Introduction

The Phantom 4 by SZ DJI TECHNOLOGY CO., LTD. has earned a reputation as a flagship drone, combining advanced flight control, robust wireless communication, and impressive imaging capabilities. Designed for both enthusiasts and professionals, the Phantom 4 is engineered to deliver stable, high-quality aerial footage and intelligent autonomous flight. Its sophisticated hardware and software integration enable precise maneuvering, obstacle avoidance, and seamless remote operation, setting a high bar in the consumer drone market.

A crucial aspect of the Phantom 4’s legitimacy and market presence is its FCC certification under FCC ID SS3-T650A1609. While there is no specific grant date listed, this certification is essential: it confirms the device meets stringent US regulatory standards for radio frequency (RF) emissions and electromagnetic interference (EMI). This compliance not only ensures legal sale and operation within the United States but also attests to the drone’s adherence to safety and performance benchmarks.

This article provides a comprehensive analysis of the Phantom 4, focusing on its key features, technical specifications, wireless technologies, internal hardware, and regulatory compliance. Whether you’re a drone enthusiast, engineer, or tech-savvy consumer, you’ll find an in-depth exploration of what makes the Phantom 4 a standout in its class.

Key Features & Specifications

The DJI Phantom 4 (Model: T650A) is a sophisticated quadcopter that integrates advanced flight capabilities, robust wireless connectivity, and user-centric design. Below are its standout features and technical specifications, along with the practical implications of each.

Key Features

- Rear LED

- Enhances visibility and orientation during flight, aiding both manual piloting and automated return functions.

- Mobile Device Holder

- Securely mounts smartphones or tablets to the remote controller, enabling real-time video streaming and telemetry via the DJI app.

- SSD Port

- Allows high-speed, large-capacity storage for 4K video and high-resolution images, crucial for professional-grade footage.

- HDMI Port

- Supports direct output to external monitors or streaming devices, ideal for live broadcasts or FPV (first-person view) flying.

- Link Button

- Facilitates secure pairing between the drone and the remote controller, ensuring encrypted and interference-resistant communication.

- Flight Mode Switch (A(Atti), S(Sports), P(Positioning))

- Enables rapid selection among Attitude, Sports, and Positioning modes, balancing agility, speed, and stability for different flight scenarios.

- Return to Home (RTH) Button

- Instantly commands the drone to autonomously return to its takeoff point, enhancing safety during signal loss or low battery.

- Front LED

- Provides orientation cues and system status, assisting in visual tracking and diagnostics.

Technical Specifications

- Max Ascent Speed: 6 m/s (Sport Mode)

- Delivers rapid vertical mobility, suitable for dynamic aerial maneuvers and obstacle avoidance.

- Altitude Sensing System Operating Environment: Surface with no sound-absorbing features

- Ensures optimal performance of ultrasonic and visual sensors for precise altitude hold.

- Detecting Range:

- Forward: 10 Hz

- Upward: 20 Hz

- Responsive obstacle detection, critical for safe autonomous navigation.

- Satellite Positioning Systems: GPS/GLONASS

- Dual-constellation support provides robust, accurate global positioning for stable hover and waypoint navigation.

- Operating Temperature: -10°C to 40°C

- Broad temperature tolerance enables reliable operation in diverse environments.

- Obstacle Sensing Range (Front): 0.7 – 30 m

- Wide detection range minimizes collision risk during complex flight paths.

- Gimbal Controllable Range (Pan): ±320°

- Extensive camera articulation for flexible aerial photography and videography.

- Altitude Sensing Detecting Frequency: 20 Hz

- High-frequency altitude updates support smooth, responsive flight.

Additional Wireless & Power Specs

- Wi-Fi: 2.4 GHz and 5.8 GHz bands

- Dual-band operation reduces interference and maximizes transmission range and quality.

- Bluetooth: Present (details not specified)

- Likely used for device pairing, short-range communication, or accessory integration.

- Battery:

- Flight Time: Up to 25 minutes per charge

- Balances high performance with reasonable endurance for most aerial tasks.

- Remote Controller Battery: 6000 mAh LiPo 2S

- High-capacity controller battery ensures extended remote operation sessions.

These features and specifications collectively position the Phantom 4 as a versatile tool for aerial imaging, surveying, and autonomous flight, with an emphasis on reliability, user experience, and regulatory compliance.

Operating Frequencies

The Phantom 4 (FCC ID SS3-T650A1609) operates on the following frequency bands, as documented in its FCC filing:

| Frequency Range (GHz) | Output Power (mW) | FCC Rule Part |

|---|---|---|

| 2.4065–2.4765 | 144 | 15CCC |

| 5.173–5.845 | 350 | 15E38 |

- 2.4 GHz band is widely used for Wi-Fi and drone control links, offering a balance of range and interference resilience.

