Introduction

The RoboMaster EP Core by SZ DJI TECHNOLOGY CO., LTD. stands as a flagship educational robotics platform, purpose-built for STEAM environments where hands-on learning meets advanced engineering. Designed to empower both teachers and students, the EP Core seamlessly integrates mechanical, electronic, and programming skills into a single, versatile solution. Its robust suite of sensors, actuators, and connectivity options offers an ideal playground for exploring robotics, AI, and real-world problem solving.

A key milestone in its journey to the classroom is its FCC certification under FCC ID SS3-RMEPCORE. This regulatory approval confirms that the RoboMaster EP Core complies with stringent U.S. standards for radio frequency emissions and electromagnetic compatibility, making it legal for sale and operation in the United States. The FCC ID not only assures users of its safety and reliability in wireless communications but also signifies the device’s adherence to industry best practices in engineering and manufacturing.

In this article, we’ll dissect the RoboMaster EP Core from every angle: exploring its standout features and specifications, analyzing its wireless and RF capabilities, delving into its sophisticated internal components, and highlighting the regulatory and educational value it brings to STEAM classrooms. Whether you’re an educator, engineer, or robotics enthusiast, this comprehensive teardown and analysis will provide the insights you need to understand what sets the RoboMaster EP Core apart.

Key Features & Specifications

The RoboMaster EP Core is more than just a programmable robot—it’s a modular, high-performance learning platform engineered for advanced robotics education. Below is a breakdown of its key features and technical specifications, with explanations highlighting their practical impact.

Key Features

- Omnidirectional Motion Control

- Motion controller with omnidirectional wheel motion control algorithm enables smooth, precise maneuvering in any direction. The use of Mecanum wheels allows for advanced movement not possible with standard wheel configurations, critical for robotics competitions and real-world navigation tasks.

-

Integrated power management and motor management ensure efficient and reliable operation, minimizing downtime and optimizing performance.

-

Wireless Connectivity

- Wi-Fi and router connectivity provide robust, low-latency control and programming interfaces. The system supports both 2.4 GHz and 5 GHz bands, maximizing flexibility in diverse environments.

-

App compatibility across iOS, Android, Windows, and Mac enables true cross-platform play and learning, supporting a wide range of devices in the classroom.

-

Robotic Arm

-

A fully functional robotic arm expands the EP Core’s capabilities for manipulation, object handling, and custom tool integration—ideal for both curriculum-driven tasks and open-ended exploration.

-

High-Quality Camera

-

The built-in camera features a 1/4-inch CMOS sensor, 5MP effective pixels, and a 120° field of view, supporting both high-resolution stills and smooth 720p/30fps live video for remote driving, vision processing, or AI experiments.

-

Audio System

-

Integrated 2.5 mm, 2 W speaker enables sound output for multimedia projects, alerts, or interactive activities, enhancing engagement and communication.

-

Expandable & Programmable

- Official SDK allows for hardware expansion, supporting custom sensors, actuators, and third-party integrations.

- Rich teaching resources and a continually-updated competition database foster ongoing learning and challenge-driven exploration.

Technical Specifications

- Camera

- Max Still Photo Resolution: 2560×1440 pixels

- Sensor: 1/4″ CMOS, 5MP effective pixels

- FOV: 120°

- Max Video Resolution: 1080p/30fps (FHD), 720p/30fps (HD)

- Photo Format: JPEG

- Video Format: MP4

- Max Video Bitrate: 16 Mbps

-

Live View Quality: 720p/30fps

-

Wireless

- Wi-Fi: IEEE802.11a/b/g/n; 2.4 GHz, 5.1 GHz, 5.8 GHz

- Bluetooth: Present (details not specified)

-

Max Transmission Distance (Wi-Fi):

- FCC: 2.4 GHz 140 m, 5.8 GHz 90 m

- CE: 2.4 GHz 130 m, 5.8 GHz 70 m

- SRRC: 2.4 GHz 130 m, 5.8 GHz 130 m

- MIC: 2.4 GHz 130 m

-

Chassis

- Omnidirectional Chassis with Mecanum wheels for agile, multi-directional movement

-

Max Chassis Rotational Speed: 600°/s

-

Battery & Power

- Battery Type: LiPo 3S

- Capacity: 2400 mAh

- Energy: 25.92 Wh

- Battery Life (in use): 35 mins (at 2.0 m/s on flat surface)

- Battery Life (standby): Approx. 100 mins

-

Maximum Charging Power: 29 W

-

Storage

-

Supported SD Cards: microSD up to 64 GB

-

Networking

- Recommended Routers: TP-Link TL-WDR8600, TL-WDR5640 (China); TP-Link Archer C7, NETGEAR X6S (International)

These features and specifications highlight the RoboMaster EP Core’s versatility, performance, and suitability for both foundational and advanced robotics education.

