Introduction

The Matrice 200 V2 by SZ DJI TECHNOLOGY CO., LTD. stands at the forefront of industrial UAV solutions, engineered specifically for professionals who demand robust performance and reliability in challenging environments. As a versatile flight platform, the Matrice 200 V2 is tailored for complex missions such as infrastructure inspections, search and rescue, surveying, and aerial cinematography. Its advanced airspace awareness, redundant safety features, and intelligent flight systems enable precise control and dependable operation, even in environments where traditional navigation aids may fail.

A critical milestone in the device’s journey to market is its FCC certification, identified by FCC ID SS3-GL900A1811. This certification not only means the drone is legally authorized for sale and operation in the United States, but also ensures it complies with stringent RF emission and electromagnetic interference standards. For industrial users and commercial operators, this translates to confidence in both regulatory compliance and operational safety.

In this analysis, we’ll delve into the Matrice 200 V2’s standout features, detailed technical specifications, wireless capabilities, and a deep-dive teardown of its internal components. We’ll also explore regulatory insights gleaned from its FCC filing, and discuss practical use cases that highlight its appeal for professionals in demanding fields.

Key Features & Specifications

The Matrice 200 V2 is designed as a workhorse for industrial and professional applications, integrating cutting-edge technology to ensure safety, precision, and versatility. Below are the key features and technical specifications that define this platform:

Key Features

- Built-in AirSense: Provides real-time airspace awareness by receiving ADS-B signals, alerting operators to nearby manned aircraft for enhanced safety in shared airspace.

- Dual GNSS Support (GPS + GLONASS): Ensures robust positioning and navigation accuracy, particularly beneficial in environments where one system may be blocked or degraded.

- Wide Operating Temperature Range: Functions reliably from -4° to 122° F (-20° to 50° C), supporting year-round operations in diverse climates.

- OCUSYNC 2.0 Remote Controller: Offers stable, long-range HD video transmission and robust anti-interference performance, essential for critical missions.

- Safety Beacons (Top and Bottom): High-visibility LED beacons facilitate identification during night flights or low-light conditions, improving operational safety and compliance.

- Advanced Visual Sensors: Enable precise hovering and positioning, even indoors or in GNSS-denied environments, supporting missions in warehouses, tunnels, or under bridges.

- Versatile Remote Controller Outputs: HDMI, SDI, and USB outputs enable seamless integration with professional video workflows and external displays.

Technical Specifications

- Downward Vision System:

- Operating Range: <32.8 feet (10 m)

- Velocity Range: <32.8 ft/s (10 m/s) at a height of 6.56 feet (2 m)

- Max Wind Resistance: 39.4 ft/s (12 m/s), enabling stable flight in challenging weather conditions.

- Ultrasonic Sensor Environment: Optimized for non-absorbing, rigid surfaces; performance decreases on thick carpeting or soft materials.

- GNSS Module: GPS + GLONASS for redundant, high-precision navigation.

- Dimensions (Folded): 722 × 282 × 242 mm (propellers and landing gears excluded).

- Intelligent Flight Battery:

- Type: TB55-7660mAh-22.8V

- Capacity: 7660 mAh

- Energy: 174.6 Wh

- Operating Temperature: -4° to 122° F (-20° to 50° C)

- Net Weight (Single Battery): Approx. 885 g

- Max Flight Time: 38 minutes (no payload), 24 minutes (with 6.14 kg takeoff weight)

- Remote Controller:

- Run Time: Approximately 4 hours (WB37-4920mAh-7.6V battery)

- Outputs: HDMI, SDI, USB

- Max Angular Velocity: Pitch: 300°/s, Yaw: 150°/s

Wireless & Connectivity

- Wi-Fi: Dual frequency support (2.4 GHz and 5.8 GHz), allowing flexible operation in crowded or interference-prone environments.

- Bluetooth: Present (details unspecified), likely used for quick device pairing or auxiliary communications.

Benefits in Practice:

These features collectively ensure the Matrice 200 V2 is ready for demanding missions—whether it’s maintaining precise flight in strong winds, operating safely at night, or capturing vital data in GNSS-denied zones. The dual-battery system offers redundancy and extended flight endurance, while the OCUSYNC 2.0 controller provides the robust, low-latency connectivity that professionals require.

