Introduction

The DJI MINI 4 PRO, crafted by SZ DJI TECHNOLOGY CO., LTD., represents a new generation of compact, high-performance consumer drones. Designed for aerial photography, videography, and intelligent flight features, this drone delivers professional-grade capabilities in a lightweight, portable form factor. With its advanced vision systems and robust wireless connectivity, the MINI 4 PRO is engineered for both hobbyists and professionals seeking precision, reliability, and ease of use.

A critical milestone in the product’s journey to market is its FCC certification under FCC ID SS3-MT4MFVD23. This certification is not merely a regulatory checkbox; it affirms that the MINI 4 PRO meets stringent U.S. electromagnetic interference (EMI) and radio-frequency (RF) emission standards. Compliance ensures the device is legal to sell and operate in the United States, providing confidence in its safety and reliable operation within shared wireless environments.

In this comprehensive analysis, we’ll explore the MINI 4 PRO’s standout features, dissect its technical specifications, examine its advanced internal components through teardown insights, and review its regulatory standing. Whether you’re a drone enthusiast, engineer, or tech analyst, this deep dive will illuminate what sets the DJI MINI 4 PRO apart in a competitive landscape.

Key Features & Specifications

The DJI MINI 4 PRO offers a compelling blend of intelligent flight features, robust build quality, and state-of-the-art wireless technology. Below is a detailed look at its key features and technical specifications, highlighting the benefits for users and situating the drone in the context of modern UAV (Unmanned Aerial Vehicle) design.

Key Features

-

Horizontal Omnidirectional Vision System:

Employs an array of vision sensors to detect obstacles in all horizontal directions, dramatically improving autonomous navigation and collision avoidance for safer, more reliable flights. -

Downward Vision System:

Advanced downward-facing sensors enable precise hovering, accurate landings, and enhanced positioning, even in environments where GPS signals are weak or unavailable. -

Power Button:

Intuitive and easily accessible, allowing quick power-on and power-off sequences for streamlined operation and safety. -

USB-C Port:

Modern, versatile connectivity for charging, data transfer, and firmware updates, ensuring compatibility with a wide array of devices and accessories. -

Battery Buckles:

Secure battery mounting mechanism designed for rapid battery swaps and safe, vibration-resistant retention during flight. -

Customizable Button:

User-programmable for quick access to preferred functions, enhancing workflow efficiency and user experience. -

Frame Arms:

Robust, lightweight arms provide structural integrity while supporting the drone’s compact, foldable design for maximum portability. -

Mobile Device Holder:

Integrated into the remote controller, accommodating a range of smartphones and tablets for real-time video streaming and intuitive control.

Technical Specifications

- Operating Frequencies:

- 2.400–2.4835 GHz (Wi-Fi/Bluetooth)

- 5.150–5.250 GHz (Wi-Fi)

-

5.725–5.850 GHz (Wi-Fi)

-

Battery Options:

- Intelligent Flight Battery Plus (Model: BWX162-3850-7.38):

- Capacity: 3850 mAh

- Standard Voltage: 7.38 V

- Max Charging Power: 58 W

-

Intelligent Flight Battery (Model: BWX140-2590-7.32):

- Capacity: 2590 mAh

- Standard Voltage: 7.32 V

- Max Charging Power: 37 W

-

Operating Temperature Range:

-

-10°C to 40°C (14°F to 104°F)

-

Charging Temperature Range:

-

5°C to 40°C (41°F to 104°F)

-

Aircraft Models:

-

MT4MFVD, MT4MFVDB

-

Wireless Connectivity:

- Wi-Fi: Dual-band, supporting 2.4 GHz and 5 GHz for robust, low-latency video transmission and control

-

Bluetooth: Present (details not specified), likely for quick pairing and device management

-

Other Hardware Highlights:

- High-density, multi-layer PCBs for space efficiency and signal integrity

- Advanced power management and local regulation for optimal efficiency and flight time

- Precision thermal and EMI management for stable operation in demanding environments

These specifications collectively position the DJI MINI 4 PRO as a versatile, high-performance drone that excels in both recreational and professional scenarios. Its combination of intelligent sensing, robust wireless architecture, and modular battery design ensures adaptability and reliability across a range of applications.

