Introduction

The Phantom 4 by SZ DJI TECHNOLOGY CO., LTD. (Model: T650A) stands as a benchmark in the evolution of consumer and professional drones, offering a blend of advanced flight control, robust wireless connectivity, and intelligent automation. Designed for aerial photography, mapping, and versatile UAV operations, the Phantom 4 delivers both performance and reliability. Its sophisticated systems are matched by an equally rigorous approach to regulatory compliance, evidenced by its FCC certification under FCC ID SS3-GL6D10A1609.

While the FCC grant date for this device is listed as “None,” its appearance in the FCC database confirms that it has undergone the necessary evaluations to ensure electromagnetic compatibility and RF emission standards are met within the United States. This certification is not just a legal formality; it assures users that the device is safe, reliable, and ready for commercial distribution.

In this article, we’ll dissect the Phantom 4’s key features and specifications, explore its wireless technology and operating frequencies, and provide an expert-level teardown analysis of its internal components. We’ll also examine its regulatory journey, offering insights into what the FCC filing reveals about its compliance and design. Whether you’re a drone enthusiast, an RF engineer, or simply curious about the technology inside one of DJI’s flagship platforms, this comprehensive review delivers the technical depth and clarity you need.

Key Features & Specifications

The Phantom 4 is engineered for aerial excellence, balancing user-friendly controls with advanced automation and robust wireless capabilities. Below are the standout features and core technical specifications that define the Phantom 4 (Model: T650A):

Key Features

- Rear LED: Provides clear visual status feedback, aiding orientation and safety during flight.

- Mobile Device Holder: Securely mounts smartphones or tablets to the remote controller for live video feeds and telemetry.

- SSD Port: Enables high-speed storage expansion, crucial for 4K video and high-resolution imaging workflows.

- HDMI Port: Direct video output for live broadcasting, FPV goggles, or external monitors.

- Flight Mode Switch (A/S/P modes): Instantly toggles between Atti (Attitude), Sport, and Positioning modes for tailored flight control, from GPS-assisted stability to high-speed manual maneuvers.

- Link Button: Simplifies binding of the aircraft to its remote controller, ensuring secure communication.

- Return to Home (RTH) Button: Automatic, intelligent flight path return for added safety and ease of use.

- Front LED: Enhances visual orientation, especially in low-light or complex environments.

Technical Specifications

- Remote Controller Max Transmission Distance:

- FCC: 5000 m (5.8 GHz, unobstructed, interference-free)

- CE: 2000 m (5.8 GHz, unobstructed, interference-free)

- Benefit: Supports long-range, reliable control for professional mapping, inspection, or creative projects.

- Max Ascent Speed: 6 m/s (Sport mode)

- Meaning: Enables rapid altitude changes, useful for dynamic aerial shots or obstacle avoidance.

- Detecting Range:

- Forward: 10 Hz

- Upward: 20 Hz

- Advantage: Fast sensor refresh rates contribute to real-time obstacle detection and avoidance.

- Satellite Positioning Systems: GPS/GLONASS

- Benefit: Enhanced global coverage and redundancy for precise navigation and stability.

- Operating Temperature: -10°C to 40°C

- Practicality: Wide operational window supports use in diverse environments, from cold mornings to hot afternoons.

- Obstacle Sensing Range (Front): 0.7 – 30 m

- Safety: Early detection and avoidance of obstacles, reducing crash risk.

- Gimbal Controllable Range (Pan): ±320°

- Imaging: Broad camera movement for cinematic shots and comprehensive scene coverage.

- Altitude Sensing Detecting Frequency: 20 Hz

- Precision: Smooth, accurate altitude hold for stable flight and video.

- Wi-Fi: 2.4 GHz and 5.8 GHz bands supported

- Bluetooth: Present, details not specified in manual

- Battery:

- Flight Time: Approx. 25 minutes

- Remote Controller: 6000 mAh LiPo 2S

These features and specifications collectively enable the Phantom 4 to deliver a seamless, high-performance flying experience. The integration of multiple wireless bands, rapid sensor updates, and robust control mechanisms makes it suitable for both professional and advanced hobbyist applications.

Operating Frequencies

The Phantom 4 (FCC ID SS3-GL6D10A1609) is certified to operate on the following frequencies, as detailed in its FCC filings:

| Frequency Range (GHz) | Output Power (mW) | FCC Rule Part |

|---|---|---|

| 2.404–2.4788 | 834 | 15CCC2.12.412 |

| 2.462 | 566 | 15CCC2.25.727 |

| 5.8213 | 240 | 15E38 |

| 15.745–5.825 | 145 | 15E38 |

These frequency bands encompass both 2.4 GHz and 5.8 GHz ISM bands, supporting robust Wi-Fi and telemetry links critical for high-bandwidth video transmission, remote control, and real-time data exchange. The specified output power levels ensure compliance with FCC regulations, balancing range, performance, and minimal interference with other spectrum users.

