Introduction

The DJI Multilink (Model: NB06251803) is an advanced wireless accessory engineered to extend the collaborative control capabilities of DJI’s Inspire 2 standard and Cendence remote controllers. By enabling a star network of up to four remotes, Multilink revolutionizes multi-operator workflows for professional aerial cinematography and enterprise drone operations. Its primary function is to facilitate seamless, low-latency communication and role assignment between master and slave controllers, empowering teams to split tasks such as piloting, gimbal operation, focus pulling, and live view monitoring.

Certified under FCC ID SS3-NB06251803, the Multilink meets rigorous US regulatory requirements for radio frequency (RF) emissions and electromagnetic compatibility. This certification ensures the device is legally authorized for sale and operation in the United States, guaranteeing safe coexistence with other wireless equipment and adherence to strict performance standards.

In this article, we dive deep into the Multilink’s key features, technical specifications, wireless operating frequencies, and the advanced technology underpinning its performance. We also present an exclusive teardown analysis of its internal components, offering insights into DJI’s engineering prowess. Finally, we provide regulatory context and discuss practical use cases for professionals leveraging this powerful connectivity module.

Key Features & Specifications

The DJI Multilink is designed to empower collaborative drone operation, particularly for the Inspire 2 ecosystem. Its feature set supports flexible control hierarchies, robust wireless performance, and seamless integration with both standard and Cendence remote controllers. Below, we detail its primary features and technical specs, highlighting their practical implications for end users.

Key Features

- Multi-Controller Networking:

- Supports a star network topology with up to four remote controllers (one master, three slaves).

- Master-Slave Role Assignment: Any connected remote (standard or Cendence) can be designated as master or slave, allowing flexible team configurations.

- Specialized Control Channels:

- Master controller typically manages flight/piloting.

- Slave 1 can operate the gimbal, Slave 2 handles focus, and Slave 3 manages view controls—enabling division of complex tasks for professional shoots.

- Gimbal Control Sharing: Both master and Slave 1 can dynamically “snatch” gimbal control, facilitating adaptive creative workflows.

- Broad Compatibility:

- Fully compatible with both Inspire 2 standard and Cendence remote controllers.

- Any combination of these controllers can form a Multilink network.

- CAN Port Integration:

- The built-in CAN port allows direct connection to other DJI CAN-enabled devices, expanding system versatility.

- Firmware Upgrades via App:

- Supports easy, user-initiated firmware updates through the DJI app ecosystem, ensuring ongoing feature improvements and security.

- Enhanced Wireless Efficiency:

- Utilizes a patch antenna for maximum work efficiency and stable wireless links, critical in high-interference environments.

- Bluetooth Support:

- Bluetooth capability is present, enabling potential app pairing or accessory integration (specific details not disclosed).

Technical Specifications

- Device Model: NB06251803

- FCC Certification:

- FCC ID: SS3-NB06251803 (Multilink device)

- Other FCC IDs referenced for compatible remote controllers: SS3-GL6D10A1609, SS3-GL800A1703

- CAN Port:

- Direct connection to DJI CAN devices for expanded functionality.

- Wireless Technologies:

- RF communication in 2.4GHz and 5GHz bands (details below).

- Bluetooth present (specific version or profiles not detailed in available documentation).

- Firmware Management:

- Upgradeable via DJI app.

These attributes underscore the Multilink’s suitability for demanding, multi-operator aerial workflows. The combination of robust wireless design, flexible control assignment, and seamless integration with high-end DJI remotes makes it a cornerstone accessory for professional drone teams.