Operating Frequencies

The wireless capabilities of the Matrice 200 V2, as documented in its FCC ID SS3-GL900A1811 filing, are defined by its supported frequency ranges and output power levels. These determine the platform’s communication range, interference resilience, and regulatory compliance.

| Frequency Range (GHz) | Output Power (mW) | FCC Rule Part |

|---|---|---|

| 2.4725 | 77 | 15CCC2.35.7285 |

| 2.4775 | 81 | 15CCC2.22.4105 |

| 5.8395 | 8 | 15ECC3.3 |

| 5.8445 | 9 | 15ECC3.25.7355 |

| 5.8465 | 76 | 15ECC3.15.7305 |

| 12.4035–2.4775 | 448 | 15CCC2.12.4055 |

These bands are critical for the drone’s remote control, video downlink, telemetry, and possibly Wi-Fi/Bluetooth communications. The output power levels are carefully calibrated to maximize range and reliability while ensuring compliance with FCC RF emission rules.

Technology Deep Dive

The Matrice 200 V2 leverages a combination of advanced wireless and sensor technologies to deliver robust, interference-resistant performance. Its dual-band Wi-Fi (2.4 GHz and 5.8 GHz) enables flexible operation, allowing users to select the optimal frequency for their environment and minimize the risk of interference from other wireless devices. Bluetooth support, though not detailed, likely facilitates quick setup and device pairing, streamlining field operations.

The selected frequency bands are standard for professional drone platforms, offering a balance between range (lower frequencies) and available bandwidth (higher frequencies). Output power levels are optimized to ensure strong, reliable links for control and video transmission without exceeding regulatory limits—a necessity for legal operation in the US market.

The use of advanced RF shielding, multi-layer PCB design, and external antennas (as seen in internal component analysis) further enhances signal integrity and minimizes EMI/RFI, ensuring consistent performance even in electromagnetically noisy environments. The integration of OCUSYNC 2.0 technology in the remote controller underscores the platform’s focus on low-latency, high-fidelity communication, critical for real-time video and responsive control.

Test reports within the FCC filing confirm that the Matrice 200 V2 meets stringent standards for RF emissions and electromagnetic compatibility, supporting its use in sensitive industrial and commercial settings.

In-Depth Internal Component Analysis / Teardown

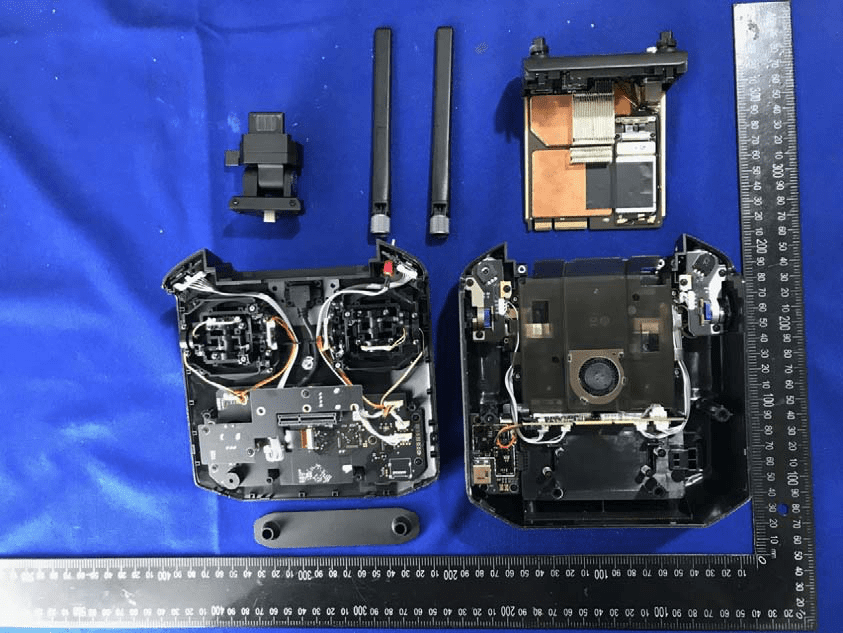

Disassembled Remote Controller & Module Overview

A comprehensive internal view reveals the sophisticated engineering underpinning the Matrice 200 V2 remote controller. The main PCB showcases a dense arrangement of microcontrollers, RF transceivers, and power management ICs, many of which reside beneath robust EMI/RFI shields—an indicator of the platform’s focus on minimizing wireless interference. The board’s multi-layer construction, abundant via stitching, and controlled impedance traces highlight meticulous attention to signal integrity and power distribution. Dual external dipole antennas, connected via micro-coaxial cables, facilitate omnidirectional communication in the 2.4 GHz and 5.8 GHz bands. Connectors for HDMI, SDI, USB, and flat cables underscore the controller’s versatility, while the presence of tactile switches and gimbal joystick assemblies reflect its ergonomic, mission-critical design. The power section, clearly separated from sensitive analog/RF domains, features substantial capacitors and inductors for stable operation. Overall, the modular, serviceable layout and robust shielding exemplify professional-grade build quality.