Technology Deep Dive

The Phantom 4 leverages a sophisticated suite of wireless technologies, primarily utilizing the 2.4 GHz and 5.8 GHz ISM bands for Wi-Fi and proprietary RF communications. The inclusion of Bluetooth (as indicated in the manual) suggests the platform supports close-range pairing or auxiliary device connectivity, although detailed Bluetooth specifications are not provided.

Operating across dual-band Wi-Fi not only enhances resilience to interference—essential in environments crowded with 2.4 GHz signals—but also enables high-throughput video streaming and responsive remote control. The carefully regulated output power levels further strike a balance between extended range (up to 5 km under FCC rules) and adherence to safety and emission standards.

In practical terms, these technologies ensure the Phantom 4 can maintain low-latency, high-fidelity links for live HD video transmission, precise telemetry, and reliable fail-safe features such as Return to Home. The use of advanced modulation and error-correction techniques, as inferred from the device’s high transmission distances and rapid sensor polling rates, underscores its capability to operate in complex, interference-prone environments.

Test reports summarized in the FCC documentation confirm that the device meets stringent RF exposure and electromagnetic compatibility requirements, validating its robust design and safe operation within regulated spectrum bands.

In-Depth Internal Component Analysis / Teardown

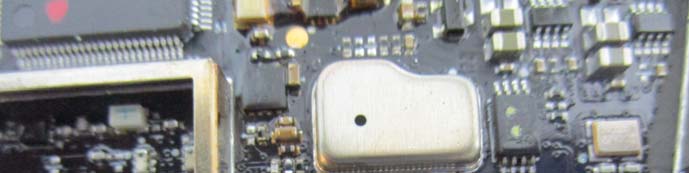

Main PCB with DJI SoC, Analog Devices Signal Processor, and High-Density Layout

A close-up of the Phantom 4’s main PCB reveals a densely packed array of surface-mount components, anchored by several high-profile integrated circuits. On the left, an Analog Devices AD80403BBCZ chip is present—an advanced signal processing component likely dedicated to high-speed sensor data acquisition or real-time video handling. At the center, a DJI-branded ‘B101’ IC suggests a custom SoC or microcontroller, potentially orchestrating flight control, sensor fusion, and proprietary communication protocols. Adjacent to this, a probable memory chip is positioned for rapid access to the main processor. The PCB itself is a multi-layer, high-quality FR4 board with meticulous passive placement and robust EMI shielding, as evidenced by a partially visible metal shield can. The design reflects DJI’s commitment to performance, reliability, and manufacturability, with the modularity and integration level expected of a flagship drone.

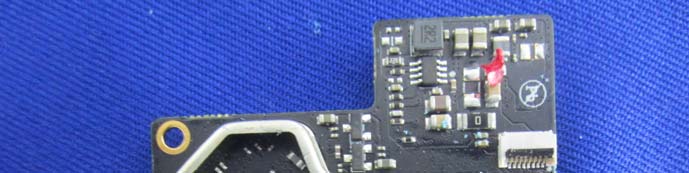

RF-Shielded PCB Section with Power Management and High-Speed Interconnects

This section of the PCB is characterized by its black soldermask, high component density, and the presence of a prominent metal shield can—hallmarks of EMI/RFI protection for sensitive RF or analog circuitry. The edge of a large, unidentified IC hints at processing or RF transceiver roles, while several smaller ICs likely handle power management and signal conditioning. The visible connector at the board’s edge suggests high-speed data or RF signal transfer to other modules, such as cameras or antennas. The layout features numerous vias and careful ground management, indicative of a multi-layer, interference-resistant design. The inclusion of a crystal oscillator and robust local power regulation further support stable operation of high-frequency circuits, essential for the Phantom 4’s advanced navigation and communication functions.

Controller IC, Switching Power Supply, and EMI Shielding

A closer examination reveals a major IC (marked ‘621P5046’) in a fine-pitch quad flat package, likely serving as a microcontroller or DSP for subsystem management—potentially handling flight control or sensor data processing. Surrounding this are precision-placed passive components, a large inductor (suggesting the presence of a switching regulator), and a nearby metal shield can for EMI suppression. The PCB’s layered structure is evident through abundant vias and ground pours, supporting complex routing and robust power distribution. The test points, such as one labeled ‘1V2,’ indicate a well-organized power architecture with dedicated rails for core logic. This section’s build quality and design sophistication exemplify the engineering rigor behind the Phantom 4’s stability and feature set.

