Introduction

The MATRICE 300 RTK, developed by SZ DJI TECHNOLOGY CO., LTD (DJI), stands as a flagship commercial drone platform designed for professional applications that demand reliability, precision, and advanced flight capabilities. As a highly adaptable UAV, the Matrice 300 RTK (model: M300 RTK) is engineered to support a wide variety of payloads and mission profiles, ranging from industrial inspections and mapping to search and rescue operations. With its robust build and advanced onboard technology, the M300 RTK delivers industry-leading performance and operational flexibility.

A crucial milestone for any wireless device in the United States is FCC certification, and the Matrice 300 RTK has secured this under FCC ID SS3-RM500E1910. This certification not only affirms legal eligibility for sale and operation within the US but also guarantees compliance with stringent RF emission and electromagnetic interference standards set by the FCC. The device is intended exclusively for adult users, with safety guidelines explicitly stating it is not suitable for individuals under 18.

In this comprehensive analysis, we’ll explore the Matrice 300 RTK’s standout features, technical specifications, wireless capabilities, and a detailed teardown of its internal components. We’ll also provide regulatory insights and real-world use cases, offering a complete perspective for tech enthusiasts, engineers, and professionals evaluating this advanced drone platform.

Key Features & Specifications

The Matrice 300 RTK is engineered for demanding aerial missions, combining state-of-the-art flight technology with robust construction and versatile safety systems. Below are the primary features and technical specifications that set the M300 RTK apart in the professional UAV market.

Key Features

-

Smart Controller with Built-in GPS:

Enables precise control and real-time telemetry, enhancing situational awareness and mission planning capabilities. -

FPV Cameras:

Integrated first-person-view cameras provide pilots with live visual feedback, crucial for navigation and obstacle avoidance. -

Obstacle Avoidance:

Advanced sensors enable the drone to autonomously detect and avoid obstacles, significantly reducing the risk of in-flight collisions. -

Landing Protection:

The system evaluates ground conditions from 2 meters above, ensuring safe and suitable landing environments, minimizing damage risk. -

Multiple Flight Modes:

Supports a range of flight profiles, from manual piloting to automated missions, catering to diverse operational requirements. -

Compliance with GEO Zones and Local Regulations:

Built-in geofencing helps the drone automatically respect airspace restrictions, keeping operations compliant and safe. -

Auxiliary Lights:

Enhances visibility in low-light environments, supporting safer operation during night or limited-visibility missions. -

Multiple Safety and Flight Assistance Features:

Includes return-to-home, advanced redundancy, and customizable alerts to assist pilots and enhance operational safety.

Technical Specifications

- Maximum Take-off Weight (with payload): 9 kg (after attachment of external equipment)

- Maximum Aircraft Weight with External Equipment: 9 kg

- Maximum Wind Speed for Operation: 12 m/s (27 mph)

- Operating Temperature: -20° to 50°C (-4° to 122°F)

- Recommended Storage Temperature (Aircraft & Batteries): 22° to 30°C (71° to 86°F)

- IP44 Protection Rating: With TB60 Intelligent Flight Batteries, offering resistance to water splashes and solid particles.

- Rainfall Limitation: Not recommended to fly when rainfall exceeds 100 mm / 24 h

Additional Wireless Specifications

- Wi-Fi: Present (details not specified in the available documentation)

- Bluetooth: Present (details not specified in the available documentation)

These features and specifications highlight the Matrice 300 RTK’s suitability for professional operations where reliability, environmental resilience, and advanced safety are non-negotiable. The robust IP44 rating, wide operating temperature range, and high wind tolerance make it ideal for challenging field conditions, while the intelligent flight systems and compliance features ensure smooth, lawful, and efficient missions.

