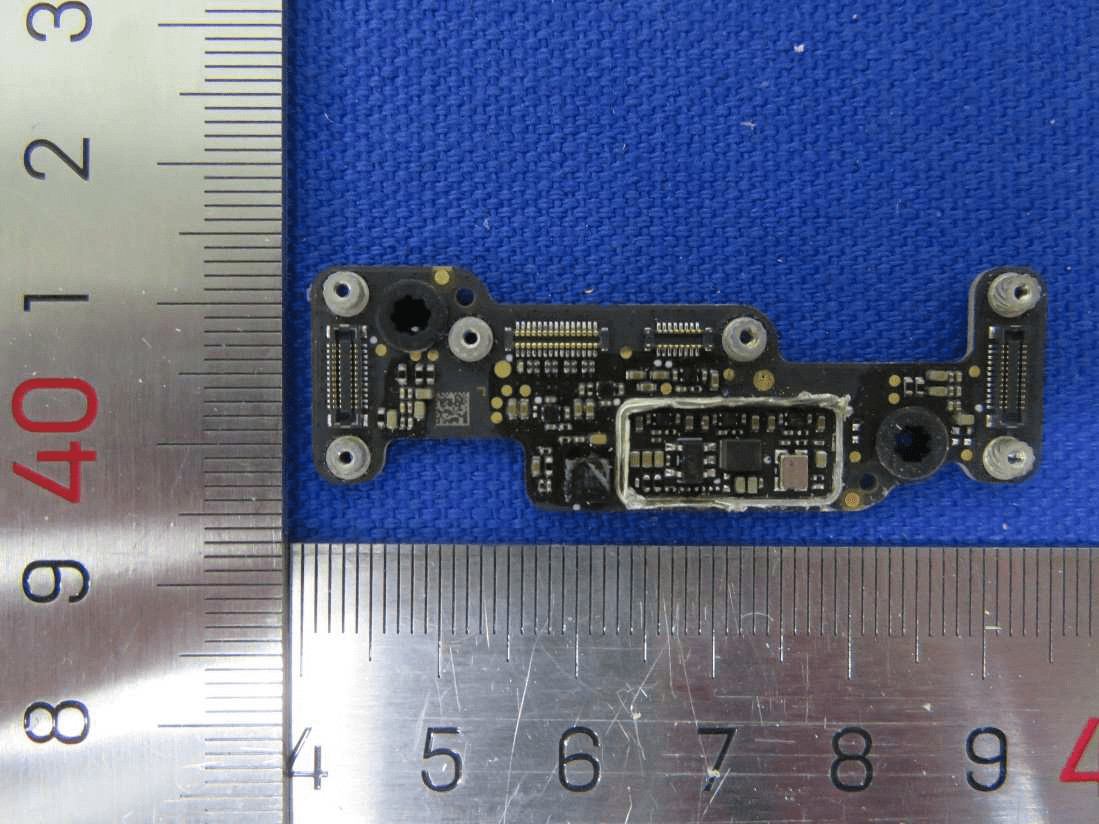

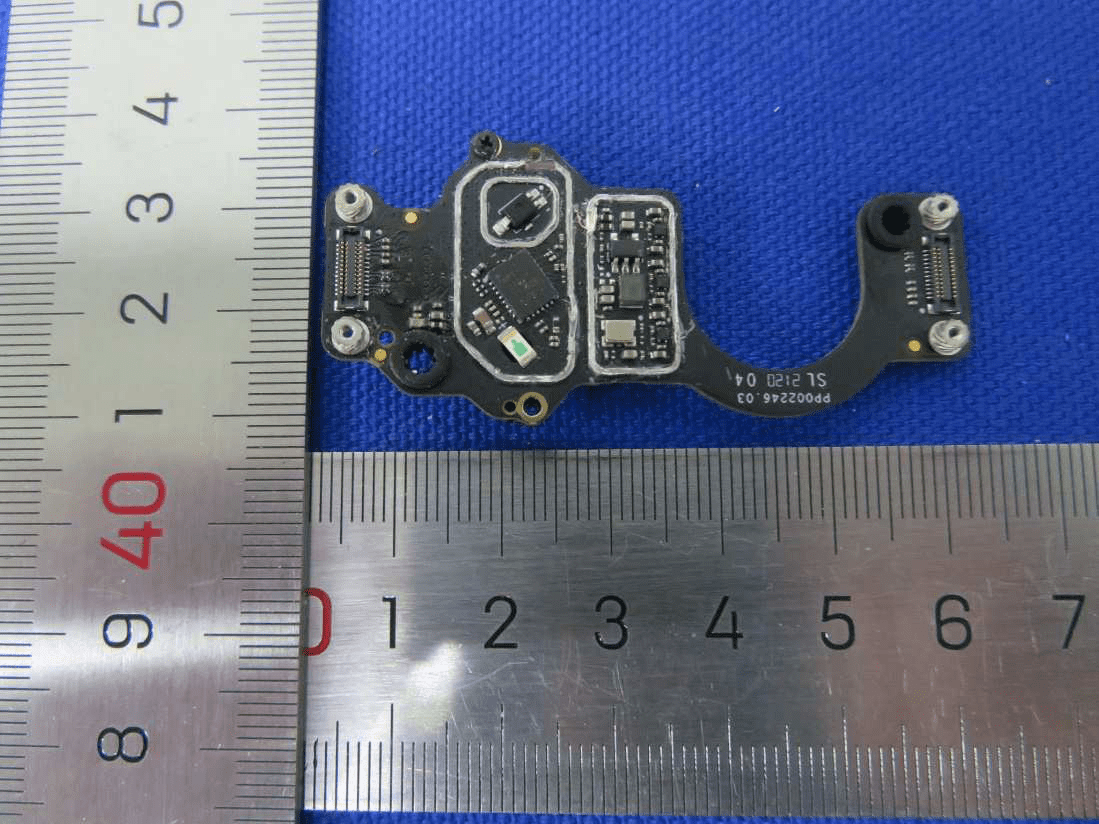

This elongated, densely populated PCB (circa 45mm x 15mm) is a testament to advanced, miniaturized electronics engineering. Featuring multiple QFN and BGA ICs—including one under a dedicated shield can—this board likely manages high-speed data or sensitive analog signals. Three fine-pitch connectors at the edges facilitate modular integration with other subsystems, such as sensors or RF modules. The presence of numerous test points and a strong grounding strategy, combined with robust mechanical mounting, reflect a design optimized for signal integrity and reliability. Such a module would be critical for navigation, environmental sensing, or communication functions within the drone dock system, where precision and resilience are paramount.

Miniaturized high-density PCB with shielded IC, connectors, and robust test points.