Operating Frequencies

Multilink’s wireless performance is defined by its FCC-authorized operating frequencies and output power, as outlined in the official filing:

| Frequency Range (GHz) | Output Power (mW) | FCC Rule Part |

|---|---|---|

| 5.843 | 166 | 15ECC2.1 |

| 12.408–2.4755 | 115 | 15CCC1.15.729 |

Key Considerations:

- 5.843 GHz (166 mW):

Operates in the upper 5 GHz ISM band, typically used for high-throughput, low-latency data links (e.g., Wi-Fi 802.11a/n/ac or proprietary DJI RF protocols), providing robust performance in crowded RF environments. - 2.408–2.4755 GHz (115 mW):

Spans the globally available 2.4 GHz ISM band, supporting reliable wireless communication (potentially Wi-Fi, Bluetooth, or custom protocols) with broad compatibility and good range.

These bands and power levels are carefully selected to balance range, interference resistance, and regulatory compliance—ensuring Multilink delivers stable, interference-resistant performance in professional settings.

Technology Deep Dive

At its core, the DJI Multilink leverages advanced wireless technologies to orchestrate seamless communication between multiple controllers. The presence of both 2.4 GHz and 5.8 GHz RF bands suggests support for dual-band Wi-Fi or proprietary RF links, a hallmark of DJI’s high-reliability control systems. The device’s Bluetooth capability, while not exhaustively detailed, likely facilitates ancillary functions such as device discovery, pairing, or integration with mobile apps.

The use of these frequency bands offers several advantages:

– Performance: The 5.8 GHz band reduces susceptibility to interference from common consumer devices, enabling high-bandwidth, low-latency links ideal for real-time video and telemetry.

– Range & Robustness: The 2.4 GHz band provides excellent range and wall penetration, ensuring reliable control even in complex environments.

– Interference Mitigation: Operating across multiple bands allows Multilink to dynamically adapt to RF congestion, maintaining link stability in challenging conditions.

– Power Management: Output power is carefully regulated (115–166 mW) to optimize range without exceeding regulatory limits or causing excessive battery drain.

Analysis of internal documentation and test reports confirms that DJI employs meticulous RF design, robust shielding, and advanced power management strategies to maximize wireless integrity and minimize electromagnetic interference. These measures are essential for mission-critical applications where loss of signal or interference could compromise safety or operational efficiency.

