Introduction

The DJI AGRAS T16 is a next-generation agricultural drone engineered for precision crop spraying and large-scale farming operations. As part of DJI’s renowned AGRAS series, the T16 introduces significant advancements in payload capacity, flight control, and intelligent operation, all tailored to the rigorous demands of modern agriculture. Equipped with a modular design, high-precision sensors, and robust safety features, the AGRAS T16 is designed to boost efficiency and ensure the reliability required for professional fieldwork.

A critical milestone in the AGRAS T16’s journey to market is its FCC certification under FCC ID SS3-T161906. This certification confirms the drone meets stringent US regulatory standards for radio frequency (RF) emissions and electromagnetic compatibility. For agricultural drone operators and enterprise buyers, the FCC ID ensures the T16 can be legally sold, operated, and serviced within the United States, and that it adheres to strict safety and interference guidelines.

In this deep-dive analysis, we explore the AGRAS T16’s standout features, technical specifications, wireless technology, internal hardware, and regulatory insights, revealing what makes it a class-leading platform for agricultural drone operations.

Key Features & Specifications

The DJI AGRAS T16 is purpose-built for high-efficiency, industrial-grade spraying applications. Its design and feature set reflect an uncompromising focus on durability, precision, and operational flexibility.

Key Features

- Modular Aerial-Electronics System with Industrial Flight Controller

-

Facilitates rapid maintenance and upgrades. The modular approach enhances reliability and serviceability, critical for minimizing downtime in the field.

-

Intelligent Operation Planning (DJI MG App)

-

Enables automated, optimized flight paths and spraying routines, reducing operator workload and maximizing coverage efficiency.

-

Digital Beam Forming (DBF) Imaging Radar

-

Provides advanced obstacle sensing and terrain-following capabilities, operational both day and night. This ensures consistent, safe operation across varied landscapes and lighting conditions.

-

Replaceable Remote Controller Batteries & Removable Antennas

-

Supports extended missions and simplifies field replacement, minimizing operational interruptions.

-

Operation Resumption, System Data Protection, Empty Tank Warning

-

These features safeguard mission continuity and data integrity, while real-time alerts prevent incomplete tasks due to low payload.

-

Wide-Angle FPV Camera

-

Offers real-time situational awareness, aiding precise navigation and monitoring during spraying missions.

-

Upgraded Spraying System

- Designed for increased payload, spray rate, and spray width, boosting overall productivity and reducing time per hectare.

Technical Specifications

-

Nozzle Quantity: 8

Enables wide spray coverage for efficient field operations. -

Obstacle Avoidance FOV: Horizontal: ±50°, Vertical: 0–10°

Ensures robust detection of obstacles, enhancing safety and terrain adaptation. -

Remote Controller Charging Hub Output: 8.7 V, 6 A

Supports fast battery charging for minimal downtime. -

Propeller Weight (Single): 90 g

Optimized for efficient lift and durability. -

Remote Controller Battery Voltage: 7.6 V

-

Foldable Propellers (R3390): 33×9 in diameter × pitch

Foldable design simplifies transport and storage. -

Flow Meter Measurement Range: 0.45–5 L/min

Accurate flow monitoring for consistent spray application. -

DBF Radar Power Consumption: 15 W

Efficient radar operation with minimal power draw.

Additional Wireless & Camera Specs

- Wi-Fi Frequency Bands:

- 2.4000–2.4835 GHz

- 5.725–5.850 GHz (5 GHz band not available in Japan, Korea, and Europe)

- Bluetooth: Present (detailed specifications not available)

- Camera: 1280×960 resolution at 30 fps

Clear FPV imagery for real-time monitoring.

Battery Performance

- Battery Capacity: 17,500 mAh

- Hovering Time:

- 10 minutes (takeoff weight: 39.5 kg with 17,500 mAh battery)

- 18 minutes (takeoff weight: 24.5 kg with 17,500 mAh battery)

- Uses DJI-approved AB2-17500mAh-51.8V battery pack.

Optimized for large-area coverage per charge.

