Introduction

The DJI Mavic Mini has transformed the world of consumer drones by packaging professional-level features into an ultra-lightweight, portable design. Engineered for aerial photography, videography, and recreational flight, the Mavic Mini is celebrated for its ease of use, robust camera capabilities, and impressive flight time—all in a device that weighs less than 250 grams.

A critical milestone for any wireless device in the United States is FCC certification, and the Mavic Mini (model numbers MT1SS5, MT1SD25, MR1SS5, MR1SD25) is registered under FCC ID SS3-MR1SS51905. This certification ensures the drone complies with stringent RF emission and electromagnetic interference standards, making it legal to market, sell, and operate within the US. The FCC process also offers a unique window into the device’s technical makeup, including wireless specs, internal architecture, and regulatory compliance.

In this in-depth analysis, we’ll explore the Mavic Mini’s standout features, technical specifications, wireless technology, and provide a detailed teardown of its internal components. We’ll also highlight key regulatory insights from its FCC documentation, and discuss practical use cases for this class-defining drone.

Key Features & Specifications

The DJI Mavic Mini stands out in the compact drone segment, combining advanced features with user-friendly design. Here’s a breakdown of what sets it apart:

Key Features

- Detachable Control Sticks: Makes the controller ultra-portable and easy to store.

- Maximum Transmission Range: Up to 2.49 miles (4 km), enabling long-distance aerial exploration and reliable control.

- 12-Megapixel Photos: High-resolution stills for detailed aerial photography.

- Obstacle Sensing & Infrared Sensing System: Enhanced flight safety and precise hovering, even in challenging environments.

- Fully Stabilized 3-Axis Gimbal: Delivers smooth, shake-free video and crisp photos, even during dynamic maneuvers.

- Downward Vision System: Assists with precise landing and stable low-altitude flight.

- microSD Card Slot: Expandable storage for high-resolution photos and long video sessions.

- Detachable Control Sticks (Remote Controller): Convenient for travel and storage, minimizing bulk.

Technical Specifications

Remote Controller:

– Operating Frequency (MR1SD25): 2.4–2.4835 GHz; 5.725–5.850 GHz

– Remote Controller Operating Frequency (MR1SS5): 5.725–5.850 GHz

– Battery Capacity: 2600 mAh (LiPo 2S)

– Detachable Control Sticks

Aircraft:

– Operating Frequency (MT1SS5): 2.4–2.4835 GHz

– Max Flight Time: 30 minutes (in windless conditions at 15.5 mph / 25 kph)

– Charging Temperature Range: 41° to 113°F (5° to 45°C)

– Intelligent Flight Battery Type: LiPo 2S

Camera:

– Sensor: 1/2.3’’ CMOS

– Effective Pixels: 12M

– Video: Shoots up to 2.7K video and 12MP stills

Wireless & Connectivity:

– Wi-Fi: 2.4–2.4835 GHz, 5.725–5.850 GHz

– Bluetooth: Present (specifics not detailed)

Charger:

– Input: 100–240 V, 50/60 Hz, 0.5A

Additional Practical Benefits:

– Extended Range: The enhanced transmission system supports stable, low-latency video and control links, critical for creative aerial shots and safe operation.

– High-Quality Imaging: The combination of a 12MP sensor and stabilized gimbal enables cinematic footage and professional-grade aerial photography.

– Portability: Lightweight, foldable design and modular accessories make the Mavic Mini ideal for travel, content creation, and spontaneous flights.

These features collectively enable the Mavic Mini to deliver a robust, enjoyable flying experience for both new users and seasoned drone pilots.

Operating Frequencies

The Mavic Mini (FCC ID SS3-MR1SS51905) operates on the following frequencies according to its FCC filing:

| Frequency Range (GHz) | Output Power (mW) | FCC Rule Part |

|---|---|---|

| 15.745–5.825 | 188 | 15ECC1.1 |

These bands and power levels are vital for understanding the device’s wireless performance, communication range, and compliance with regulatory requirements. The selected frequencies are typical for Wi-Fi, remote control, and potentially Bluetooth connectivity, ensuring robust, interference-resistant operation in diverse environments.