Operating Frequencies

The Matrice 300 RTK (FCC ID SS3-RM500E1910) operates across a broad spectrum of frequencies, as disclosed in its FCC filing. These frequencies underpin the drone’s wireless communication, control, and data transmission capabilities.

| Frequency Range (GHz) | Output Power (mW) | FCC Rule Part |

|---|---|---|

| 2.402–2.48 | 4 | 15CCC1.12.402 |

| 2.462 | 40 | 15CCC |

| 2.4725 | 134 | 15CCC2.42.412 |

| 2.4745 | 486 | 15CCC2.22.4055 |

| 2.4775 | 428 | 15CCC2.12.4055 |

| 2.4775 | 471 | 15CCC2.32.4105 |

| 2.48 | 1 | 15CCC2.72.4035 |

| 5.24 | 41 | 15ECC |

| 5.795 | 38 | 15ECC |

| 5.825 | 39 | 15ECC |

| 5.8395 | 38 | 15ECC3.45.745 |

| 5.8445 | 38 | 15ECC3.35.7355 |

| 15.775 | 40 | 15ECC |

| 62.4205–2.4625 | 19 | 15CCC2.55.18 |

| 65.19–5.23 | 38 | 15ECC |

| 75.21 | 39 | 15ECC |

| 85.7305–5.8445 | 414 | 15ECC3.25.7305 |

| 95.7455–5.8295 | 41 | 15ECC3.55.755 |

The diversity of these frequency bands enables the drone to support multiple wireless technologies (such as Wi-Fi and Bluetooth) and proprietary communication links, optimizing performance for control, telemetry, and payload data transmission while ensuring compliance with regulatory standards.

Technology Deep Dive

The Matrice 300 RTK leverages a suite of wireless technologies to deliver robust, low-latency communication and precise positioning—essential for mission-critical drone operations. The presence of both Wi-Fi and Bluetooth modules (as confirmed in the technical documentation) allows the drone and its controller to maintain reliable links for command, telemetry, and payload data.

The use of the 2.4 GHz and 5 GHz ISM bands supports high-throughput, low-latency data transmission, vital for real-time video downlink, FPV, and telemetry. The broad range of output powers across these frequencies suggests adaptive power management, balancing range, interference mitigation, and battery life. Bluetooth provides short-range connectivity, likely for device pairing, diagnostics, or peripheral integration.

The device’s multi-band, multi-protocol design ensures operational resilience in congested RF environments. The inclusion of a high-performance GNSS module (detailed in the teardown below) further enhances positional accuracy, critical for RTK operations. Internal documentation and test reports highlight the system’s compliance with RF exposure and emission limits, ensuring both user safety and regulatory adherence. Collectively, these technologies empower the Matrice 300 RTK with industry-leading communication reliability and operational flexibility.

In-Depth Internal Component Analysis / Teardown

A thorough examination of the Matrice 300 RTK’s internal hardware reveals the sophisticated engineering underpinning its performance and reliability. Below, we analyze eight key internal images, each showcasing a unique aspect of the drone’s advanced electronics.