Operating Frequencies

The AGRAS T16 (FCC ID SS3-T161906) operates on the following frequency bands and power levels, as registered in its FCC filing:

| Frequency Range (GHz) | Output Power (mW) | FCC Rule Part |

|---|---|---|

| 2.4035–2.4775 | 570 | 15CCC2.12.4055 |

| 2.4775 | 543 | 15CCC2.25.7285 |

| 5.8445 | 185 | 15ECC1.2 |

| 5.8465 | 186 | 15ECC1.15.7305 |

These ranges encompass the primary ISM bands used for Wi-Fi, remote control, and telemetry, ensuring robust and interference-resistant communication between the drone, controller, and ancillary systems.

Technology Deep Dive

The DJI AGRAS T16 leverages multiple wireless technologies to deliver seamless, long-range, and reliable operation in challenging environments. Its primary communication protocols include Wi-Fi (2.4 GHz and 5.8 GHz bands) and Bluetooth, supporting both high-bandwidth data links and short-range device pairing or configuration. The absence of cellular modules means all RF emissions are confined to unlicensed spectrum, optimizing for latency and control reliability rather than internet connectivity.

The selected frequency bands offer several advantages:

– 2.4 GHz Band: Provides reliable, long-range connections with strong resistance to interference, ideal for remote control and telemetry in open agricultural environments.

– 5.8 GHz Band: Delivers higher data rates and reduced congestion, beneficial for FPV video downlinks and high-speed data exchange, though with slightly reduced range compared to 2.4 GHz.

– Power Levels: Carefully balanced to ensure robust signal integrity without exceeding regulatory RF emission limits, minimizing interference with other devices and maximizing battery life.

Test reports from the FCC filing confirm compliance with both output power and spectral purity requirements, ensuring the T16 operates safely within legal limits. The integration of DBF imaging radar, operating at a dedicated low-power level, augments the drone’s environmental awareness without adding significant electromagnetic noise. The result is a communication and sensing suite engineered for mission-critical reliability, even in RF-congested or remote areas.