Operating Frequencies

The RoboMaster EP Core, under FCC ID SS3-RMEPCORE, operates across several frequency bands as defined in its FCC filing. The following table summarizes its key wireless transmission parameters:

| Frequency Range (GHz) | Output Power (mW) | FCC Rule Part |

|---|---|---|

| 2.412–2.462 | 201.8 | 15CCC |

| 12.422–2.452 | 183.7 | 15CCC |

| 15.19–5.23 | 148.9 | 15ECC |

| 25.18–5.24 | 114.3 | 15ECC |

| 25.745–5.825 | 254.1 | 15ECC |

| 35.755–5.795 | 246 | 15ECC |

These frequency ranges and power levels are critical for ensuring robust wireless communication (primarily Wi-Fi and Bluetooth), enabling reliable operation in diverse environments while maintaining compliance with U.S. regulatory requirements.

Technology Deep Dive

The RoboMaster EP Core leverages advanced wireless technologies to deliver seamless connectivity and control. Its primary wireless interfaces are Wi-Fi (supporting IEEE802.11a/b/g/n standards across 2.4 GHz and 5 GHz bands) and Bluetooth (present, though specific protocol details are not listed). These technologies enable low-latency, high-bandwidth communication between the robot and user devices, supporting real-time control, video streaming, and data exchange.

Operating across both 2.4 GHz and 5 GHz Wi-Fi bands allows the EP Core to adapt to varying network environments, minimizing interference and maximizing range. The output power levels specified in the FCC filing indicate strong, reliable coverage suitable for classroom, lab, or competition settings. Bluetooth functionality further expands device pairing and accessory integration, although its primary use appears secondary to Wi-Fi.

The selection of these frequencies and power levels strikes a balance between performance and regulatory compliance. Higher output powers on 5 GHz bands enable robust short-to-medium range operation, while 2.4 GHz ensures better penetration and compatibility in crowded environments. The modular use of these technologies ensures that the RoboMaster EP Core remains responsive, energy-efficient, and versatile—key attributes for educational robotics platforms.

In-Depth Internal Component Analysis / Teardown

A close examination of the RoboMaster EP Core’s internal hardware reveals the meticulous engineering underpinning its robust performance and reliability. Below, we break down key findings from detailed component photographs, each illustrating a unique subsystem integral to the robot’s operation.