Operating Frequencies

The DJI MINI 4 PRO, under FCC ID SS3-MT4MFVD23, is certified to operate across a range of frequencies, each carefully chosen to balance performance, range, and regulatory compliance. Understanding these parameters is crucial for evaluating the drone’s wireless capabilities and real-world operation.

| Frequency Range (GHz) | Output Power (mW) | FCC Rule Part |

|---|---|---|

| 2.4035–2.4675 | 72.6 | 15CCC |

| 2.4525 | 707.9 | 15CCC |

| 2.4625 | 648.6 | 15CCC |

| 5.8195 | 413 | 15ECC |

| 5.8295 | 504.7 | 15ECC |

| 12.422–2.452 | 73.1 | 15CCC1.32.4225 |

| 12.4325–2.4425 | 711.2 | 15CCC |

| 15.7305–5.8445 | 695 | 15ECC |

| 15.7355–5.8395 | 687.1 | 15ECC |

| 25.161–5.24 | 60 | 15ECC |

| 25.17–5.23 | 64.4 | 15ECC |

| 25.7325–5.8425 | 56.1 | 15ECC |

| 35.7275–5.8445 | 92.7 | 15ECC |

| 35.745–5.825 | 28.2 | 15ECC2.45.7455 |

| 42.4045–2.4695 | 71.4 | 15CCC |

| 45.755–5.795 | 18.9 | 15ECC2.55.7555 |

| 52.4055–2.4655 | 75.2 | 15CCC |

| 55.7655–5.8095 | 480.8 | 15ECC |

| 62.4075–2.4675 | 631 | 15CCC |

| 65.775 | 25.9 | 15ECC2.6 |

| 72.412–2.462 | 127.4 | 15CCC1.22.4125 |

| 75.73012–5.84612 | 96.8 | 15ECC |

| 82.40512–2.46912 | 66.8 | 15CCC |

| 85.7302–5.8472 | 94.6 | 15ECC |

| 92.4082–2.4682 | 72.1 | 15CCC |

| 95.7285–5.8445 | 95.1 | 15ECC |

These certified frequency bands and power levels enable the MINI 4 PRO to achieve reliable, long-range wireless communication for video transmission, remote control, and telemetry, while ensuring full compliance with U.S. RF emission standards.

Technology Deep Dive

The DJI MINI 4 PRO leverages a sophisticated suite of wireless technologies centered around dual-band Wi-Fi (2.4 GHz and 5 GHz) and Bluetooth connectivity. The dual-band Wi-Fi architecture enables high-speed, low-latency video downlink and responsive remote control even in congested environments, while Bluetooth support is likely utilized for quick device pairing and short-range communication.

Operating across multiple frequencies allows the drone to dynamically select the optimal band for signal integrity and range, reducing interference from other wireless devices in the vicinity. The certified output power levels, as detailed in the FCC documentation, ensure strong, stable connections without exceeding regulatory emission limits, balancing performance with battery efficiency.

From a performance perspective, the multi-frequency approach enhances the drone’s operational range and reliability, particularly useful for real-time HD video transmission and control in complex RF environments. The careful partitioning of analog, digital, and RF domains within the internal circuitry, combined with robust EMI shielding and advanced power regulation, minimizes cross-interference and supports stable, long-duration flights.

Test reports referenced in the FCC filing confirm that the MINI 4 PRO meets stringent standards for RF exposure, electromagnetic compatibility, and emission limits, ensuring not only legal compliance but also a high degree of operational safety and reliability in real-world scenarios.