In-Depth Internal Component Analysis / Teardown

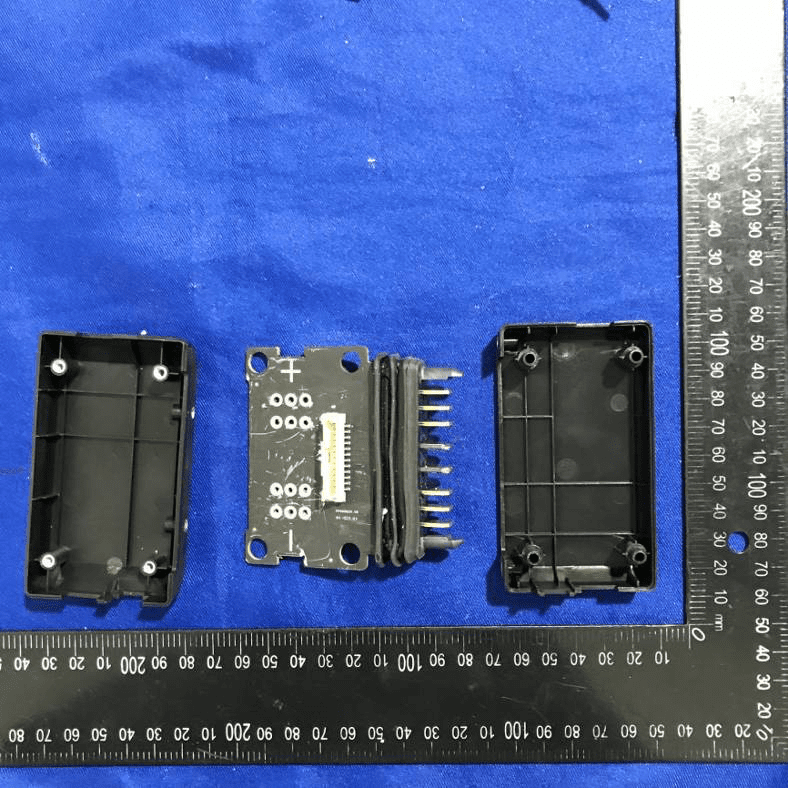

Power or Signal Distribution Module

A robust modular PCB assembly is observed, designed primarily for power or signal distribution within the drone. The board showcases a standard FR4 substrate with a black soldermask, featuring through-hole and surface-mount connectors, multiple test points, and a white FPC/FFC connector for interfacing with other subsystems. The absence of major ICs or RF features, along with heavy-duty pin headers and clear power markings, suggests this module is tasked with distributing power or signals to key drone components, such as motors or batteries. The layout prioritizes durability and serviceability, with mounting holes and a protective enclosure, aligning with the rugged demands of agricultural drone use.

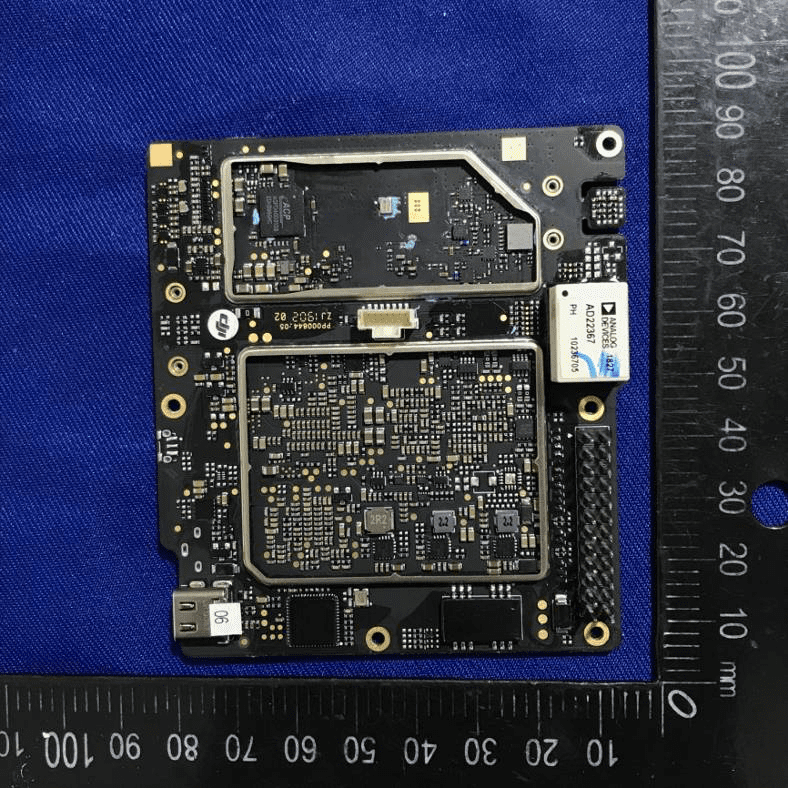

High-Density Flight Controller or Communications PCB

A sophisticated, densely populated PCB reveals the heart of the T16’s flight control or communications system. At the center, an Analog Devices AD2377 IC highlights precision analog signal acquisition, likely for flight control or sensor interfacing. Multiple QFP and BGA packages suggest the presence of microcontrollers, FPGAs, and possibly custom SoCs for real-time processing and sensor fusion. Two large EMI/RFI shields protect critical analog and RF sections, underlining the importance of noise mitigation. Power integrity is managed by several large inductors and capacitors, while a USB Micro-B connector and FPC interface allow for diagnostics and modular expansion. This multi-layer board exemplifies high-reliability design, balancing analog, digital, and RF requirements for safe, autonomous operation in demanding environments.