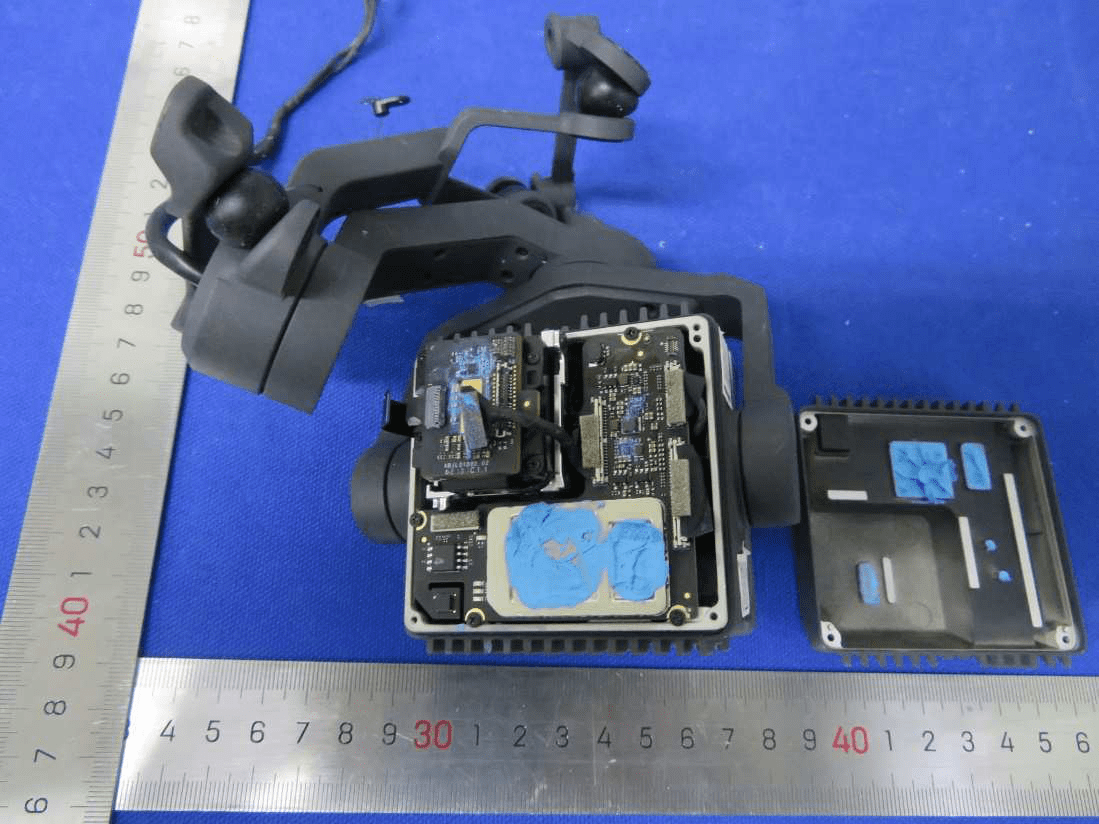

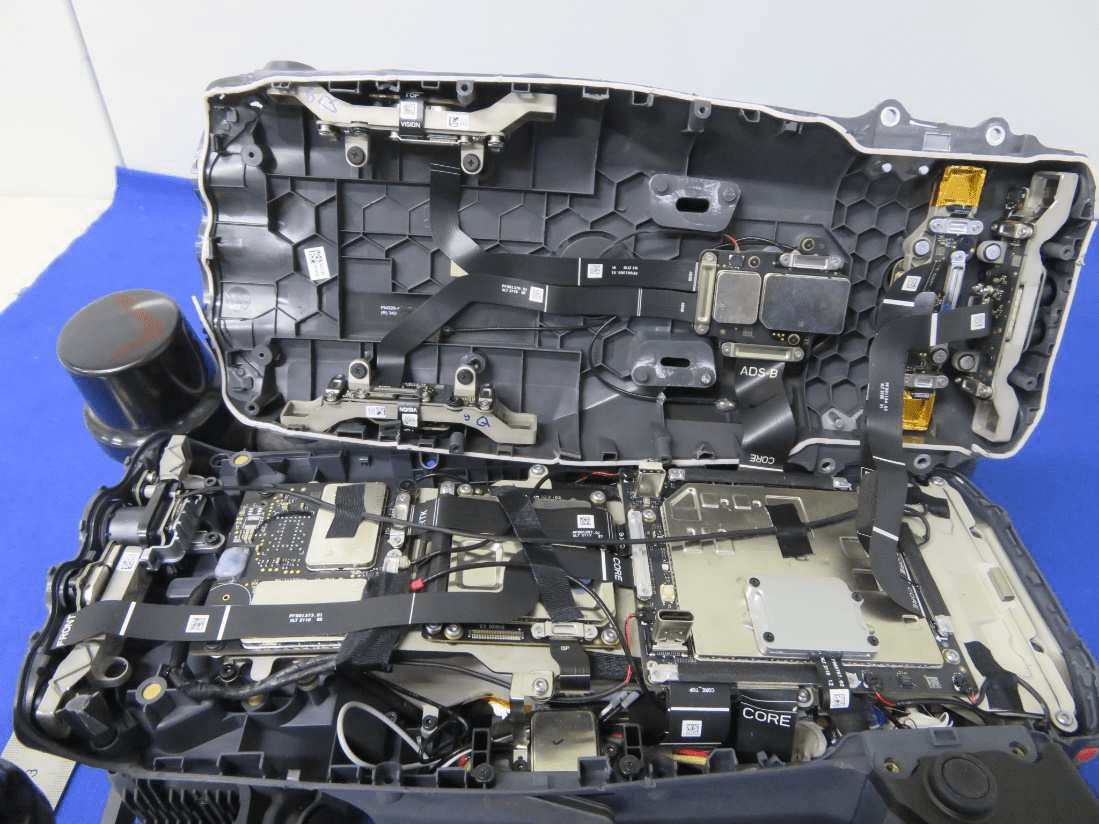

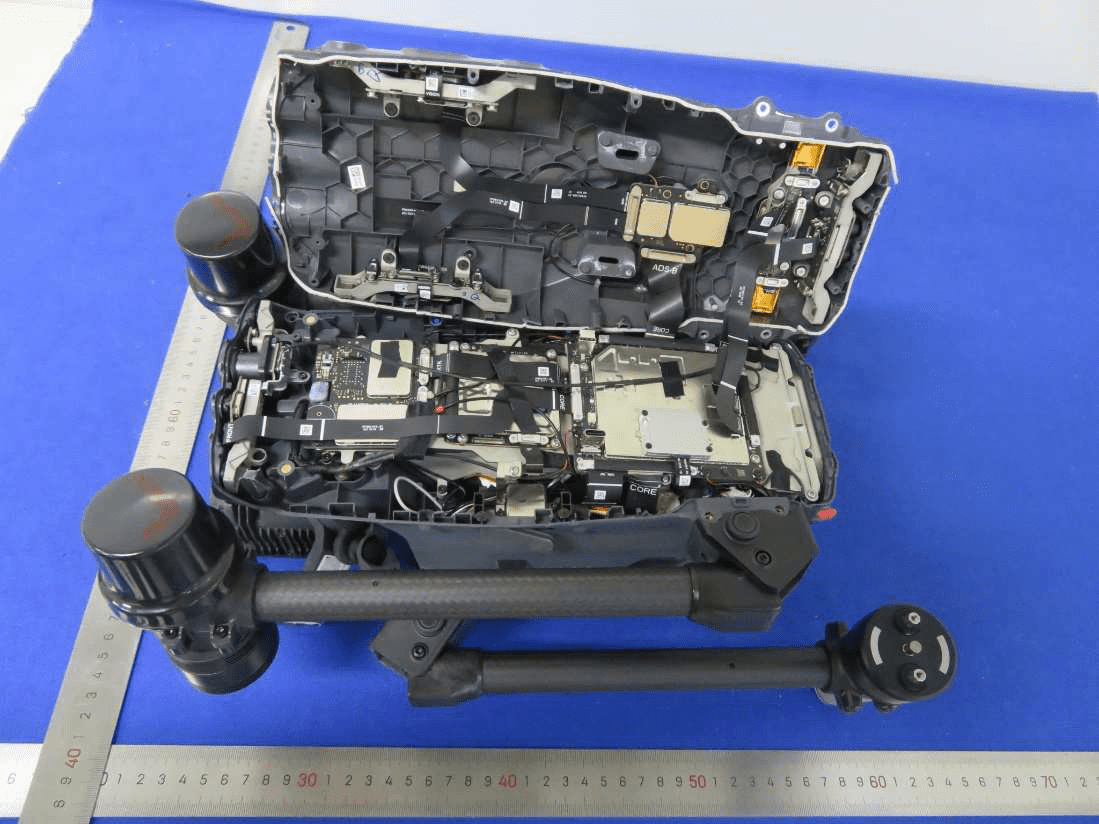

Opening the main enclosure reveals the heart of the Matrice 30 Series Dock Version: a densely packed main PCB array with extensive EMI shielding, multiple large ICs, and a network of coaxial cables and ribbon connectors. Labeled core modules—such as “CORE” and “VISION”—suggest a highly modular architecture, each with dedicated processing and sensor subsystems. The strategic use of metal shields, ground planes, and robust connectors ensures EMI control and mechanical reliability. High-current power components and well-managed cable routing support the device’s demanding flight and payload operations, while modularity aids in assembly, repair, and future upgrades. This internal organization enables the advanced autonomy, multi-band RF communication, and real-time vision processing essential for persistent, remote drone missions.