In-Depth Internal Component Analysis / Teardown

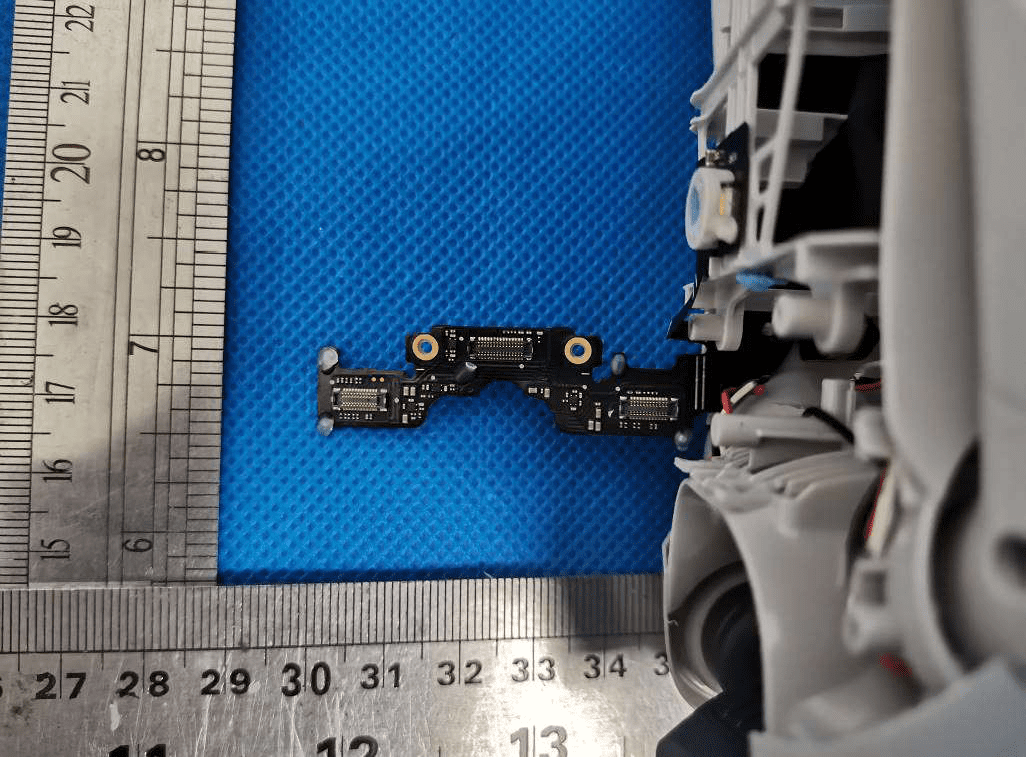

The compact, space-optimized PCB extracted from the drone’s internal assembly exemplifies DJI’s commitment to miniaturization and modularity. Densely populated with small, fine-pitch ICs and discrete components, this board likely functions as a sensor or interface module, connecting critical inputs to the main processor. The advanced multi-layer design, visible via-in-pad structures, and robust ground pours reflect high-frequency signal integrity and EMI control. Gold-plated FPC connectors enable seamless integration with other subsystems, while the absence of RF shielding indicates low emission risk. This module’s precision and layout underscore its essential role in supporting real-time sensor data acquisition for flight stability and obstacle detection.

