Introduction

The DJI FPV Air Unit, engineered by SZ DJI TECHNOLOGY CO., LTD., is a cutting-edge digital video transmission module designed to deliver immersive, low-latency first-person view (FPV) experiences for drone enthusiasts and professionals. This compact powerhouse forms the heart of high-performance racing drones, enabling seamless wireless video and control signal transmission to DJI FPV Goggles and compatible remote controllers. With its robust design, advanced wireless technology, and high-definition video capabilities, the DJI FPV Air Unit is a mainstay in the world of FPV racing and aerial cinematography.

Central to its commercial availability is the device’s FCC certification under FCC ID SS3-P1AS1901, which confirms its compliance with stringent U.S. radio frequency emission standards. This certification not only makes the DJI FPV Air Unit legal to sell and operate in the United States but also assures users of its adherence to essential safety and electromagnetic compatibility requirements.

In this article, we’ll provide a comprehensive review of the DJI FPV Air Unit’s key specifications, wireless technology, internal component design, and regulatory background. Whether you’re an FPV racer, drone builder, or tech aficionado, this teardown and analysis will uncover what makes this device a standout in its class.

Key Features & Specifications

The DJI FPV Air Unit stands out for its integration of high-performance wireless video transmission with a compact, modular design optimized for racing drones and advanced FPV setups. Below, we break down its most notable features and technical specifications, explaining their practical significance for users.

Key Features

- Seamless Compatibility: Works directly with DJI FPV Goggles and DJI FPV remote controllers, ensuring a streamlined, plug-and-play experience for pilots.

- Versatile I/O: Equipped with USB-C, MMCX, a 3-in-1 port, and a microSD card slot, allowing for flexible data transfer, firmware updates, and onboard video recording.

- Ultra-Wide Field of View (FOV): Captures expansive footage with a 150° diagonal, 122° horizontal, and 93° vertical FOV, ideal for situational awareness and cinematic perspectives.

- Long-Range Digital Transmission: Offers up to 4 km range (FCC/SRRC: 4 km; CE: 0.7 km; MIC: 2.5 km), supporting both short-range racing and long-distance exploration.

- Low-Latency HD Video: End-to-end latency as low as <28 ms at 720p120, providing real-time responsiveness critical for racing and acrobatic maneuvers.

- 5.8 GHz Digital Video Signal: Utilizes the 5.8 GHz band, minimizing interference and enabling high-bandwidth, stable video transmission.

- Integrated Wireless Flight Data: Simultaneously transmits video, control signals, and flight controller information wirelessly, reducing cable clutter and system complexity.

- Onboard Recording: Supports microSD card recording in MP4 format, capturing flight footage directly from the air unit.

- Optimized Channel Bandwidth: Each channel features 20 MHz bandwidth, balancing high video quality with efficient spectrum use.

Technical Specifications

- Camera Sensor: 1/3.2” CMOS, 4 million effective pixels, rolling shutter.

- Video Format: MP4 (MPEG4); Live view modes: 720p120 (<28 ms latency), 720p60 (<40 ms latency).

- Physical Dimensions (Camera): 27.4 × 21.1 × 20.1 mm.

- Antenna Options: 3.63 g (MMCX straight), 3.87 g (MMCX elbow), 5.4 g (reverse polarity female SMA), supporting external diversity antennas for robust signal reception.

- Coaxial Cable Length: 100 mm, facilitating flexible installation.

- Wi-Fi Capabilities: 5.8 GHz digital video signal; communication frequency: 5.725–5.850 GHz.

- Bluetooth: Present (specifics not detailed in current documentation).

- I/O Interfaces: USB-C, MMCX, 3-in-1 port, microSD card slot.

Practical Benefits

- Racing Performance: Ultra-low latency and long-range transmission give racers the split-second feedback needed for high-speed, precise control.

- Aerial Cinematography: Wide FOV and HD recording deliver immersive, high-quality footage for creative projects.

- Modular Integration: Multiple interface options and external antenna support allow for custom builds tailored to specific drone platforms.

- Regulatory Compliance: FCC ID SS3-P1AS1901 certification ensures safe, legal operation in demanding RF environments.