- 5.8 GHz band provides higher data throughput and is less congested, ideal for HD video transmission and robust control even in RF-dense environments.

- The specified output power levels ensure compliance with US regulations while maximizing operational range and signal reliability.

Understanding these frequencies is vital for assessing the drone’s wireless capabilities, interference mitigation, and suitability for various environments.

Technology Deep Dive

The Phantom 4’s wireless subsystem is centered on dual-band Wi-Fi (2.4 GHz & 5.8 GHz) and Bluetooth technologies. These enable high-bandwidth video downlink, low-latency control, and seamless pairing between the aircraft, remote controller, and mobile devices. The dual-band approach provides flexibility to switch frequencies, minimizing interference from other Wi-Fi networks or competing RF sources, a common challenge in urban and event environments.

Operating in the 2.4 GHz band allows for extended range and reliable penetration through obstacles, while the 5.8 GHz band supports higher data rates and clearer channels, particularly for live HD video streaming. Bluetooth, though less detailed in the specs, likely facilitates quick device pairing and potential accessory integration, enhancing the user experience.

The specified output powers (144 mW for 2.4 GHz, 350 mW for 5.8 GHz) strike a balance between maximizing range and adhering to regulatory constraints. This ensures strong, consistent communication between the drone and its controller, even in challenging RF environments. Careful power management also helps optimize battery life and minimize heat generation—a critical consideration in compact, high-performance UAVs.

Test report summaries, while not exhaustively detailed here, emphasize that the Phantom 4 underwent rigorous validation for RF emissions, signal integrity, and compliance with FCC Part 15 requirements. This ensures not only legal operation but also reliable, interference-resistant performance in the field.

In-Depth Internal Component Analysis / Teardown

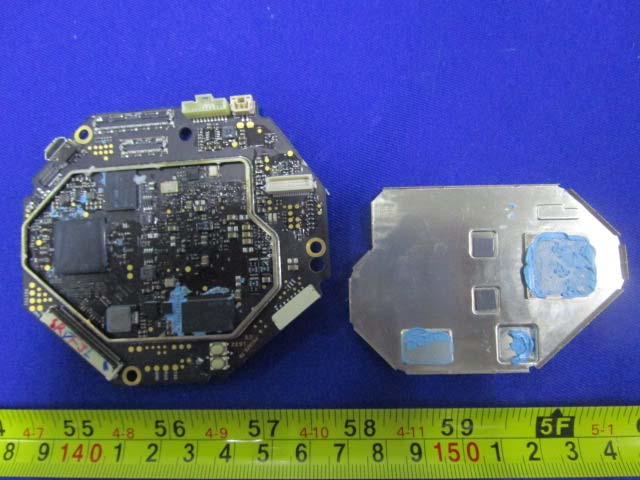

Phantom 4 Main PCB Assembly: Processing and RF Core

Beneath the Phantom 4’s robust exterior lies a meticulously engineered PCB that serves as the drone’s central nervous system. The octagonal, multi-layer board is densely packed with high-performance components. At its heart sits a large BGA chip—likely an ARM-based SoC—responsible for managing flight control, video processing, and system coordination. Adjacent smaller BGAs and QFNs suggest integrated memory and secondary controllers. The board’s layout reveals extensive differential pair routing, optimized for high-speed data and RF signals, while the strategic placement of numerous vias and ground pours ensures exceptional EMI/RFI suppression. Connectors along the board’s edge, probably U.FL or similar, facilitate modular antenna attachment for Wi-Fi, GPS, and telemetry. The substantial EMI shield, with thermal pads for heat dissipation, underscores the focus on both signal integrity and thermal management. Power regulation is handled by prominent inductors and capacitors, providing clean voltage rails for the digital, analog, and RF domains. Overall, this PCB exemplifies high-density, modular engineering tailored for the demands of aerial robotics.

Shielded High-Performance Controller Board

Another critical internal assembly is characterized by a compact octagonal PCB dominated by a large metal shield and heatsink, indicative of high-power or RF-sensitive processing beneath. This shield likely conceals the main flight controller SoC, memory, and wireless transceivers, serving dual roles of EMI containment and thermal dissipation. The board’s design features a dense array of connectors—FPC/FFC for camera or sensor modules, board-to-board links, and possibly a micro-USB or proprietary interface—enabling modular integration with the drone’s subsystems. The visible power regulation section, marked by large capacitors and inductors near the connectors, suggests multiple voltage domains for digital, analog, and RF circuits. The robust shielding and careful via placement highlight DJI’s commitment to minimizing interference and maximizing reliability, both critical for stable flight and uninterrupted communication.

