Introduction

The DJI Matrice 200 V2 (Model: M200 V2) stands at the forefront of industrial drone technology, catering to professionals who demand reliability, advanced features, and robust performance in challenging environments. Whether for infrastructure inspections, public safety, surveying, or specialized aerial data collection, the Matrice 200 V2 is engineered to excel where mission-critical precision and ruggedness are paramount.

A pivotal milestone in the Matrice 200 V2’s journey to market is its FCC certification under FCC ID SS3-M200V21811. This regulatory approval is more than a formality—it certifies that the drone meets stringent US standards for electromagnetic interference and radio frequency (RF) emissions, ensuring lawful operation and marketplace eligibility. For enterprise users, the FCC ID is a badge of assurance that the platform’s wireless systems are both robust and compliant.

In this comprehensive analysis, we’ll dissect the Matrice 200 V2’s key features, technical specifications, operating frequencies, wireless technologies, and internal components. Drawing on teardown evidence and regulatory documentation, this article delivers expert insights into what makes the Matrice 200 V2 a benchmark for professional UAVs.

Key Features & Specifications

The DJI Matrice 200 V2 is purpose-built for demanding industrial and professional applications, offering a blend of intelligent flight features, advanced safety systems, and rugged hardware. Here’s a detailed look at its standout features and core specifications:

Key Features

- Smart Flight Features: Enables complex aerial maneuvers and automated flight paths for capturing advanced shots and streamlining mission workflows.

- Built-in AirSense: Integrated ADS-B receiver increases airspace awareness by alerting operators to nearby manned aircraft—crucial for safety in shared airspace.

- Wide Operating Temperature: Functions reliably in extreme conditions, from -4° to 122° F (-20° to 50° C), making it suitable for harsh industrial environments.

- Dual GNSS (GPS+GLONASS): Ensures precise positioning and redundancy for enhanced navigation accuracy, even in challenging or GNSS-denied environments.

- DJI OcuSync 2.0 Technology: Delivers up to 7 km of reliable, low-latency transmission for video and control, supporting dual-frequency operation for interference mitigation.

- Advanced Power Management: Features dual intelligent flight batteries (TB55) for improved safety, redundancy, and flight duration.

- Enhanced Hovering Precision: Maintains stability even indoors or when GNSS is unavailable, thanks to its sophisticated vision and sensor systems.

Technical Specifications

- Downward Vision System Operating Range: <32.8 feet (10 m)

- Downward Vision System Velocity Range: <32.8 ft/s (10 m/s) at 6.56 feet (2 m) altitude

- Max Wind Resistance: 39.4 ft/s (12 m/s), enabling operation in breezy conditions

- Ultrasonic Sensor Environment: Optimized for non-absorbing, rigid surfaces; thick carpeting may reduce performance

- Intelligent Flight Battery (TB55):

- Charging Temp: 41° to 104° F (5° to 40° C)

- Operating Temp: -4° to 122° F (-20° to 50° C)

- Capacity: 7660 mAh, 22.8 V, 174.6 Wh, LiPo 6S

- Max Flight Time: Up to 38 min (no payload); 24 min (takeoff weight: 6.14 kg)

- Remote Controller Battery (WB37): 4920 mAh, 7.6 V; up to 4 hours operation

- Dimensions (Folded, excl. props/landing gear): 722 × 282 × 242 mm

- Wireless Connectivity:

- Wi-Fi: Dual frequency support (2.4 GHz and 5.8 GHz)

- Bluetooth: Present (specifics not detailed)

- Safety & Redundancy: Redundant IMUs, barometers, and advanced diagnostics for mission-critical reliability

Benefits & Practical Impact

- Operational Flexibility: Wide temperature and wind resistance ranges make it suitable for diverse field scenarios.

- Safety & Compliance: AirSense and redundant systems minimize risk, meeting the stringent requirements of professional operators.

- Mission Efficiency: Smart automation and robust wireless links streamline workflows, reduce downtime, and enable data-rich missions.

