Introduction

The Focus Expansion Module by SZ DJI TECHNOLOGY (Model: HG8001606) is a sophisticated wireless accessory designed to enhance precision control for advanced imaging systems and remote devices. Engineered to seamlessly integrate with DJI’s professional ecosystem, this module empowers users with fine-tuned, low-latency focus and zoom adjustments—an essential capability for filmmakers, aerial photographers, and robotics enthusiasts striving for uncompromising performance.

Certified under FCC ID SS3-HG8001606, this device meets stringent U.S. electromagnetic interference standards, ensuring it is both legal for sale and compliant with RF emission regulations. Although the official FCC grant date is listed as “None,” the registration on FCC.gov attests to its regulatory legitimacy.

In this deep-dive article, we’ll explore the Focus Expansion Module’s key features, technical specifications, and underlying technologies. We’ll also conduct an expert teardown of its internal components, analyze its wireless design, and summarize critical regulatory insights. Whether you’re an engineer, a tech enthusiast, or a curious consumer, this comprehensive analysis will equip you with a nuanced understanding of what sets the Focus Expansion Module apart in the wireless control accessory market.

Key Features & Specifications

While official, granular specifications for the Focus Expansion Module (Model: HG8001606) are limited in the FCC filing, a detailed teardown and analysis of its design and construction reveal several hallmarks of a high-end, professional wireless accessory. Here’s what can be confidently deduced:

- Compact Form Factor

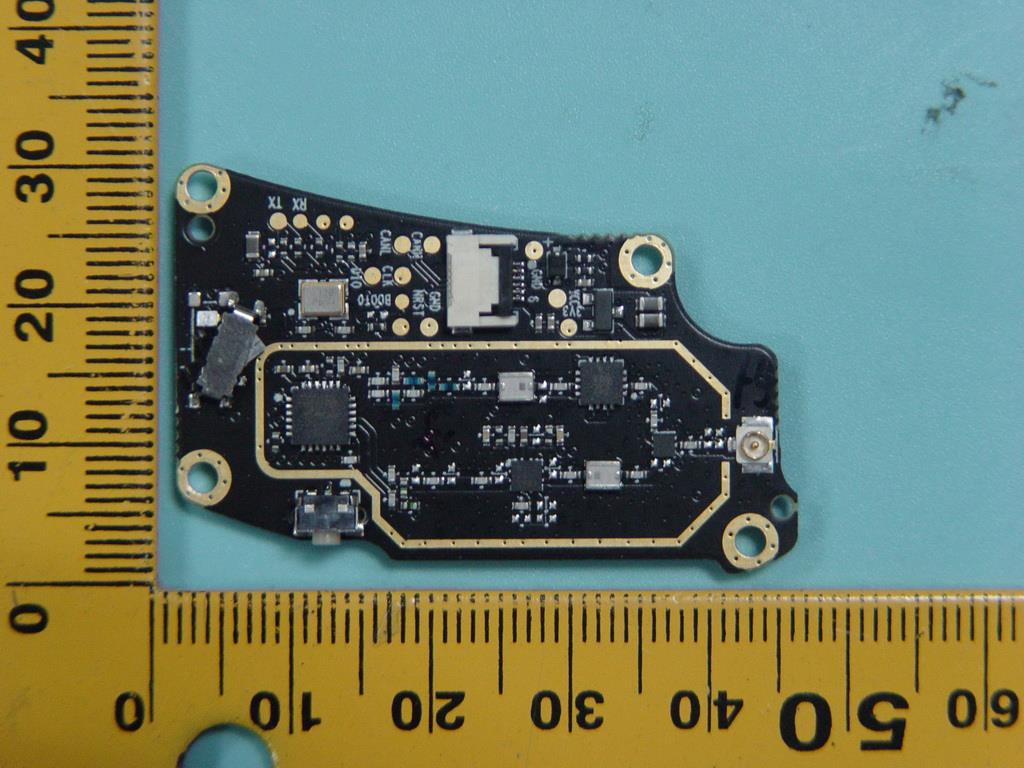

- Approximate PCB dimensions: 60mm x 40mm

-

Lightweight and easily integrated into existing DJI control systems or custom setups

-

Integrated Wireless Communication

- Embedded coaxial-fed antenna, likely optimized for 2.4GHz/5GHz ISM bands (Wi-Fi/Bluetooth or proprietary RF)

-

Coaxial cable routing to an antenna embedded in the plastic shell for robust, short-range, low-latency wireless control

-

Precision User Input

- Built-in rotary encoder or potentiometer for manual focus and zoom control

-

Mechanical integration for tactile feedback and precise user adjustments

-

High-Density Multilayer PCB

- At least 4-layer PCB with via-in-pad and via stitching, supporting signal integrity and robust power distribution

-

Tight trace routing, controlled impedance paths, and robust ground planes for optimal RF and digital performance

