Introduction

The DJI Air 3, developed by SZ DJI TECHNOLOGY CO., LTD., represents a significant leap in consumer and professional drone technology. Designed for aerial photography, mapping, and advanced flight operations, this drone blends robust engineering with intelligent automation. The Air 3 excels in flight stability, obstacle avoidance, and high-quality image capture, making it a favorite among enthusiasts and professionals alike.

A pivotal milestone for the DJI Air 3 is its FCC certification under FCC ID SS3-EB3WBC2303. This approval is not merely a regulatory formality—it is a badge of compliance that ensures the device meets stringent US requirements for radio frequency emissions, electromagnetic compatibility, and safety. Only with such certification can a device be legally marketed and operated within the United States.

In this article, we dissect the DJI Air 3 in detail—exploring its key features, technical specifications, wireless technologies, internal component architecture, and the regulatory landscape defined by its FCC filing. Whether you’re an engineer, a drone hobbyist, or simply curious about what powers DJI’s latest marvel, this comprehensive analysis will provide unique insights drawn directly from regulatory documentation and expert teardown.

Key Features & Specifications

The DJI Air 3 is engineered to deliver exceptional flight stability, intelligent sensing, and versatile control. Its feature set and technical specifications reflect a focus on performance, reliability, and user experience.

Key Features

-

Horizontal Omnidirectional Vision System

Ensures 360° obstacle detection for safer, more autonomous flight—crucial for navigating complex environments. -

Downward Vision System

Enhances landing precision and enables advanced functions like terrain-follow and precision hovering. -

Power Button

Streamlined aircraft activation and battery status checks, improving operational convenience. -

USB-C Port

Supports modern, high-speed data transfer and charging, facilitating quick media offloads and firmware updates. -

Aircraft Status Indicators

Real-time LED feedback on flight status, battery level, and connectivity, ensuring pilots are always informed. -

Battery Buckles

Secure the intelligent flight battery, preventing accidental ejection during aggressive maneuvers or hard landings. -

Dongle Compartment Cover

Provides storage for wireless dongles or accessories, reflecting thoughtful mechanical design. -

Remote Controller with Touchscreen and Customizable Buttons

Offers an intuitive user interface with tactile feedback, supporting personalized flight modes and camera controls.

Technical Specifications

Remote Controller:

– Model: RC331

– Battery Capacity: 4241 mAh

Offers extended runtime, supporting longer missions and reduced downtime.

– Wi-Fi Protocol: 802.11a/b/g/n/ax

Ensures compatibility with the latest wireless standards for robust, low-latency transmission.

– Transmitter Power (EIRP):

– 2.4 GHz: <26 dBm (FCC), <20 dBm (CE/SRRC/MIC)

– 5.1 GHz: <23 dBm (FCC/CE)

– 5.8 GHz: <26 dBm (FCC/SRRC), <14 dBm (CE)

– Operating Frequency Bands:

– 2.400–2.4835 GHz

– 5.150–5.25 GHz

– 5.725–5.850 GHz

– Operating Temperature: -10°C to 40°C (14°F to 104°F)

Ensures reliable operation in diverse environmental conditions.

Aircraft:

– Wi-Fi Support:

– 802.11a/b/g/n (Aircraft)

– 802.11a/b/g/n/ax (Remote Controller)

– Bluetooth:

Present (specific details not provided), likely used for auxiliary functions such as device pairing or accessory communication.

Intelligent Flight Battery:

– Model: BWX233-4241-14.76

– Capacity: 4241 mAh

Provides ample power for extended flights, supporting high-drain operations like 4K video recording or long-distance missions.

Benefits & Practical Implications

- Advanced Vision Systems:

Omnidirectional and downward vision systems deliver superior obstacle avoidance, enabling safer autonomous flights and precision landings. - High-Performance Wireless:

Multi-band Wi-Fi and high transmitter power allow for stable, long-range control and real-time HD video transmission, even in RF-congested environments. - Robust Build and User-Centric Design:

Modular components, secure battery mounting, and customizable controls support a wide range of missions, from cinematic shoots to industrial inspections.