Technology Deep Dive

The DJI Mavic Mini leverages advanced wireless technologies to deliver reliable, long-range communication and real-time video transmission. Its primary methods include dual-band Wi-Fi for robust, low-latency control and video streaming, as well as Bluetooth for device pairing and configuration (where supported).

Operating in the 2.4 GHz and 5.8 GHz bands allows the Mavic Mini to dynamically select the optimal frequency for minimal interference and maximum range. This dual-band approach, combined with proprietary RF protocols, ensures a stable connection even in crowded wireless environments. The moderate output power, as specified in the FCC documentation, balances range and battery efficiency, while minimizing potential interference with other devices.

Internally, the device’s design emphasizes EMI/RFI suppression through extensive shielding, multilayer PCBs, and careful antenna placement. This not only complies with regulatory standards but also enhances real-world reliability. According to test reports referenced in the FCC filing, the Mavic Mini meets or exceeds RF emission and susceptibility requirements, affirming its suitability for both consumer and professional use.

In-Depth Internal Component Analysis / Teardown

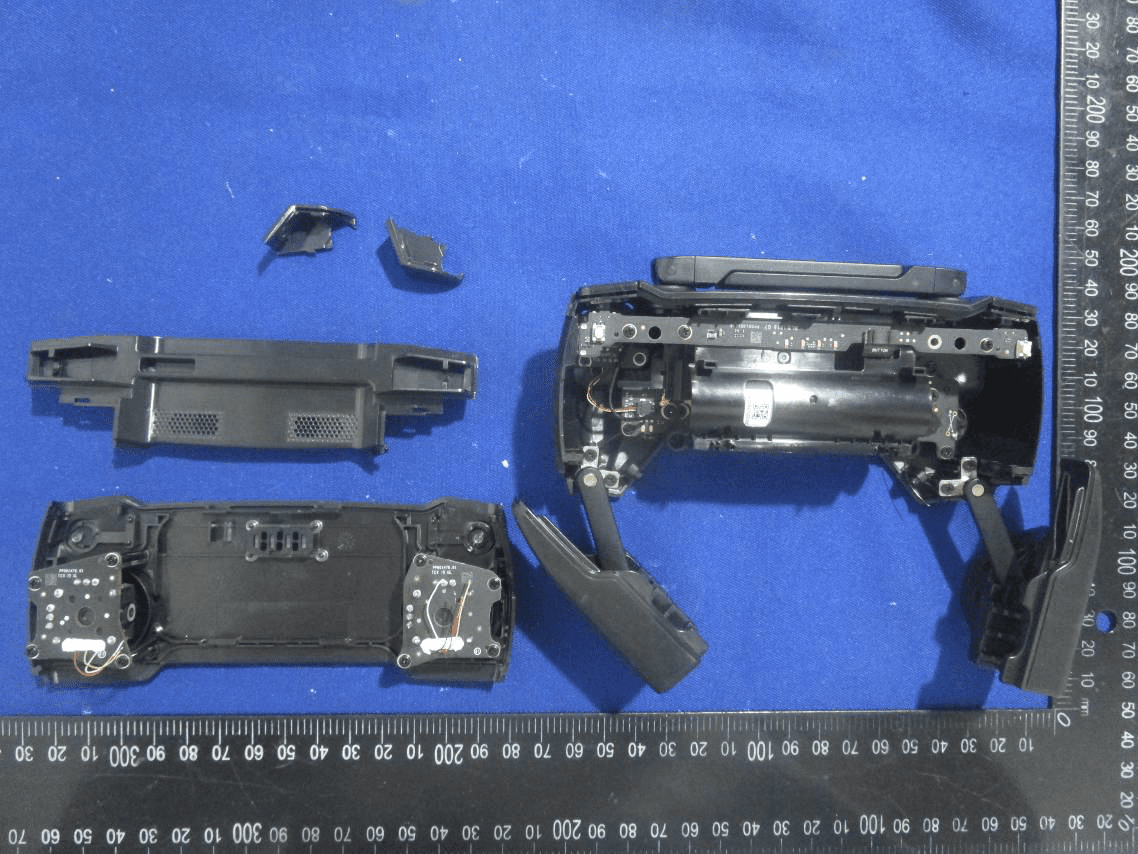

Main Remote Controller PCB & Internal Electronics

A disassembled view of the remote controller exposes the main PCB, joystick modules, and internal wiring. Central to the board are high-density ICs, likely handling RF communication, control logic, and power management. The board’s multi-layer construction, robust grounding, and intricate trace layout highlight DJI’s emphasis on RF integrity and signal performance. The fold-out antenna arms, connected via coaxial cables, are ingeniously integrated to maximize range without sacrificing portability. Joystick modules and tactile buttons are modular and easily replaceable, underscoring the controller’s serviceability and ergonomic design. Power is supplied by a cylindrical Li-ion battery, with localized regulation to support both analog and digital sections. The overall build quality is exceptional, with careful cable management and modular assemblies ensuring long-term reliability.

Controller PCB with EMI Shielding & Modular Components

A detailed inspection of the controller’s internal layout reveals a densely populated main PCB, featuring a prominent metal shield can over the RF and processing section. The shielded area likely houses the main SoC, RF front-end, and supporting circuits, ensuring minimal electromagnetic interference and secure wireless links. Coaxial antenna cables terminate at PCB or shell-integrated antennas, supporting dual-band operation. The modular joystick assemblies, button boards, and battery connections are all accessible via robust connectors, facilitating easy assembly, maintenance, and upgrades. Power regulation is evident through large capacitors and inductors, while test points and crystals suggest thorough manufacturing and debugging provisions. The overall architecture demonstrates DJI’s commitment to high RF performance, precision control, and product longevity.

