Introduction

The Agras T25, engineered by SZ DJI TECHNOLOGY CO., LTD., stands at the forefront of agricultural drone technology. Purpose-built for precision spraying and spreading, this advanced UAV elevates the efficiency and accuracy of modern farming operations. Its robust design, intelligent systems, and modular payload capacity allow for versatile use in diverse agricultural scenarios, from crop dusting to targeted fertilization.

A pivotal milestone for the Agras T25 is its FCC certification under FCC ID SS3-RD241608RF. This designation confirms that the device adheres to stringent US regulations for radio frequency emissions and electromagnetic compatibility, making it legally saleable and operable within the United States. Such compliance ensures not just regulatory approval, but also a baseline for operational safety and interference mitigation.

In this article, we deliver an authoritative, expert perspective on the Agras T25. We’ll break down its key features and technical specifications, explore its wireless and RF technologies, conduct a detailed teardown analysis of its internal components, and provide regulatory insights gleaned from its FCC documentation. Whether you’re an engineer, a tech enthusiast, or an industry professional, this deep dive will illuminate what sets the Agras T25 apart in the competitive landscape of agricultural drones.

Key Features & Specifications

The Agras T25 brings together advanced drone engineering and intelligent agricultural solutions. Here’s a comprehensive look at its standout features and detailed technical specifications:

Key Features

-

Coaxial Dual Propeller Structure:

Delivers a powerful, stable wind field, enhancing lift and enabling the drone to carry heavier payloads while maintaining flight stability in challenging weather conditions. -

25 kg Spreading Payload:

Supports up to 25 kilograms of material for spreading operations, dramatically increasing efficiency for large-scale agricultural tasks. -

Phased Array Radar System & Binocular Vision System:

Integrates multi-directional radar and stereo vision to provide 360-degree obstacle detection and avoidance, ensuring safe, automated operation even in complex field environments. -

System Data Protection & Empty Tank Functions:

Protects critical system data and alerts users when tanks are empty, minimizing downtime and preventing operational errors. -

Ultra HD FPV Camera with Tiltable Gimbal:

Offers real-time, high-definition field monitoring from above. The adjustable gimbal enables flexible viewing angles, supporting automated image capture for field analysis and documentation. -

Upgradeable Spraying System:

The spraying module can be expanded with two additional sprinklers, allowing for tailored application rates to match specific crops or field conditions. -

Internal and External OCUSYNCTM Image Transmission Antennas:

Ensures robust, low-latency video and telemetry transmission, maximizing control and situational awareness over extended distances. -

Aircraft Status Indicators:

Provides clear, real-time feedback on system status, enhancing operational safety and user convenience.

Technical Specifications

- Wireless Transmission Power (EIRP):

- 2.4 GHz Band:

- <33 dBm (FCC), <20 dBm (CE/SRRC/MIC)

-

5.8 GHz Band:

- <33 dBm (FCC), <23 dBm (SRRC), <14 dBm (CE)

-

Operating Frequency Ranges:

- 2.4000–2.4835 GHz

-

5.725–5.850 GHz

-

Phased Array Radar:

- Rear Radar Operating Voltage: DC 15 V

- Forward Radar Transmitter Power: <20 dBm (NCC/MIC/KC/CE/FCC)

- Forward Radar Operating Voltage: DC 15 V

- Forward Radar Power Consumption: 23 W

-

Rear Radar Operating Temperature: 0° to 45° C (32° to 113° F)

-

GNSS (Global Navigation Satellite System) Support:

-

GPS L1, GLONASS F1, BeiDou B1I, Galileo E1, QZSS L1

-

Wireless Connectivity:

- Wi-Fi Bands: 2.4000–2.4835 GHz, 5.725–5.850 GHz

-

Bluetooth: Present (detailed specs not specified)

-

Camera System:

-

Ultra HD FPV camera with a tiltable gimbal, capable of automated high-definition field image collection.

-

Power System:

- Intelligent Flight Battery (compatible only with official DJI flight batteries).

Benefits in Practice:

These specifications translate to a drone capable of operating efficiently in large-scale, demanding agricultural environments. The phased array radar and binocular vision provide industry-leading safety and autonomy, while the high payload and modular spraying system allow for rapid, customized field treatments. The robust wireless transmission ensures reliable connectivity and control, even in challenging RF environments.