Operating Frequencies

The DJI Air 3 (FCC ID SS3-EB3WBC2303) operates across multiple frequency bands, supporting a versatile array of wireless functions. The following table summarizes the frequency ranges, output power, and corresponding FCC rule parts as detailed in its FCC filing:

| Frequency Range (GHz) | Output Power (mW) | FCC Rule Part |

|---|---|---|

| 2.402–2.48 | 3.5 | 15CCC1.72.4035 |

| 2.452 | 39.9 | 15CCC1.92.4225 |

| 2.4525 | 575.4 | 15CCC1.65.161 |

| 2.462 | 57.9 | 15CCC1.82.4125 |

| 2.4625 | 647.1 | 15CCC1.52.422 |

| 2.4675 | 650.1 | 15CCC1.42.412 |

| 2.4682 | 120.5 | 15CCC1.22.4075 |

| 2.46912 | 121.3 | 15CCC1.12.4045 |

| 2.4695 | 119.4 | 15CCC1.32.4055 |

| 5.23 | 120.5 | 15ECC2.35.7275 |

| 5.24 | 124.5 | 15ECC2.25.17 |

| 5.795 | 67.6 | 15ECC2.115.775 |

| 5.825 | 80.2 | 15ECC2.15.7455 |

| 5.8295 | 555.9 | 15ECC2.95.755 |

| 5.8395 | 676.1 | 15ECC2.85.745 |

| 5.8425 | 113 | 15ECC2.65.7355 |

| 5.8445 | 814.7 | 15ECC2.75.7325 |

| 5.84612 | 86.9 | 15ECC2.45.7305 |

| 5.8472 | 101.6 | 15ECC2.55.7285 |

These frequency allocations and power levels enable robust, interference-resistant wireless communications, supporting both control and real-time video transmission while adhering to regulatory constraints.

Technology Deep Dive

The DJI Air 3 leverages advanced wireless technologies to deliver reliable, long-range control and real-time data transmission. Its primary wireless communication is based on multi-band Wi-Fi (2.4 GHz and 5 GHz), with support for protocols up to 802.11ax (Wi-Fi 6) in the remote controller. This ensures high data throughput, low latency, and robust signal integrity, vital for live HD video streaming and low-lag flight commands.

Bluetooth is also present, likely facilitating auxiliary functions such as device pairing, quick setup, or accessory integration. The wide frequency range and high Effective Isotropic Radiated Power (EIRP) specified in the FCC documentation allow the Air 3 to maintain strong connections even in challenging RF environments, such as urban areas with heavy Wi-Fi congestion.

Operating across both 2.4 GHz and 5 GHz bands, the Air 3 can dynamically select the optimal channel to minimize interference and maximize range. Higher output power on certain channels further extends operational distance and enhances penetration through obstacles. These capabilities are balanced against power consumption and regulatory requirements, as evidenced by the detailed compliance testing documented in the FCC filing.

Test reports referenced in the FCC documentation confirm the device’s adherence to emissions, spurious output, and safety standards, ensuring both performance and compliance. The multi-band, multi-protocol design reflects DJI’s commitment to delivering seamless, reliable operation in a variety of use cases and environments.