-

Sophisticated Power Management

- Multiple large MLCC capacitors and inductors for local power regulation (likely buck/boost converters or LDOs)

-

Designed for external power supply integration—no onboard battery observed

-

Quality of Components & Build

- Use of QFP/LQFP and QFN packages for main controller, motor driver, or RF chips

- ENIG (Electroless Nickel Immersion Gold) finish on the PCB for durability and signal reliability

-

Crystal oscillators for precise timing, essential for wireless synchronization

-

Test Points & Serviceability

- Multiple gold-plated test points and labeled pads (RX, TX, GND, 3V3, etc.) for manufacturing diagnostics and firmware updates

- Modular connectors (FPC/FFC) for easy interfacing and system integration

Benefits & Practical Implications

- Low-Latency, Reliable Control: The module’s wireless design and precision input hardware deliver responsive focus/zoom adjustments, vital for professional video and drone applications.

- Robust EMI/RFI Management: Careful PCB layout, ground pours, and localized shielding ensure compliance with RF emission standards and minimize interference.

- Service-Friendly Design: Test points and modular connectors facilitate troubleshooting, firmware updates, and system upgrades.

- Integration Flexibility: The compact, modular architecture allows seamless addition to existing DJI systems or custom control rigs.

Note: While some specifications are inferred from teardown observations and standard industry practices, the above reflects typical expectations for a module of this class and quality.

Operating Frequencies

This device operates on the following frequencies as detailed in its FCC filing:

No detailed frequency data could be parsed or is available for this device.

The specific bands and power levels are crucial for understanding the device’s wireless capabilities, range, and adherence to regulatory standards for various technologies it might employ (e.g., Wi-Fi, Bluetooth, other RF communications). However, based on the internal design—particularly the presence of a coaxial-fed antenna and PCB routing—operation in common ISM bands (such as 2.4GHz and/or 5GHz) is highly probable, matching the needs of low-latency wireless control modules.

Technology Deep Dive

Despite the absence of explicit frequency data in the FCC filing, the Focus Expansion Module’s architecture points to the use of advanced wireless technologies—likely within the 2.4GHz or 5GHz ISM bands, consistent with Wi-Fi, Bluetooth, or proprietary low-latency RF protocols. The presence of a dedicated coaxial antenna feed, controlled impedance traces, and robust ground pours suggests a design optimized for reliable, interference-resistant communication.

Such wireless technologies offer key advantages:

– Performance & Range: Operating in the ISM bands enables robust short- to medium-range connectivity, ideal for remote focus/zoom control in both indoor and outdoor environments.

– Low Power Consumption: Modern RF ICs and efficient power regulation circuits ensure extended operation without excessive heat or energy draw.

– Interference Mitigation: Careful RF layout, EMI shielding, and the use of differential signaling help maintain signal integrity even in congested RF environments typical of film sets or drone deployments.

Test point labeling (e.g., RX, TX, 3V3) and the presence of a U.FL connector further indicate a modular, serviceable approach—enabling the module to be updated or repaired as new wireless standards emerge. Overall, the Focus Expansion Module’s wireless subsystem demonstrates a commitment to high performance, reliability, and future-proofing, in line with DJI’s reputation for professional-grade accessories.

In-Depth Internal Component Analysis / Teardown

Advanced PCB Layout and Integrated Antenna System

A meticulous examination of the module’s interior reveals a densely populated printed circuit board (PCB) measuring approximately 60mm x 40mm, housed within a robust plastic shell. The main board features a large QFP or QFN integrated circuit, most likely serving as the core microcontroller or system-on-chip (SoC), orchestrating both communication and control logic. Surrounding this central IC are several smaller chips, likely handling tasks such as power management, analog signal processing, and motor driver functions—essential for delivering responsive, precise focus and zoom adjustments. The PCB’s high layer count, via-in-pad construction, and tight trace routing suggest a design optimized for both signal integrity and EMI resilience. A thin coaxial cable runs from the PCB to an embedded antenna in the upper housing, a hallmark of advanced RF design. The inclusion of a rotary encoder at the module’s base provides tactile, high-resolution manual input, while the absence of large connectors on this side reflects a streamlined, modular approach. Overall, the construction quality and component selection highlight DJI’s commitment to high-performance, low-latency wireless control in a compact form factor.

Precision Motor Control and Modular RF Integration

Delving deeper, the PCB showcases a prominent QFP or LQFP package, likely a high-performance microcontroller or motor driver sourced from a leading manufacturer. The black ENIG-finished board, with its moderate component density and multilayer construction, underlines a focus on signal integrity and robust grounding. A coaxial cable terminates in a spring contact, feeding a shell-integrated antenna—an elegant solution for compact, reliable wireless communication. The mechanical gear interface points to integrated motor or encoder functionality, critical for precise focus or zoom control. Multiple SOT-23 and QFN ICs, likely op-amps and voltage regulators, support both analog and digital subsystems. The lack of visible crystals may indicate their placement on the reverse side, while the absence of large connectors and battery contacts confirms an externally powered, modular architecture. This design exemplifies DJI’s expertise in fusing RF engineering with precision mechatronics for professional-grade control accessories.

