Introduction

The DJI Phantom 4 Pro/Pro+ is a flagship model in DJI’s renowned Phantom series, engineered to set benchmarks in aerial imaging and intelligent flight. Designed for both professional creators and advanced enthusiasts, this quadcopter delivers a robust combination of high-resolution imaging, autonomous flight capabilities, and advanced obstacle avoidance—making it a preferred choice for aerial photography, mapping, and industrial inspection.

A critical aspect of the Phantom 4 Pro/Pro+’s legitimacy in the U.S. market is its FCC certification, under FCC ID SS3-WM331A1609 (grant date: None). This certification confirms that the drone complies with strict U.S. regulations for radiofrequency (RF) emissions, ensuring it is legal to market, sell, and operate within the United States. Meeting FCC standards not only ensures user safety and minimal interference with other devices but also demonstrates DJI’s commitment to regulatory compliance and product excellence.

In this article, we provide a comprehensive analysis of the DJI Phantom 4 Pro/Pro+—covering its standout features, precise technical specifications, deep-dive technology insights, teardown-based internal component review, and an expert look at its regulatory documentation and use cases.

Key Features & Specifications

The DJI Phantom 4 Pro/Pro+ stands out in the competitive drone landscape with a suite of high-end features and technical advancements. Below, we break down the core capabilities and what they mean in real-world use.

Key Features

-

Intelligent Flight Modes:

The drone supports multiple autonomous flight modes, including ActiveTrack, TapFly, Draw, Gesture, and more, allowing pilots to capture complex shots with minimal manual input and enhanced safety. -

Obstacle Sensing System:

Equipped with front, rear, and side sensors, the Phantom 4 Pro/Pro+ offers comprehensive obstacle detection, reducing collision risk and enabling safer, smarter flight in complex environments. -

DJI GO App Compatibility:

Real-time monitoring, camera control, and flight telemetry are accessible via the DJI GO app, providing pilots with a live HD video downlink and intuitive control. -

High-Speed Performance:

Capable of reaching speeds up to 44.7 mph (20 m/s) in Sport mode, the drone can quickly cover large areas, ideal for dynamic shots or surveying. -

3-Axis Gimbal Stabilization:

Integrated gimbal stabilization across pitch, roll, and yaw axes ensures ultra-smooth footage, even in windy or high-movement scenarios. -

Imaging Excellence:

Features a 1-inch CMOS sensor camera, capturing 20 MP stills and 4K video at up to 60fps, supporting professional-grade photography and cinematography. -

Vision Positioning System:

Enables precise hovering and stable indoor flight, even when GPS signals are weak or unavailable. -

Live HD Video Downlink:

Transmits real-time high-definition video to the remote controller/display, essential for framing and monitoring shots in real time.

Technical Specifications

- Still Photography Modes:

- Single shot

- Burst shooting (3/5/7/10/14 frames)

- Auto Exposure Bracketing (AEB)

-

Time-lapse

-

Maximum Ascent Speed:

- Sport mode: 6 m/s

-

GPS mode: 5 m/s

-

Operating Temperature Range:

32° to 104° F (0° to 40° C) -

Weight (with Battery & Propellers):

1380 g -

Electronic Shutter Speed:

8 – 1/8000 s -

Photo Formats:

JPEG, DNG (RAW), J+R -

Video Recording Modes:

- H.265 and H.264 codecs

-

Up to 4096×2160 60p @ 100Mbps

-

Obstacle Sensing System Measuring Frequency:

10 Hz -

Bluetooth:

Bluetooth present (details not specified)

Camera Specifications (Extracted)

-

Sensor:

1’’ CMOS; Effective pixels: 20 MP -

Max Image Size:

- 3:2 Aspect Ratio: 5472×3648

- 4:3 Aspect Ratio: 4864×3648

-

16:9 Aspect Ratio: 5472×3078

-

Video Recording Modes:

- H.265 UHD: 4096×2160 24/25/30p @ 100Mbps

- H.264 UHD: 4096×2160 24/25/30/48/50/60p @ 100Mbps

- H.265/H.264 FHD: 1920×1080 24/25/30/48/50/60/120p @ up to 80Mbps

- H.265/H.264 HD: 1280×720 24/25/30/48/50/60/120p @ up to 65Mbps

-

Multiple intermediate resolutions and frame rates

-

Battery:

- Voltage: 15.2 V

- Battery Type: LiPo 4S

- Net Weight: 468 g

- Capacity: 5870 mAh

- Max Flight Time: Approx. 29 minutes

- Energy: 89.2 Wh

Operating Frequencies

The DJI Phantom 4 Pro/Pro+ (FCC ID SS3-WM331A1609) operates on the following frequency bands, as detailed in its FCC filing:

| Frequency Range (GHz) | Output Power (mW) | FCC Rule Part |

|---|---|---|

| 12.4065-2.4765 | 767 | 15CCC |

| 15.73-5.845 | 392 | 15E38 |

These frequency ranges encompass standard 2.4 GHz and 5.8 GHz ISM bands commonly used for Wi-Fi and drone remote control links, as well as potential Bluetooth operation. The specified output power levels are carefully regulated to balance range, penetration, and compliance with RF emission limits. This ensures robust wireless communication, minimal interference with other spectrum users, and legal operation under FCC Part 15 rules.