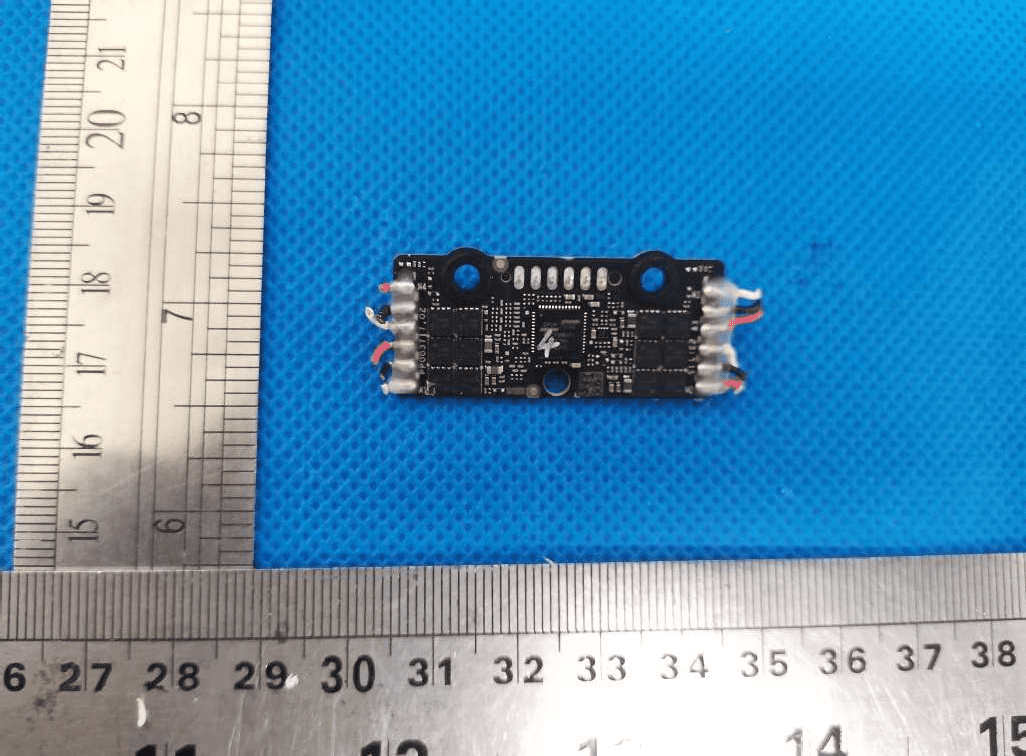

The motor controller PCB module showcases a sophisticated, high-reliability design tailored for UAV power electronics. At its core is a dedicated microcontroller, likely running advanced ESC firmware, surrounded by powerful MOSFETs for efficient brushless motor control. The direct-soldered motor and power wires minimize weight and maximize electrical reliability, critical for airborne applications. The board’s multi-layer structure and heavy copper pours are optimized for high current handling and thermal management. No antennas or RF components are present, affirming its specialized function. This board epitomizes the robust, compact engineering required for flight-critical systems, directly supporting rapid, precise propulsion control in the MINI 4 PRO.

The opened drone chassis reveals the main processing assembly, a densely integrated, multi-layer PCB populated with high-performance BGA ICs and shielded RF sections. Key functions—including flight control, real-time video processing, and wireless transmission—are consolidated under extensive EMI shields, ensuring signal integrity in the presence of high-frequency digital and RF activity. Multiple micro-coaxial connectors route signals to distributed antennas, while FPC connectors link to camera, gimbal, and sensor modules. Large power inductors and capacitors indicate robust, multi-stage power regulation, supporting mission-critical reliability. This assembly is the technological heart of the MINI 4 PRO, orchestrating all core operations with efficiency and precision.

The mainboard PCB, isolated for inspection, demonstrates advanced engineering with its high component density and modular connector layout. Large ICs—likely the main processor, memory, and RF transceivers—are strategically positioned and thermally managed with blue interface pads. Labeled antenna pads (ANT0–ANT3) suggest dedicated paths for Wi-Fi, FPV, or GPS antennas. Metal shield frames and ground stitching reinforce EMI protection, while visible differential pair routing supports high-speed data transfer. The presence of multiple FPC connectors and test points indicates a design prioritizing both performance and serviceability. This mainboard is central to the drone’s real-time flight and communication capabilities.