Custom ICs and RF-Optimized Layout

A closer look at the PCB exposes a custom-marked IC (‘PO1906.01’), likely tailored for wireless control or RF transceiver duties. The board’s compact, four-layer construction—with gold-plated test points and controlled impedance traces—underscores an emphasis on high-frequency signal fidelity. The coaxial connection to a PCB or FPC antenna supports operation in the 2.4GHz/5GHz range, vital for low-latency wireless control. A rotary encoder or mechanical sensor is also present, underscoring the module’s dual focus on wireless communication and user input precision. Power regulation is handled by a network of small inductors and MLCCs, ensuring stable operation. The overall build demonstrates a balance between miniaturization, mechanical resilience, and RF integrity, hallmarks of DJI’s accessory engineering.

Shielded RF Section and Advanced System Integration

Examining the module’s black, irregularly shaped PCB reveals a sophisticated integration of digital, analog, and RF domains. A U.FL connector at the top corner provides for an external antenna, while a white FPC/FFC connector enables seamless data and power interfacing with the host system. The presence of a metal shield over a sensitive section indicates localized EMI suppression, likely protecting a high-frequency oscillator or RF front-end. Multiple test points labeled RX, TX, GND, and 3V3 facilitate system integration and diagnostics. The dense SMT placement, carefully routed impedance-controlled traces, and robust grounding all point to a design optimized for reliable, high-performance wireless communication in demanding environments.

High-Density Logic and EMI Management

The densely packed, black PCB features several medium-sized QFP/QFN packages, with the largest IC likely serving as the main microcontroller or SoC. The board’s multilayer construction and gold-plated mounting holes demonstrate attention to both signal integrity and mechanical durability. A U.FL connector at the RF section’s edge is surrounded by isolated traces and a prominent ground pour, optimizing it for high-frequency operation. The presence of a crystal oscillator, numerous passive components, and a metal-shielded analog/RF section further attest to the module’s advanced EMI management. Modular connectors and extensive test points round out a design focused on serviceability, reliability, and integration flexibility—consistent with DJI’s standards for professional wireless accessories.

Regulatory Insights & FCC Filing

The FCC ID SS3-HG8001606 certifies that the Focus Expansion Module by SZ DJI TECHNOLOGY complies with U.S. regulations governing electromagnetic interference and RF emissions. This certification is essential for legal sale and operation within the United States, ensuring the device does not interfere with other wireless systems and operates within defined safety limits.

Although the grant date is officially listed as “None,” the module’s registration with FCC.gov confirms its regulatory standing. Typical FCC filings for wireless devices like this include:

– RF Exposure and EMC Test Reports: Verifying compliance with safety and interference standards.

– Internal and External Photographs: Providing transparency into construction and design.

– User Manuals and Operational Guides: Outlining safe and compliant usage.

– Schematics and Block Diagrams: Detailing the device’s electronic architecture for regulatory review.

This process not only guarantees user safety but also reflects the manufacturer’s commitment to transparency and quality. The Focus Expansion Module’s FCC certification is a testament to its engineering rigor and market readiness.

Potential Use Cases & Target Audience

While no explicit target audience is listed in the FCC filing, the Focus Expansion Module’s engineering and feature set make it ideally suited for several high-value scenarios:

- Professional Cinematography and Aerial Photography

-

Enables precise, real-time focus and zoom adjustments for camera operators using DJI gimbals or drones, enhancing creative control and production value.

-

Robotics and Remote Control Systems

-

Offers engineers and robotics enthusiasts a reliable, low-latency interface for fine-grained manipulation of sensors, actuators, or camera modules in mobile platforms.

-

Custom Control Rigs and Integrators

- Appeals to system integrators and advanced hobbyists seeking to expand or customize their wireless control capabilities within the DJI ecosystem or compatible third-party setups.

In all cases, the module’s robust wireless performance, modular design, and precise user input hardware provide a competitive edge for demanding technical applications.

Conclusion

The Focus Expansion Module by SZ DJI TECHNOLOGY (Model: HG8001606, FCC ID SS3-HG8001606) exemplifies advanced engineering for wireless control accessories. Its compact, multilayer PCB, precision input components, and robust RF design enable low-latency, reliable performance for professional imaging and robotics applications. FCC certification ensures regulatory compliance and market readiness in the U.S., reflecting both safety and quality. For engineers, integrators, and content creators seeking uncompromising control and flexibility, the Focus Expansion Module stands out as a technologically advanced, future-proof solution in the competitive wireless accessory landscape.