Operating Frequencies

The Agras T25, as detailed in its FCC filing, operates on the following wireless frequency bands:

- 2.4000–2.4835 GHz (commonly used for Wi-Fi, Bluetooth, and proprietary RF links)

- 5.725–5.850 GHz (utilized for high-bandwidth Wi-Fi and other ISM-band communications)

- GNSS Bands: GPS L1, GLONASS F1, BeiDou B1I, Galileo E1, QZSS L1

The transmitter power levels—up to 33 dBm in the 2.4 GHz and 5.8 GHz bands (FCC)—enable significant range and robust signal penetration, critical for reliable operation in expansive or obstructed field environments.

Note:

No additional detailed frequency data was available from the FCC filing for this device. The specified bands and power levels are crucial for understanding the Agras T25’s wireless capabilities, ensuring compliance with regulatory limits, and optimizing range and reliability for its intended agricultural uses.

Technology Deep Dive

The Agras T25 leverages a suite of advanced wireless technologies to deliver reliable performance and robust connectivity in challenging agricultural environments. Its primary wireless interfaces operate in the 2.4 GHz and 5.8 GHz ISM bands, which are widely used for Wi-Fi, Bluetooth, and proprietary drone communication protocols. These bands are selected for their balance of range, bandwidth, and resilience to interference, making them ideal for real-time video transmission, telemetry, and remote control.

The inclusion of both internal and external OCUSYNCTM antennas enhances signal stability and extends operational range, allowing operators to maintain a strong link even when the drone is operating at the edge of line-of-sight. The device’s support for multiple GNSS constellations (GPS, GLONASS, BeiDou, Galileo, QZSS) ensures accurate positioning and reliable navigation, which is critical for automated flight paths and precision agriculture tasks.

Operating at transmitter powers up to 33 dBm (FCC) provides robust RF coverage, but also necessitates careful adherence to regulatory limits to minimize interference with other devices and ensure electromagnetic compatibility. The phased array radar system, operating at DC 15 V and consuming up to 23 W, utilizes advanced RF design to deliver precise obstacle detection and terrain following, further enhancing the drone’s autonomous capabilities.

These technologies collectively enable the Agras T25 to deliver high reliability, extended operational range, and safe, precise performance in the demanding, interference-prone environments typical of modern agriculture.