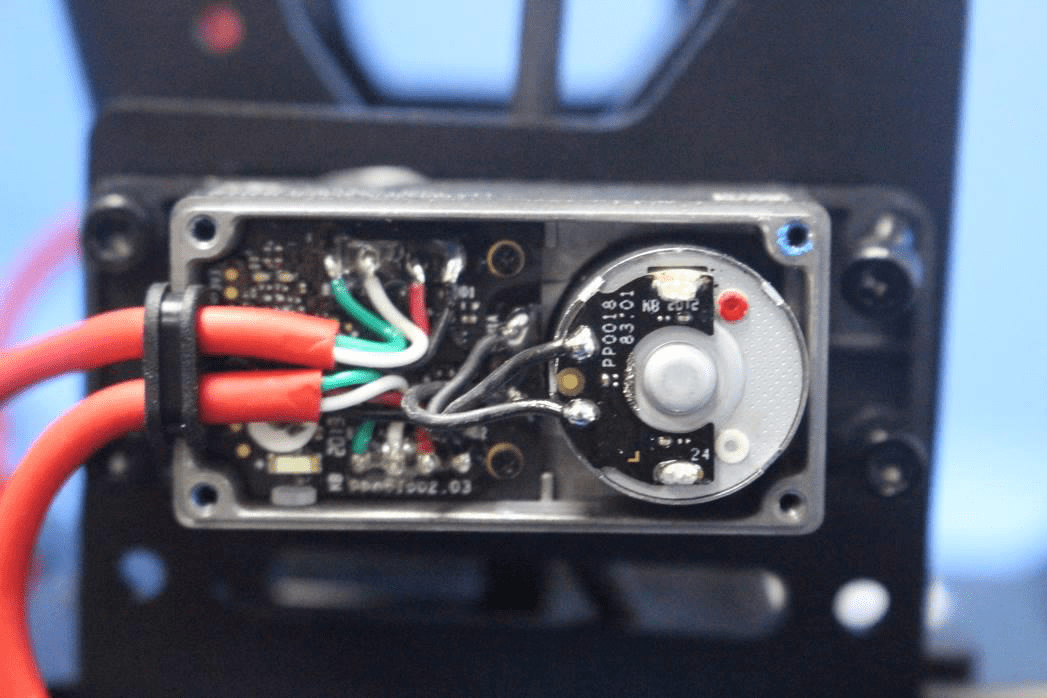

The first revealed module showcases a high-quality actuator or sensor assembly, integral to the RoboMaster EP Core’s precise motion control. The compact black PCB, housed within a sturdy metal enclosure, is densely populated with SMD components, including what are likely op-amps, MOSFETs, or microcontrollers. Thick red wires suggest high-current delivery for a DC motor, while color-coded signal wires provide robust connectivity for position feedback—possibly via Hall or optical sensors mounted on the round encoder PCB. The absence of removable connectors and the use of direct soldering indicate a design focus on durability and vibration resistance, essential for mobile robotics. The integration of motor control, feedback, and power management within a single, shielded enclosure demonstrates DJI’s commitment to precision and reliability in actuator design, enabling the EP Core’s advanced omnidirectional movement and responsive control.

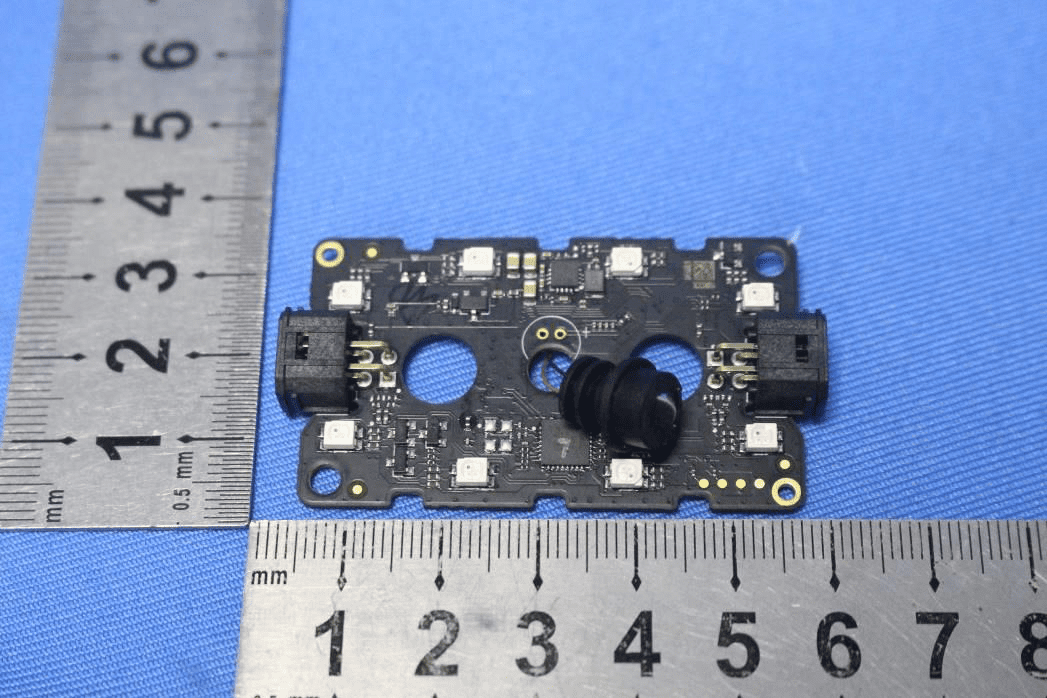

The next internal view highlights a compact, densely populated PCB assembly, likely serving as a vision or sensing module within the RoboMaster EP Core. The board’s symmetrical layout, with dual 4-pin connectors and a central optical or IR sensor, suggests use in stereo vision, obstacle detection, or environmental sensing. Multiple white LEDs flank the sensor, providing illumination or status indication. The presence of numerous vias and controlled impedance traces, combined with a probable 4-layer construction, reflects a design optimized for signal integrity and modularity. Large capacitors and inductors point to onboard voltage regulation, ensuring stable power delivery for sensitive components. This level of engineering enables the EP Core to accurately perceive its environment, facilitating autonomous navigation, line following, or interactive classroom challenges.

