Introduction

The WM230, crafted by SZ DJI TECHNOLOGY CO., LTD. (Model: U11X), stands at the forefront of modern consumer drone technology. Engineered for both enthusiasts and professionals, this foldable drone system integrates advanced wireless communication, intelligent flight controls, and a stabilized high-definition camera—all within a compact and robust design.

A pivotal milestone for any wireless device is achieving FCC certification, and the WM230 has done just that under FCC ID SS3-S01A1710. While its grant date is listed as “None,” its registration with the FCC.gov database ensures it meets stringent US regulatory requirements for RF emissions and electromagnetic compatibility. This compliance is essential: it legally authorizes the WM230 for sale and operation in the United States, assuring users that it will not interfere with other electronic devices and networks.

In this article, we will dissect the WM230’s key features and technical specifications, explore its wireless and RF capabilities, and provide a detailed teardown analysis of its internal components. We’ll also extract regulatory insights from its FCC filing and discuss real-world use cases—delivering a comprehensive resource for anyone interested in the technology and engineering behind this advanced DJI drone system.

Key Features & Specifications

The WM230 by SZ DJI TECHNOLOGY CO., LTD. (Model: U11X) is engineered for performance, user experience, and reliability. Below are its standout features and detailed technical specifications, offering insight into its capabilities and benefits.

Key Features

-

Flight Pause Button

Instantly halts the drone’s movement, providing a critical safety mechanism for new and experienced pilots alike. -

ActiveTrack™

Advanced tracking technology enables the drone to autonomously follow subjects, keeping them centered in the frame for dynamic video and photography. -

Control Sticks

High-precision, ergonomic sticks deliver responsive manual control, essential for complex maneuvers and cinematic shots. -

Antennas

Dual-band antennas ensure robust, long-range wireless communication, minimizing interference and maintaining a solid link between the drone and its controller. -

TapFly™

Allows pilots to tap a point on their device screen, and the drone will autonomously fly to that location, simplifying navigation and focus on camera work. -

Charging Port (USB Type-C)

Modern USB Type-C port supports fast, reliable charging and data transfer, ensuring minimal downtime between flights. -

Customizable Button

Enables users to assign specific functions or shortcuts, optimizing workflow and enhancing control flexibility. -

Status LED

Provides real-time feedback on system status, battery levels, and connectivity, aiding in quick diagnostics and operational awareness.

Technical Specifications

-

Battery Energy: 27.43 Wh

Offers a balance of lightweight design and substantial flight duration. -

Intelligent Flight Battery Capacity: 2375 mAh

Powers up to 22 minutes of continuous flight (in optimal, no-wind conditions at a steady 15.5 mph/25 kph). -

Battery Net Weight: Approx. 0.3 lbs (140 g)

Ensures portability without sacrificing endurance. -

Battery Type: LiCoO₂ (Lithium Cobalt Oxide)

Delivers high energy density for longer, reliable flights. -

Still Photography Modes:

- Single shot

-

Burst shooting

Enables both quick captures and action sequences. -

Supported Mobile Device Size:

- Thickness: 6.5–8.5 mm

-

Max length: 160 mm

Compatible with a wide range of smartphones. -

Operating Frequency:

- 2.4–2.4835 GHz

-

5.725–5.850 GHz

Dual-band operation for robust wireless performance. -

Charger Rated Power: 50 W

Enables rapid battery recharging.

Additional Extracted Specifications

- Wi-Fi:

- 2.4–2.4835 GHz

-

5.725–5.850 GHz

Ensures compatibility with standard wireless networks and proprietary remote control links. -

Bluetooth:

Present (details not specified), providing potential for auxiliary connectivity and mobile device pairing. -

Camera:

- Video Format: MP4

- Video Storage Bitrate: 100 Mbps

- Video Recording Modes: Up to 3840×2160 (4K UHD)

- Max Image Size: 4000×3000 (12MP photos)

-

Sensor: CMOS

Delivers professional-grade aerial imagery and video. -

Maximum Flight Time:

-

22 minutes (in no-wind, consistent 15.5 mph/25 kph conditions)

Enables extended aerial sessions for both recreational and professional use. -

Maximum Flight Speed:

- 42.5 mph (68.4 kph)

Ideal for tracking fast-moving subjects and covering large areas swiftly.