Technology Deep Dive

The Phantom 4 Pro/Pro+ leverages advanced wireless technologies—primarily Wi-Fi and possibly Bluetooth—for real-time command, control, and video transmission. The primary wireless links operate in the 2.4 GHz and 5.8 GHz ISM bands, which are standard for high-speed, low-latency communications between the drone and its remote controller or mobile device. Bluetooth support (details not specified) may be used for auxiliary device pairing or configuration.

Operating within these frequency bands allows the drone to achieve a strong balance between range, data throughput, and resistance to interference. The relatively high output power (up to 767 mW) supports extended operational range, enabling pilots to maintain reliable connections even in challenging RF environments. The multi-band capability also provides resilience against congestion by allowing automatic frequency selection.

From an engineering perspective, the use of controlled impedance PCB routing and robust grounding—evident in the device’s internal design—further enhances wireless performance and minimizes susceptibility to EMI (electromagnetic interference). This is critical in a drone platform, where simultaneous operation of GPS, video transmission, and control links must coexist without mutual interference.

In-Depth Internal Component Analysis / Teardown

DJI’s engineering prowess is evident in the Phantom 4 Pro/Pro+’s internal architecture. Below, we provide a detailed analysis of nine key internal photographs, revealing insights into the device’s design, component selection, and manufacturing quality.

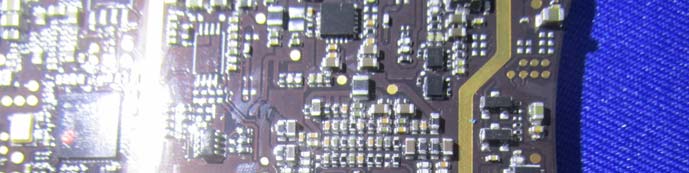

The central section of the mainboard reveals a custom DJI-branded IC, likely a proprietary SoC or MCU, serving as the heart of the drone’s flight control system. Its high pin count and prominent placement indicate responsibility for critical real-time tasks such as sensor fusion, stabilization, and command processing. Surrounding the main controller are supporting ICs for power regulation and signal interfacing, with robust ground via stitching and a multi-layer PCB structure. The layout demonstrates careful impedance control, essential for high-speed and RF signals. The absence of visible antenna structures in this view suggests modular antenna placement elsewhere, while the dense population and high-quality materials underscore DJI’s commitment to reliability and EMI control.

A densely populated PCB section showcases multiple medium-sized ICs—likely a mix of analog front-ends, power management controllers, and possibly microcontrollers or RF transceivers. The board’s dark soldermask and intricate via network suggest a sophisticated multi-layer design, optimized for signal integrity and EMI performance. The presence of wide power traces and a high density of passive components points to complex power regulation and signal conditioning. No explicit connectors or antennas are evident, indicating this module’s focus on internal signal processing and subsystem control, crucial for the drone’s advanced flight and communication features.

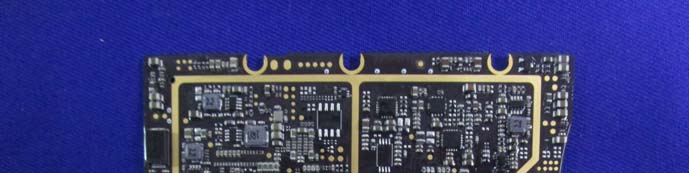

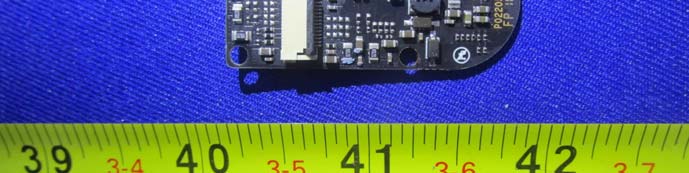

This image highlights a segment of PCB featuring a prominent 2.2 µH inductor, an essential component for power conversion and filtering. The gold-plated edge contacts and fine trace routing suggest a high-reliability interconnect, possibly for modular assembly. The board’s dense SMD population and multi-layer construction point toward power management or analog signal conditioning functions. Stitching vias and ground pours are abundant, reflecting a design optimized for EMI suppression and stable electrical performance—vital for sensitive avionics and sensor integration.