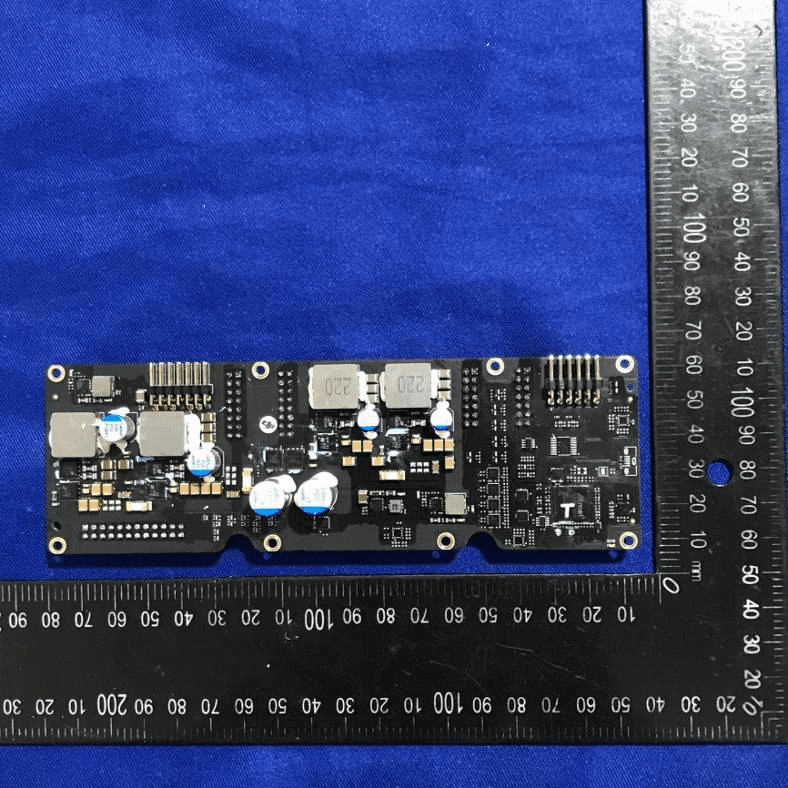

Power Management or Motor Control Board

This densely packed PCB is engineered for high-current power management or electronic speed control (ESC). The board features large gray inductors, substantial electrolytic and ceramic capacitors, and multiple MOSFETs or power ICs, all indicative of robust DC-DC conversion and motor drive circuitry. The gold-finger edge connectors and high-current pin headers suggest direct interfacing with motors or battery packs. Careful PCB design, including extensive ground pours and stitching vias, reflects a focus on EMI/EMC control and power integrity. The absence of RF components confirms its role in power delivery rather than communications. Such a board is essential for the T16’s ability to drive multiple motors efficiently and safely, supporting heavy payloads and extended mission durations.