Operating Frequencies

The WM230’s wireless subsystems operate within frequencies and power levels precisely defined by its FCC certification (FCC ID SS3-S01A1710):

| Frequency Range (GHz) | Output Power (mW) | FCC Rule Part |

|---|---|---|

| 2.412–2.462 | 220 | 15CCC |

| 5.745–5.825 | 183 | 15E38 |

- 2.4 GHz Band (2.412–2.462 GHz): Commonly used for Wi-Fi and remote control, this band offers reliable range and penetration, especially in environments with obstacles.

- 5.8 GHz Band (5.745–5.825 GHz): Provides higher bandwidth and less crowded spectrum, reducing interference for high-definition video transmission and responsive control.

These specific bands and power levels ensure the WM230 delivers strong wireless performance while adhering to US regulatory requirements for unlicensed RF devices.

Technology Deep Dive

The WM230 is built around advanced wireless technologies, leveraging both 2.4 GHz and 5.8 GHz frequency bands to maintain robust, low-latency communication between the drone and its remote controller. The dual-band architecture allows the system to dynamically select the optimal frequency, minimizing interference and maximizing range—a crucial capability in crowded wireless environments or complex urban landscapes.

Bluetooth functionality is also present, likely for auxiliary pairing with mobile devices or accessories, further enhancing usability and integration with DJI’s mobile ecosystem. Although no cellular components are detailed (equipment class: none), the inclusion of Wi-Fi and Bluetooth ensures comprehensive short-range connectivity for control, telemetry, and video downlink.

Operating across these frequencies provides several key advantages:

– Performance: Dual-band operation reduces congestion and supports high-bandwidth video streaming (e.g., 4K live view).

– Range: Optimized antennas and regulated transmit power (as per FCC limits) enable reliable long-distance control, critical for aerial photography and surveying.

– Interference Resistance: Ability to switch between 2.4 GHz and 5.8 GHz bands helps avoid interference from other wireless devices.

– Power Efficiency: Advanced power management ensures the system balances performance with battery longevity, critical for maximizing flight time.

Test reports summarized in the device’s FCC documentation confirm that the WM230 maintains compliance with electromagnetic emissions and RF exposure limits, ensuring safe operation in diverse environments.