Main PCB assembly with extensive shielding, modular sections, and robust power management.

This small, irregularly shaped black PCB (about 40mm x 20mm) is densely packed, with a central QFN/BGA IC surrounded by high-density passive components and two fine-pitch FPC connectors. The board’s shape and mounting holes indicate it fits a specific mechanical enclosure, likely as a sensor or interface module. Possible crystal oscillators or MEMS sensors hint at timing or environmental sensing roles. The area around the main IC appears to have been shielded for EMI protection, ensuring reliable operation in noise-sensitive applications. This board exemplifies DJI’s approach to modular, miniaturized sensor integration, supporting high-reliability operation within the Matrice 30 Series Dock Version.

Sensor/interface PCB with central IC, FPC connectors, and high component density.

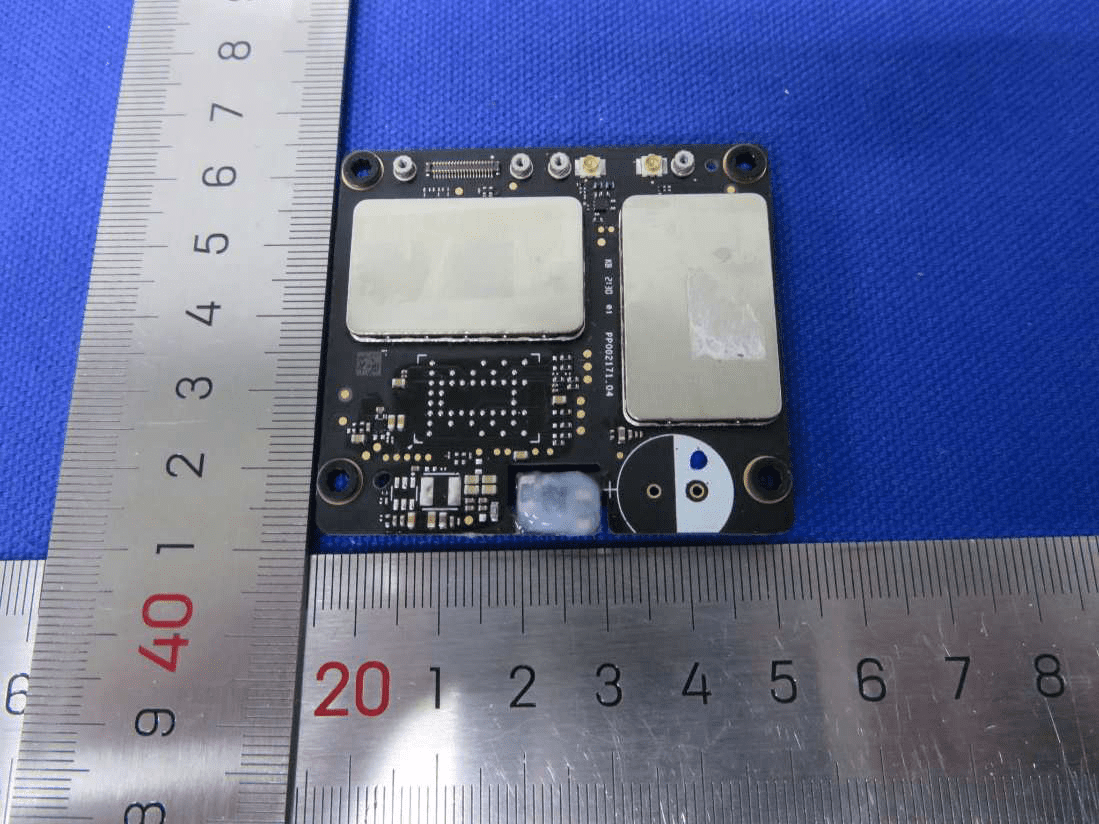

A high-density PCB with two prominent metal shield cans indicates this board’s role in handling sensitive RF or high-speed digital communication tasks. The presence of U.FL connectors for external antennas and a fine-pitch board-to-board connector underscores its role as a wireless communication or GNSS module. Large capacitors and inductors provide local power regulation, while robust grounding and shielded areas ensure electromagnetic compatibility. Test points and crystals suggest support for diagnostics and precise timing. This module is essential for the drone’s reliable, interference-free connectivity—whether for Wi-Fi, GPS, or proprietary RF communication within the docked system.