In-Depth Internal Component Analysis / Teardown

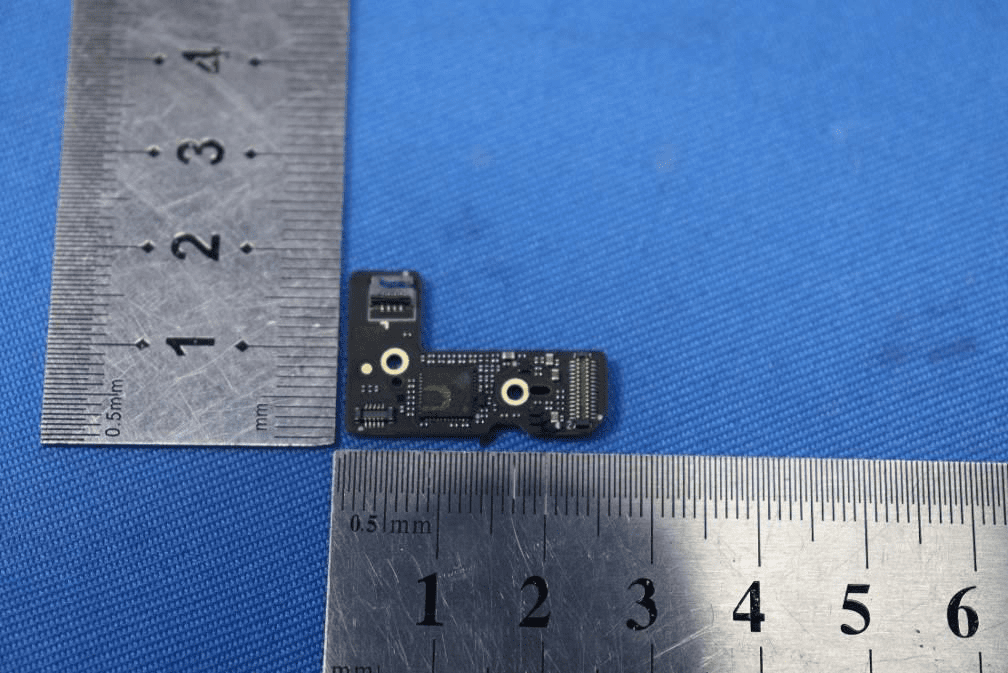

Compact Sensor or Interface Module

A compact, high-density PCB presents a sophisticated blend of sensor integration and robust interconnectivity. The board’s irregular shape and diminutive size, coupled with the use of black ENIG finish and at least four PCB layers, signify its role as a specialized, modular component within the drone. Fine-pitch QFN and WLCSP packages dominate, likely encompassing sensor, power management, and interface ICs. The presence of a fine-pitch FPC connector and gold-plated test points suggests high-speed data transfer—potentially serving a vision or environmental sensor function. Dense ground via stitching and copper pours prioritize EMI control without bulky shielding, vital for maintaining low weight and high signal integrity. The board’s circular aperture and mounting features indicate precision placement for sensing tasks, likely supporting the Air 3’s obstacle avoidance or navigation capabilities.

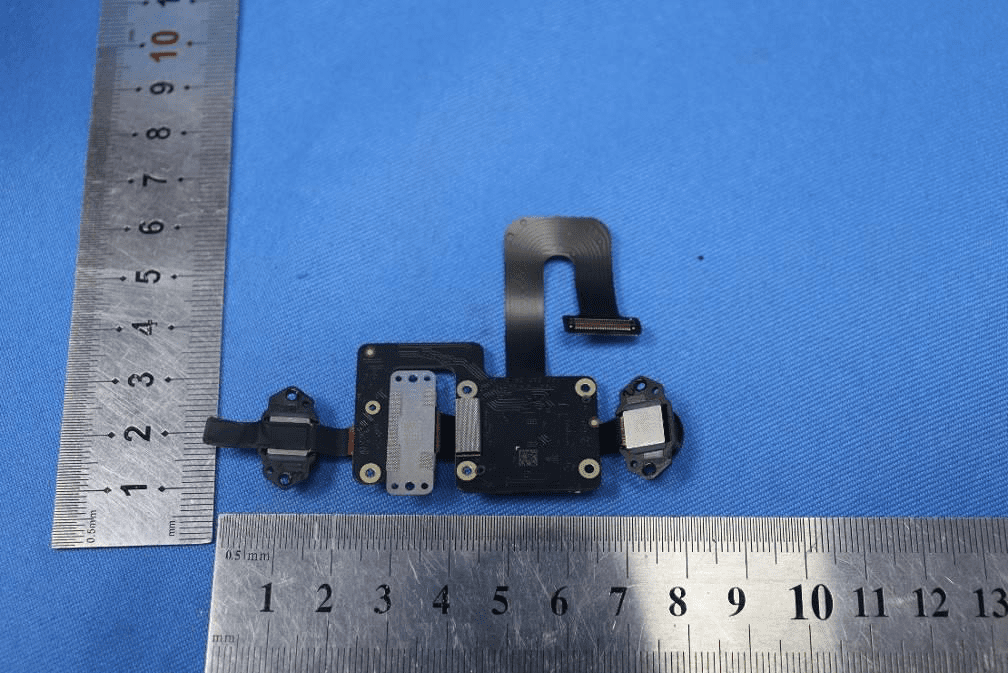

Integrated Camera or Vision Module Assembly

This assembly exemplifies DJI’s approach to modular, vibration-resistant sensor design. The small, black multi-layer PCB utilizes flex cable interconnects, enabling tight integration within the drone’s gimbal or vision systems. Prominent metallic shields cover sensitive analog and digital circuits, likely protecting image sensors or IMUs from EMI. The fine-pitch connectors facilitate high-speed data—essential for camera streams or sensor fusion. The use of flex PCB technology and robust soldered shields underscores the need for both mechanical durability and signal integrity in flight. Twin sensor modules at either end of the assembly, coupled with a central electronics hub, indicate this module’s probable role in the Air 3’s vision or navigation systems, supporting features such as omnidirectional obstacle detection and autonomous navigation.