In-Depth Internal Component Analysis / Teardown

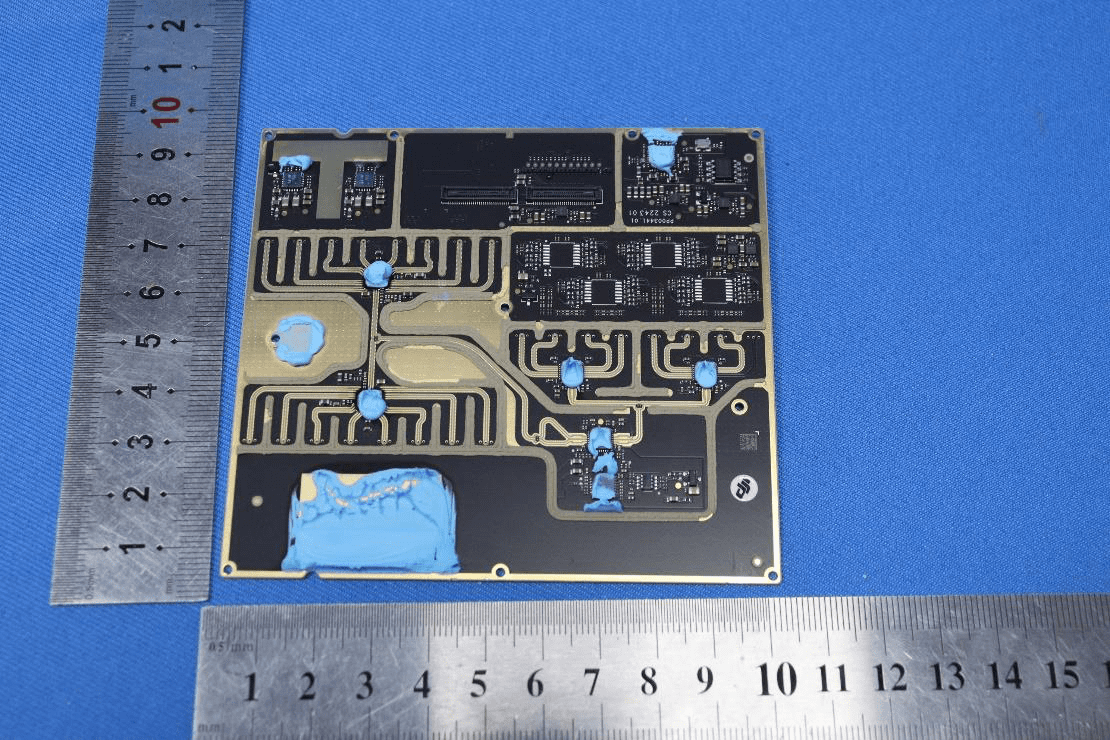

Sophisticated RF Subsystem with Integrated Antennas

A high-resolution internal photograph reveals a meticulously engineered PCB, blending analog/RF and digital circuitry. Prominent in the design are several ICs—likely a mix of analog front-end, signal processing, and microcontroller/interface chips—strategically placed for symmetry, suggesting phased array or multi-channel RF functionality. The board’s multi-layer construction, gold (ENIG) finish, and black soldermask reflect a premium build, optimized for high-frequency signal integrity. Noteworthy are the integrated trace antennas, visible as meandering gold patterns, indicative of a phased array or MIMO configuration. Extensive ground pours and via stitching mitigate EMI, while a large edge connector provides high-speed data and power interfaces. The use of thermal interface material over sensitive areas highlights a focus on both EMI shielding and thermal management. This board is a cornerstone of the Agras T25’s radar or advanced wireless communication system, embodying DJI’s commitment to RF performance, modularity, and reliability.