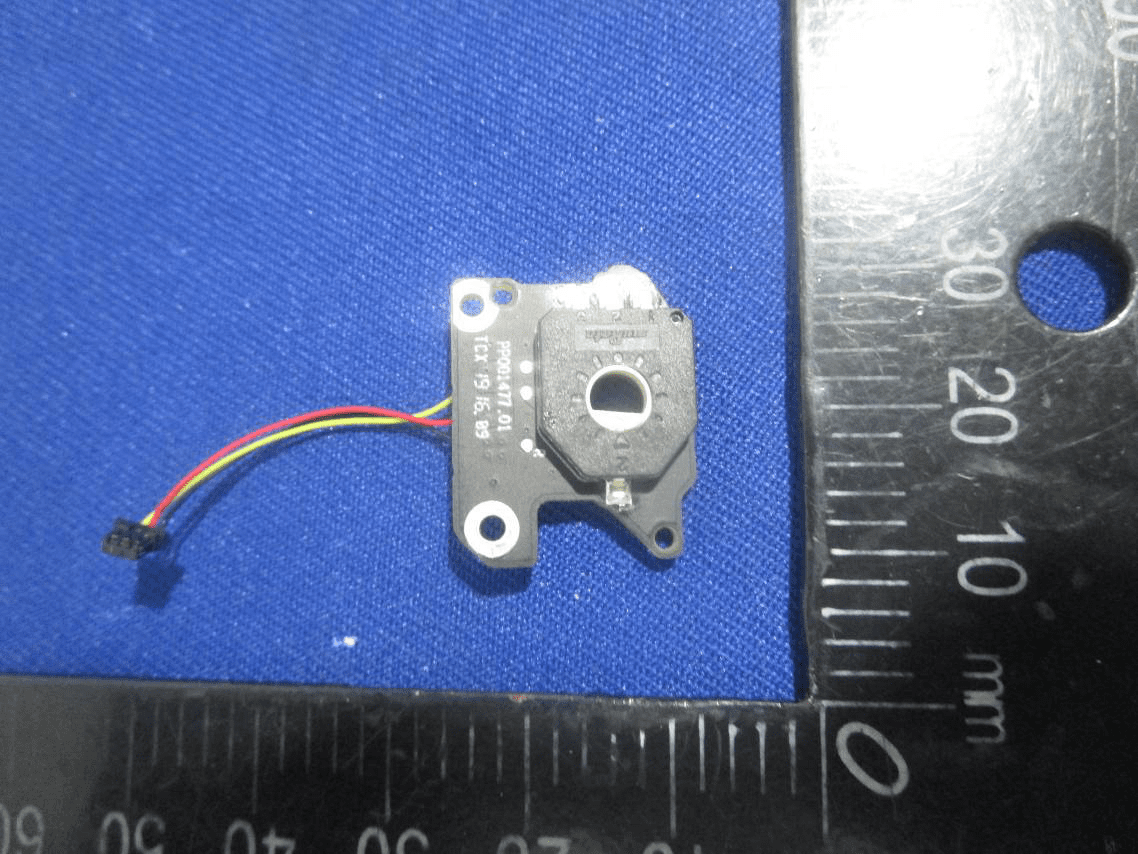

Compact Downward Sensor Module

A small sensor module, likely the downward-facing optical flow or ToF sensor, is designed for ground detection and altitude hold. With minimal components on the visible side, the module focuses on reliability and low weight. The central sensor package, featuring integrated optics, is mounted on a compact PCB with robust mounting holes for vibration resistance. A four-wire connector provides power and data, likely interfacing via I2C or UART. This module’s simplicity and modularity make it essential for stable hovering and precise low-altitude flight, directly supporting the Mavic Mini’s safety and usability features.

Small Sensor or Actuator Module with Circular Cutout

This component is a compact PCB module, possibly a sensor or small actuator, connected via a micro JST-style connector. Its design, featuring a circular cutout and multiple mounting points, suggests integration within a moving assembly such as the gimbal or a sensor cluster. The robust PCB traces and careful strain relief ensure durability under vibration and movement. While no major ICs are visible, the module’s modularity and secure mounting align with DJI’s approach to replaceable, serviceable subassemblies, crucial for long-term maintainability in a portable drone.