A compact, high-density PCB area is dominated by small analog and mixed-signal ICs, likely responsible for sensor signal conditioning or precise power regulation. The presence of an FPC connector indicates modular interfacing, possibly with camera or IMU modules. Numerous test points facilitate in-circuit testing and quality control during manufacturing. The black soldermask, dense component layout, and careful ground via placement signal a premium, EMI-conscious design—consistent with the needs of a high-performance drone subsystem.

Central to this board are two custom-marked ICs, probably serving as motor controllers or MOSFET drivers for the drone’s brushless motors. The wide traces and grouped vias underscore high-current handling, essential for rapid and stable motor response. Supporting passive components and robust wiring ensure power integrity and durability. The board’s layout and construction quality reflect DJI’s focus on efficient, reliable motor control—critical for precise flight dynamics and safety.

A close-up of the power distribution interface reveals a robust gold-plated connector and thick PCB traces, engineered for high-current delivery from the battery to the drone’s subsystems. The secure mounting hardware and modular design enhance mechanical stability and serviceability. Abundant ground vias and careful trace separation ensure minimal voltage drop and safe, efficient power flow—key for maintaining flight performance under demanding conditions.

This section of PCB reveals tightly clustered microcontrollers, power management ICs, and analog front-end chips, arranged for optimal signal routing and noise suppression. Gold-plated edge connectors and isolation slots support modular assembly and EMI partitioning. The presence of large capacitors and inductors underscores the board’s focus on stable power delivery and signal integrity. Such design choices are essential for the reliability of flight control and sensor processing modules.

A compact board featuring a large FPC connector is displayed, suggesting a dedicated interface for critical subsystems such as cameras or sensors. The high-density SMD layout, multi-layer construction, and extensive ground vias indicate a design tailored for signal integrity and robust interconnection. The presence of a crystal oscillator highlights the importance of precise timing for synchronized operations across the drone’s modules.

This shielded PCB module demonstrates advanced RF engineering, with a metallic can ensuring EMI/RFI suppression over sensitive analog or RF circuitry. The visible spiral trace likely serves as an integrated PCB antenna—an efficient, space-saving solution for GPS or ISM band communications. The mounting hole and compact form factor reflect attention to both mechanical robustness and electromagnetic compatibility, crucial for maintaining reliable navigation and communication links.

Regulatory Insights & FCC Filing

The FCC ID SS3-WM331A1609 designation attests that the DJI Phantom 4 Pro/Pro+ meets stringent U.S. electromagnetic compatibility (EMC) and RF emission standards. This certification, with a registration handled by FCC.gov (grant date: None), is a prerequisite for legal sale and operation in the United States, ensuring the device does not cause harmful interference and is safe for users.

FCC filings for this drone include a comprehensive set of technical documents:

– Test reports for RF exposure and EMC compliance

– Internal and external photographs for transparency and verification

– User manuals detailing safe operation, intelligent flight features, camera and gimbal controls, and battery management

– Schematics and block diagrams outlining hardware architecture

Key user and technical insights can be found in the Phantom 4 Pro/Pro+ user manuals, which provide detailed instructions on setup, intelligent flight modes, camera operation, obstacle sensing, and safety requirements. These documents reinforce the device’s advanced feature set and DJI’s focus on safe, reliable operation.

Potential Use Cases & Target Audience

While the Phantom 4 Pro/Pro+ is engineered for versatility, certain user profiles and scenarios stand out:

-

Professional Aerial Imaging:

Photographers and filmmakers benefit from the 20 MP camera, 4K/60fps recording, and 3-axis gimbal, enabling crisp, stable shots for commercial projects, real estate, or cinematic productions. -

Industrial Inspection & Mapping:

Surveyors and inspectors leverage the intelligent flight modes and obstacle sensing for precise, automated data capture—ideal for construction, agriculture, or infrastructure monitoring. -

Advanced Hobbyists & Educators:

Tech enthusiasts and STEM educators use the Phantom 4 Pro/Pro+ to explore aerial robotics, programming, and imaging, taking advantage of its robust flight safety features and live HD video streaming via the DJI GO app.

The combination of intelligent automation, advanced safety, and professional imaging makes the Phantom 4 Pro/Pro+ suitable for demanding users who require both creative flexibility and operational reliability.

Conclusion

The DJI Phantom 4 Pro/Pro+ (Model: Phantom 4 Pro/Pro+, FCC ID SS3-WM331A1609) exemplifies advanced drone engineering, blending high-performance imaging, autonomous flight, and robust safety systems into a single, FCC-compliant package. Its sophisticated internal architecture, powerful wireless capabilities, and meticulous regulatory adherence position it as a top choice for professionals and enthusiasts alike. As aerial technology continues to evolve, the Phantom 4 Pro/Pro+ stands as a benchmark for reliability, innovation, and market readiness—fully cleared for takeoff in the U.S. and beyond.