Operating Frequencies

The DJI FPV Air Unit’s wireless performance is defined by its carefully selected operating frequencies and power levels, as documented in its FCC filing under FCC ID SS3-P1AS1901:

| Frequency Range (GHz) | Output Power (mW) | FCC Rule Part |

|---|---|---|

| 5.7305–5.8445 | 282 | 15EMO15.7355 |

| 5.8395 | 268 | 15EMO2 |

These frequencies place the device within the 5.8 GHz ISM band, a spectrum widely used for FPV video transmission due to its balance of bandwidth, range, and resistance to interference. The specified output power supports robust, long-distance digital links while adhering to regulatory limits for unlicensed wireless devices. This careful calibration ensures the air unit’s transmission is both powerful enough for reliable FPV operation and compliant with U.S. federal regulations.

Technology Deep Dive

The DJI FPV Air Unit leverages a combination of advanced wireless technologies to achieve its hallmark low latency and high reliability. Operating primarily in the 5.8 GHz band, the air unit utilizes digital video transmission protocols akin to modern Wi-Fi standards, offering both high bandwidth and strong resistance to interference common in crowded radio environments. The presence of Bluetooth, as indicated in the technical specifications, suggests potential support for auxiliary connectivity or device pairing, although specific application details are not disclosed in the current documentation.

Operating within the 5.8 GHz spectrum enables the air unit to deliver fast, high-definition video streams while minimizing latency—an essential attribute for FPV racing and acrobatics. The channel bandwidth of 20 MHz is optimized for maintaining video quality without excessive spectrum consumption, and the use of external diversity antennas further enhances signal integrity and range. Power levels, as specified in the FCC filing, are carefully set to maximize operational distance (up to 4 km) while ensuring compliance with RF exposure and emission standards.

Test reports and internal documentation highlight the air unit’s robust electromagnetic compatibility (EMC) performance, advanced RF shielding, and efficient power management, all of which contribute to its stable, reliable operation in dynamic, interference-prone drone environments.

In-Depth Internal Component Analysis / Teardown

Full Device Teardown: Main PCBs, Antennas, and Shielding

A comprehensive teardown of the DJI FPV Air Unit reveals two densely populated, multi-layer PCBs at the core of its design. The main board features a prominent shielded section, likely housing the primary SoC responsible for video processing, wireless transmission, and system control. Adjacent components include power management ICs, high-speed memory, and RF front-end modules. Dual external antennas connect via U.FL connectors, optimized for 5.8 GHz operation and minimal signal loss. Robust EMI/RFI shielding, extensive thermal pads, and high-grade connectors indicate a focus on performance, signal integrity, and heat dissipation. The camera module connects via a flat flex cable, and numerous test points suggest a mature, serviceable design. Overall, the build quality and engineering choices reflect a production-grade FPV video transmission system built for reliability and high-speed operation.

