Introduction

The DJI Phantom 3 Professional (Model: W323B) is a benchmark in consumer and prosumer aerial imaging, seamlessly integrating advanced flight controls, robust safety features, and a high-performance camera system. As a quadcopter designed for capturing ultra-high-definition video and still images, it has set industry standards for reliability, usability, and image quality. At the heart of its legal distribution and operation in the United States lies its FCC certification, specifically under FCC ID SS3-GL3001510. While this device’s grant date is listed as None, its registration with the FCC means it meets rigorous RF emission and electromagnetic interference standards—ensuring both safety and regulatory compliance for end users.

This article delivers an expert-level, comprehensive breakdown of the Phantom 3 Professional’s key specifications, wireless technology, internal components, and regulatory standing. Drawing from official FCC documentation, internal teardown photos, and user manual extracts, we’ll explore the engineering sophistication behind this iconic drone, from its intelligent flight systems to the intricate PCB assemblies that power its aerial prowess.

Key Features & Specifications

The DJI Phantom 3 Professional is engineered for both performance and safety, offering a suite of intelligent features and robust hardware. Here’s an in-depth look at what sets it apart:

Key Features

- Flight Limits & No Fly Zones: Integrated geofencing and altitude restrictions enhance operational safety, preventing accidental entry into restricted airspace.

- Sony EXMOR 1/2.3″ Camera Sensor: Delivers 12.4 MP effective pixels for crisp stills and detailed video capture, ensuring professional-grade imaging.

- Advanced Photography Modes: Includes burst shooting, auto exposure bracketing (AEB), and multiple still modes for creative flexibility.

- Auto Takeoff and Landing: Simplifies operation for beginners and professionals alike, ensuring smooth and safe launches and recoveries.

- 3-Axis Gimbal Stabilization: Provides ultra-smooth video and sharp stills by eliminating unwanted vibrations and movement.

- Vision Positioning System: Enhances stability and precision during indoor or GPS-denied flights, leveraging downward sensors for accurate hovering.

- Integrated Flight Simulator: Allows pilots to practice maneuvers and build confidence without risking the actual aircraft.

- Controllable Gimbal Pitch: Offers real-time, remote adjustment of the camera angle for creative shot composition.

Technical Specifications

- Intelligent Flight Battery:

- Net Weight: 370 g

- Capacity: 4480 mAh

- Type: LiPo 4S

- Voltage: 15.2 V

- Energy: 68 Wh

- Max Charging Power: 100 W

- Max Flight Time: ~24 minutes

- Operating Temperature: -10°C to 40°C

- Flight Performance:

- Max Flight Altitude: 6000 m

- Operating Temperature: 0°C to 40°C (aircraft & remote)

- Camera System:

- Sensor: Sony EXMOR 1/2.3” (Effective pixels: 12.4 M; Total: 12.76 M)

- Video Recording Modes:

- UHD: 4096x2160p24/25, 3840x2160p24/25/30

- FHD: 1920x1080p24/25/30/48/50/60

- HD: 1280x720p24/25/30/48/50/60

- Electronic Shutter Speed: 8s – 1/8000s

- Wireless Connectivity:

- Wi-Fi: Present (details N/A)

- Bluetooth: Present (details N/A)

- Remote Controller:

- Operating Temperature: 0°C – 40°C

Practical Implications

These features empower both novice and professional pilots to capture cinematic footage with minimal risk and maximum creative control. The robust battery and advanced camera system make the Phantom 3 Professional ideal for extended shoots, while intelligent safety features and the vision positioning system ensure reliable operation even in challenging environments. The integration of Wi-Fi and Bluetooth provides flexible connectivity for real-time video streaming and device pairing, although specific protocol details are not disclosed in the FCC filing.

Operating Frequencies

The DJI Phantom 3 Professional (Model: W323B, FCC ID SS3-GL3001510) operates on the following wireless frequencies and power levels per its FCC documentation:

| Frequency Range (GHz) | Output Power (mW) | FCC Rule Part |

|---|---|---|

| 2.404–2.47 | 303 | 15C1 |

These frequencies are central to the device’s wireless communication capabilities, supporting robust RF links for flight control and video transmission while ensuring compliance with U.S. regulatory standards.

Technology Deep Dive

The Phantom 3 Professional leverages a combination of Wi-Fi and Bluetooth technologies to facilitate real-time control and video transmission. Operating primarily within the 2.4 GHz ISM band, the device achieves a balance between long-range connectivity and minimal interference, which is essential for both video downlink and responsive flight command.