Operating Frequencies

The Matrice 200 V2 (FCC ID SS3-M200V21811) operates across multiple RF bands, as documented in its FCC filing. Understanding these frequencies is essential for assessing wireless performance, range, and regulatory compliance:

| Frequency Range (GHz) | Output Power (mW) | FCC Rule Part |

|---|---|---|

| 2.4725 | 410 | 15CCC2.35.7285 |

| 2.4775 | 400 | 15CCC2.22.4105 |

| 5.8395 | 113 | 15ECC1.3 |

| 5.8445 | 121 | 15ECC1.25.7355 |

| 5.8465 | 13 | 15ECC1.15.7305 |

| 2.4035–2.4775 | 57 | 15CCC2.12.4055 |

These bands cover the widely used 2.4 GHz and 5.8 GHz ISM frequencies—standard for Wi-Fi, telemetry, and control links—enabling robust, interference-resistant communication. Output power levels are carefully tuned to maximize range while ensuring regulatory compliance.

Technology Deep Dive

The Matrice 200 V2 leverages a suite of wireless technologies to deliver long-range, low-latency communication and reliable control. Its dual-frequency Wi-Fi (2.4 GHz and 5.8 GHz) capabilities are essential for maintaining strong connections in environments with variable interference, while Bluetooth support (details not specified) likely facilitates device pairing, configuration, or accessory integration.

The specified frequency bands and output powers reflect a careful balance between range, data throughput, and power consumption. Operating within the 2.4 GHz and 5.8 GHz ISM bands allows for compatibility with global regulations and the use of advanced features like MIMO and frequency hopping, which are crucial for OcuSync 2.0’s robust video and telemetry transmission. The moderate output power ensures strong links without excessive RF emissions, reducing the risk of interference with other equipment and prolonging battery life.

The lack of cellular technology (as indicated by the equipment class) means all communications are handled via proprietary RF and Wi-Fi links, offering high bandwidth and low latency critical for real-time video and responsive controls. Internal documentation highlights the use of advanced RF design methodologies—such as multi-layer PCBs, EMI shielding, and controlled-impedance traces—to ensure both performance and compliance.

In-Depth Internal Component Analysis / Teardown

A close examination of the Matrice 200 V2’s internal hardware reveals a sophisticated, modular architecture designed for durability, serviceability, and high-performance operation in the field. Below, we detail the most significant findings from component photographs:

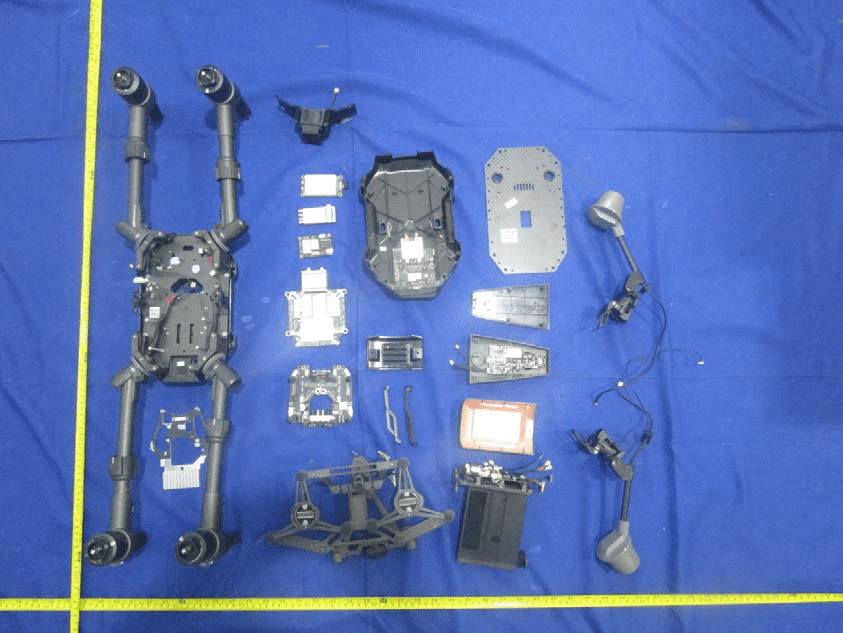

Teardown Layout: Complete System Overview

A comprehensive teardown presents a meticulously organized array of the Matrice 200 V2’s internal components. Multiple PCBs, antenna assemblies, and mechanical modules are laid out for inspection. Key highlights include densely populated boards with large SoCs, MCUs, and FPGAs—indicative of advanced processing for flight control, video, and telemetry. The use of multilayer PCBs (6+ layers), extensive EMI/RFI shielding, and modular connectors demonstrates DJI’s commitment to RF integrity and serviceability. Power management components, robust battery connectors, and multiple antenna types support high-current delivery and MIMO/diversity communication. The overall build quality is exemplary, reflecting the drone’s enterprise-grade mission profile.