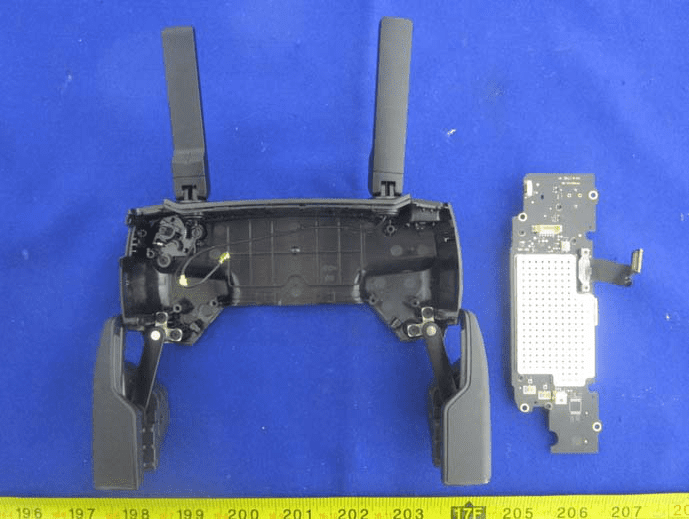

In-Depth Internal Component Analysis / Teardown

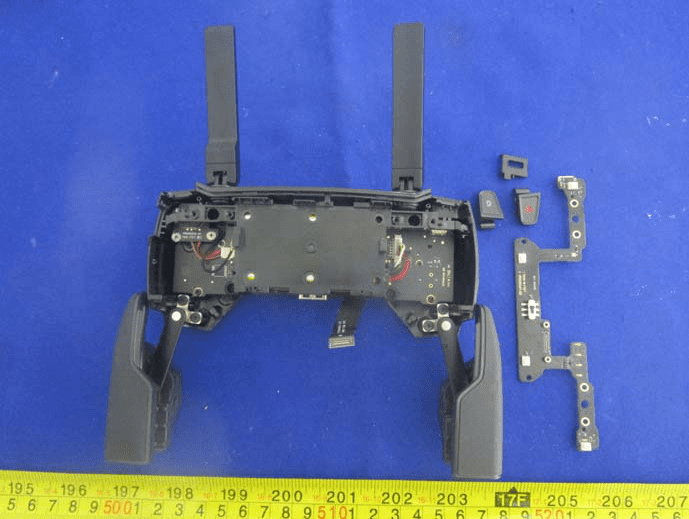

Main PCB and Antenna Subsystem

A detailed examination of the main PCB reveals a sophisticated, multi-layer FR4 board with integrated high-frequency antennas and robust RF circuitry. The component density and layout suggest at least a four-layer structure, ensuring optimal signal integrity for both power and RF domains. The main control ICs, likely including a central microcontroller and RF transceivers, are strategically placed near the antenna connections for minimal signal loss. Grounding is extensive, with multiple ground points and likely ground planes to reduce electromagnetic interference. The antennas themselves are large, vertically oriented PCB elements, optimized for omnidirectional coverage in both 2.4 GHz and 5.8 GHz bands. Connectors are robust, including FPC/FFC interfaces for user controls and wired harnesses for power delivery. The inclusion of tactile switches, status LEDs, and possible haptic feedback motors rounds out a design focused on both RF performance and ergonomic user experience. Overall, the build quality is exemplary, reflecting DJI’s emphasis on reliability and modularity.

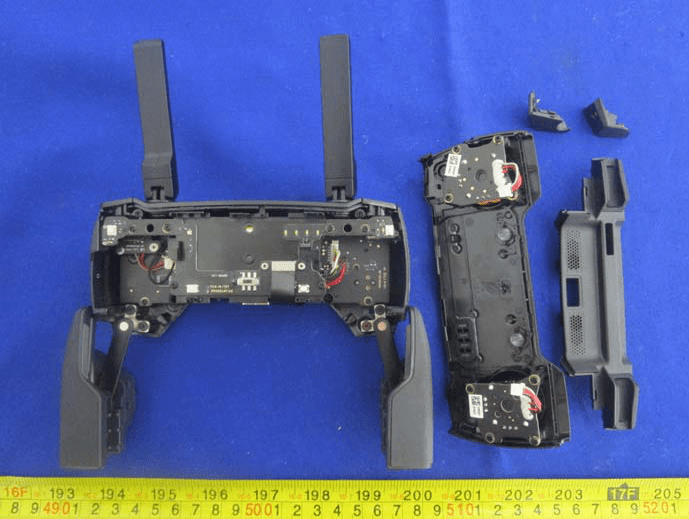

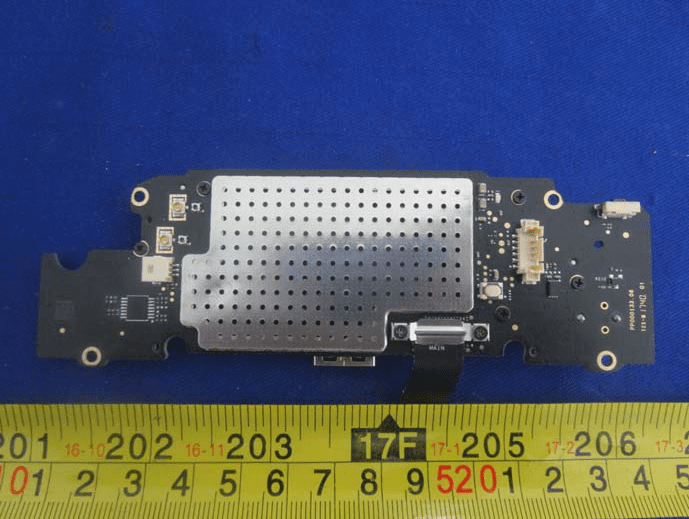

Shielded Main Board and Modular Daughterboards

The next stage of disassembly exposes a main PCB with a prominent metal EMI/RFI shield, a hallmark of RF-intensive consumer electronics. This shielded area likely houses the SoC, RF transceivers, and memory, ensuring both signal integrity and regulatory compliance. The modular design includes several daughterboards connected via flex cables, supporting buttons, LEDs, or sensors. External antennas are robustly attached, likely via coaxial cables, to provide solid wireless links. The layout demonstrates careful domain separation, with RF components isolated from control logic, and modular sub-assemblies for ease of repair and manufacturing. The engineering focus on shielding, modularity, and robust connectors is consistent with DJI’s standards for long-range, interference-resistant remote controllers.