The specified frequency range (2.404–2.47 GHz) aligns with standard Wi-Fi and Bluetooth bands, enabling reliable connection between the drone, its remote controller, and companion mobile devices. With an output power of 303 mW, the system is optimized for robust signal integrity over significant distances, reducing the likelihood of dropouts or latency—critical for first-person view (FPV) piloting and precision control.

From an engineering perspective, the use of external antennas (as evidenced in the teardown analysis) and advanced RF front-end design helps minimize electromagnetic interference and maximize range. The focus on EMI/RFI shielding, differential pair routing, and power regulation, visible in the internal PCB design, further enhances wireless performance while keeping power consumption in check.

Test reports and user manuals corroborate these findings, highlighting the device’s commitment to low-latency, high-quality video streaming and secure command transmission—cornerstones for safe, professional drone operation.

In-Depth Internal Component Analysis / Teardown

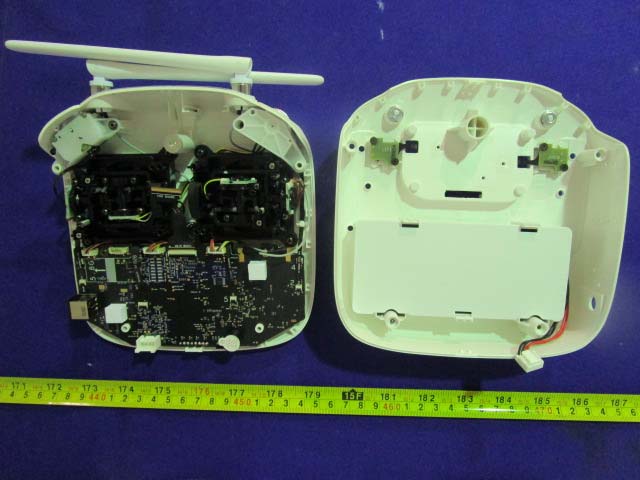

Main Controller PCB and Antenna Assembly

The remote controller’s interior reveals a meticulously engineered PCB, featuring several integrated circuits that likely include the main microcontroller/SoC, RF transceivers, and memory modules for firmware storage. The board’s construction, a standard green FR4 with a compact, high-density layout, indicates a 4-layer design optimized for EMI/RFI suppression—vital in RF-intensive environments. Two external rod antennas, connected via U.FL-like coaxial cables, are strategically placed for optimal 2.4 GHz/5.8 GHz operation. The presence of numerous test points, FPC/FFC connectors, and robust power regulation components (large capacitors and inductors) reflects a design focused on serviceability, reliable power delivery, and superior RF performance. The overall modularity and clean layout underscore DJI’s commitment to robust, low-latency wireless control.

Main PCB with Gimbal Assemblies and Connectors

A closer examination of the controller’s main PCB showcases a densely populated, likely 4- to 6-layer board, equipped with multiple ICs, including a probable ARM Cortex-M SoC, RF transceivers, and flash memory. The dual external dipole antennas highlight the focus on extended range and reliable signal transmission. High component density, numerous vias, and robust grounding strategies ensure optimal EMI/RFI control. Prominent mechanical gimbal assemblies for the control sticks utilize potentiometers or Hall sensors for precise user input. Multiple connectors—USB, FPC/FFC, and battery—support modularity and ease of repair. The overall build quality, mechanical robustness, and sophisticated RF design are indicative of a high-end, professional-grade remote controller.