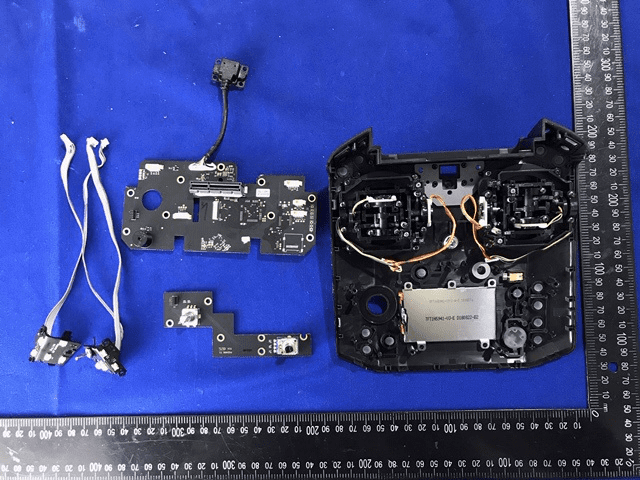

Modular Sensor Assemblies & Antenna Boards

A detailed teardown of the sensor and interface modules highlights the Matrice 200 V2’s modular approach to system integration. Multiple green FR4 PCBs, each with high-density connectors and shielded regions, host a mix of microcontrollers, power management ICs, and sensor interfaces. Trace antennas and coaxial connectors indicate support for 2.4 GHz/5.8 GHz or GPS communications, while the presence of lens-equipped sensor modules points to advanced visual and navigational capabilities. The use of shield cans over sensitive sections, controlled impedance routing, and vibration-isolated mounting all reflect a design focused on RF performance and reliability. Power regulation is evident through the presence of inductors and capacitors, supporting stable sensor operation. The overall assembly is compact and organized, enabling easy replacement or upgrade—a testament to the drone’s emphasis on maintainability and mission flexibility.

Controller Subsystem & Joystick Mechanisms

Inspection of the controller’s interior reveals multiple interconnected PCBs, with visible QFP and QFN ICs likely serving as the main microcontroller, RF transceivers, and power management units. The main board’s multi-layer design, dense via network, and differential pair routing support high-speed data and robust RF performance. Prominent joystick gimbal assemblies and tactile switches ensure responsive manual control, while FPC/FFC connectors facilitate modular integration with auxiliary subsystems. Large metal shield cans, soldered for maximum EMI protection, safeguard sensitive RF and digital sections. Power integrity is maintained through strategically placed capacitors and inductors, and the inclusion of test points and crystals further supports reliable operation and serviceability. The overall design reflects a commitment to durability, precision, and professional-grade performance.