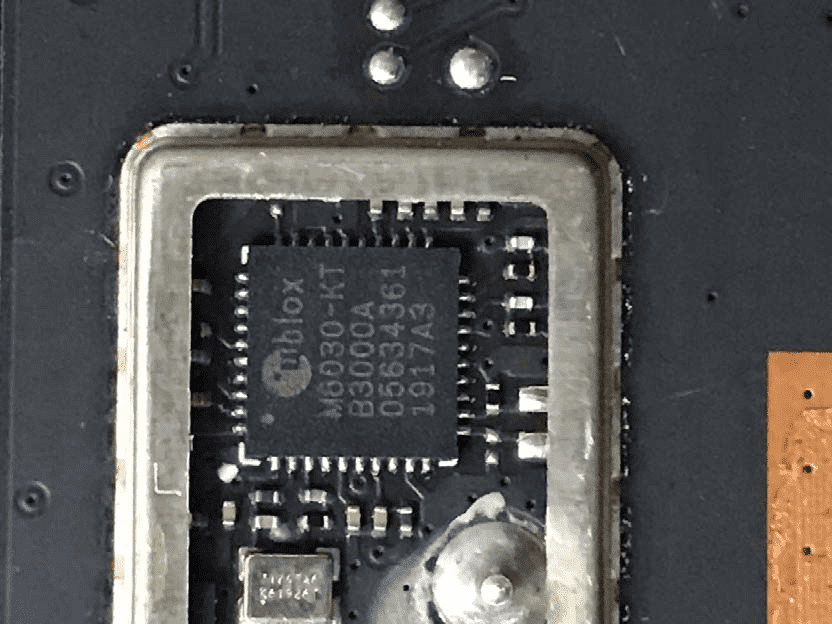

The section of the PCB housing the u-blox M8030-KT GNSS receiver exemplifies DJI’s commitment to precise, reliable navigation. This high-sensitivity, low-power chip is central to the drone’s RTK capabilities, enabling centimeter-level positioning by processing signals from multiple satellite constellations. The dense arrangement of passives and the presence of a crystal oscillator ensure optimal RF performance and timing accuracy. Robust metal shielding minimizes interference, while the multi-layer black PCB and meticulous via placement reflect a design focused on signal integrity and electromagnetic compatibility. This subsystem is critical for flight stability, autonomous navigation, and safe operation in complex environments.

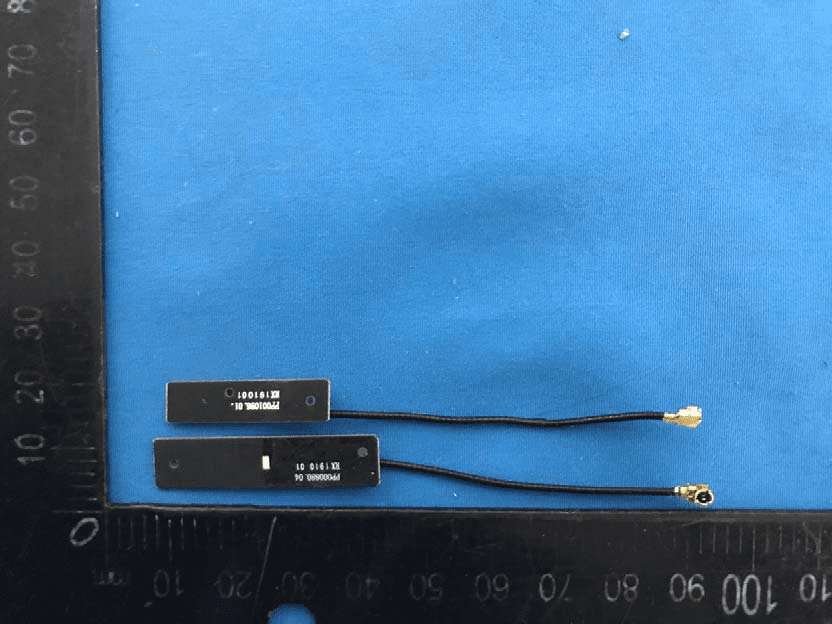

The dual PCB trace antennas, each equipped with a coaxial U.FL connector, are indicative of the system’s modular and high-reliability RF design. These antennas are likely dedicated to Wi-Fi, telemetry, or GPS reception, supporting robust multi-band communication between the drone and its controller. The labeled part numbers and revision codes suggest custom tuning for the Matrice 300 RTK’s specific frequency requirements. Their compact, rugged construction ensures consistent performance across varied operational environments, while the modular connectors facilitate easy assembly, testing, and potential upgrades.