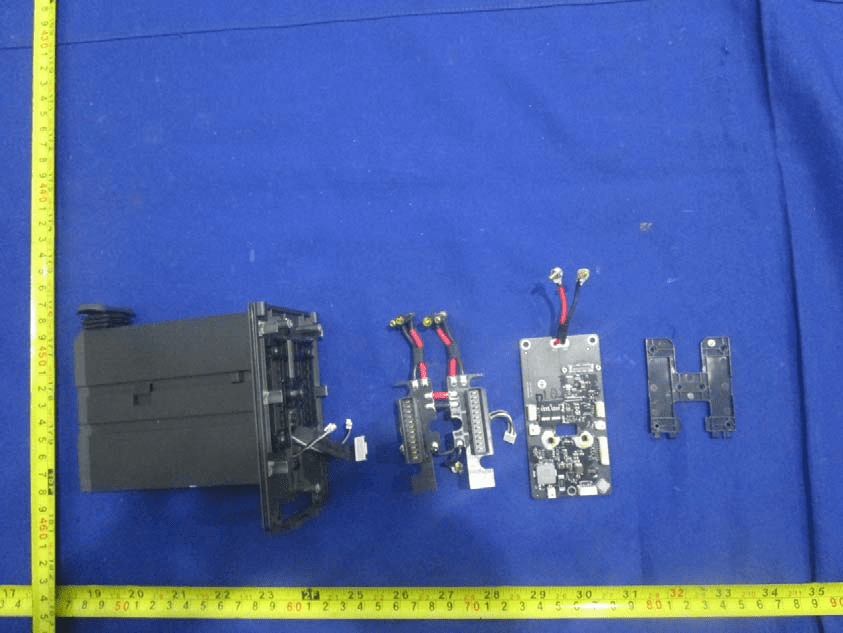

Power Management and Distribution Board

This module showcases a high-density black PCB engineered for power management and battery interface. Prominent features include large ICs (likely MCUs or power controllers), thick copper traces, and robust high-current connectors with thick gauge wiring—vital for safely delivering power to propulsion and onboard systems. The presence of multiple vias, differential pairs, and secure mounting reflects a design focused on reliability and thermal management. Dual coaxial connectors suggest integration with external telemetry or GNSS antennas. The sophisticated layout and component selection underscore the drone’s emphasis on power safety, monitoring, and modular assembly.

Battery/power management board with high-current connectors and robust PCB design.

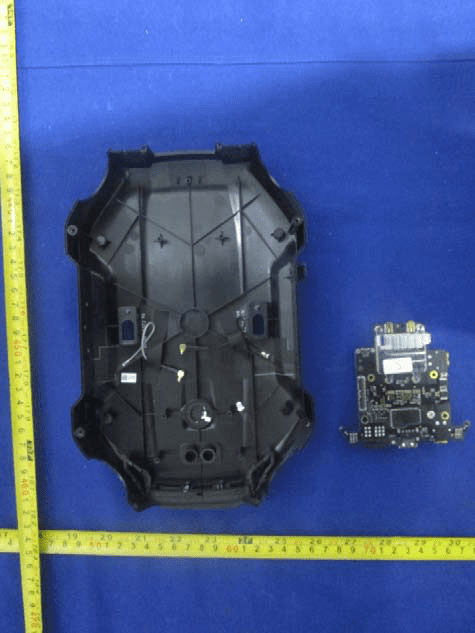

Main Processing and Communication Assembly

A densely populated main board is revealed, featuring a central BGA package (likely the flight controller SoC) surrounded by memory, RF transceivers, and power management ICs. The use of multi-layer PCB construction, extensive EMI shielding, and high-density connectors supports complex, high-speed data flows essential for real-time telemetry, video, and sensor integration. Coaxial antenna cables with U.FL connectors enable modular RF connectivity. The mechanical housing integrates mounting points and cable routing, reflecting a design optimized for vibration resistance and ease of maintenance.