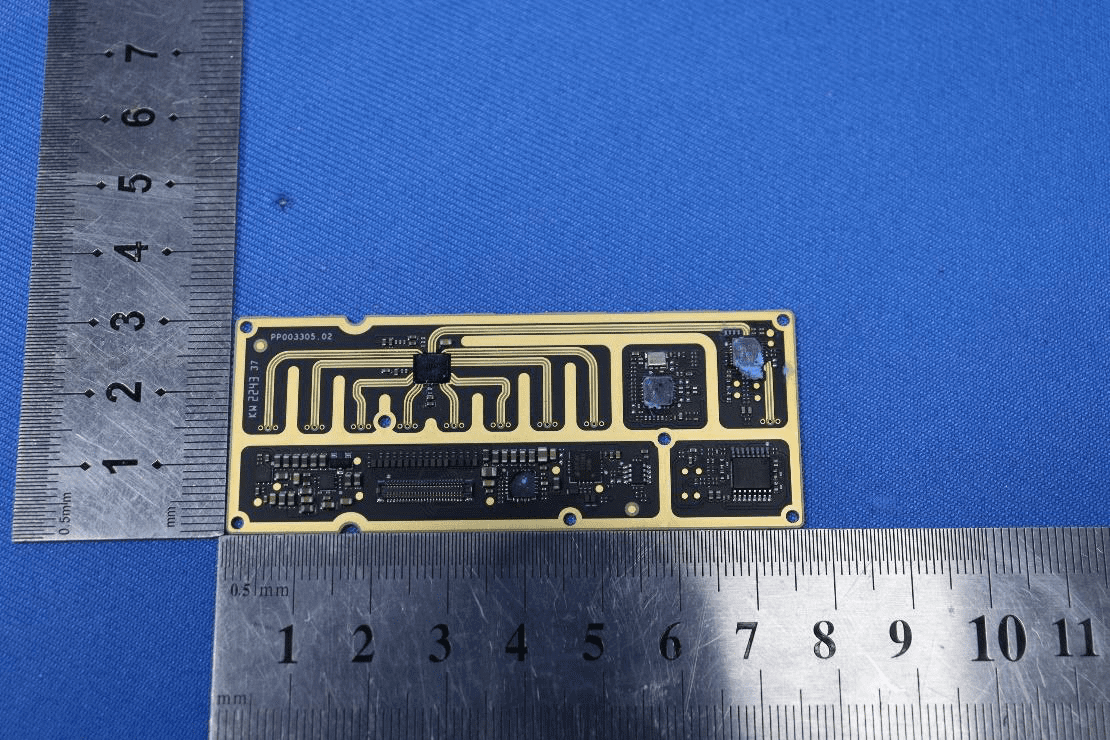

Advanced Mixed-Signal & RF Design for Wireless Communication

Another internal view showcases a densely populated PCB, exemplifying advanced mixed-signal and RF engineering. Multiple medium-sized QFN/BGA ICs—likely comprising analog front-ends, RF circuitry, and digital logic—are thermally coupled for efficient heat dissipation. The upper section features controlled-impedance traces and a distinctive PCB-integrated antenna, tailored for 2.4 GHz or 5.8 GHz operation. The lower section’s fine-pitch components suggest high integration of digital processing. Robust power regulation is evident from the presence of large capacitors and inductors, while numerous crystals provide clock sources for RF and digital subsystems. The meticulous layout, extensive ground vias, and use of thermal interface materials underscore a design optimized for compactness, EMI control, and high-frequency reliability. This board likely supports telemetry, remote control, or navigation, ensuring interference-resistant performance in the demanding field conditions faced by the Agras T25.

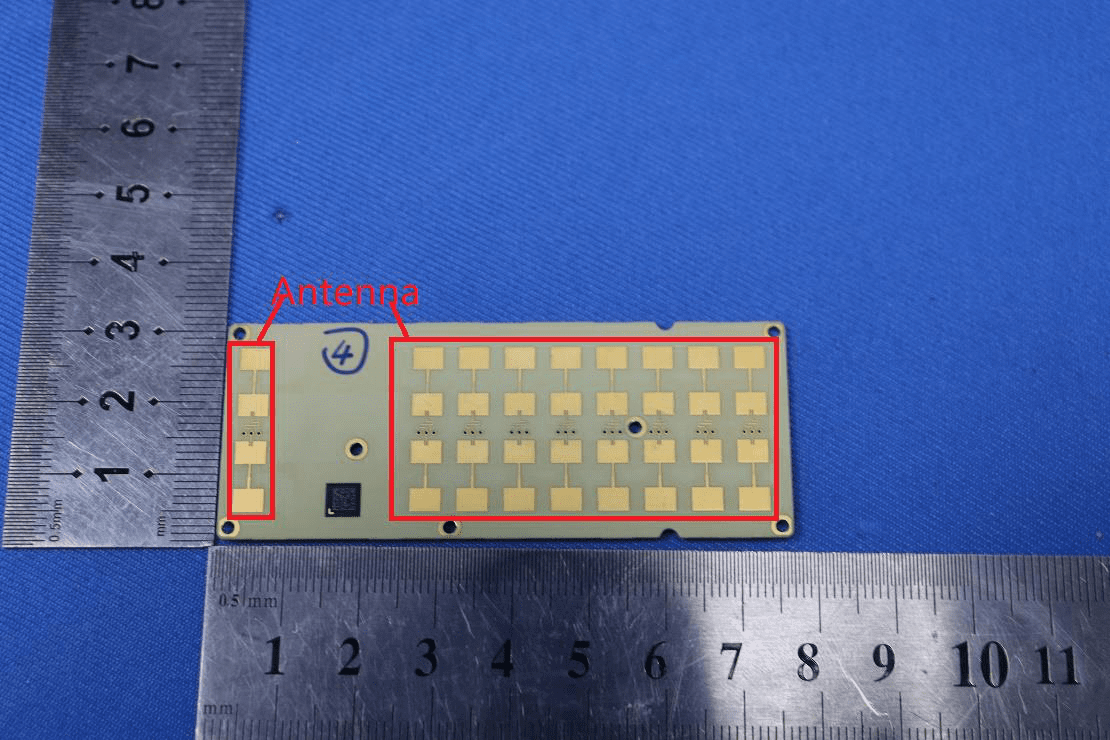

High-Density Planar Antenna Array for Advanced Telemetry

A compact PCB, dominated by a 5×4 grid of planar patch antenna elements, highlights DJI’s expertise in high-frequency RF design. Each gold-plated patch is precisely connected, forming a phased array or MIMO antenna system ideal for high-gain, directional communication or GNSS positioning. The board’s thin profile, gold finish, and precise mounting holes facilitate optimal placement within the drone’s enclosure. With minimal active components—a single small IC, possibly for antenna switching—the design is highly specialized for RF performance. The integration of such a dense antenna array directly into the PCB minimizes losses and maximizes reliability, supporting advanced telemetry and positioning functions vital to the Agras T25’s autonomous operation.