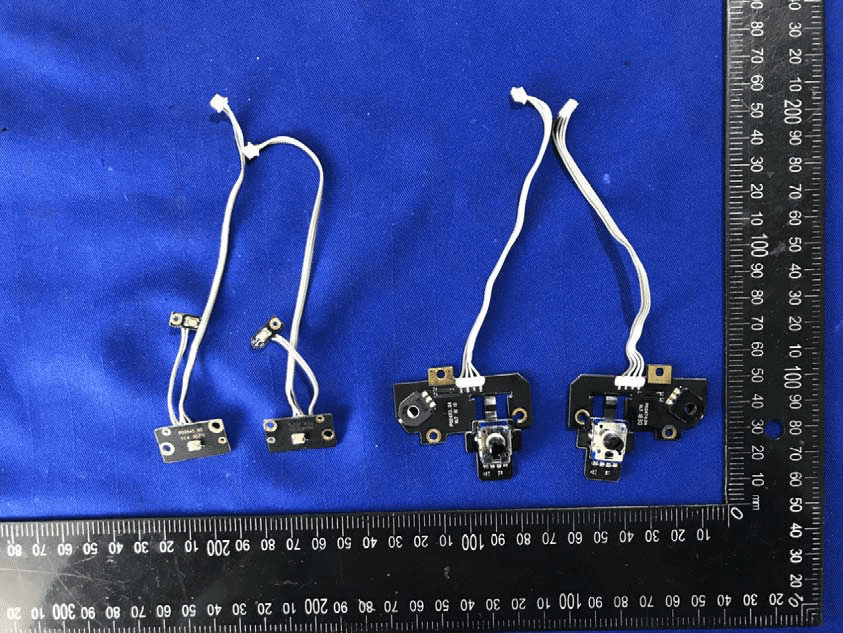

Sensor Modules for Obstacle Detection

The sensor modules exhibit a clean, modular design using black ENIG-finished PCBs with attached ribbon cables. The rightmost boards feature lens assemblies, likely for optical or IR sensing, crucial for obstacle avoidance and precise positioning. Minimal power components and the absence of RF-specific elements suggest these are dedicated, low-frequency sensor boards, relying on the main system for power regulation. The use of robust connectors and mounting holes ensures secure integration and easy replacement. The design prioritizes reliability and modularity, supporting the platform’s advanced navigation and safety features.

Simple Support Modules & Antenna Breakouts

A set of small, green PCBs with minimal component density serve as simple sensor mounts, antenna breakouts, or interface boards. Some feature wire elements acting as monopole or dipole antennas, likely for low-frequency RF such as GPS or telemetry. The sparse layout and basic grounding reflect their passive or semi-passive role. Modular connectors facilitate straightforward integration, and the simplicity of design supports reliability and ease of maintenance—key for distributed sensor or antenna systems within the drone’s airframe.

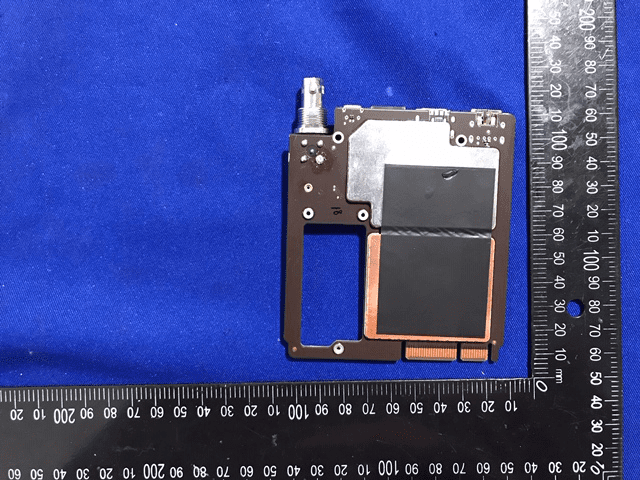

Shielded RF/Communications Module

A densely populated, dark-colored PCB features extensive EMI/RFI shielding and a coaxial connector for external antenna integration. The shielded areas likely conceal critical RF transceivers, SoCs, or MCUs, essential for high-frequency communication. The gold-finger edge connector supports high-speed board-to-board data transfer, and the multi-layer design ensures signal integrity. Robust grounding and modularity reflect the engineering rigor required for mission-critical UAV communications and video transmission.

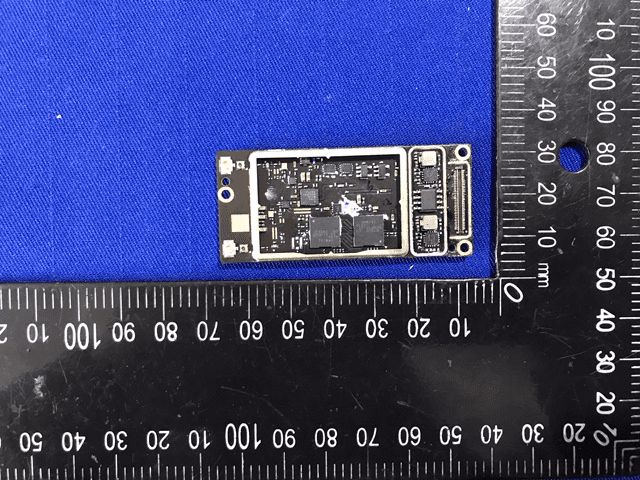

High-Density Processing or Sensor Interface Module

This compact, black PCB features several major BGA or QFN ICs, shielded central sections, and a high-density connector for integration with the main drone system. The presence of crystals, large capacitors, and inductors points to sophisticated onboard power regulation and precise timing. The multi-layer construction and robust shielding underscore its role as a critical subsystem—potentially handling flight control, communications, or sensor data processing—engineered for high performance and minimal interference.