Main PCB: high-density processing, RF sections, and EMI shielding exposed.

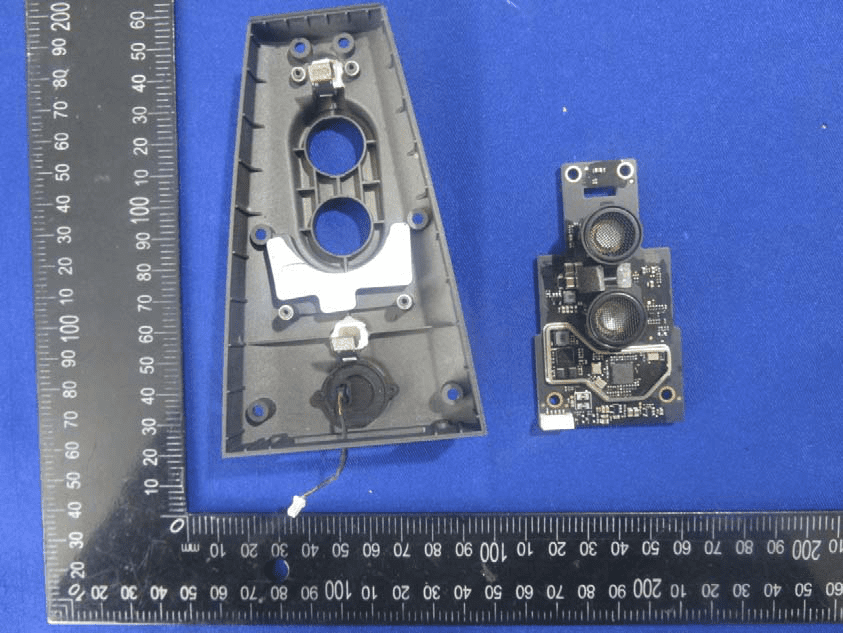

Stereo Vision / Obstacle Avoidance Module

A compact PCB is paired with dual lens assemblies, likely forming a stereo vision sensor for obstacle detection or navigation. The board features a microcontroller or image processor, power regulation circuitry, and a high-speed connector for data/power. Careful signal routing and robust grounding are evident, supporting high-fidelity image capture and processing. The plastic housing includes a buzzer or small speaker, likely for status alerts. This module exemplifies the Matrice 200 V2’s focus on safety and autonomous flight capability.

Stereo vision sensor module with dual lenses and high-speed data interface.