Peripheral Interface Board with Signal Distribution Connectors

This PCB, finished in black with a clear silkscreen, is dedicated to signal distribution rather than processing. It features multiple connectors labeled PHOTO, ISO, SWITCH, SIGNAL, and VIDEO, as well as a flat flex connector—likely serving the camera, gimbal, or related peripherals. The absence of major ICs and RF-specific routing confirms its role as an interface or breakout board, facilitating modular assembly and ease of maintenance. Gold-plated pads, test points, and clear labeling underscore DJI’s attention to serviceability and manufacturing quality, supporting the device’s modular design philosophy.

Densely Populated Main Board with Shielding and RF Provisions

Here, the PCB exhibits high component density and multiple large ICs, likely encompassing the system’s main SoC, RF transceivers, and supporting MCUs. The use of black ENIG-finished PCB, extensive via networks, and visible copper tape and blue thermal pads point to advanced RF isolation and thermal management practices. The arrangement suggests the presence of dedicated antenna modules for Wi-Fi, Bluetooth, or GPS, connected via coaxial or FPC connectors. Shielding elements and robust connectors reinforce the board’s role as the Phantom 4’s central hub for data processing, communication, and control.

PCB Trace Antenna, Power Management, and Modular Interconnects

This section features a distinctive white/silver PCB trace antenna along the edge, likely dedicated to 2.4 GHz or 5.8 GHz wireless communication. The surrounding area is densely populated with SMD passives and a small IC, probably for power management or logic interfacing. A white FPC/FFC connector provides modular connectivity to sensors or peripheral boards. The ground pours, decoupling capacitors, and test points indicate a design optimized for signal integrity, low noise, and ease of assembly. The use of a trace antenna within the PCB highlights DJI’s focus on integrating RF performance directly into the electronic architecture.

Regulatory Insights & FCC Filing

The FCC ID SS3-GL6D10A1609 assigned to the Phantom 4 (Model: T650A) is a testament to its compliance with U.S. electromagnetic interference and radio frequency emission standards. Although the grant date is listed as “None,” its registration on FCC.gov affirms that the device has passed rigorous laboratory testing for safe and lawful operation in the United States.

FCC filings for devices like the Phantom 4 typically encompass a wide array of documentation: comprehensive test reports (RF exposure, EMC), detailed internal and external photographs, user manuals, schematics, and block diagrams. These documents collectively ensure that the product not only meets technical and safety requirements but also provides transparency for regulators and consumers alike.

The user manual (as summarized from ‘Users-Manual-3155881.pdf’) details essential procedures for preparing, operating, and maintaining the aircraft (T650A) and its remote controller (GL6D10A). It covers battery safety, camera and gimbal installation, and offers operational guidance, reflecting DJI’s commitment to user education and product longevity. The available test reports confirm the device’s adherence to FCC guidelines for RF emissions and electromagnetic compatibility, ensuring both robust performance and minimal risk of interference with other wireless devices.

Potential Use Cases & Target Audience

The Phantom 4’s advanced features and robust wireless architecture make it ideal for a range of demanding applications:

- Professional Aerial Imaging and Surveying

-

With its long-range transmission, stabilized gimbal, and high-quality imaging support, the Phantom 4 is a go-to tool for filmmakers, real estate professionals, and surveyors requiring precise, high-resolution aerial data.

-

Industrial Inspection and Mapping

-

The combination of GPS/GLONASS navigation, obstacle sensing, and extended flight time suits infrastructure inspection, agricultural mapping, and construction site monitoring, where reliability and data integrity are paramount.

-

Advanced Enthusiast and Educational Use

- For drone hobbyists, STEM educators, and research institutions, the Phantom 4 offers a platform for experimentation, training, and hands-on learning in robotics, aeronautics, and wireless communication.

These scenarios leverage the Phantom 4’s blend of performance, modularity, and compliance, addressing both professional and advanced consumer needs.

Conclusion

The Phantom 4 by SZ DJI TECHNOLOGY CO., LTD. (Model: T650A) represents a pinnacle of drone engineering, seamlessly integrating advanced flight control, robust wireless technologies, and user-friendly features within a rigorously compliant design. Its FCC certification under FCC ID SS3-GL6D10A1609 underscores its commitment to safety, performance, and regulatory standards.

From its modular, high-density internal architecture to its versatile operating frequencies and comprehensive user support, the Phantom 4 remains a benchmark for reliability and capability in the aerial robotics market. For professionals and enthusiasts alike, it delivers a compelling combination of innovation, quality, and compliance—setting the standard for what a modern drone can achieve.