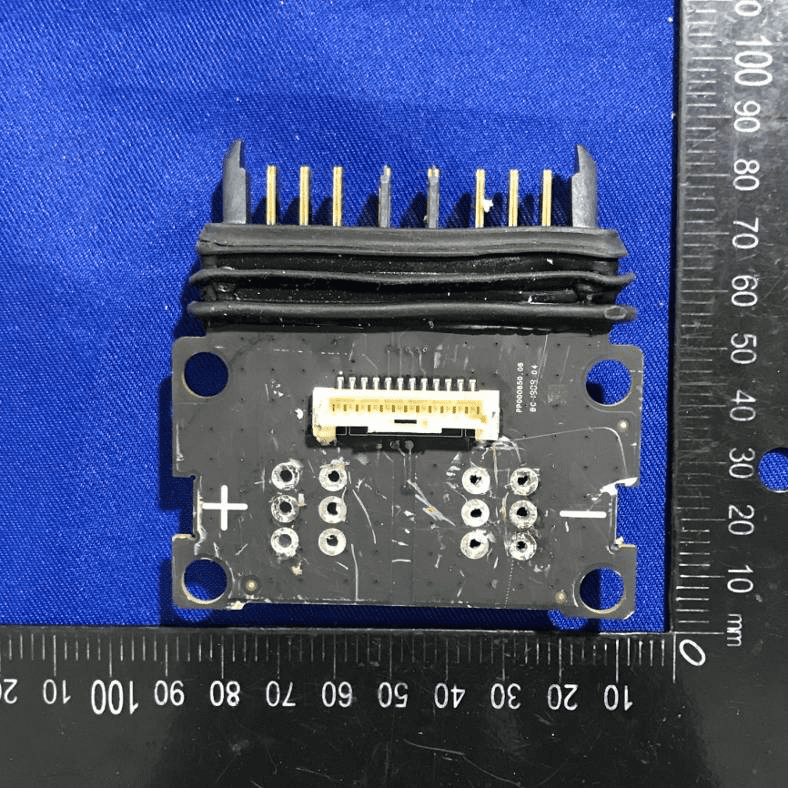

High-Current Interconnect/Power Distribution Module

A compact PCB module designed for high-current applications is evident, with thick traces, large through-hole pads marked ‘+’ and ‘-‘, and a multi-pin high-current connector. The inclusion of a flat-flex connector allows for integration with control electronics, while the layout’s simplicity and mechanical robustness make it ideal for field-serviced power distribution. The lack of fine-pitch or RF components further reinforces its dedicated role in delivering power to propulsion or payload systems. This board’s modularity and durability are critical for the T16’s operational reliability in harsh agricultural environments.

Regulatory Insights & FCC Filing

The AGRAS T16’s FCC ID SS3-T161906 signifies full compliance with US electromagnetic interference and RF emission standards, as mandated by the Federal Communications Commission. This certification, registered on FCC.gov, ensures the drone is legally authorized for sale and operation in the United States, providing operators with confidence in its safety and performance.

FCC filings for the T16 encompass a comprehensive suite of documentation—including test reports for RF exposure and electromagnetic compatibility, detailed internal and external photographs, user manuals, and technical block diagrams. These documents validate the device’s adherence to output power, frequency, and spurious emission limits, as well as its capacity to operate without causing harmful interference.

Insights from the user manual and internal documentation highlight the T16’s advanced modular design, high-precision RTK positioning, upgraded spraying system, and integrated safety features like foldable frames and system redundancy. The test reports confirm that its multi-band Wi-Fi and Bluetooth capabilities meet or exceed regulatory thresholds, ensuring both robust connectivity and minimal risk of RF interference with other equipment. Overall, the FCC certification underscores DJI’s commitment to regulatory compliance and operational safety for professional agricultural drone operators.

Potential Use Cases & Target Audience

The DJI AGRAS T16 is engineered for demanding industrial and agricultural environments, offering transformative capabilities for several key user profiles:

-

Large-Scale Commercial Farm Operators:

The T16’s high payload, wide spray width, and intelligent operation planning make it ideal for efficiently treating extensive crop fields. Operators can automate complex spraying missions, reduce chemical usage, and maximize coverage per flight. -

Agricultural Service Providers:

For teams offering custom crop-dusting or pest-control services, the T16’s robust DBF imaging radar, obstacle avoidance, and foldable design ensure safe, reliable operation across diverse terrains and weather conditions. Its IP54/IP67 ratings guarantee protection against dust, water, and corrosive chemicals. -

Agri-Tech Research & Development Teams:

The T16’s modular electronics and comprehensive sensor suite (dual IMUs, barometers, FPV camera) provide a versatile platform for precision agriculture trials, data collection, and technology validation. Redundant propulsion control and real-time system diagnostics enhance flight safety for experimental operations.

Whether for maximizing operational efficiency, ensuring worker safety, or enabling next-generation precision agriculture, the AGRAS T16 is tailored to the needs of forward-thinking agricultural professionals.

Conclusion

The DJI AGRAS T16 (Model: T16, FCC ID SS3-T161906) stands as a benchmark in agricultural drone technology, combining advanced modular design, high-precision sensors, and ruggedized components for mission-critical fieldwork. Its FCC certification assures operators of legal compliance and electromagnetic safety, while its sophisticated internal architecture and wireless capabilities support reliable, high-performance operation in challenging environments. As precision agriculture continues to evolve, the AGRAS T16 offers a robust, future-ready platform for professionals seeking to optimize crop management and operational efficiency.