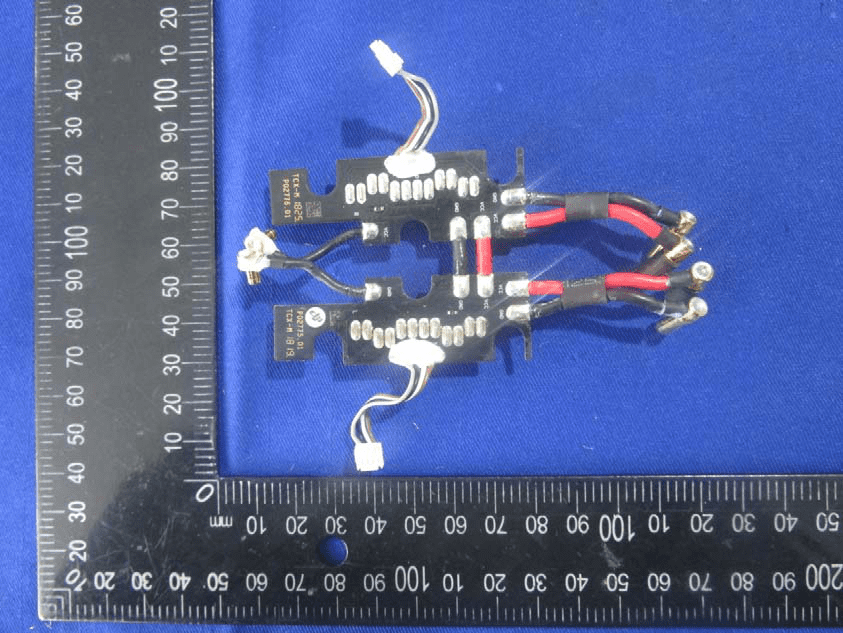

Dual Power Distribution/Current Sensing Boards

This pair of symmetrical, black PCBs is purpose-built for high-current distribution or current sensing—critical for motor power delivery and monitoring. The design prioritizes reliability, featuring thick copper traces, large solder pads, and heavy gauge wires with ring lugs for secure mounting. Surface-mount shunt resistors and discrete semiconductors support current sensing and protection. The absence of complex ICs or RF components signals a singular focus on robust, fail-safe power management for the drone’s propulsion system.

Power distribution/current sensing boards for motor power delivery.

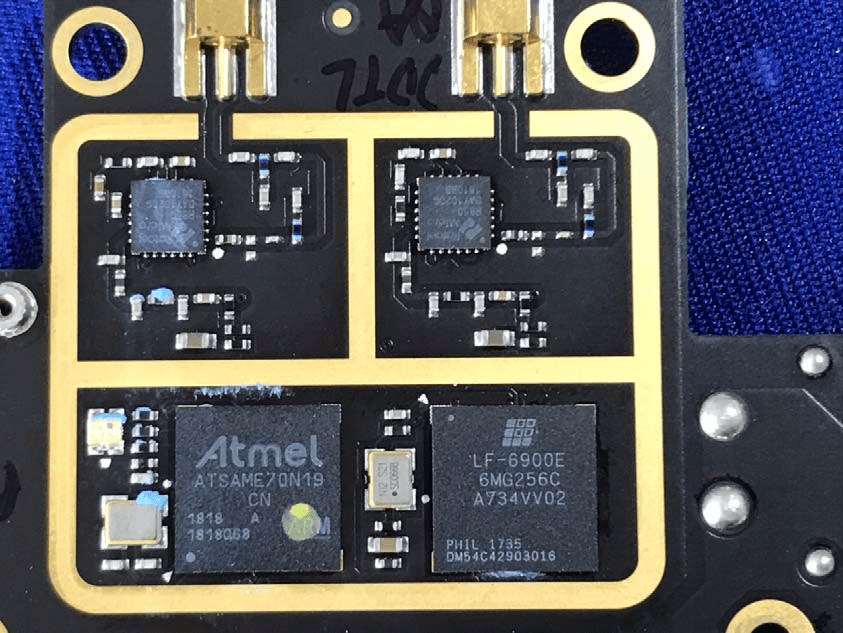

RF Processing and Control Section

A close-up of a high-quality black PCB exposes the Atmel ATSAME70N19 ARM Cortex-M7 microcontroller, paired with a likely custom memory or control IC. Gold-plated RF traces lead to edge-mounted U.FL connectors for external antennas, demonstrating meticulous RF design for minimal signal loss and strong EMI immunity. The multi-layer board, ENIG finish, and precise separation of analog and digital domains reinforce the platform’s commitment to high-performance wireless communication and robust telemetry links.

RF section: ARM Cortex-M7 MCU and dual RF antenna interfaces.