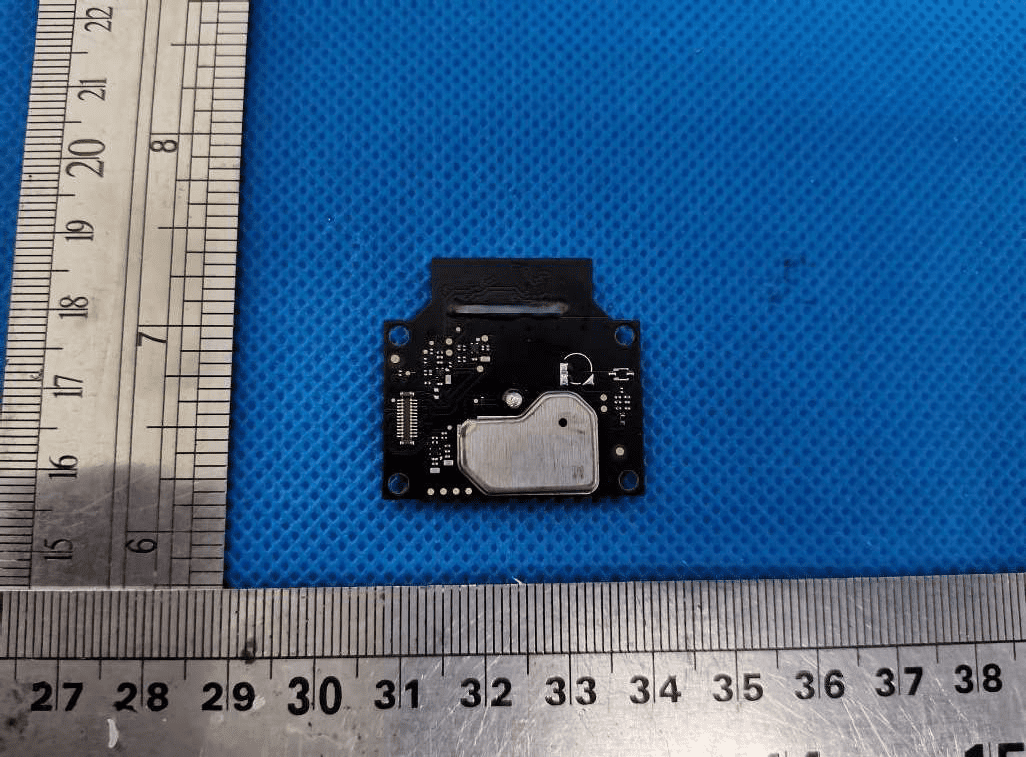

This compact PCB module features a prominent metal shield, likely protecting sensitive RF or vision circuitry. Surrounding discrete components and a fine-pitch connector point to its role as a sensor, navigation, or communication module. The presence of robust EMI shielding, gold-plated contacts, and a crystal oscillator highlights its high-frequency operation and precision timing. Advanced PCB techniques—multi-layer design, via stitching, and careful separation of analog and digital domains—ensure signal integrity and reliability. This module’s engineering supports critical subsystems such as vision, radar, or wireless communication, integrating seamlessly into the drone’s broader architecture.