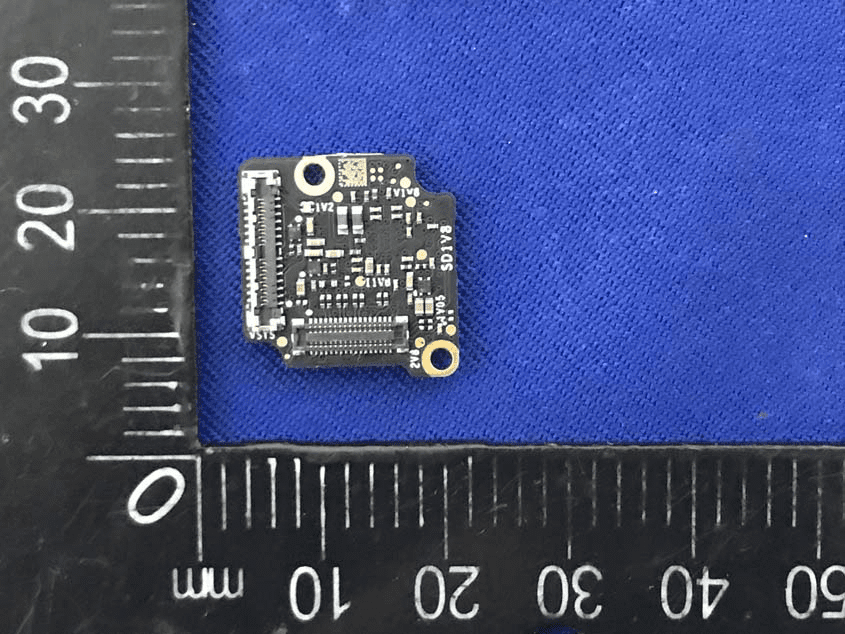

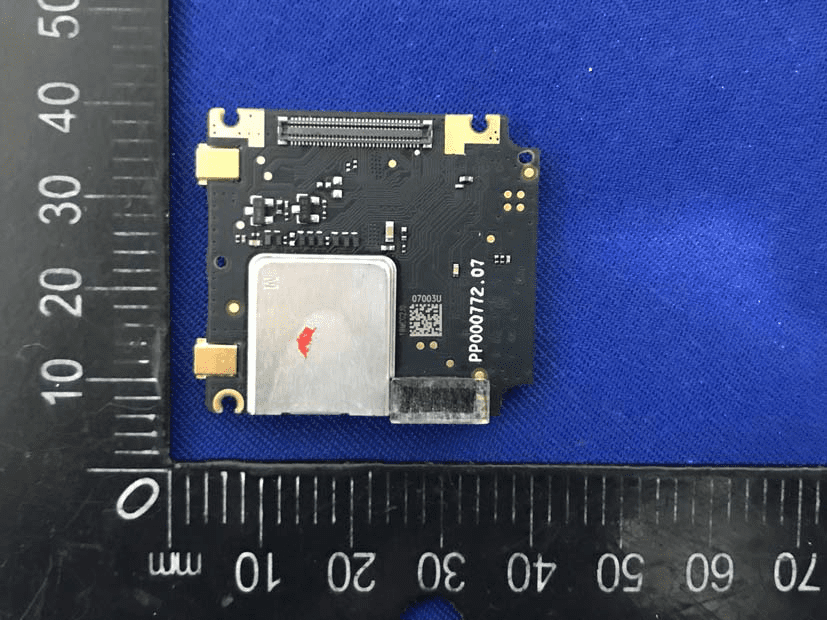

Miniaturized RF or Power Module: Compact High-Density PCB

This small, approximately 15mm x 15mm PCB exemplifies advanced miniaturization. At its center is a prominent IC, likely serving as a microcontroller, RF transceiver, or power management unit. Surrounding components include PMICs or RF front-end chips, local power regulation elements, and numerous fine-pitch traces indicative of high-speed signal routing. The board’s multi-layer design, via-in-pad construction, and ground via stitching ensure optimal EMI control and signal integrity. Gold-plated pads and mounting points support both mechanical stability and electrical connectivity, while the absence of onboard antennas suggests external connections. Overall, this module demonstrates DJI’s commitment to integrating sophisticated RF or power management capabilities into a minimal footprint for space-constrained drone applications.

Interface or Sensor Board: Modular Connectivity and Signal Integrity

A close examination of this compact PCB (approx. 18mm x 18mm) reveals its likely role as an interface or sensor board within the air unit. The absence of large ICs suggests main processing occurs elsewhere, while the presence of fine-pitch FPC/FFC connectors points to high-speed data transfer—potentially for camera or sensor interfacing. Careful grounding, ground pours, and via stitching minimize EMI, and the dense population of passives and small regulators ensures clean power delivery for sensitive circuits. The modular design, with multiple test points and robust connector choices, supports rapid assembly and reliable high-speed operation in the demanding environment of FPV drones.