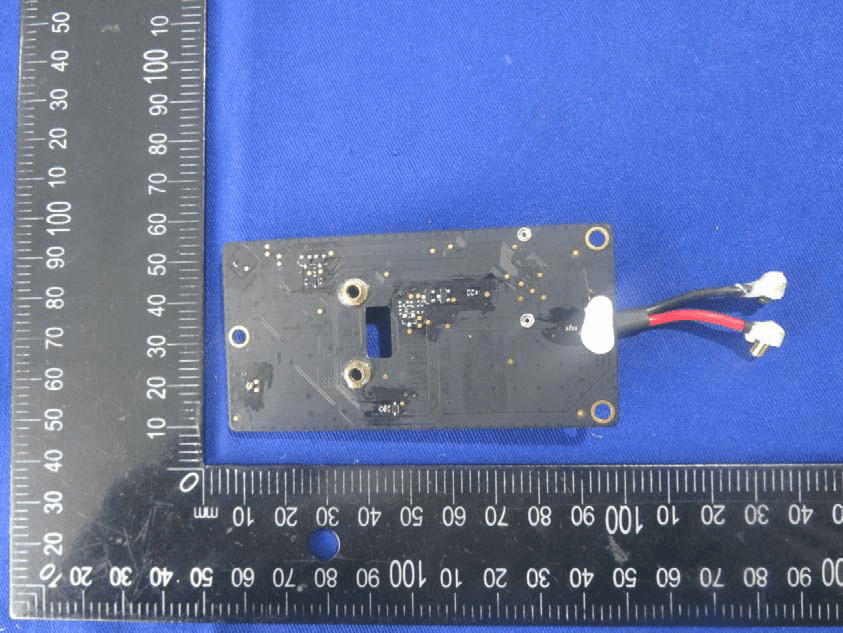

Secondary PCB (Back Side) – Power/Sensor Interface

This view displays the reverse side of a rectangular black PCB, likely a power distribution or sensor interface module. While major ICs are absent on this side, the presence of multi-layer construction, gold-plated mounting holes for grounding, and robust wiring with strain relief highlights attention to reliability in demanding flight conditions. Modular connectors support power and signal integration, and the design underscores the drone’s focus on serviceability and vibration resistance.

Rear PCB: robust wiring, grounding, and strain relief for power/sensor integration.

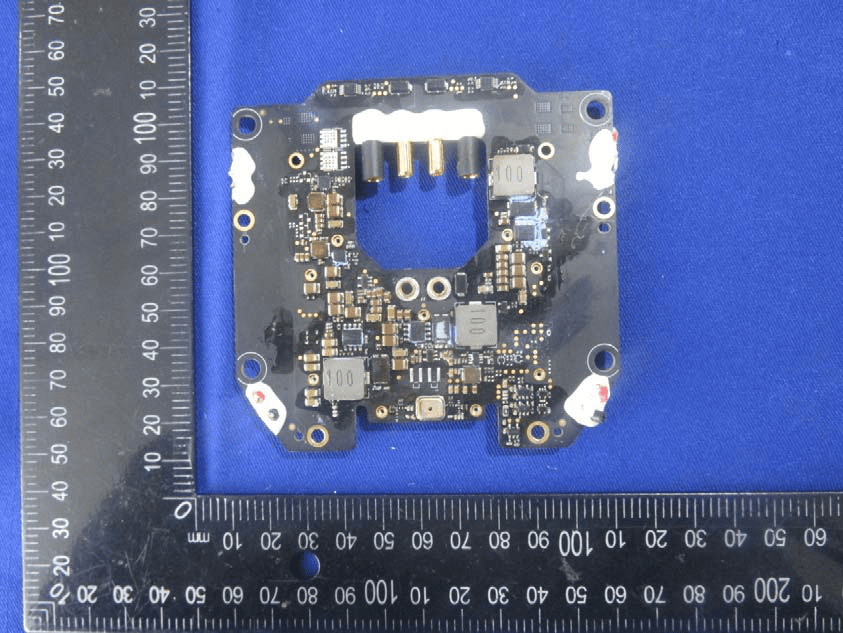

Power Regulation and Motor Control Board

A densely packed black PCB, approximately 70mm square, features large inductors, capacitors, and multiple power management ICs. Pogo pin connectors and FPC/FFC interfaces suggest modularity for subsystem integration. The compact layout, via stitching, and test points indicate a design optimized for high-current handling, signal integrity, and ease of diagnostics—likely serving as a power regulator or motor control board within the drone’s propulsion system.

Motor control/power regulation PCB with inductors and modular connectors.