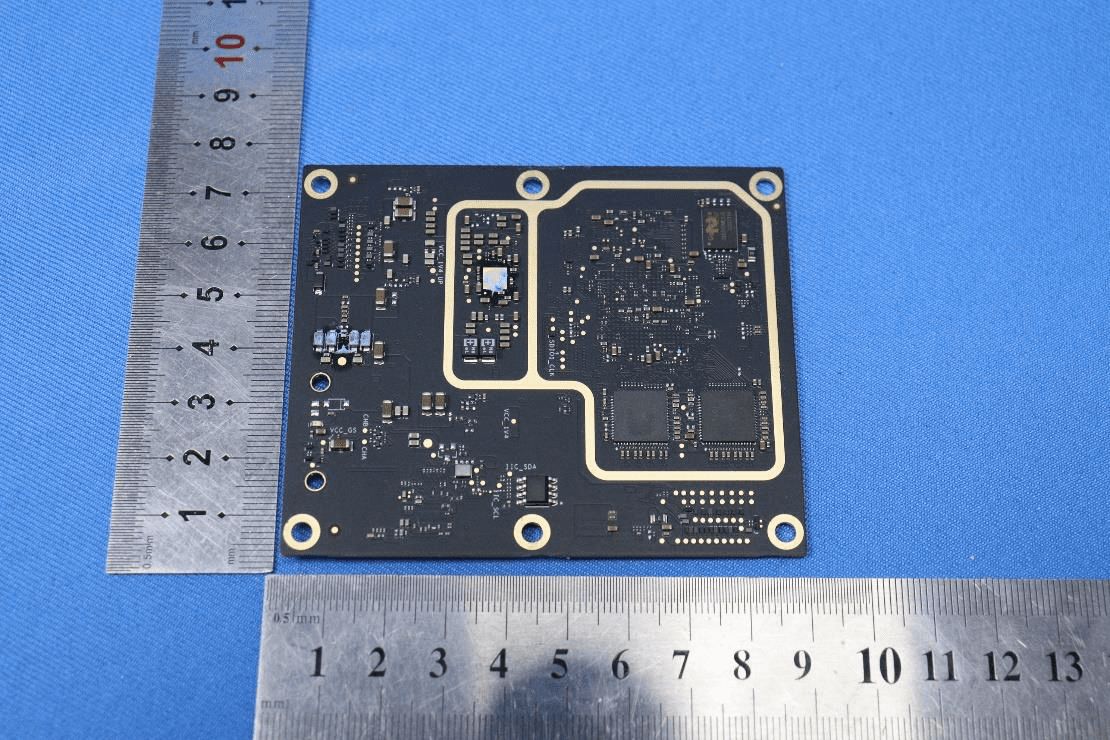

Embedded Controller PCB with High-Speed Processing

One internal assembly reveals a sophisticated PCB featuring several major ICs, including what are likely a microcontroller or SoC and associated memory. The gold-bordered, densely populated central region suggests a dedicated RF or sensitive analog section, with robust via stitching for EMI containment. Local power regulation is handled by visible inductors and capacitors, ensuring stable operation of critical subsystems. The presence of a fine-pitch board-to-board connector and multiple test points underscores the board’s modularity and serviceability. This assembly likely serves as a key control or sensor interface module, supporting real-time data processing and communication within the Agras T25’s integrated avionics suite.