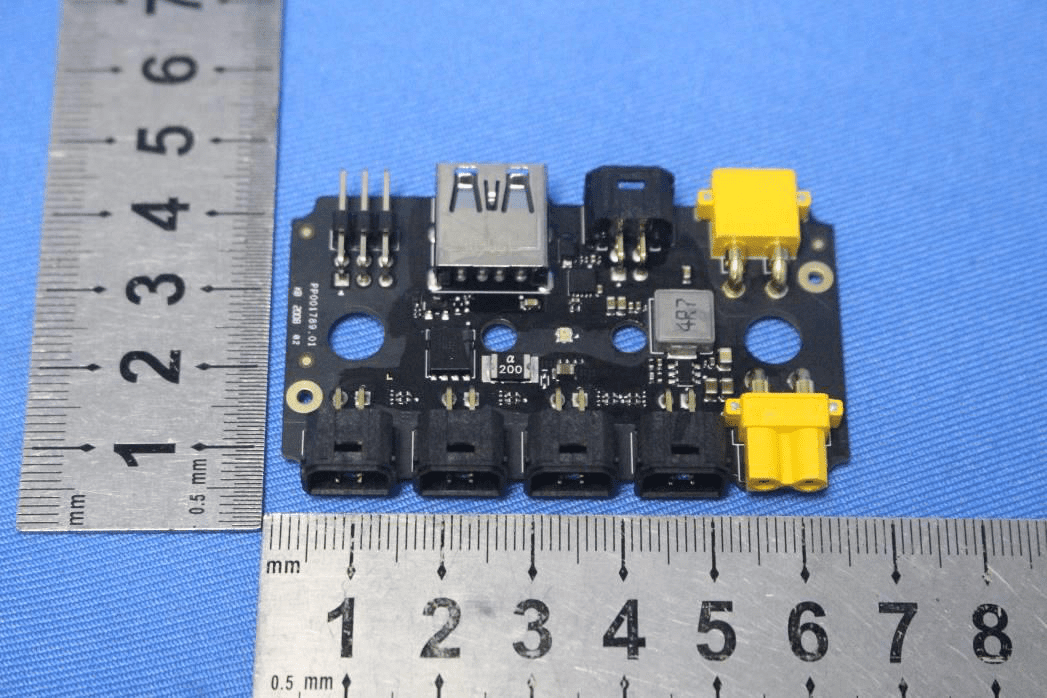

A further teardown reveals a robust power and I/O distribution board, characterized by its clean connector layout and high-current handling capabilities. Dominated by two yellow XT30 connectors and a USB-A port, this PCB is designed for modular power delivery to motors, sensors, or other peripherals. The central IC, likely a power management or distribution controller, oversees power flow and monitoring. Multiple barrel jacks and a 4-pin header provide extensive expansion options, while large copper pours and thick traces ensure minimal voltage drop and heat buildup during operation. The absence of major processing or RF components underscores the board’s dedicated role in safe, reliable power management—a cornerstone for educational robotics platforms that demand both flexibility and robustness.