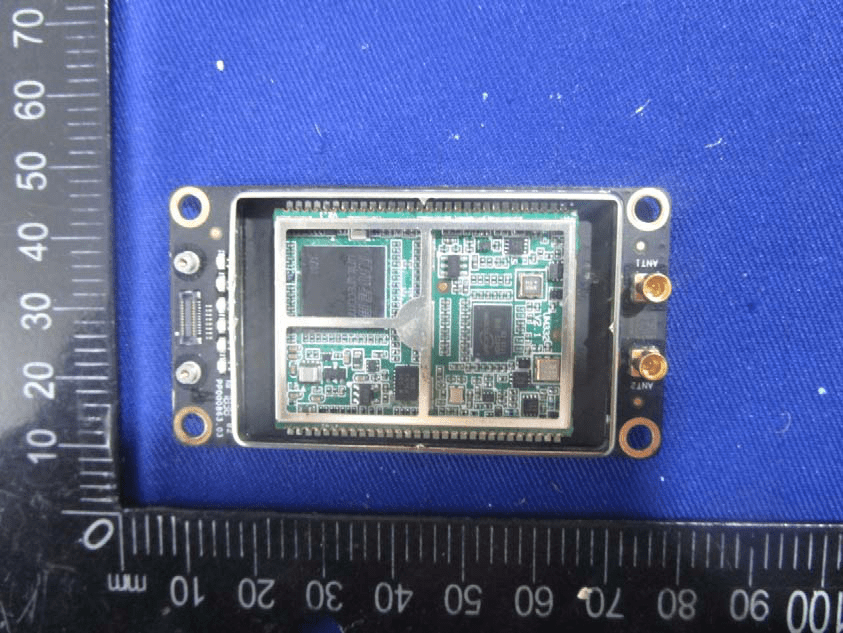

Dual-Antenna RF Communications Module

This module embodies DJI’s RF engineering expertise. The green multi-layer PCB hosts a shielded central section containing RF transceivers and power ICs, flanked by U.FL connectors labeled ANT1 and ANT2 for dual-antenna (MIMO or diversity) support. High-speed, controlled-impedance traces, robust ground planes, and test points are evident. The module’s compact, modular design and comprehensive shielding ensure reliable, interference-resistant wireless telemetry and control—vital for the Matrice 200 V2’s long-range operation.

Dual-antenna RF module: shielded transceivers and high-density PCB layout.

Regulatory Insights & FCC Filing

The Matrice 200 V2, certified under FCC ID SS3-M200V21811, has undergone rigorous testing to meet US electromagnetic interference and RF emission standards. This certification, registered with the FCC, is mandatory for legal sale and operation in the United States, ensuring that the device does not interfere with other wireless equipment and complies with all relevant safety regulations.

FCC filings for the M200 V2 include comprehensive documentation such as RF exposure test reports, electromagnetic compatibility (EMC) results, internal and external photographs, user manuals, and detailed block diagrams. These documents collectively verify that the drone’s wireless systems (including Wi-Fi, telemetry, and control links) operate within permitted frequency bands and power levels.

Key insights from the user manual and internal documentation emphasize the Matrice 200 V2’s industrial-grade construction, redundant safety systems, and advanced flight features—all designed to maximize reliability, safety, and operational flexibility. These features are validated through the FCC certification process, providing assurance to enterprise users that the drone is both technologically advanced and regulatory compliant.

Potential Use Cases & Target Audience

With its advanced capabilities, the DJI Matrice 200 V2 is tailored for industrial and professional users who require a dependable aerial platform for complex missions. Here are some practical scenarios where the M200 V2 excels:

- Infrastructure Inspection: Utility companies and civil engineers can leverage the drone’s smart flight features, precise GNSS positioning, and robust transmission links to safely inspect power lines, bridges, and pipelines—reducing risk and increasing efficiency.

- Public Safety & Emergency Response: Firefighters, police, and search-and-rescue teams benefit from the drone’s dual-battery redundancy, obstacle avoidance, and rapid deployment. Enhanced hovering precision and AirSense improve operational safety in dynamic, unpredictable environments.

- Surveying & Mapping: Surveyors and GIS professionals use the M200 V2’s intelligent automation, high wind resistance, and extended flight times to capture accurate geospatial data—even in remote or GNSS-challenged locations.

The Matrice 200 V2’s combination of rugged hardware, intelligent automation, and regulatory compliance makes it a top choice for professionals who demand mission-critical reliability and advanced aerial capabilities.

Conclusion

The DJI Matrice 200 V2 (Model: M200 V2) is a masterclass in industrial drone engineering—melding robust design, intelligent automation, and reliable wireless communication, all certified under FCC ID SS3-M200V21811. Its advanced internal components, comprehensive safety features, and regulatory compliance position it as a leader in the professional UAV market. For organizations that require a powerful, adaptable, and trustworthy flight platform, the Matrice 200 V2 sets the standard for what’s possible in modern commercial drone operations.