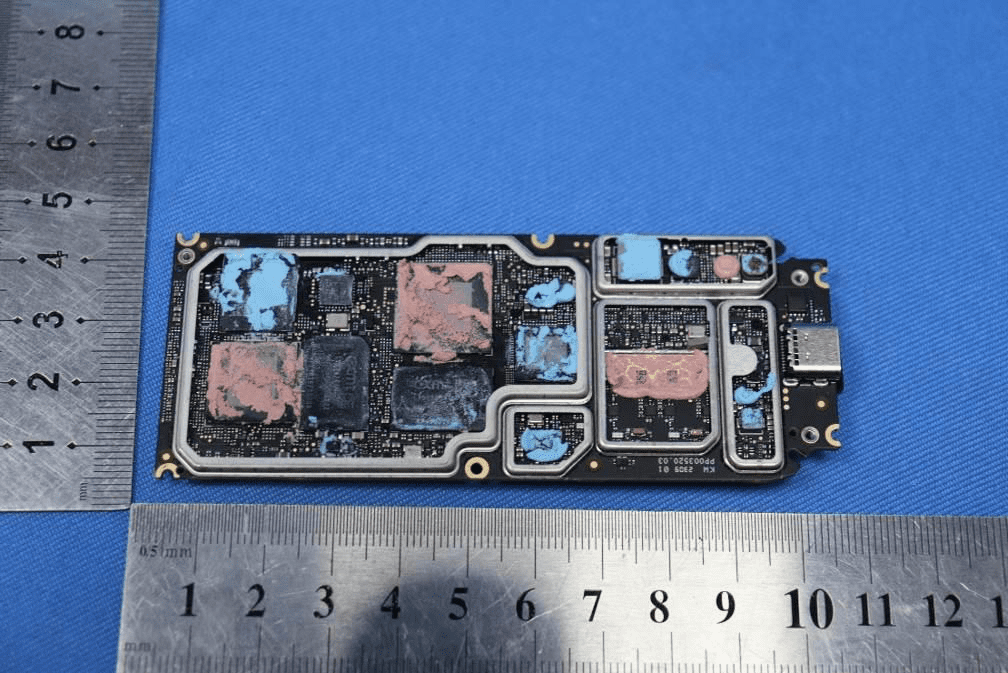

Core Logic and RF Processing Board

A densely populated, multi-layer PCB forms the heart of the DJI Air 3’s processing and wireless functions. Large BGA-packaged ICs, partially obscured by thermal interface material, suggest the presence of a high-performance SoC, memory, and possibly RF transceivers. Extensive via-in-pad and microvia structures accommodate high-speed signals and robust power distribution. Gold edge connectors and test points enable modular expansion and manufacturing diagnostics, while the absence of visible antennas hints at off-board or FPC antenna integration. Multiple EMI shields (removed for analysis) and dedicated power management sections, evidenced by large inductors and capacitors, ensure reliable operation amidst the harsh electromagnetic environment of a drone. This board orchestrates flight control, real-time video processing, and long-range wireless communications, underlining DJI’s expertise in compact, EMI-hardened electronics.