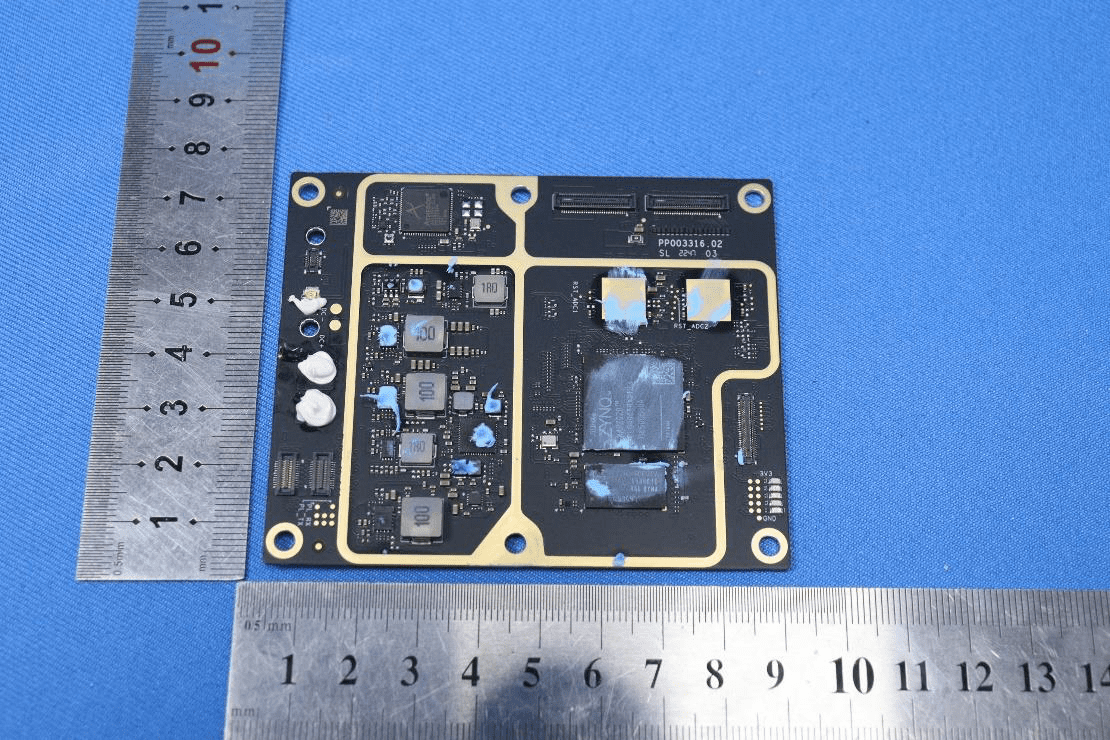

Main Processing Board with FPGA-Based Sensor Fusion

A detailed internal image reveals a high-quality PCB centered around a Xilinx FPGA or SoC, underscoring the Agras T25’s advanced processing capabilities. The multi-layer, gold-plated board features dense component placement, differential pair routing for high-speed signals, and robust power management with multiple inductors and capacitors. High-density FPC connectors provide modular integration with sensors or communication modules, while multiple crystals ensure precise timing. The blue thermal compound on major ICs indicates provisions for heat dissipation in the final assembly. This board is likely the main control hub, handling real-time sensor fusion, flight control, and machine vision—critical for the drone’s autonomous operation and advanced obstacle avoidance.