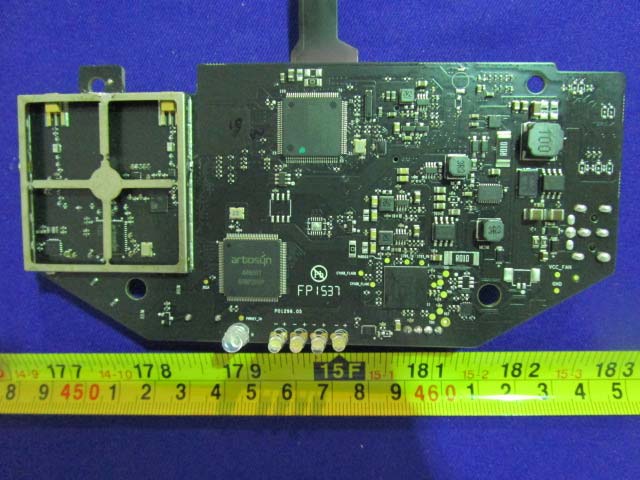

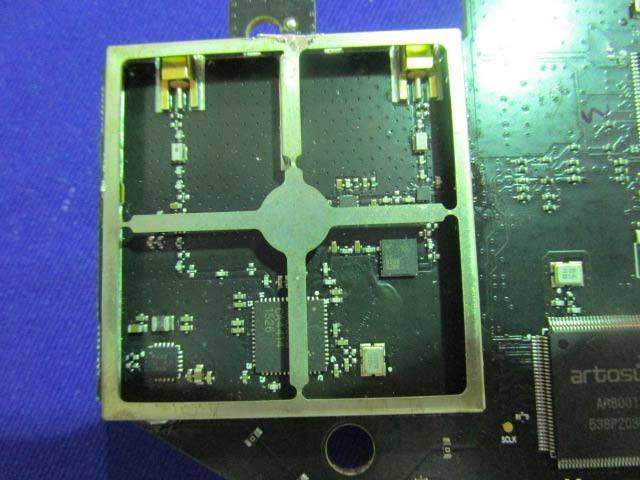

Video Transmission/FPV PCB with Artosyn SoC

Within the drone’s main electronics, a high-density black PCB houses the Artosyn FP1537 SoC—renowned for video processing and wireless transmission. This chip likely manages real-time video encoding/decoding and FPV downlink, supported by a secondary microcontroller or FPGA for system control. The board’s 4+ layer construction, extensive differential pair routing, and robust ground pours are tailored for high-speed data and RF signal integrity. A soldered metal RF shield can isolates sensitive RF circuits, while multiple DC-DC converters ensure efficient power delivery. The presence of numerous oscillators and test points reflects a focus on precise timing and manufacturability. This assembly exemplifies DJI’s sophisticated approach to wireless video and telemetry.

Video Processing Module and RF Shielding

This PCB segment features the Artosyn FP1537 SoC prominently, likely dedicated to HD video streaming and possibly flight control logic. The dense, multi-layer board employs via stitching and differential routing for EMI control and high-speed signal integrity. A large metal shield can covers the RF front-end, while multiple power regulators and oscillators support the board’s diverse functional requirements. Extensive test points and modular connectors indicate a design intended for both performance and serviceability. The board’s sophistication underlines DJI’s commitment to low-latency, reliable video transmission—a critical feature for professional aerial imaging.

Close-Up: Artosyn AR8001 SoC and Shielded RF Section

A detailed view of the Artosyn AR8001 SoC, housed on a multi-layer PCB with fine-pitch traces and robust grounding, reveals the heart of the drone’s wireless video or telemetry processing. Adjacent to the SoC, a metallic shield can protects sensitive RF or analog circuitry, reducing EMI and ensuring regulatory compliance. Surrounding passives and a likely voltage regulator support the SoC’s complex I/O demands. This section’s design—balancing high performance, EMI control, and modularity—reflects the engineering rigor essential for reliable, real-time wireless communication in aerial applications.

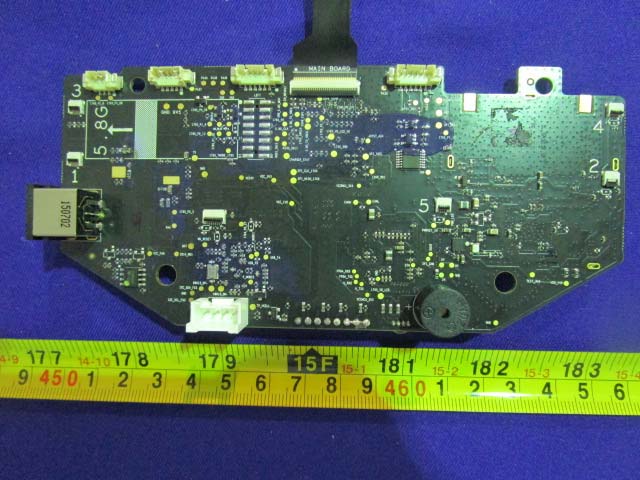

5.8 GHz RF Board with Connectors and Shielding

This module, marked with a 5.8G shielded area, is likely dedicated to high-frequency video transmission or remote control. The dark soldermask, dense via stitching, and multi-layer construction demonstrate careful signal and EMI management. Key features include a U.FL-like coaxial connector for antenna attachment, multiple FPC/FFC connectors for subsystem interfacing, and a robust power regulation stage. The presence of a piezo buzzer, crystals, and abundant test points further highlights the design’s focus on usability, timing precision, and manufacturability. This board exemplifies the advanced RF and system integration necessary for professional drone operation.