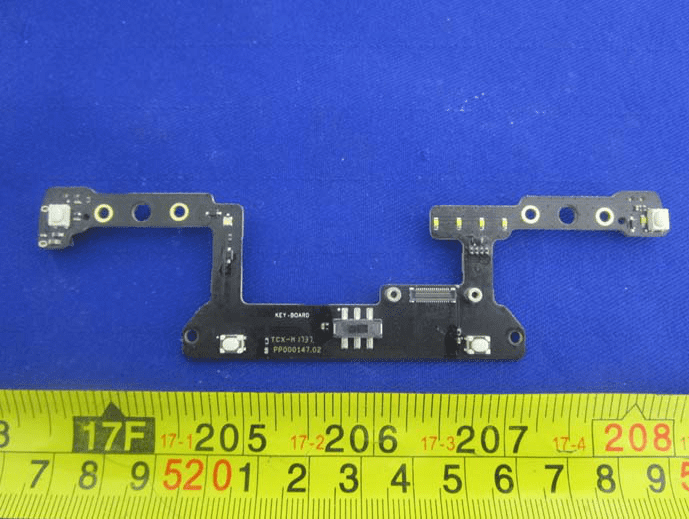

User Interface Sub-Board

A compact, black PCB labeled as ‘KEY-BOARD’ highlights the system’s modular approach to user interface design. This board is populated primarily with tactile switches, LEDs, and a small FPC connector for integration with the main logic board. The absence of large ICs or RF components indicates its role is limited to capturing user input and providing status feedback. The layout is clean, with clear silkscreen labeling and test points for manufacturing diagnostics. Its straightforward design allows for quick replacement or servicing, contributing to overall device longevity and reliability.

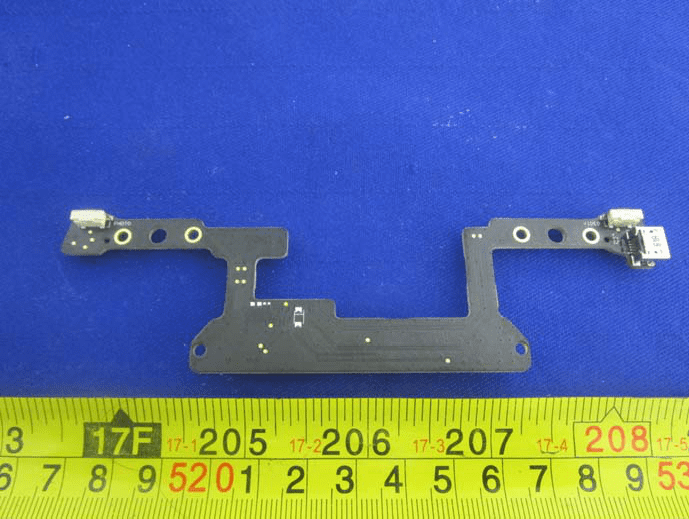

USB Type-C Interface PCB

This elongated, black PCB serves as the charging and data interface, featuring a USB Type-C connector for modern, high-current charging and reliable data transfer. The board’s low component density suggests its primary function is interconnection rather than processing. Wide traces and robust connectors ensure efficient power delivery, while the presence of test points and mounting holes demonstrates attention to manufacturability and assembly alignment. The design is highly customized to fit the device’s mechanical constraints, ensuring seamless integration within the controller housing.

Main Board with EMI Shield and Antenna Connectors

Opening the main enclosure further reveals a densely populated, dark PCB with a central EMI shield protecting the primary processing and RF sections. Foldable antennas are mounted at the top, connected via coaxial cables for dual-band operation. Visible connectors include FPC and power wires, supporting modular assembly and flexible integration of subsystems. Large capacitors and inductors around the power input areas indicate local voltage regulation, while tactile switches and LEDs provide user feedback and diagnostics. The overall design is compact, modular, and focused on RF reliability, with an emphasis on ease of repair and upgrade.