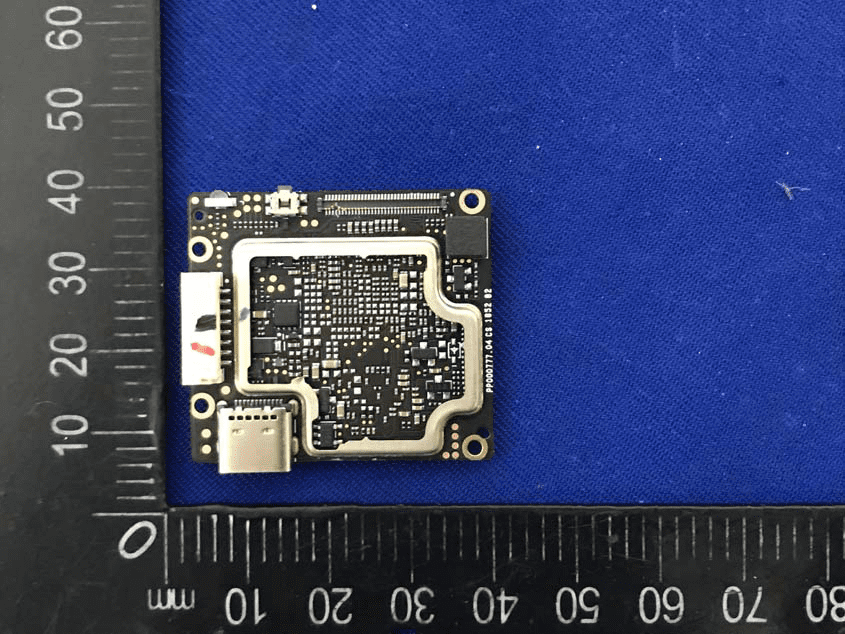

Main Processing Board: Shielded SoC, USB-C, and Power Management

This densely populated, square PCB is the heart of the air unit’s processing and wireless transmission. A large EMI shield covers the main SoC, RF transceivers, and memory, ensuring both performance and regulatory compliance. Exposed connectors include a USB-C port for firmware and data, a white FPC/FFC connector for video or control signals, and several mounting points for mechanical and electrical stability. Power management is handled by large capacitors and inductors arrayed near the shielded section, and a thermal pad under the shield aids in dissipating heat generated by high-speed operations. The overall layout demonstrates DJI’s expertise in balancing size, thermal management, and signal integrity for FPV video streaming.

Core PCB with RF Shield and U.FL Antenna Connector

This compact, black PCB showcases advanced digital and RF engineering. A prominent RF shield covers the main SoC or transceiver, with a coaxial U.FL connector enabling external antenna attachment for high-quality 5.8 GHz transmission. The board integrates a USB-C port, a large FPC connector, and multiple power regulation components, all arranged to support high-bandwidth, low-latency video processing. Extensive ground vias, differential pair routing, and a robust EMI strategy are evident throughout, ensuring reliable operation even in high-interference environments typical of drone racing.

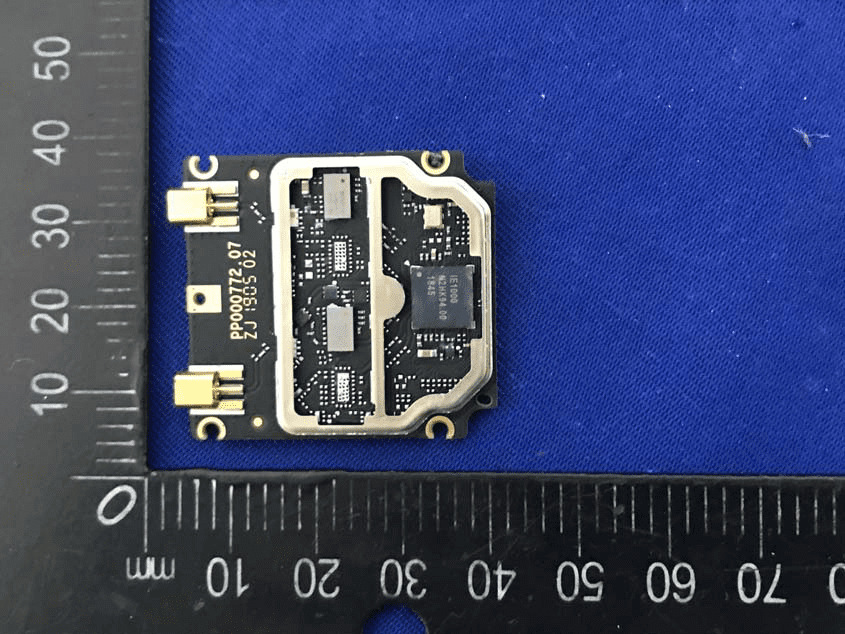

High-Frequency RF/Processor Board with Custom IC and Dual Antenna Ports

This board features a custom or semi-custom IC, likely an RF transceiver or high-speed digital processor, paired with two gold-plated U.FL connectors for external antennas—enabling diversity or MIMO operation. The layout is optimized for RF performance, with controlled impedance traces, ground pours, and extensive shielding. An FPC/FFC connector allows integration with other subsystems, while local power regulation components ensure stable operation. The design is modular, robust, and thoroughly optimized for the demands of low-latency, high-bandwidth wireless video transmission in FPV environments.