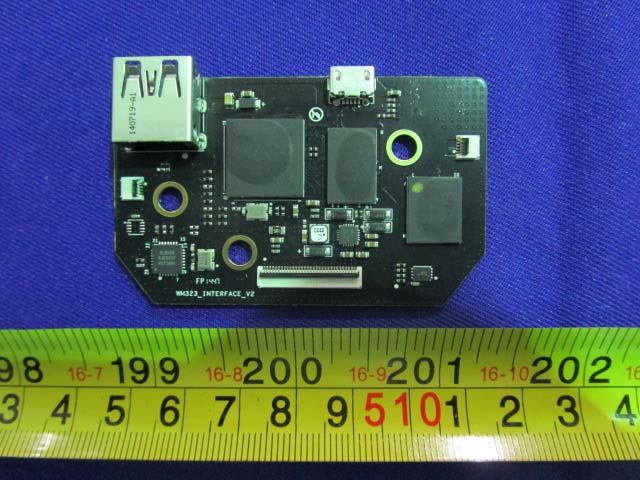

Interface Board with USB and FPC Connectivity

The W323_INTERFACE_V2 board is a compact, black PCB featuring three major ICs (likely a microcontroller, memory, and interface controller), standard USB-A and micro-USB ports, and a large FPC connector. The differential pair traces and dense via patterns indicate high-speed data routing, while robust grounding ensures EMI suppression. The modular layout and presence of multiple test points support easy assembly and diagnostics. This board likely manages data transfer between the camera, gimbal, and main controller, reflecting DJI’s modular, service-oriented design philosophy.

RF Section with Artosyn SoC and EMI Shield

A partially open metal shield exposes the RF section, anchored by the Artosyn AR8001 SoC. The board’s black soldermask, fine-pitch ICs, and numerous ground vias highlight its high-frequency design focus. Yellow U.FL connectors at the shield’s edge facilitate external antenna connections. The compact, shielded layout ensures minimal RF leakage and robust signal integrity, supporting the drone’s demanding wireless communication needs. The integration of test points and decoupling passives further cements the board’s manufacturability and reliability in the field.

Unpopulated Control/Interface PCB

This bare PCB, shown component-side down, reveals footprints for a variety of ICs (SOIC, QFP), connectors, and passives. The dark green FR4 material, abundant vias, and labeled test points suggest a 4–6 layer design engineered for modularity, signal integrity, and mechanical stability. Silkscreen designations indicate zones for analog, digital, and RF domains, with mounting holes for secure assembly. While unpopulated, the board’s layout and construction quality are indicative of a key control or interface module within the Phantom 3 Professional’s architecture.

Regulatory Insights & FCC Filing

The FCC ID SS3-GL3001510 certifies that the DJI Phantom 3 Professional (Model: W323B) complies with stringent U.S. electromagnetic interference and RF emission standards. Although the grant date is listed as None, its registration on FCC.gov legitimizes its sale and operation within the United States, assuring users of its safe and interference-free wireless performance.

FCC filings for this model encompass a wealth of technical documentation, including:

- Test Reports: Detailing RF exposure, electromagnetic compatibility (EMC), and output power measurements.

- Internal/External Photos: Offering a visual record of the device’s construction and antenna configuration.

- User Manuals: Comprehensive guides outlining operational procedures, safety protocols, technical specifications, and preflight checklists.

- Schematics & Block Diagrams: Technical blueprints for regulatory and service reference.

Key insights from the user manuals highlight the Phantom 3 Professional’s emphasis on safety, flight restrictions, calibration, and advanced features such as intelligent flight modes and integrated camera controls. The documentation reinforces the device’s focus on reliability, regulatory compliance, and user education—critical factors for both novice and professional operators.

Potential Use Cases & Target Audience

The DJI Phantom 3 Professional, with its powerful imaging capabilities and advanced flight systems, serves a diverse range of users:

- Aerial Photographers & Videographers: Professionals and hobbyists seeking stable, high-resolution 4K footage and creative camera controls for cinematic projects, real estate, or event coverage.

- Surveyors & Inspectors: Technicians requiring reliable, GPS-stabilized flight and real-time video downlink for infrastructure inspection, mapping, or agricultural monitoring.

- STEM Educators & Robotics Enthusiasts: Individuals or institutions leveraging the flight simulator, programmable controls, and modular design for educational demonstrations, research, or drone technology experimentation.

Its blend of intelligent automation, robust safety features, and regulatory compliance ensures that the Phantom 3 Professional is accessible yet powerful, supporting a broad spectrum of aerial imaging applications.

Conclusion

The DJI Phantom 3 Professional (Model: W323B, FCC ID SS3-GL3001510) exemplifies the intersection of advanced engineering, regulatory compliance, and user-centric design in modern drone technology. Its FCC certification not only affirms its adherence to strict RF emission standards but also underpins its legal status in the U.S. market. With a sophisticated internal architecture, powerful imaging system, and comprehensive safety features, the Phantom 3 Professional remains a top-tier choice for aerial imaging professionals and enthusiasts alike—demonstrating DJI’s commitment to quality, innovation, and operational integrity in every flight.