Wireless Communication and Sensor Interface Board

A further teardown reveals a compact, densely populated PCB likely dedicated to wireless communication and sensor interfacing. The most substantial IC sits under a soldered metal shield, typical for RF transceivers or Wi-Fi/Bluetooth SoCs, ensuring protection from EMI and stable high-speed operation. The board features fine-pitch routing, robust grounding, and well-placed crystals for precise clock generation. Multiple connectors, including FPC/FFC and a possible micro-USB port, facilitate modular connections to cameras, gimbals, or the main controller. Mechanical reinforcements and adhesive around connectors enhance vibration resistance—a necessity for drones. The use of large capacitors and power inductors indicates local voltage regulation, supporting sensitive analog and digital circuits. This board exemplifies DJI’s focus on modularity, EMI control, and reliable high-speed communication essential for real-time video transmission and sensor data handling.

Power Management and Sensor Interface Module

Examining another internal board, one finds a high-density black PCB with a robust edge connector secured by screws, signaling its role in high-reliability power or sensor interfacing. The component layout is compact, with numerous SMT passives, large capacitors, and inductors indicating the presence of power regulation circuits. Differential routing and extensive via stitching suggest signal integrity and EMI control are paramount. While no discrete antennas or EMI shields are visible here, the board’s design points to functions such as motor control, gimbal stabilization, or sensor data aggregation. The use of high-quality materials and careful assembly reinforces DJI’s reputation for durability and precision in aerial platforms.

Modular Antenna and Housing Assembly

A partial internal teardown showcases the Phantom 4’s modularity, featuring a compact green PCB with multiple connectors and a white coaxial cable terminating in a blue-taped end—clearly an antenna assembly for Wi-Fi, Bluetooth, or telemetry. The presence of this thin coaxial cable underscores the drone’s focus on maintaining RF performance while minimizing weight. The PCB itself, though less densely populated than others, still demonstrates careful placement of connectors and passives for reliable subsystem communication. The adjacent housing section and visible wiring suggest integration with motors or gimbal mechanisms, highlighting DJI’s approach to modular, serviceable design in a compact footprint.

Regulatory Insights & FCC Filing

The FCC ID SS3-T650A1609 assigned to the Phantom 4 (Model: T650A) is a testament to its compliance with US regulations on electromagnetic interference and RF emissions. Although no specific grant date is listed, the registration by FCC.gov confirms that the device has been evaluated against stringent standards, making it legal for sale and operation within the United States.

An FCC filing typically includes a comprehensive suite of documentation: laboratory test reports for RF exposure and electromagnetic compatibility (EMC), high-resolution internal and external photographs, user manuals, block diagrams, and sometimes schematics. These documents provide transparency into the device’s design, manufacturing quality, and regulatory adherence.

For the Phantom 4, the Users-Manual-3179044.pdf is particularly informative. It offers detailed guidance on aircraft and remote controller setup, battery safety, camera and gimbal installation, and operational protocols. This manual underscores the manufacturer’s commitment to user safety, regulatory compliance, and optimal performance in real-world conditions.

The FCC certification process ensures that the Phantom 4 not only meets technical requirements for RF emissions but also upholds standards for user safety and device reliability, reinforcing its standing in the competitive drone market.

Potential Use Cases & Target Audience

The Phantom 4’s advanced features and robust engineering open it to a wide range of applications, including:

- Aerial Photography and Cinematography

- Professionals and enthusiasts can capture high-resolution images and 4K video, leveraging stable flight, obstacle avoidance, and a controllable gimbal for creative shots.

- Surveying and Mapping

- Engineers, construction managers, and surveyors can utilize the Phantom 4’s GPS/GLONASS and precise altitude sensing for site mapping, volumetric analysis, and progress monitoring.

- STEM Education and Research

- Educational institutions and researchers benefit from the drone’s programmable flight modes and data collection capabilities, making it a valuable tool for robotics, environmental, and engineering studies.

These scenarios highlight the Phantom 4’s versatility, serving both creative and technical users who demand reliability, advanced features, and regulatory compliance.

Conclusion

The Phantom 4 by SZ DJI TECHNOLOGY CO., LTD. (Model: T650A, FCC ID SS3-T650A1609) stands as a benchmark in consumer and professional drone technology. Its blend of advanced flight control, robust wireless communication, and high-quality imaging is matched by a meticulously engineered internal design. FCC certification under SS3-T650A1609 affirms its compliance with US standards for RF emissions and legal operation. Whether for creative, technical, or educational use, the Phantom 4 exemplifies DJI’s commitment to performance, reliability, and regulatory excellence—solidifying its place among the most respected aerial platforms in the industry.