Shielded PCB with Modular External Antenna Connectors

This assembly demonstrates DJI’s focus on RF integrity and modularity. The prominent EMI shield covers sensitive transceiver or SoC components, while two U.FL connectors facilitate external antenna attachment, supporting robust wireless links in the 5.8 GHz band. The presence of a fine-pitch FPC/FFC connector and multiple mounting holes indicates ease of integration and mechanical stability. Silkscreen markings assist in traceability and assembly. The overall layout is consistent with a high-frequency, high-bandwidth video transmission system, with every design choice supporting performance and reliability.

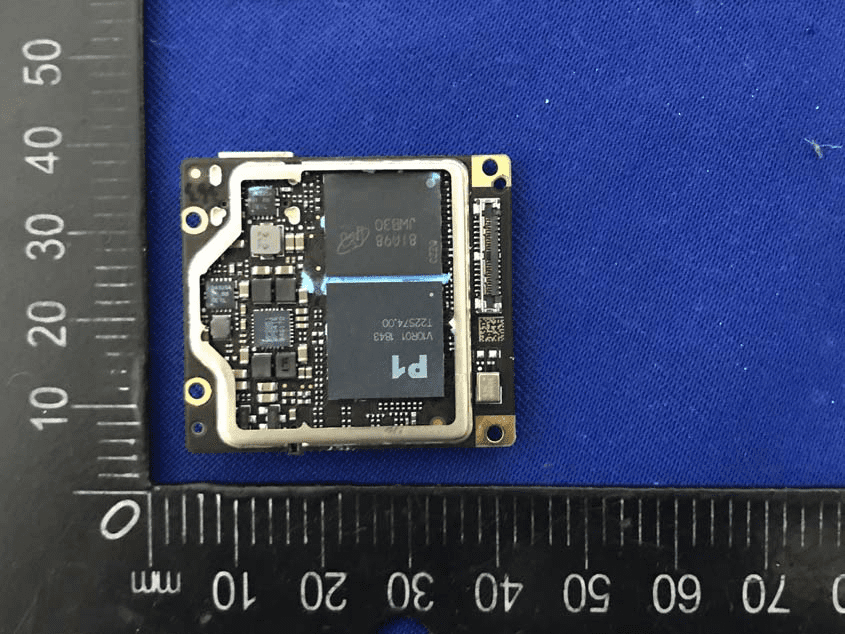

Processing Board with Custom SoC, Memory, and EMI Shielding

A close look at this densely populated PCB reveals a custom SoC, paired with memory and supported by multiple power regulation and timing components. The EMI shield ensures minimal interference, while the presence of a U.FL connector and FPC/FFC interface supports external antennas and modular integration. The layout demonstrates careful planning for signal integrity, power delivery, and mechanical robustness, all critical for high-speed FPV video transmission.