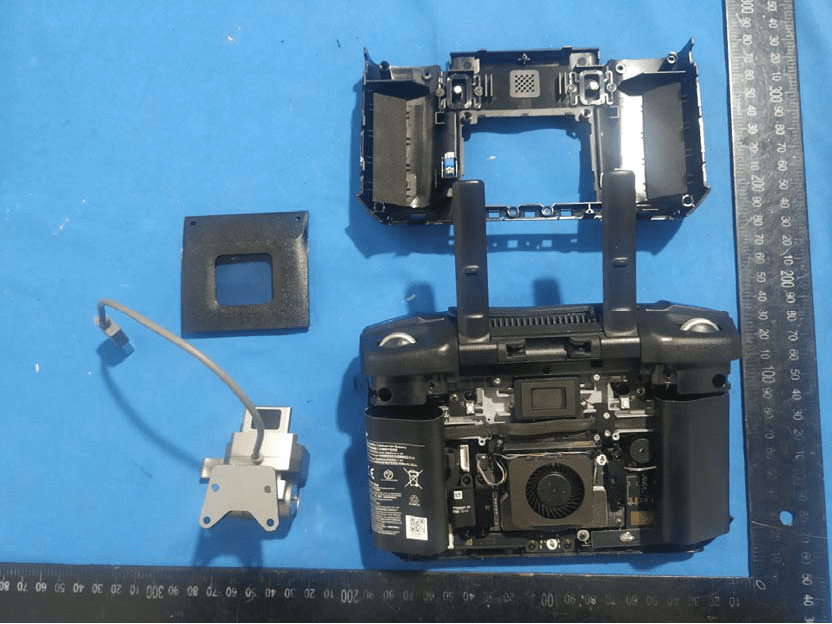

The remote controller’s main PCB showcases an intricate assembly of high-performance digital and RF subsystems. The centrally located processor, protected by a dedicated cooling fan and metal shielding, likely handles video processing, wireless communication, and system management. Surrounding ICs facilitate memory, RF transceivers, and power management, while robust connectors ensure secure integration with batteries, displays, and external modules. The twin external antennas and modular battery packs highlight DJI’s focus on signal reliability and operational endurance. Overall, this layout exemplifies a balance of high data throughput, thermal efficiency, and serviceability—attributes vital for demanding field use.

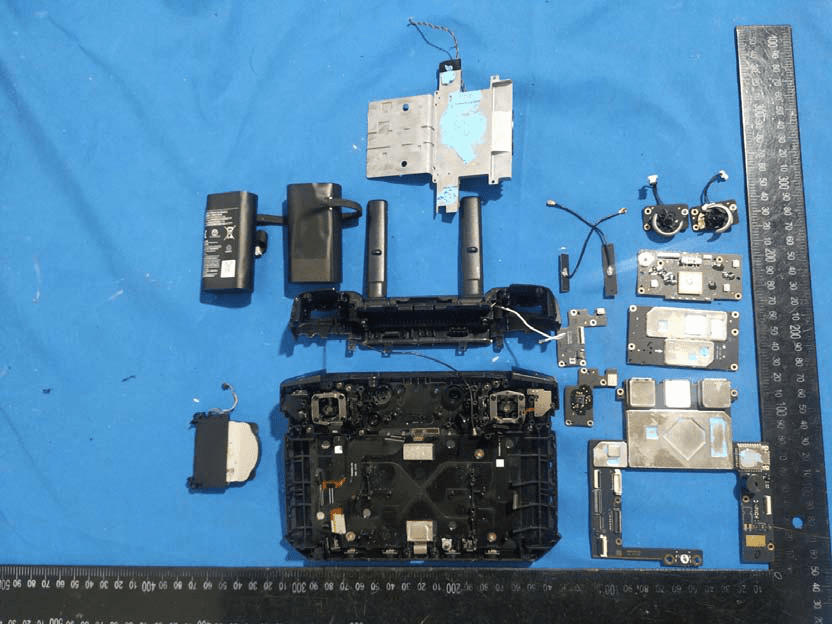

A detailed teardown of the controller’s internal modules reveals a high-density, multi-layer PCB ecosystem. Multiple shielded zones protect sensitive RF and high-speed digital circuits, while exposed BGA and QFP ICs point to powerful SoCs and MCUs managing video, flight control, and communication. The presence of diverse antenna modules and robust connectors enables flexible, multi-band operation. Power management components and battery interfaces are engineered for reliability and resilience. The systematic layout, extensive grounding, and EMI suppression reflect a design optimized for low-latency control, robust data links, and real-time processing, fully supporting the Matrice 300 RTK’s professional-grade requirements.