RF/high-speed digital PCB with dual shield cans and U.FL antenna connectors.

The main PCB of the Matrice 30 Series drone showcases advanced integration, with a central SoC surrounded by memory, power management, and RF transceivers. Multiple FPC and coaxial connectors enable modular assembly, supporting various subsystems such as cameras, sensors, and communication modules. Extensive use of metal shields minimizes EMI, critical for maintaining signal integrity across multi-band RF and high-speed data lines. The presence of robust battery connectors and power handling components ensures the board can support high-current loads for motors and payloads. This densely populated, multi-layer board is the operational core, orchestrating flight control, video processing, telemetry, and power management for demanding enterprise missions.

Main drone PCB with SoC, memory, RF transceivers, and extensive shielding.

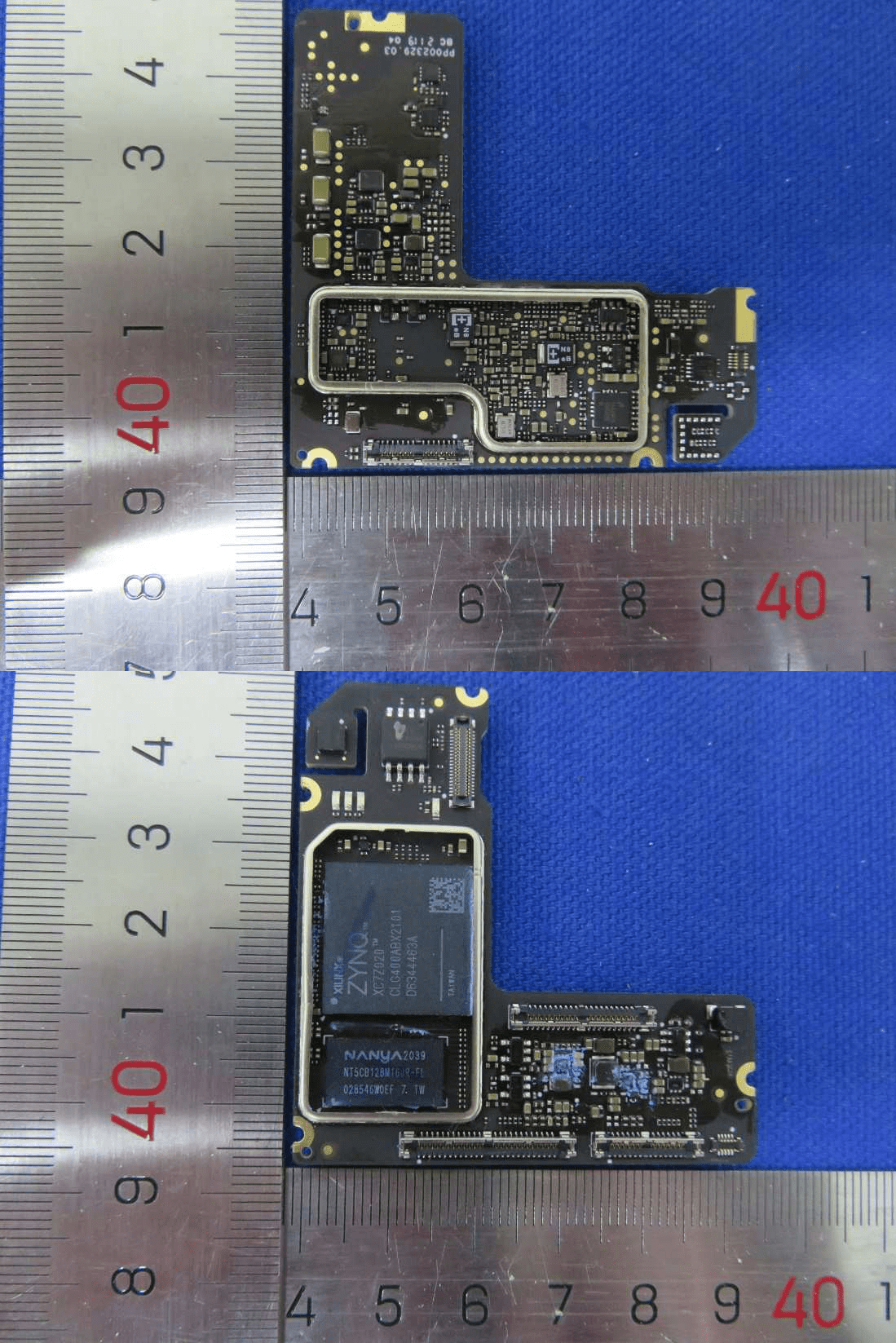

A standout feature of the internal hardware is the use of a Xilinx Zynq SoC, combining ARM processing with FPGA flexibility, partnered with high-speed Nanya DRAM. The multi-layer PCB is meticulously laid out, with differential pair routing for high-speed signals and robust grounding for EMI control. Shield cans protect sensitive analog and RF sections, while several FPC connectors provide high-bandwidth interfaces for cameras, sensors, or displays. The high integration and modularity of this board enable real-time data fusion, autonomous control, and advanced communication functions, positioning it as the computational nerve center of the dock system.

Central processing PCB with Xilinx Zynq SoC, DRAM, and shielded RF sections.