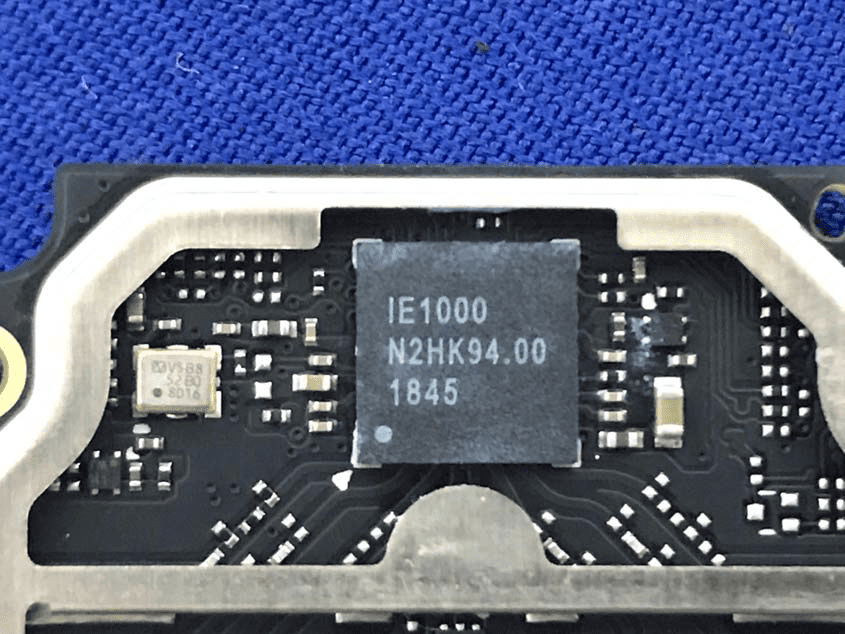

High-Frequency Board with Custom IC and Crystal Oscillator

This section of the PCB is dominated by a custom or semi-custom IC, likely the core of the device’s video or RF processing. Accompanied by a precision crystal oscillator, it ensures accurate timing for high-speed data and wireless transmission. The black solder mask, dense via placement, and robust ground pours all point to a multi-layer design optimized for RF performance and EMI suppression. The presence of a metal shield further reduces interference, making this board a textbook example of advanced RF and digital PCB engineering.

Shielded, High-Density Wireless Module

This compact, black PCB is a hallmark of DJI’s wireless engineering. A large EMI shield protects the main RF or SoC section, with gold-plated edge pads likely serving as RF or board-to-board connectors. The fine-pitch FPC/FFC connector and modular layout facilitate integration, while the overall design prioritizes high-frequency performance, signal integrity, and reliability. Test points and passives scattered across the board support manufacturing and in-field diagnostics, making this module as serviceable as it is sophisticated.

Regulatory Insights & FCC Filing

The FCC certification under FCC ID SS3-P1AS1901 marks the DJI FPV Air Unit as compliant with U.S. electromagnetic interference (EMI) and radio frequency (RF) emission standards. This certification, registered by FCC.gov, is essential for legal sale and operation within the United States, ensuring the device does not cause harmful interference and operates safely within regulated frequency bands.

FCC filings for devices like the DJI FPV Air Unit typically include a wide array of documentation: RF exposure and EMC test reports, internal and external photographs, user manuals, technical block diagrams, and schematics. These documents collectively verify that the device’s wireless performance, emission levels, and electromagnetic compatibility meet regulatory requirements.

Insights from the user manual and test documentation confirm that the DJI FPV Air Unit is engineered for high-performance digital video transmission in the 5.8 GHz band, with a transmission range up to 4 km and minimum latency under 28 ms. The filings also highlight the device’s advanced RF shielding, robust power management, and modular antenna design—critical factors for reliable, interference-resistant FPV operation.

By achieving FCC certification, the DJI FPV Air Unit assures users and integrators that it is both safe and legal to deploy in a wide range of FPV drone applications, conforming to industry standards for RF emissions and operational safety.

Potential Use Cases & Target Audience

The DJI FPV Air Unit is purpose-built for demanding FPV (First Person View) applications, serving a diverse range of users and scenarios:

- FPV Racing Enthusiasts: Competitive drone pilots rely on the air unit’s ultra-low latency (as low as 28 ms) and stable 720p120 video transmission for real-time maneuvering at high speeds. Its robust wireless link ensures uninterrupted control and video feed even in RF-congested environments.

- Aerial Cinematographers: Content creators and filmmakers benefit from the wide FOV and high-definition recording capabilities, capturing immersive, dynamic footage directly onto a microSD card. The system’s compatibility with DJI FPV Goggles enables live monitoring and precise shot composition.

- Custom Drone Builders and Integrators: Engineers and hobbyists building custom drones appreciate the air unit’s modular interfaces (USB-C, MMCX, FPC/FFC), external antenna support, and regulatory compliance. The device’s flexibility makes it suitable for a variety of drone platforms, from compact racers to larger aerial photography rigs.

Across all these scenarios, the DJI FPV Air Unit’s combination of range, performance, and reliability empowers users to push the boundaries of FPV flight and aerial imaging.

Conclusion

The DJI FPV Air Unit by SZ DJI TECHNOLOGY CO., LTD. stands as a benchmark in digital FPV video transmission, distinguished by its robust wireless technology, modular design, and exceptional low-latency performance. Its FCC certification under FCC ID SS3-P1AS1901 underscores its compliance with U.S. regulatory standards, making it both a reliable and legal choice for demanding FPV pilots and drone builders. Through meticulous engineering—evident in its internal components, shielding, and interface options—the air unit delivers the performance and flexibility required for modern racing drones and aerial cinematography. As FPV technology continues to evolve, the DJI FPV Air Unit remains a pivotal component for anyone seeking the highest standards in wireless video transmission and real-time drone control.