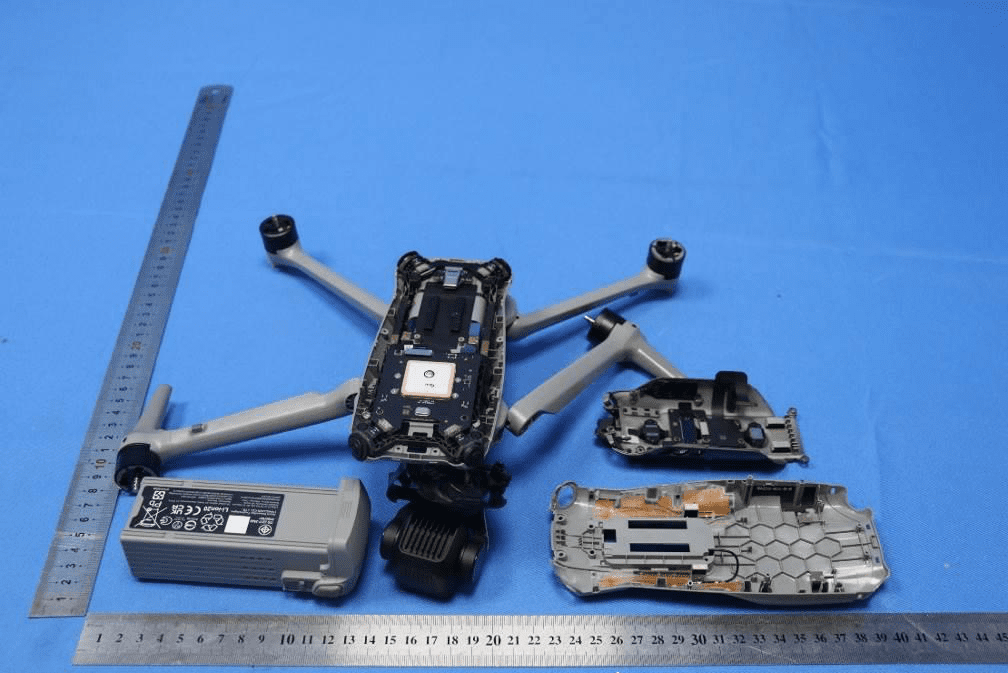

Drone Assembly with Main PCB, Battery, and Antenna Structures

A partially disassembled view of the DJI Air 3 reveals the integration of its main PCB, intelligent flight battery, and internal antenna systems. The central PCB, protected by a substantial metal shield, is the nexus for flight control, wireless communication, and power management. Robust connectors link the removable LiPo battery, gimbal, and sensor modules, supporting high current delivery and modular repairs. Embedded copper traces within the housing serve as internal antennas for 2.4 GHz and 5 GHz operation, optimizing RF performance without external protrusions. The mechanical structure features honeycomb reinforcement for strength and weight savings, while extensive shielding and compact layout reflect an emphasis on EMI control and reliability. This architecture ensures the Air 3 can deliver long flight times, stable video transmission, and precise control, even under demanding conditions.

Regulatory Insights & FCC Filing

The assignment of FCC ID SS3-EB3WBC2303 to the DJI Air 3 confirms its compliance with US FCC regulations for RF emissions, electromagnetic compatibility, and user safety. This certification, registered with FCC.gov, is critical for legal sale and operation within the United States, ensuring the drone does not cause harmful interference with other wireless devices.

FCC filings for the DJI Air 3 include a comprehensive suite of documentation—ranging from test reports on RF exposure and electromagnetic compatibility to detailed internal and external photographs, block diagrams, and user manuals. These documents provide transparency regarding the device’s technical operation and regulatory compliance.

The user manual provides an overview of the Air 3’s aircraft and remote controller, detailing component identification, operational instructions, and technical specs. Test reports confirm the device’s adherence to output power, spurious emissions, and frequency stability requirements, as mandated by FCC rules. Internal documentation further validates the engineering rigor behind the Air 3’s design, particularly in areas such as EMI shielding, antenna integration, and modular construction.

Through these filings, DJI demonstrates not only regulatory compliance but also a commitment to product safety, RF performance, and robust engineering practices.

Potential Use Cases & Target Audience

The DJI Air 3’s advanced features and robust wireless architecture make it suitable for a variety of demanding applications:

-

Aerial Photography and Cinematography

With its omnidirectional vision system and high-quality camera modules, the Air 3 is ideal for content creators who require stable, dynamic shots and intelligent flight modes in diverse environments. -

Industrial Inspection and Surveying

The drone’s precise navigation, extended range, and reliable wireless communication make it a powerful tool for infrastructure inspection, mapping, and surveying—enabling professionals to safely access and document hard-to-reach locations. -

Research and Development/Advanced Hobbyists

Tech enthusiasts and researchers benefit from the Air 3’s modular design, sophisticated sensor suite, and programmable controls, supporting experimentation in robotics, environmental monitoring, or autonomous flight.

While the device is accessible to skilled consumers, its feature set and regulatory compliance also position it well for professional and enterprise scenarios where reliability, safety, and data integrity are paramount.

Conclusion

The DJI Air 3 by SZ DJI TECHNOLOGY CO., LTD. (Model: EB3WBC) stands as a testament to modern drone engineering—melding advanced vision systems, high-performance wireless communication, and robust internal architecture. Its FCC certification under FCC ID SS3-EB3WBC2303 guarantees regulatory compliance, enabling legal operation and sale in the US market. Through meticulous design and rigorous testing, the Air 3 delivers a balance of power, intelligence, and reliability, setting a new benchmark for aerial platforms in both consumer and professional domains. As drone technology continues to evolve, the Air 3 exemplifies the integration of regulatory rigor and cutting-edge innovation.