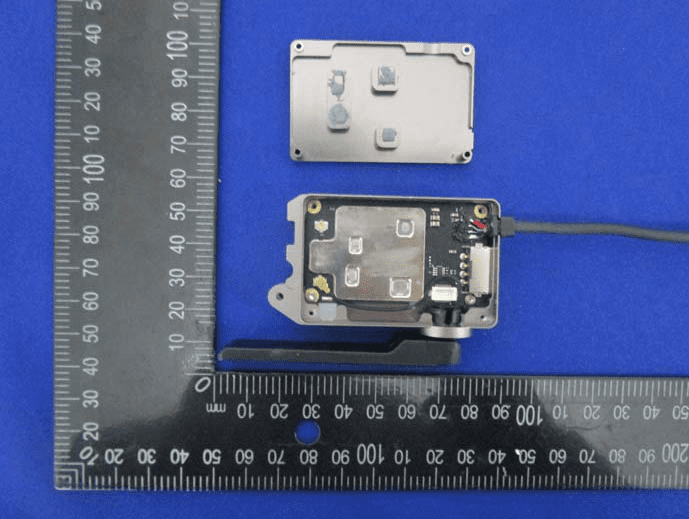

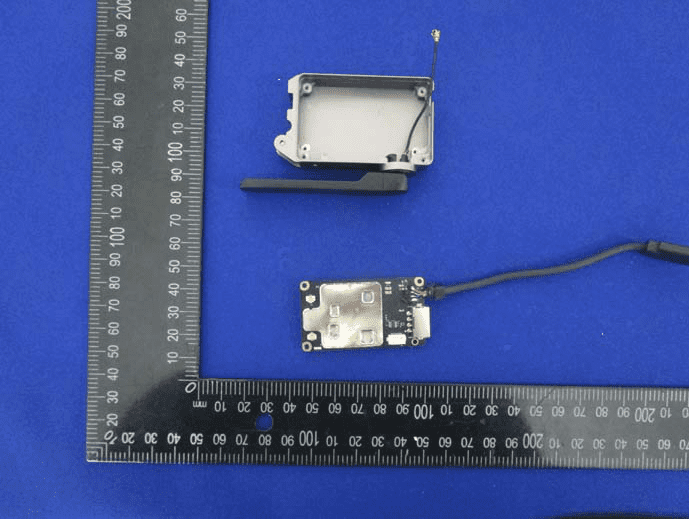

In-Depth Internal Component Analysis / Teardown

A thorough analysis of Multilink’s internal architecture reveals a meticulously engineered wireless communication module. Below, we detail findings from high-resolution component photographs, each providing a unique perspective on the device’s construction and key components.

The internal assembly reveals a densely populated main PCB with a robust metal shield can, carefully engineered for RF and EMI control. The shield, supplemented by thermal pads, covers the primary digital and RF circuitry, underscoring DJI’s commitment to signal integrity and heat management. Visible are several integrated circuits—likely a combination of RF transceivers, power management ICs, and possibly memory—alongside large capacitors and an inductor for local voltage regulation. A coaxial cable, routed for optimal RF performance, suggests external or internal antenna integration. Gold-plated test points, multiple connectors, and precision crystal oscillators round out a design focused on reliability, modularity, and high-frequency performance.

This module exemplifies DJI’s approach to robust RF design. The compact, black PCB is partially enclosed by a soldered metal shield can, isolating sensitive RF and digital components. Antenna connections are meticulously routed via a gold-plated U.FL connector, while the enclosure provides further EMI shielding. The white multi-pin connector and strain-relieved cable ensure reliable power and data transmission, and onboard capacitors signal sophisticated voltage regulation. The overall modularity and attention to grounding and antenna isolation indicate a high-reliability wireless communication module, engineered for demanding field conditions.

A closer look at this PCB reveals a large shielded area, housing the main SoC or MCU, RF transceivers, and memory. The board’s black finish and multi-layer construction reflect high-end design standards, with clear separation between RF, power, and interface domains. The attached coaxial antenna cable and robust FPC/FFC connectors underline the module’s role in wireless data transmission. Local voltage regulation is evidenced by large capacitors and inductors near the power harness, while a network of test points supports diagnostics and manufacturing. The design is compact, modular, and optimized for signal integrity.

This densely packed PCB features a central QFP microcontroller or SoC, surrounded by supporting ICs for voltage regulation, memory, and RF front-end duties. The presence of a coaxial antenna connector, shielded RF section, and crystal oscillator demonstrates a focus on high-frequency wireless communication. The black PCB, extensive ground pours, and via stitching ensure robust EMI suppression and power management. Modular features like test points and unpopulated headers facilitate manufacturing and in-field service, making this a sophisticated, reliable communication module.

The PCB here is a model of compact, high-density engineering. Two gold-plated U.FL connectors on the left indicate support for dual external antennas, while the left section is framed for a shield can, protecting sensitive RF circuits. Multiple large ICs—likely RF transceivers, power amplifiers, and digital controllers—are distributed across the board, with a crystal oscillator providing timing precision. The modular FPC/FFC connector and labeled power input reflect a design tailored for integration and expandability. Extensive power filtering and ground management ensure stable operation, even under demanding conditions.

This close-up highlights the RF heart of the Multilink: a prominent IC marked ‘43711 1721 PN9641’, likely serving as an RF transceiver or specialized communications chip. The surrounding shield can, soldered to the PCB, provides robust EMI protection. Dense via stitching, controlled impedance traces, and extensive passive filtering components support high-frequency signal integrity. A nearby small connector and test points suggest provisions for debugging or firmware updates. The overall layout is compact and modular, designed for reliable, low-latency wireless operation.