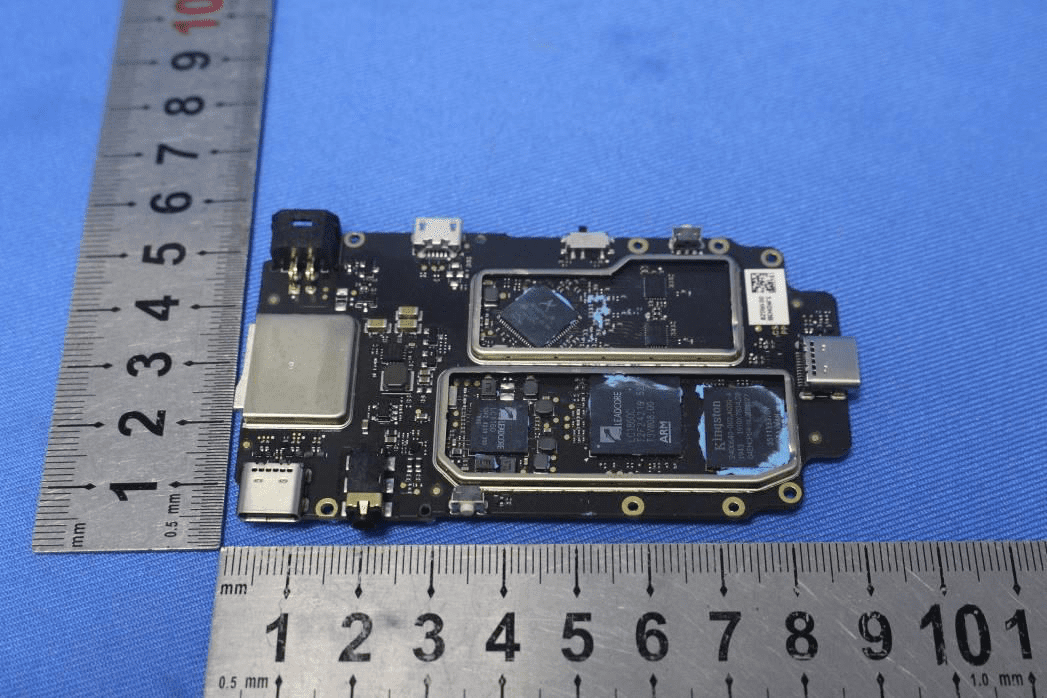

Finally, the heart of the RoboMaster EP Core is revealed in its mainboard—a densely packed PCB featuring high-performance processing and memory components. Central to this board is a prominent ARM-based SoC, flanked by Micron DRAM or NAND flash chips, all evidence of a system designed for real-time control, multimedia processing, and advanced computation. The board’s multi-layer construction, extensive ground pours, and differential pair routing ensure signal integrity and EMI suppression, critical for wireless and high-speed data interfaces. Large metal shields and thermal management features highlight DJI’s focus on reliability and performance. Multiple FPC connectors, a USB-C port, and possible U.FL connectors for external antennas point to extensive modularity and connectivity. This mainboard is the command center, orchestrating the EP Core’s motion, sensing, wireless communication, and app integration—underscoring its status as a cutting-edge educational robotics platform.

Regulatory Insights & FCC Filing

The FCC ID SS3-RMEPCORE is a testament to the RoboMaster EP Core’s compliance with U.S. regulatory standards for radio frequency emissions and electromagnetic compatibility. This approval, issued by the FCC, is essential for legal sale and use within the United States, ensuring the device operates safely within defined RF exposure limits and does not interfere with other wireless devices.

FCC filings for the RoboMaster EP Core typically encompass a wealth of technical documentation, including test reports (detailing RF output, EMC, and SAR compliance), internal and external photographs, user manuals, block diagrams, and schematics. These documents collectively verify that the device meets all regulatory requirements and provides transparency into its design and operation.

Insights from the user manual and FCC documentation highlight the EP Core’s status as an all-in-one educational robotics solution. It boasts an official SDK for hardware expansion, a suite of mechanical accessories, and a robust cross-platform app for programming, control, and gameplay. The internal documentation further underscores the device’s modularity, high build quality, and careful attention to EMI/EMC compliance—crucial for reliable operation in busy classroom or competition environments. Ultimately, the FCC ID SS3-RMEPCORE not only ensures legal compliance but also signals a commitment to quality, safety, and engineering excellence.

Potential Use Cases & Target Audience

The RoboMaster EP Core is meticulously crafted for the modern STEAM classroom, catering to educators and learners seeking a hands-on, future-ready robotics experience. Here are a few standout scenarios:

-

Interactive Robotics Curriculum: Teachers can leverage the EP Core’s official SDK, rich teaching resources, and mechanical expansion capabilities to deliver engaging lessons in programming, engineering, and robotics. Students gain practical experience with real-world sensors, actuators, and wireless networking, fostering critical thinking and problem-solving skills.

-

Robotics Competitions and Challenges: With its omnidirectional chassis, high-resolution camera, and modular architecture, the EP Core is ideal for participation in robotics competitions. The continually-updated competition database provides fresh challenges, while the robust app ensures seamless control and coding opportunities across platforms.

-

Advanced Research and Prototyping: For engineering students or clubs, the EP Core serves as a versatile prototyping platform. Its robust power management, expansion ports, and cross-platform SDK support rapid experimentation with AI, computer vision, or autonomous navigation algorithms.

In all these scenarios, the EP Core’s durability, regulatory compliance, and educational focus make it a standout choice for both structured learning and creative exploration.

Conclusion

The RoboMaster EP Core by SZ DJI TECHNOLOGY CO., LTD. is a masterfully engineered educational robotics platform, blending robust hardware, advanced wireless connectivity, and comprehensive programming support into a single, FCC-certified solution. Its approval under FCC ID SS3-RMEPCORE assures educators and institutions of its safety, reliability, and legal compliance for use in the U.S. market. With its modular design, high-performance components, and deep integration with teaching resources, the EP Core sets a new standard for STEAM robotics education—empowering the next generation of innovators, engineers, and problem solvers.