High-Performance Communication/Processing Board

A high-density, multi-layer PCB with several large BGA ICs, connectors (including microSD, micro-USB, and HDMI), and a prominent coaxial RF connector is indicative of a module dedicated to communication, video processing, or advanced control tasks. The board’s careful RF layout, differential pair routing, and robust grounding ensure high-bandwidth, low-latency data transfer—essential for real-time video and telemetry in professional drone operations.

Shielded RF/Communication Subsystem

This dark-colored PCB is densely populated with shielded sections and a gold-finger edge connector, reflecting its role as a modular RF or data communication subsystem. The presence of an external antenna connector and extensive EMI/RFI control measures highlight its importance in maintaining reliable, interference-free operation. The design is compact, robust, and engineered for seamless integration with the Matrice 200 V2’s avionics.

USB Interface and Power Management Board

A single-sided, black PCB with a connected USB port and several major ICs demonstrates the Matrice 200 V2’s commitment to modularity and serviceability. The board’s design features careful analog/digital domain separation, local power regulation, and provisions for EMI/RFI shielding. Differential pair routing near the USB interface supports high-speed data transfer, while board-to-board connectors enable flexible integration with sensors, cameras, or the main flight controller.

Regulatory Insights & FCC Filing

The FCC ID SS3-GL900A1811 assigned to the Matrice 200 V2 confirms its compliance with US federal standards for electromagnetic interference and radio frequency emissions. This certification, registered by FCC.gov, is mandatory for any device emitting RF energy to ensure it does not cause harmful interference with other electronic systems. Achieving this status signifies that the Matrice 200 V2 meets all requirements for legal sale and operation within the United States.

FCC filings encompass a wide range of critical documentation, including RF exposure and EMC test reports, internal and external photographs, user manuals, and schematic/block diagrams. These materials provide transparency into the device’s safety, emissions profile, and design integrity.

According to the user manual and internal documentation, the Matrice 200 V2 is engineered for industrial reliability, integrating redundant sensors, advanced power management, and robust safety features. Test reports confirm its adherence to RF emission limits, validating its suitability for use in sensitive environments—from infrastructure inspection sites to emergency response operations. The internal photographs and technical analyses within the FCC filing underscore the device’s sophisticated, modular design and meticulous attention to EMI/RFI control.

Potential Use Cases & Target Audience

The Matrice 200 V2’s feature set and robust engineering make it ideal for a range of professional and industrial applications:

- Infrastructure Inspection & Utilities: Utility companies and infrastructure operators can deploy the Matrice 200 V2 for inspecting power lines, bridges, and pipelines. Its advanced visual sensors, high wind resistance, and long flight endurance enable safe, efficient surveys—even in GNSS-denied or hazardous environments.

- Search & Rescue / Emergency Response: First responders benefit from the platform’s rapid deployment, dual-battery redundancy, and high-visibility beacons, allowing for safe operation in low-light or complex airspace. Precision hovering and obstacle avoidance support critical SAR missions where reliability is paramount.

- Aerial Surveying & Cinematography: Surveyors and filmmakers leverage the Matrice 200 V2’s precise flight controls, smart flight features, and versatile payload integration for capturing complex shots or collecting accurate geospatial data—indoors or outdoors, regardless of environmental challenges.

These scenarios illustrate why the Matrice 200 V2 is trusted by professionals who demand mission-critical performance, safety, and regulatory compliance.

Conclusion

The Matrice 200 V2 by SZ DJI TECHNOLOGY CO., LTD. (Model: M200 V2, FCC ID SS3-GL900A1811) sets a high bar for industrial drone platforms, blending robust engineering, advanced wireless technology, and comprehensive safety features. Its FCC certification assures users of legal compliance and operational reliability, while the detailed teardown reveals a modular, serviceable architecture built for demanding missions. Whether deployed for infrastructure inspection, emergency response, or precision surveying, the Matrice 200 V2 stands as a testament to DJI’s commitment to performance, safety, and innovation in professional UAV systems.