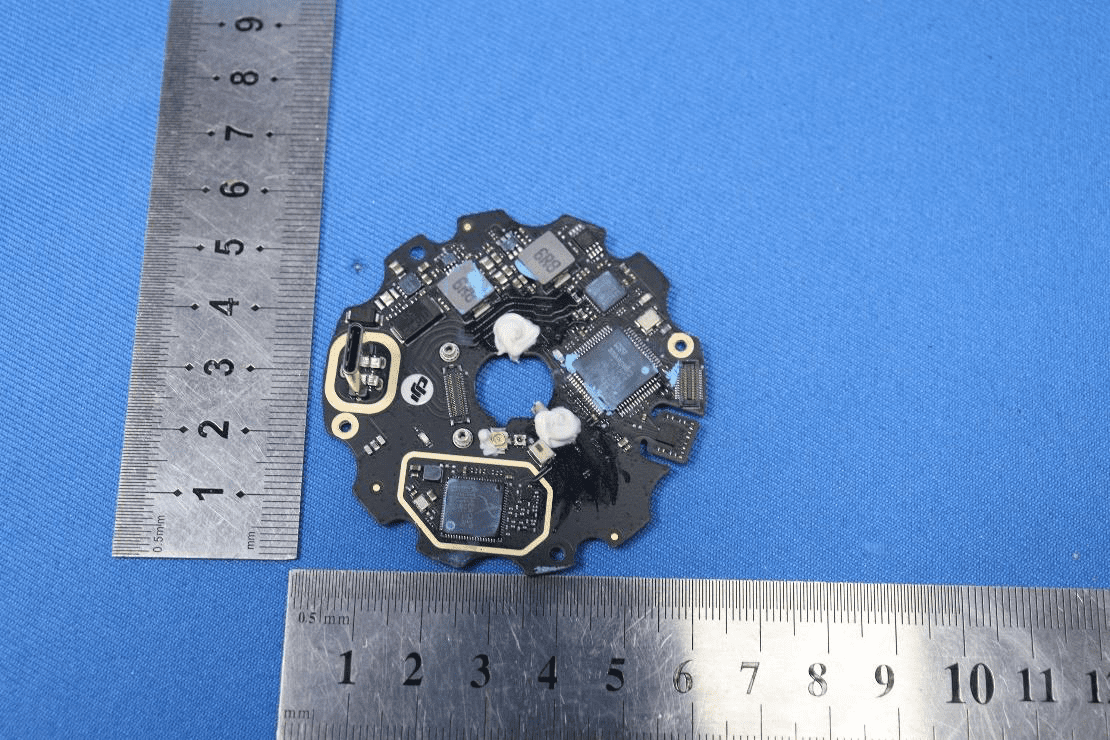

Compact Flight Controller or Sensor Fusion Module

Another internal assembly displays a compact, irregularly shaped PCB densely packed with high-integration ICs, passive components, and modular connectors. The presence of multiple crystals, large inductors, and robust power regulation components points to a board optimized for reliability and precise timing. The layout, featuring fine-pitch connectors and extensive ground pours, suggests a flight controller or sensor fusion module responsible for UAV stability, navigation, and communication. The use of multi-layer PCB design and careful EMI control further enhances operational integrity in the challenging environments faced by agricultural drones.

Regulatory Insights & FCC Filing

The Agras T25, under FCC ID SS3-RD241608RF, has successfully met the rigorous electromagnetic interference and RF emission standards set by US regulatory authorities. This certification, registered via FCC.gov, attests to the device’s legal status for sale and operation in the United States, ensuring it does not interfere with other electronic equipment or critical communication systems.

FCC filings typically encompass comprehensive documentation, including RF exposure assessments, electromagnetic compatibility (EMC) test reports, internal and external photographs, user manuals, and engineering schematics. For the Agras T25, the user manual highlights its advanced agricultural capabilities—such as a foldable truss-style body, integrated spraying and spreading systems, and omnidirectional obstacle sensing—while internal documentation details the robust safety features and modular design.

Test reports confirm that the Agras T25 operates well within regulatory limits for RF output, with careful attention to EMI containment and system reliability. The inclusion of phased array radar and multi-band wireless modules reflects a design philosophy centered on both performance and compliance. The internal photographs and engineering documentation further underscore the device’s high manufacturing quality and adherence to best practices in RF and embedded system design.

Potential Use Cases & Target Audience

The Agras T25 is engineered for a diverse range of agricultural applications, catering to both large-scale commercial operations and specialized crop management tasks:

-

Precision Crop Spraying in Large Fields:

Operators managing extensive farmland can leverage the T25’s high payload capacity and robust wind field to efficiently apply pesticides and fertilizers. The upgradable spraying system allows for tailored coverage, ensuring thorough penetration even in dense canopies. -

Orchard and Plantation Management:

With its advanced obstacle avoidance, omnidirectional sensing, and modular payload options, the T25 excels in environments with complex terrain or irregular layouts. The high-definition FPV camera and automated image capture provide valuable data for monitoring crop health and optimizing treatment strategies. -

Agrochemical Application Service Providers:

Service companies can deploy the Agras T25 for on-demand spraying and spreading operations, benefiting from its rapid deployment, foldable structure, and intelligent safety features. The empty tank alert and data protection systems minimize operational interruptions, maximizing productivity.

These scenarios demonstrate the T25’s versatility, making it an indispensable tool for modern precision agriculture where efficiency, safety, and adaptability are paramount.

Conclusion

The Agras T25 by SZ DJI TECHNOLOGY CO., LTD. stands out as a technologically advanced, feature-rich agricultural drone, meticulously engineered for high-performance field operations. Its FCC certification under FCC ID SS3-RD241608RF underscores its compliance with US regulatory standards, paving the way for widespread adoption in the American market. From its sophisticated phased array radar and integrated antenna subsystems to its modular payload and robust wireless connectivity, the T25 exemplifies the cutting edge of agricultural UAV design. For professionals seeking reliability, efficiency, and regulatory peace of mind, the Agras T25 is a compelling choice at the forefront of modern smart farming.