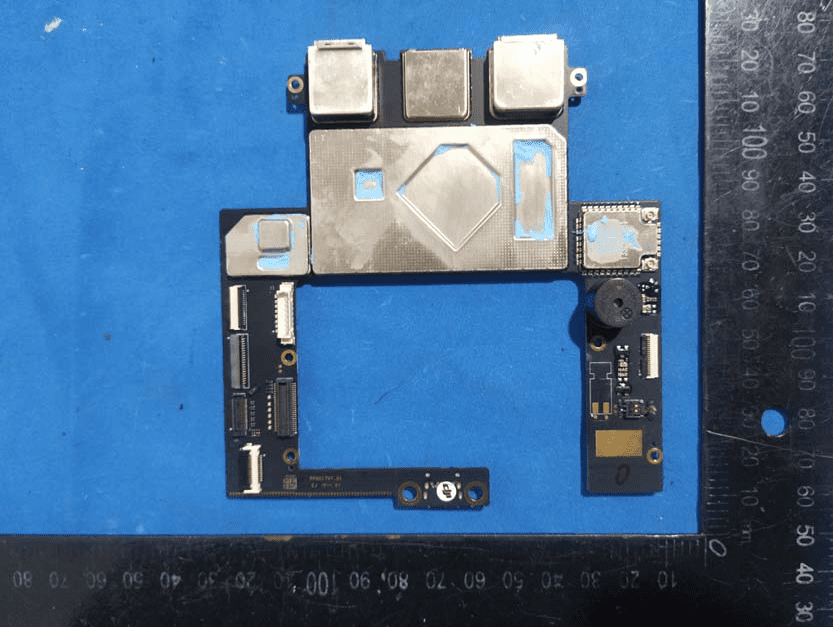

The L-shaped PCB assembly within the drone demonstrates DJI’s expertise in compact, high-performance embedded systems. Extensive metal shielding denotes critical RF, high-speed digital, and analog sections—likely housing SoCs, RF transceivers, and memory. Numerous fine-pitch FPC connectors interface with cameras, sensors, and daughterboards, supporting the drone’s modular payload architecture. Ground pours and dense via placement ensure signal integrity and EMI control, while blue thermal pads indicate thoughtful thermal management. This assembly likely orchestrates advanced flight control, sensor fusion, and communications, forming the technological backbone of the Matrice 300 RTK.

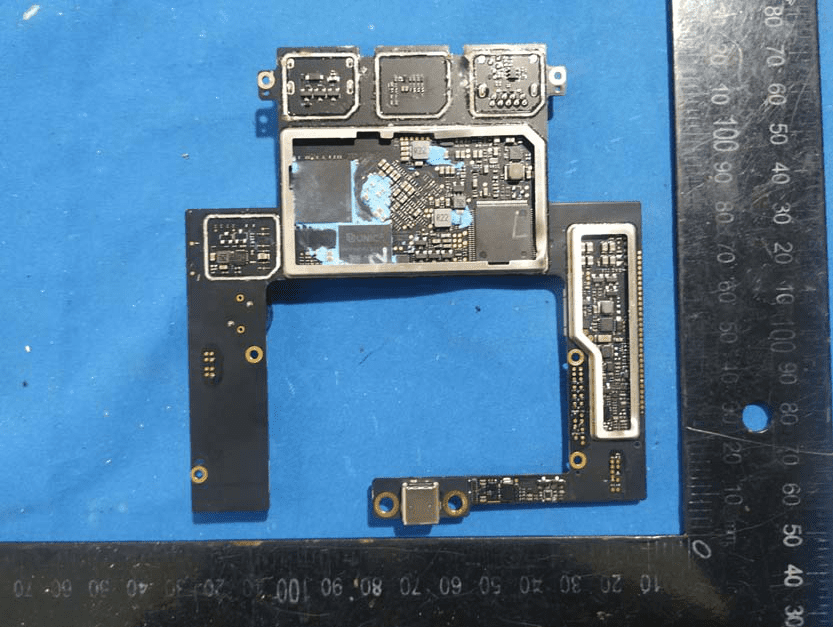

A densely populated multi-layer PCB, this module integrates several shielded functional blocks, each likely dedicated to key operations such as flight control, communications, and sensor management. The shape is customized for tight mechanical integration, and the presence of numerous gold-plated test points and connectors highlights serviceability and modularity. The smaller daughterboard may house critical sensors or interface ports. The extensive use of soldered EMI shields and high-density component placement reflect a design prioritizing RF performance, reliability, and compliance with EMI standards—attributes essential for the drone’s central controller or communications hub.