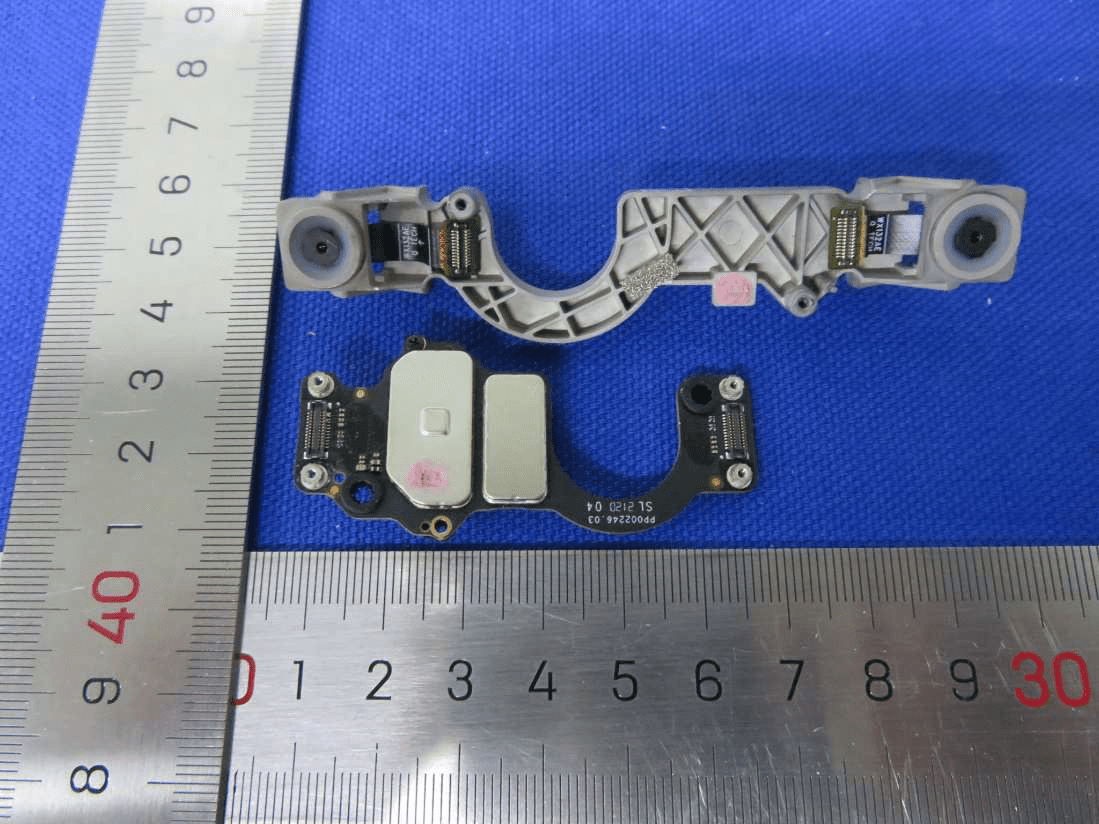

The vision/navigation subsystem is represented by a pair of compact assemblies featuring stereo camera modules and a PCB with dual EMI shields. Multiple FPC connectors and precise mounting points enable modular, serviceable integration. The camera modules provide stereoscopic imaging for depth perception, obstacle avoidance, or mapping, while the shielded PCB likely handles image signal processing and sensor fusion. The robust construction and careful EMI management ensure reliable, high-fidelity data capture and processing—critical for autonomous navigation and situational awareness in complex operational environments.

Stereo camera module assembly with shielded signal processing PCB for vision/navigation.

Regulatory Insights & FCC Filing

Achieving FCC certification under FCC ID SS3-M302110 is a cornerstone of the Matrice 30 Series Dock Version’s market readiness in the United States. This certification, registered by FCC.gov, validates that the device meets strict US standards for electromagnetic interference, RF emissions, and wireless spectrum use—ensuring it is both legal and safe for sale and deployment.

FCC filings encompass a wealth of technical documentation, including test reports for RF exposure and electromagnetic compatibility, detailed internal and external photographs, user manuals, schematics, and block diagrams. These documents collectively demonstrate the device’s compliance with regulatory requirements and provide transparency into its design and operational safeguards.

According to the user manual and internal documentation, the Matrice 30 Series Dock Version is engineered for remote, automated operations with DJI Dock and FlightHub 2. The documentation outlines essential safety, setup, compliance, and disposal instructions, reinforcing the product’s focus on professional, enterprise-grade applications. The FCC test reports confirm that the device’s wireless subsystems operate within specified limits for output power and frequency, minimizing the risk of interference with other devices or critical infrastructure.

In summary, FCC ID SS3-M302110 is both a mark of legal compliance and a testament to the rigorous engineering and testing underpinning the Matrice 30 Series Dock Version’s design.