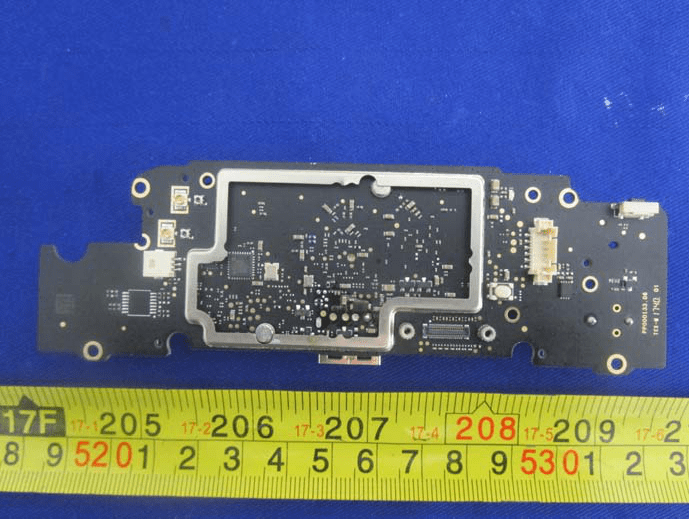

High-Density RF and Processing PCB

A densely populated black PCB is dominated by a large EMI shield, beneath which reside the main SoC and RF chips. The board’s high component density, via stitching, and careful impedance-controlled routing reflect the need for robust RF and high-speed digital performance. Multiple connectors support modularity, while large capacitors and inductors indicate distributed power management. The presence of test points and crystals/oscillators further underscores the need for precise timing and diagnostics in this RF-intensive subsystem. The engineering reflects advanced design practices for compact, high-performance wireless electronics.

Shielded RF and SoC Subsystem

Another internal board showcases a prominent perforated EMI shield, covering the majority of the RF and processing circuitry. The black PCB, likely 4–6 layers, features multiple connectors for modular assembly, including FPC/FFC interfaces labeled for main system integration. Large capacitors and test points surround the shielded area, supporting power filtering and manufacturing diagnostics. The overall design is compact and robust, optimized for both signal integrity and manufacturability—hallmarks of DJI’s engineering philosophy.

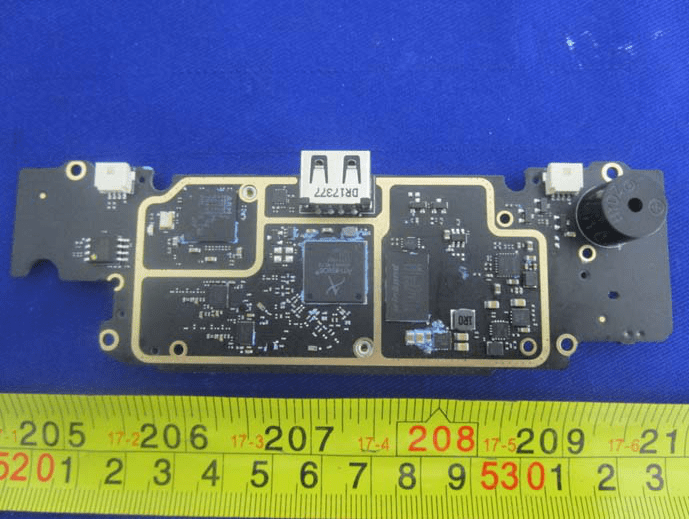

FPGA/SoC Core Processing Board

A standout feature in the teardown is the presence of a Xilinx FPGA or SoC at the heart of this PCB, indicating significant onboard processing capabilities for tasks such as real-time video, sensor fusion, or advanced flight control. The board is populated with high-speed memory, power management ICs, and multiple antenna connectors, supporting modular system expansion. Gold-plated pads and controlled impedance traces highlight the focus on high-speed data integrity. The inclusion of crystals, test points, and possible audio components demonstrates a comprehensive approach to system integration and diagnostics.