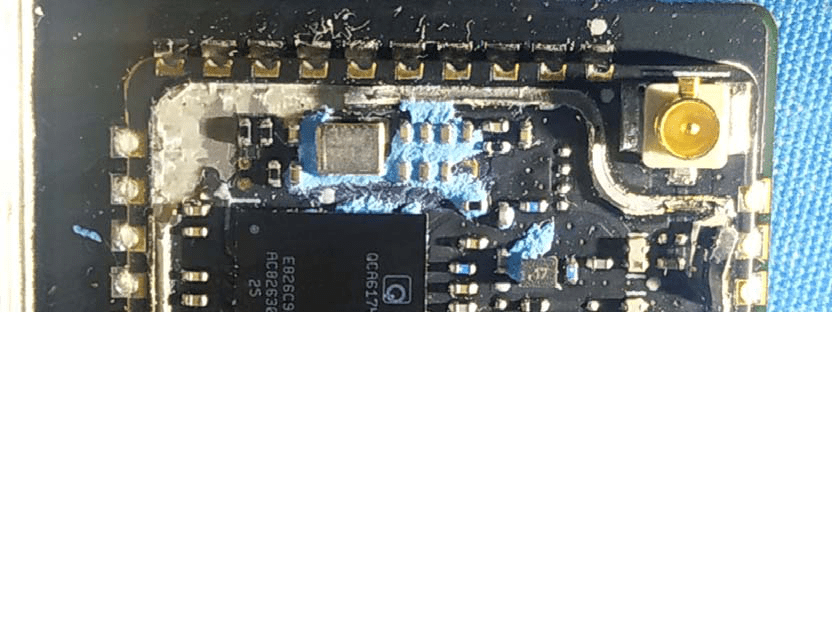

This compact wireless module centers around the Qualcomm QCA6174 chip, a dual-band Wi-Fi and Bluetooth combo IC renowned for high throughput and low-latency connectivity. The module’s design demonstrates careful RF engineering, with a U.FL connector for external antennas, differential pair routing, and robust grounding via stitching vias and ground pours. The crystal oscillator ensures stable wireless timing, while the dense array of passives supports RF filtering and power conditioning. The presence of solder residue suggests a removable shield can, prioritizing both RF integrity and serviceability. This module forms the core of the Matrice 300 RTK’s wireless communications, enabling seamless controller-drone interaction.