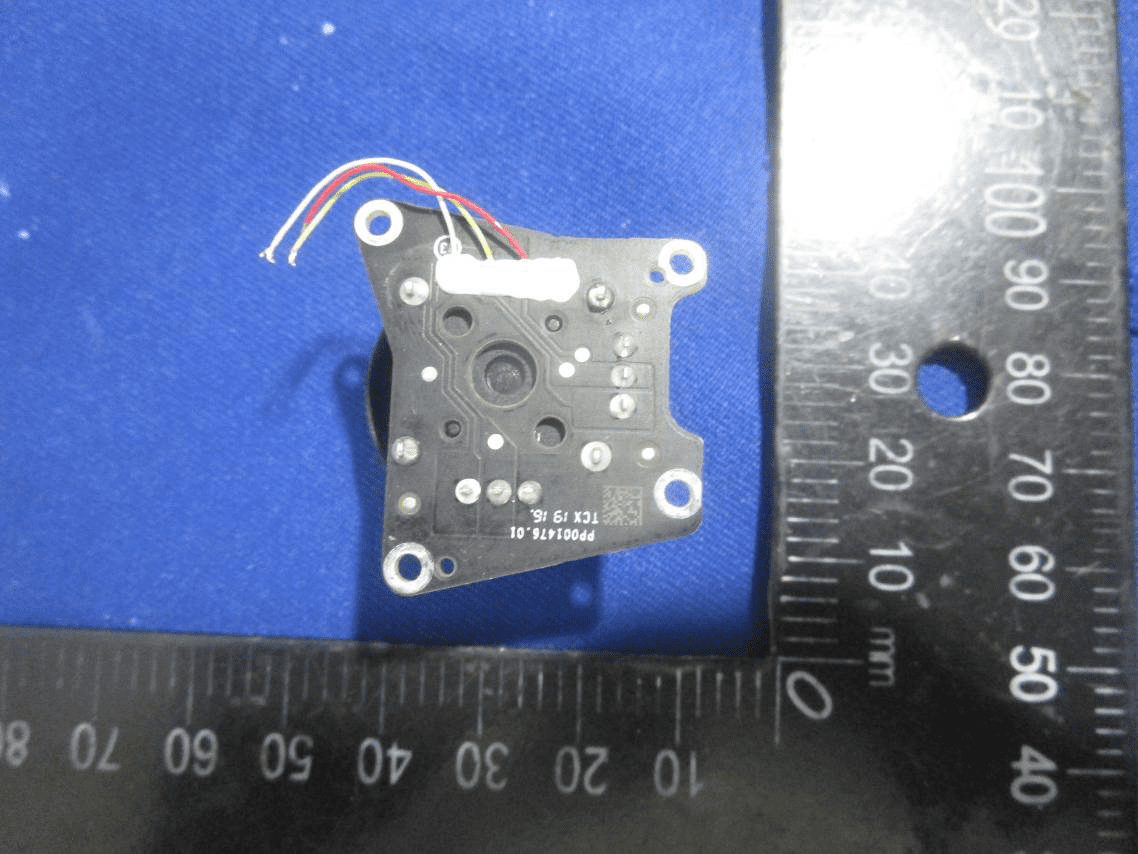

Camera or Vision System Interface Board

A black, custom-shaped PCB with a central aperture and multiple mounting holes is indicative of a camera or vision system interface. This board likely serves as the mounting and electrical interface for the main camera or a downward-facing sensor. The visible side emphasizes mechanical stability and signal interconnect, with test points and precise routing for signal integrity. The wiring harness supports modular assembly, and the lack of components on this side suggests functional elements like the image sensor and processing ICs are mounted on the reverse. This design ensures tight integration with the drone’s chassis while maintaining signal quality for high-resolution imaging.