Potential Use Cases & Target Audience

With its advanced automation, robust wireless connectivity, and industrial-grade reliability, the Matrice 30 Series Dock Version is tailored for professional users and enterprise scenarios—not for children or casual consumers. Here are several practical applications:

- Infrastructure Inspection & Monitoring: Utilities, energy companies, and transportation agencies can deploy fleets of docked Matrice 30 drones for routine inspection of power lines, pipelines, bridges, and railways. Automated missions, managed remotely via FlightHub 2, reduce human risk and maximize operational efficiency.

- Emergency Response & Public Safety: Fire departments, police, and disaster response teams can leverage the system for rapid situational assessment, search and rescue, or hazardous environment monitoring. The ability to launch on-demand missions without onsite personnel enables faster, safer response.

- Industrial Site Security & Surveillance: Enterprises can automate perimeter patrols and site inspections, using the drone’s advanced imaging and thermal capabilities to detect intrusions, equipment failures, or safety hazards—streamlining security operations and compliance reporting.

The target audience includes enterprise drone operators, industrial automation specialists, infrastructure managers, and public safety agencies seeking reliable, scalable, and unattended aerial solutions.

Conclusion

The Matrice 30 Series Dock Version by SZ DJI TECHNOLOGY CO., LTD. stands at the forefront of autonomous drone technology, offering unparalleled remote operation capabilities, industrial-grade reliability, and regulatory compliance. Its FCC certification (FCC ID SS3-M302110) not only enables legal deployment in the US but also reflects the rigorous engineering behind its design—spanning robust wireless systems, intelligent power management, and sophisticated internal hardware.

With its seamless integration into DJI Dock and FlightHub 2, the Matrice 30 Series Dock Version is poised to transform how enterprises and public agencies deploy aerial assets—delivering efficiency, safety, and insight through cutting-edge automation and connectivity.