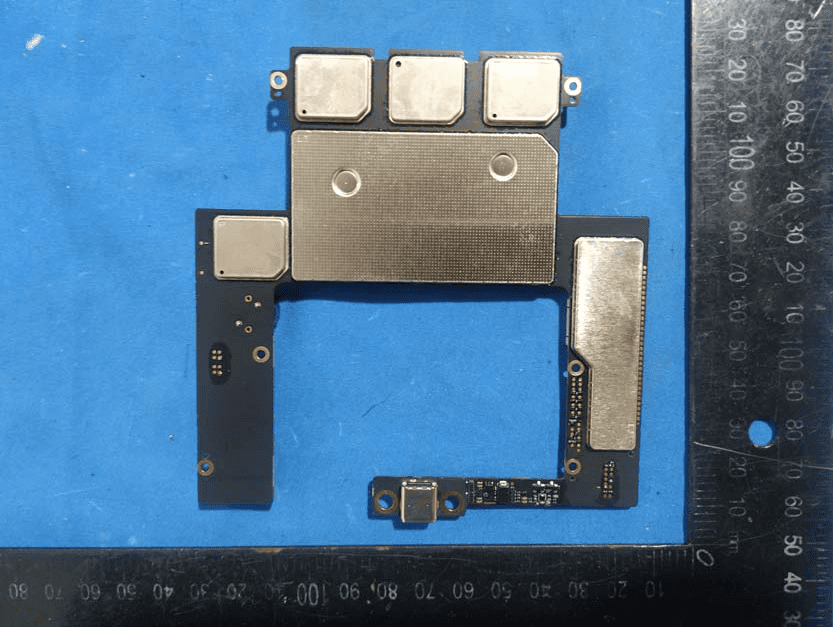

Another sophisticated PCB assembly, this board features a large BGA processor, memory chips, and multiple RF connectors, all protected by modular EMI shields. The black PCB, intricate via networks, and controlled impedance traces underscore advanced PCB manufacturing techniques. The integration of USB Type-C, board-to-board connectors, and test points facilitates diagnostics and modular expansion. Large inductors and capacitors provide clean, stable power for sensitive circuits. This assembly likely manages core flight control, real-time data processing, and multi-sensor fusion, underpinning the drone’s mission-critical performance and reliability.

Regulatory Insights & FCC Filing

The Matrice 300 RTK’s compliance with FCC ID SS3-RM500E1910 is a testament to its adherence to US electromagnetic interference (EMI) and radiofrequency (RF) emission regulations, as mandated by the Federal Communications Commission. This certification is a prerequisite for legal sale, import, and operation within the United States, ensuring that the device does not cause harmful interference or exceed exposure limits during typical use.

FCC filings for the Matrice 300 RTK encompass a broad array of documentation, including detailed test reports (covering RF exposure, conducted and radiated emissions), internal and external photographs, user manuals, and technical block diagrams. These documents collectively demonstrate the device’s conformity to relevant FCC Rule Parts, specifically those governing unlicensed wireless transmissions (such as Part 15 for Wi-Fi and Bluetooth).

Key insights from the official documentation highlight the Matrice 300 RTK’s status as a sophisticated, professional-grade aircraft. The user manual emphasizes strict operational, maintenance, and safety protocols, underscoring the drone’s intended use by trained adult operators in professional environments. The Smart Controller Enterprise, referenced in the documentation, leverages OcuSync Enterprise technology for secure, long-range HD video and telemetry transmission, supporting the drone’s advanced mission capabilities. The FCC’s thorough review process and resulting certification assure users of both regulatory compliance and a high standard of engineering integrity.

Potential Use Cases & Target Audience

The Matrice 300 RTK’s robust design, advanced wireless systems, and comprehensive safety features make it ideal for a range of demanding professional scenarios:

-

Industrial Inspection and Infrastructure Monitoring:

Utility companies, energy providers, and civil engineers can deploy the M300 RTK for detailed inspections of power lines, pipelines, bridges, and towers. The drone’s RTK precision, obstacle avoidance, and landing protection features streamline data collection while minimizing operational risk. -

Emergency Response and Search & Rescue:

First responders benefit from the drone’s real-time video downlink, FPV cameras, and reliable wireless communication. The M300 RTK enables rapid situational assessment, mapping, and delivery of rescue payloads, even in adverse weather or complex environments. -

Surveying and Mapping:

Surveyors and GIS professionals leverage the drone’s centimeter-level positioning and multi-sensor integration for high-accuracy aerial mapping, construction site monitoring, and land management. The system’s compliance with local GEO zones ensures lawful, efficient operations.

Given its advanced technology and operational complexity, the Matrice 300 RTK is designed exclusively for adults—professional pilots, engineers, and organizations—demanding uncompromising performance, safety, and regulatory compliance.

Conclusion

The Matrice 300 RTK by SZ DJI TECHNOLOGY CO., LTD (DJI), model M300 RTK, is a pinnacle of professional drone engineering, combining advanced flight technology, robust wireless communications, and comprehensive safety systems. Its FCC certification under FCC ID SS3-RM500E1910 assures both regulatory compliance and operational reliability in the United States. Through meticulous design—evident in both its external features and internal architecture—the M300 RTK empowers professionals across industries to execute complex aerial missions with precision and confidence. As the demands on commercial UAV platforms continue to grow, the Matrice 300 RTK stands out as a forward-looking solution, ready to meet the challenges of tomorrow’s aerial operations.