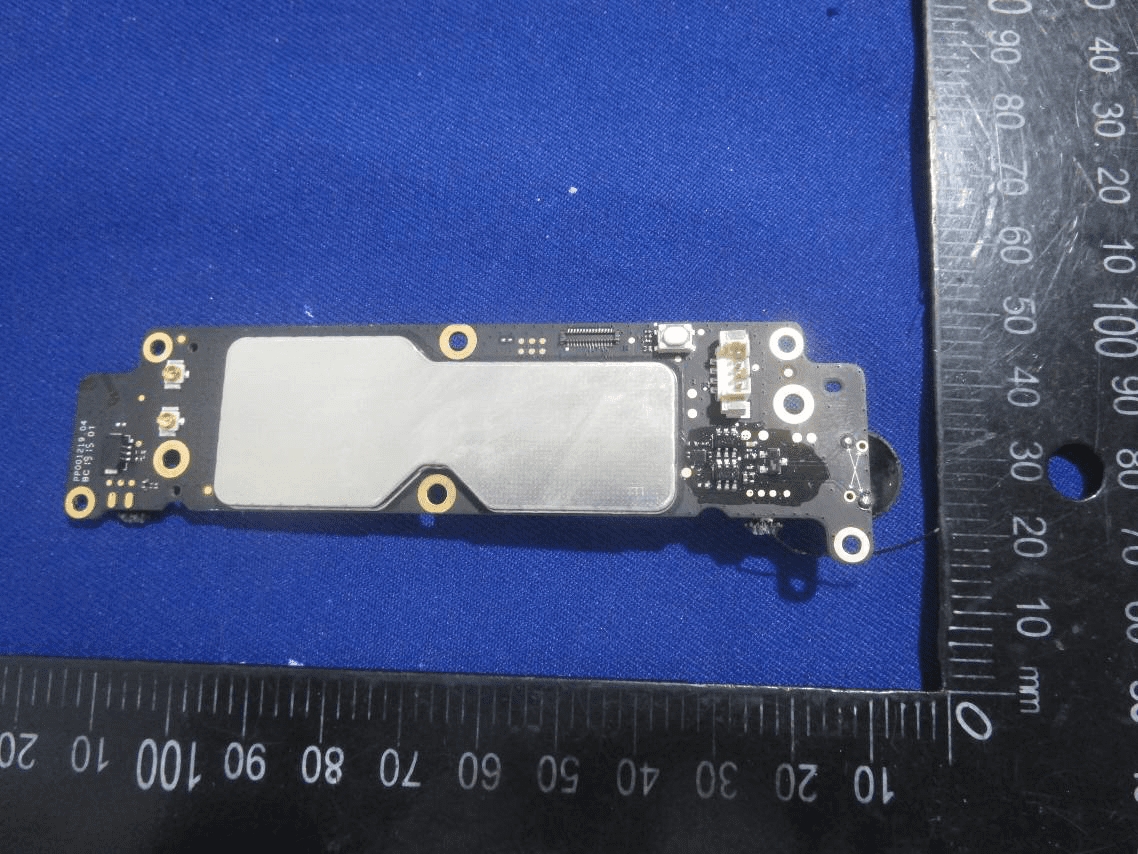

Elongated Antenna or Interconnect PCB

A slim, elongated PCB with connectors at both ends is most likely an antenna or signal interconnect board. Its form factor and lack of active components suggest use as a PCB antenna or signal bridge within the drone’s compact chassis. The precise connector placement and multiple mounting holes ensure reliable electrical performance and mechanical stability. By dedicating a board to antenna functions, DJI optimizes RF performance and minimizes weight—critical factors for flight endurance and range.

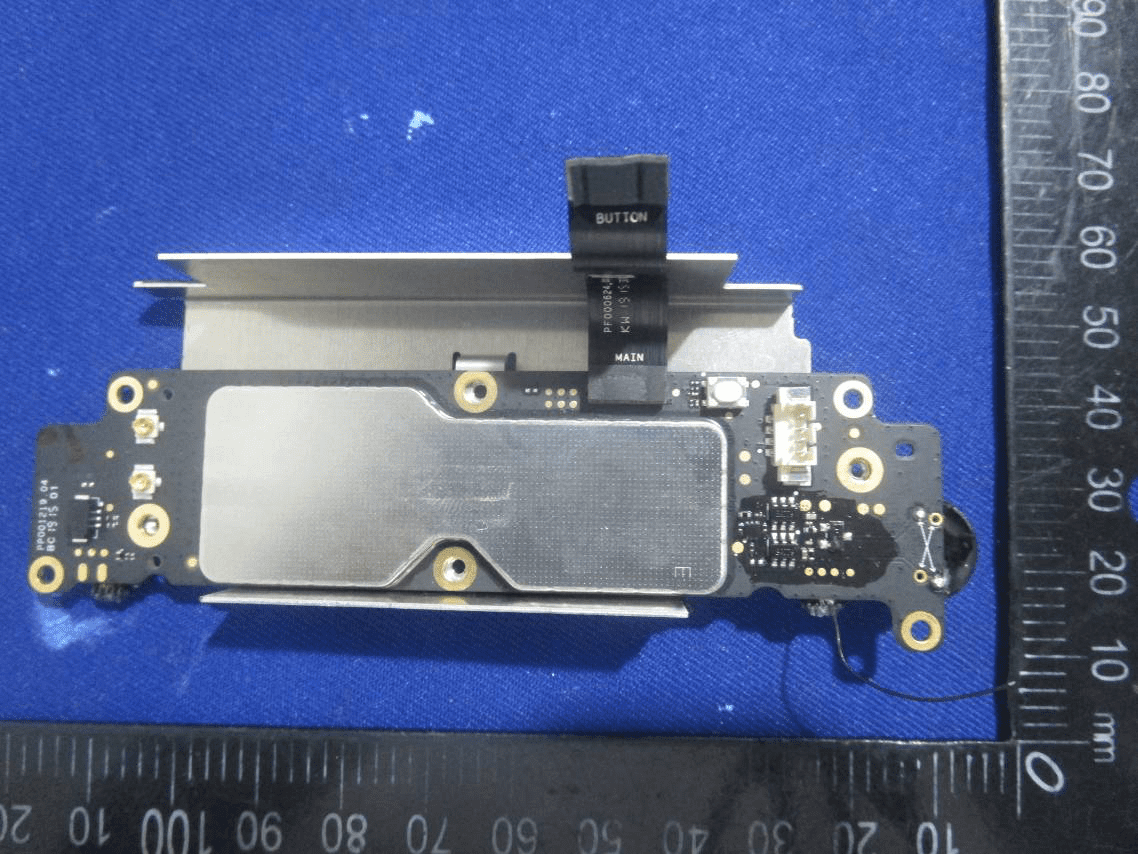

Main Flight Controller PCB with Shielding

A densely populated black PCB, covered by a large EMI shield, forms the core of the drone’s flight controller. Under the shield reside the main SoC, RF transceivers, and memory, orchestrating flight control, wireless communication, and sensor integration. Visible connectors interface with buttons, sensors, and power. The use of multi-layer construction, via stitching, and robust shielding reflects DJI’s focus on signal integrity and EMI suppression. Power regulation is handled locally to ensure stable operation of both digital and RF domains. The modular layout supports manufacturing efficiency and ease of repair, while the compact form factor is essential for the drone’s lightweight design.