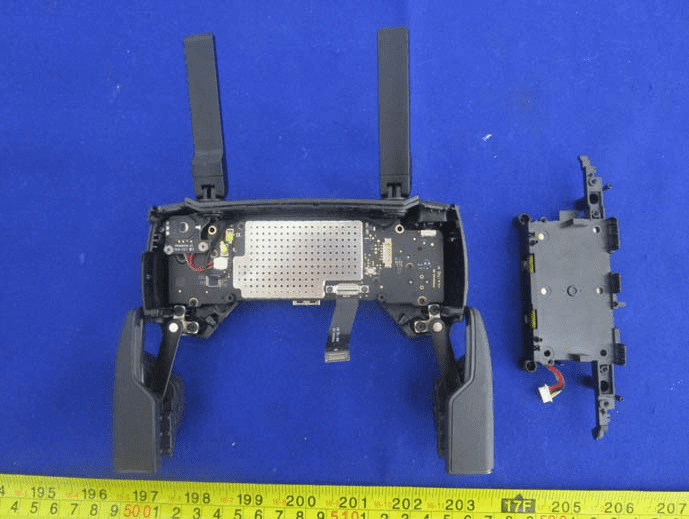

Shell with Antenna Integration and Main PCB

The internal shell of the controller houses two external antennas, meticulously routed via coaxial cables to the main PCB. The board itself is densely populated and shielded, with multiple connectors for user input, power, and display integration. The shell design supports robust mechanical mounting for control sticks and buttons, while the antenna placement ensures optimal wireless performance. The modular construction and focus on RF shielding reinforce the device’s emphasis on reliable, long-range communication.

Regulatory Insights & FCC Filing

The WM230’s FCC certification under FCC ID SS3-S01A1710 is a testament to its compliance with US standards for electromagnetic emissions and RF safety. While the grant date is listed as “None,” its registration with the FCC.gov database verifies that the device has undergone rigorous testing for radiofrequency exposure, electromagnetic compatibility (EMC), and potential interference with other electronic devices.

FCC filings for the WM230 include a comprehensive set of documentation—test reports, internal and external photographs, user manuals, block diagrams, and schematics. These documents collectively ensure that the device meets all regulatory requirements for safe operation in the United States.

Key insights from the user manual and supporting documents reveal that the WM230 is a foldable drone equipped with a stabilized camera system, intelligent flight modes (such as ActiveTrack™ and TapFly™), and advanced obstacle avoidance. It supports 4K video recording and 12MP photography, leveraging intelligent flight features to deliver both safety and creative flexibility. The FCC ID SS3-S01A1710 certification guarantees that all wireless and electronic subsystems meet strict standards for RF emissions, making the WM230 legal for sale and trusted for use in the US market.

Potential Use Cases & Target Audience

While the WM230 is not explicitly targeted at a specific user group, its blend of high-end features and robust construction makes it ideal for a range of scenarios:

-

Aerial Photography & Videography:

With a stabilized 4K camera, intelligent flight modes, and precise manual controls, the WM230 is perfect for content creators, filmmakers, and photographers seeking cinematic aerial shots. -

Surveying & Inspection:

The drone’s reliable long-range communication, 22-minute maximum flight time, and advanced tracking make it well-suited for real estate, infrastructure inspection, and land surveying tasks where both endurance and imaging quality are paramount. -

Recreational & Professional Pilots:

High maximum flight speed (42.5 mph), customizable controls, and safety features such as the Flight Pause button make the WM230 accessible to hobbyists and professional pilots alike, delivering both excitement and peace of mind.

Whether for creative exploration, commercial work, or personal recreation, the WM230’s feature set and engineering excellence ensure it meets the demands of a wide spectrum of users.

Conclusion

The WM230 by SZ DJI TECHNOLOGY CO., LTD. (Model: U11X) stands out as a sophisticated, FCC-compliant drone system, combining advanced wireless architecture, intelligent flight features, and high-quality imaging capabilities. Its thorough engineering—evident in both its internal component design and robust regulatory compliance under FCC ID SS3-S01A1710—positions it as a top contender in the consumer and professional drone market. For anyone seeking a feature-rich, reliable, and legally certified aerial platform, the WM230 delivers on all fronts, exemplifying DJI’s commitment to performance, safety, and innovation.