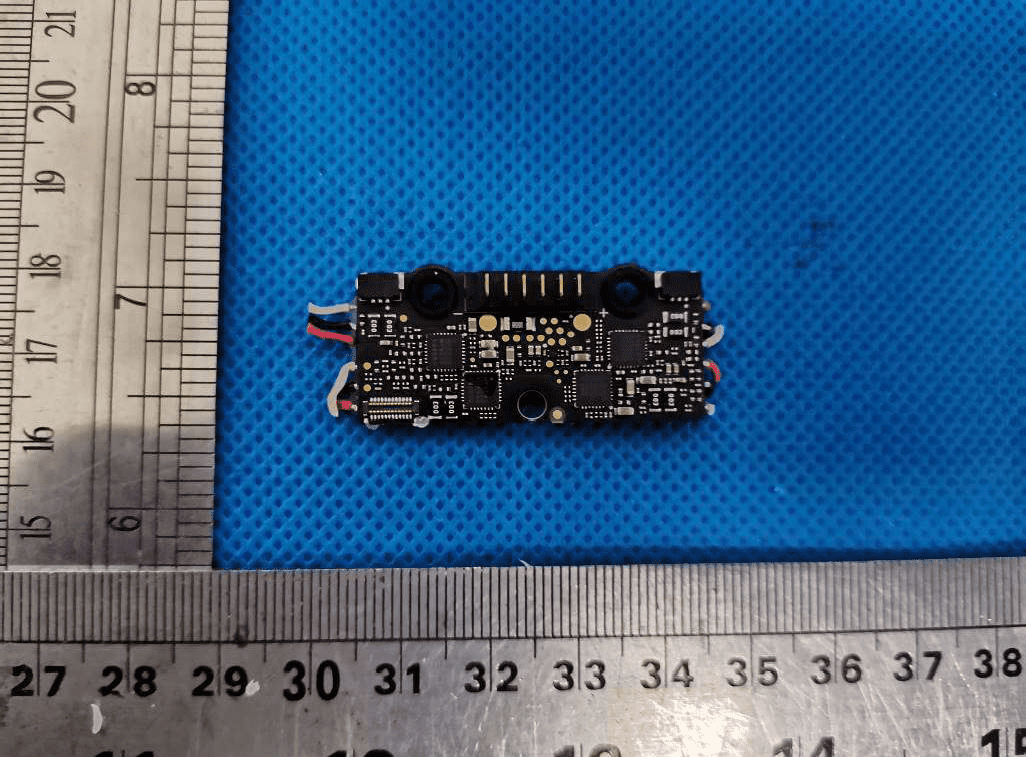

The stereo vision module demonstrates DJI’s expertise in sensor fusion and miniaturized imaging. Twin camera lenses, likely used for obstacle avoidance and depth perception, dominate the board. Supporting ICs handle high-speed image acquisition and processing, while precise differential routing ensures data integrity. Multiple wire harnesses and gold-plated edge contacts facilitate modular integration with the main flight controller. The dense, multi-layer PCB design incorporates robust local power regulation and EMC strategies. This module is pivotal for the drone’s advanced autonomous features, enabling real-time environmental awareness and intelligent navigation.

This main PCB assembly, distinguished by its green soldermask and dense population of BGA and QFN ICs, serves as a central hub for processing, power management, and RF connectivity. External antenna connectors at the edges enable multi-band operation (Wi-Fi, GPS), while robust metal shields protect sensitive analog and RF circuits. The board integrates multiple FPC connectors, a microSD slot, and large power inductors, supporting both system expansion and efficient energy distribution. The careful partitioning of analog, digital, and RF domains, coupled with extensive test points, reflects a design philosophy prioritizing reliability, modularity, and high-performance operation in the MINI 4 PRO platform.

Regulatory Insights & FCC Filing

The assignment of FCC ID SS3-MT4MFVD23 to the DJI MINI 4 PRO by SZ DJI TECHNOLOGY CO., LTD. signifies full compliance with U.S. Federal Communications Commission (FCC) standards for electromagnetic interference and RF emissions. This certification, registered by FCC.gov, is a legal prerequisite for sale and operation in the United States, ensuring that the device does not interfere with other wireless systems and operates within established safety boundaries.

FCC filings for devices like the MINI 4 PRO include a comprehensive suite of documentation: RF exposure test reports, electromagnetic compatibility (EMC) assessments, internal and external photographs, user manuals, schematics, and block diagrams. These materials collectively demonstrate the drone’s adherence to all relevant technical and safety requirements.

Insights drawn from the user manual highlight the drone’s modularity, ease of use, and technical sophistication. The documentation details component identification, operational guidance, and technical specifications, reinforcing the device’s positioning as a high-performance, user-friendly UAV. Internal documentation and test reports confirm that the MINI 4 PRO meets or exceeds all regulatory thresholds for RF exposure and emission limits, further validating its engineering quality and market readiness.

Potential Use Cases & Target Audience

With its advanced feature set and robust wireless architecture, the DJI MINI 4 PRO caters to a diverse range of users and practical scenarios:

-

Aerial Content Creators:

Photographers and videographers benefit from the drone’s omnidirectional vision systems and stable flight, enabling the capture of dynamic, high-resolution content in challenging environments. -

Recreational and Enthusiast Pilots:

The compact, foldable design, intelligent obstacle avoidance, and intuitive controls make the MINI 4 PRO ideal for hobbyists seeking a portable yet powerful drone for exploration, travel, and leisure flying. -

Professional Surveying and Inspection:

The drone’s precise vision systems, reliable wireless connectivity, and modular battery options suit professionals conducting site surveys, infrastructure inspections, or mapping, where accuracy and operational uptime are critical.

Whether for creative, recreational, or industrial applications, the MINI 4 PRO’s engineering and regulatory pedigree ensure it meets the demands of discerning users across multiple domains.

Conclusion

The DJI MINI 4 PRO by SZ DJI TECHNOLOGY CO., LTD. stands out as a meticulously engineered, FCC-certified drone (FCC ID SS3-MT4MFVD23) that blends advanced sensing, robust wireless performance, and compact design. Its high-density internal architecture, comprehensive vision systems, and modular features deliver a versatile platform for both enthusiasts and professionals. With proven compliance to U.S. regulatory standards, the MINI 4 PRO is poised to set benchmarks in its class, offering a compelling mix of innovation, reliability, and user-focused design in the ever-evolving UAV landscape.