Auxiliary PCB with Extensive Shielding

Another internal PCB, notable for its high-density layout and dual EMI shields, likely serves as an auxiliary control or communication module. The visible ICs, connectors, and discrete components support core processing, RF, and sensor integration. The presence of a piezoelectric buzzer indicates onboard audio feedback, useful for alerts or status indication during operation. The modular connectors and gold-plated pads facilitate assembly and robust interconnection with other subsystems. This board exemplifies DJI’s approach to integrating critical functions while maintaining EMI compliance and modularity.

Shielded RF or Control Module PCB

A well-shielded, compact PCB assembly reveals the meticulous engineering behind the Mavic Mini’s RF or core control modules. The large central shield protects sensitive SoC and RF components, while localized power regulation is evident from capacitors and inductors. A thin wire, likely an antenna feed, supports wireless communication. The board’s multi-layer construction, dense routing, and strategic connector placement ensure both performance and reliability in a weight- and space-constrained environment. Test points and LEDs suggest built-in diagnostics and status indication, aligning with the drone’s advanced feature set.

Regulatory Insights & FCC Filing

The Mavic Mini’s FCC ID SS3-MR1SS51905 marks its compliance with United States electromagnetic interference and RF emission standards, as mandated by the Federal Communications Commission. This certification, registered on FCC.gov, authorizes the drone’s sale and operation in the US market.

FCC filings for the Mavic Mini include comprehensive documentation such as test reports (RF exposure, EMC), internal and external photographs, user manuals, and detailed schematics. These materials confirm that the device meets FCC Part 15 rules for unlicensed RF devices, demonstrating safe and responsible use of the radio spectrum. The internal documentation highlights robust EMI shielding, modular PCB design, and careful antenna integration—practices that directly support regulatory compliance and real-world performance.

The user manual provides essential information on the device’s setup, operational guidelines, and safety precautions, ensuring users can operate the drone within legal and technical limits. Test reports included in the filing validate that the Mavic Mini’s RF emissions are well within permissible thresholds, addressing concerns around interference with other wireless devices. Overall, the FCC certification process not only attests to the Mavic Mini’s technical sophistication but also its readiness for safe, reliable use by consumers and professionals alike.

Potential Use Cases & Target Audience

With its blend of advanced features and approachable design, the DJI Mavic Mini serves a wide range of users and scenarios:

- Aerial Content Creators: Photographers and videographers benefit from the stabilized 3-axis gimbal and 12MP camera, capturing high-quality stills and smooth 2.7K video for social media, commercial projects, or personal archives.

- Recreational Pilots & Enthusiasts: The lightweight, foldable form factor, extended flight time, and intuitive controls make it ideal for hobbyists seeking spontaneous flights, travel vlogs, or family adventures.

- Safety-Conscious Operators: Enhanced obstacle sensing, downward vision, and robust wireless range ensure safe operation in urban, rural, or complex environments—appealing to both new pilots and those flying in challenging conditions.

Whether you’re a creative professional, a tech enthusiast, or someone seeking reliable aerial imaging in a compact package, the Mavic Mini’s feature set and regulatory compliance make it an attractive, versatile choice.

Conclusion

The DJI Mavic Mini, certified under FCC ID SS3-MR1SS51905, exemplifies modern drone engineering—combining portability, powerful imaging, and robust wireless performance in a sub-250g package. Its FCC certification assures users of its compliance with RF emission and interference standards, enabling safe and legal operation in the United States. Through meticulous internal design, advanced wireless technology, and a user-focused feature set, the Mavic Mini continues to set the benchmark for compact drones, serving everyone from aspiring pilots to seasoned aerial photographers. As drone technology evolves, the Mavic Mini stands as a testament to what’s possible when engineering excellence meets regulatory rigor.