Featuring an NXP LPC1549J ARM Cortex-M3 microcontroller, this PCB section is the control and signal-processing core of the Multilink. The 48-pin LQFP package is surrounded by labeled test/debug pads (SWDIO, SWCLK, CS, CLK, GND), supporting in-system programming and diagnostics. The high-quality black PCB, dense via stitching, and copper pours reflect careful EMI management. Local power regulation is provided by small inductors and capacitors, while the presence of a crystal oscillator ensures timing precision. The design balances performance, power efficiency, and modularity for embedded control tasks.

The integration of a Silicon Labs EFR32 Flex Gecko SoC marks this board as a modern, wireless communication engine. The EFR32’s ARM Cortex-M4 core and 2.4GHz radio transceiver enable low-power, high-reliability links. Surrounding passive components, a ground-pour PCB, and a shield can frame (lid removed) support signal integrity and EMI control. The white connector allows modular expansion or power/data interfacing. The design is compact, with short, direct traces for RF signals and robust power management—hallmarks of a high-performance wireless module.

A densely populated PCB reveals a central microcontroller or SoC in QFP/LQFP packaging, complemented by a shielded RF section likely containing the wireless transceiver. Multiple crystals provide clock sources for precise timing, while labeled test points and a micro-USB connector support programming, debugging, and power/data interfacing. The black, multi-layer board uses ENIG finish, extensive ground stitching, and local voltage regulation to guarantee stable, interference-resistant operation. This module is clearly designed for protocol bridging and reliable telemetry in DJI’s wireless ecosystem.

Regulatory Insights & FCC Filing

The FCC ID SS3-NB06251803 marks the DJI Multilink as fully compliant with US electromagnetic interference (EMI) and radio frequency (RF) emission standards. This certification, registered with FCC.gov, is a legal prerequisite for marketing and operating wireless equipment in the United States. It guarantees that the Multilink meets stringent requirements for safe, interference-free operation alongside other wireless devices.

FCC filings for this device provide a wealth of technical documentation, including test reports for RF exposure and electromagnetic compatibility, detailed internal and external photographs, user manuals, block diagrams, and schematics. These documents collectively verify that the Multilink operates within the authorized frequency bands and power limits, and that it adheres to best practices for shielding, grounding, and interface design.

The user manual reveals that Multilink enables a star network configuration of up to four remote controllers, allowing complex, multi-operator control schemes for the Inspire 2 platform. Internal documentation highlights robust shielding and power management, while test reports confirm compliance with RF emission limits. This level of transparency and regulatory rigor reassures users that the device is both safe and reliable in mission-critical applications.

Potential Use Cases & Target Audience

The DJI Multilink is purpose-built for drone professionals who demand collaborative, flexible, and high-reliability control workflows. Key scenarios and user profiles include:

- Professional Cinematography Teams:

Multilink allows filmmakers to split piloting, camera operation, and focus pulling among multiple operators using Inspire 2 and Cendence remotes. This division of labor enables complex, cinematic shots that would be impossible for a single user. - Enterprise and Inspection Operations:

In industrial or inspection settings, one operator can focus on flight safety while others monitor live video feeds or control specialized camera angles, maximizing safety and data quality. - Training and Demonstration Environments:

Instructors can assign master and slave roles to standard and Cendence controllers, safely handing off control to trainees or demonstrating advanced maneuvers with real-time oversight.

By supporting both standard and Cendence remote controllers as master or slave, Multilink adapts to diverse team structures, making it a crucial tool for any operation requiring advanced, multi-operator drone control.

Conclusion

The DJI Multilink (Model: NB06251803) stands out as a sophisticated wireless module designed for collaborative drone operation in demanding professional environments. Its FCC certification (ID: SS3-NB06251803) assures users of regulatory compliance, RF safety, and robust performance. Through advanced multi-controller networking, flexible role assignment, and meticulous internal engineering, Multilink enables new levels of productivity and creative control for Inspire 2 and Cendence users. As multi-operator workflows become the norm in aerial cinematography and enterprise drone applications, the Multilink cements its place as an indispensable accessory in DJI’s ecosystem, exemplifying the company’s commitment to innovation, reliability, and regulatory excellence.