Introduction

The DJI Cendence Remote Controller (Model: GL800A) stands as a flagship-grade, professional controller engineered for advanced drone operations. Designed to deliver precise, reliable, and highly customizable control, it targets power users who demand robust RF performance and flexible interface options. With an array of programmable buttons, support for dual operator setups, and seamless integration with DJI’s CrystalSky monitors, the Cendence is purpose-built for demanding aerial cinematography, industrial inspection, and enterprise drone tasks.

Crucially, this device is certified under FCC ID SS3-GL800A1703, ensuring it meets stringent US electromagnetic emission standards. While the grant date is listed as “None,” the registration guarantees the controller is legally marketable and compliant with RF regulations. This analysis provides a comprehensive look at the Cendence Remote Controller’s key features, technical specifications, wireless capabilities, and a detailed teardown of its internal components—offering unique insights for engineers, tech enthusiasts, and professionals interested in DJI’s wireless technology and regulatory compliance.

Key Features & Specifications

The DJI Cendence Remote Controller (Model: GL800A) is packed with sophisticated features and robust technical specifications tailored for professional-grade drone operations. Here’s a detailed breakdown:

Key Features

- Multiple Customizable Buttons

- Includes C1–C4, BA–BH, and more, allowing users to assign functions for streamlined workflows and rapid access to critical features.

- Dual Remote Controllers Support

- Enables master-slave operation, with each controller able to independently manage aircraft or camera controls, and operate up to 328 feet (100 m) apart for collaborative missions.

- DJI LIGHTBRIDGE Technology

- Employs DJI’s proprietary long-range digital transmission system, supporting up to 4.3 miles (7 km) of video and control link—ideal for extended-range operations.

- Dual Frequency Operation

- Supports both 2.4 GHz and 5.8 GHz bands, ensuring a stable HD video downlink and robust control signal, even in congested RF environments.

- CrystalSky Monitor Compatibility

- Features a dedicated mount and power output for DJI’s high-brightness CrystalSky monitors, enhancing visibility in outdoor conditions.

- Intelligent Battery System

- Equipped with a 4923 mAh LiPo battery, providing up to 4 hours of runtime and rapid charging support for minimal downtime.

- Optimized Storage and Charging

- Safe storage at various temperatures and fast recharge (as little as 1.5 hours with the IN2CH Charging Hub or 2 hours 24 minutes with a 180W charger).

- Rugged, Modular Design

- Engineered for field reliability, with modular subassemblies for easy servicing, and robust construction for demanding environments.

Technical Specifications

- Output Power

- 20W (when supplying power to DJI CS550 monitor)

- 12W (without monitor)

- Battery

- 4923 mAh LiPo; intelligent management for safety and longevity

- Charging time: ~1 hour 30 min (IN2CH Charging Hub) or ~2 hours 24 min (180W charger)

- Maximum run-time: ~4 hours (master-only, no monitor)

- Weight

- 1041 g (controller only)

- Storage Temperature

- <3 months: -4°F to 113°F (-20°C to 45°C)

-

3 months: 72°F to 82°F (22°C to 28°C)

- Charging Temperature

- 32°F to 104°F (0°C to 40°C)

- Wi-Fi & RF Bands

- 2.4G: LB: 2404–2478.8 MHz; 10M: 2412–2462 MHz

- 5.8G: LB: 5727–5821.3 MHz; 10M: 5745–5825 MHz

- Bluetooth

- Present (specification details not available)

- Other

- Dual remote controllers: Each can control aircraft and camera separately, up to 328 feet apart

Benefits in Practice:

These features enable mission-critical flexibility—whether for dual-operator film shoots, complex industrial inspections, or high-precision mapping. The customizable interface and robust wireless architecture ensure the Cendence remains responsive and reliable in challenging RF environments, while its modular build simplifies maintenance and upgrades.

Operating Frequencies

As documented in the FCC filing for FCC ID SS3-GL800A1703, the Cendence Remote Controller operates across multiple frequency ranges and power levels, supporting its advanced wireless communication capabilities:

| Frequency Range (GHz) | Output Power (mW) | FCC Rule Part |

|---|---|---|

| 2.404–2.4788 | 933 | 15CCC1.12.404 |

| 2.462 | 343 | 15CCC |

| 2.4788 | 933 | 15CCC3.12.412 |

| 15.727–5.8213 | 274 | 15E38 |

| 15.745–5.825 | 133 | 15E38 |

| 22.412–2.462 | 343 | 15CCC |

| 25.727–5.8213 | 274 | 15E38 |

| 25.745–5.825 | 133 | 15E38 |

These frequency allocations and power levels are critical for ensuring reliable, interference-resistant operation in both short- and long-range drone control scenarios. They align with the device’s support for dual-frequency (2.4 GHz and 5.8 GHz) operation, which is essential for robust HD video and telemetry downlinks.

Technology Deep Dive

The Cendence Remote Controller leverages a suite of advanced wireless technologies to deliver high-performance drone control and video transmission. Its primary communication links are based on Wi-Fi and proprietary RF protocols, underpinned by DJI’s LIGHTBRIDGE system. The dual-band (2.4 GHz and 5.8 GHz) operation allows for dynamic frequency selection, helping to mitigate interference and maximize range in congested environments.

Bluetooth functionality is present, likely for auxiliary device pairing or configuration, although specific implementation details are not provided in the documentation. The range and output power levels, as outlined in the FCC test data, support robust, low-latency control and HD video downlink over several kilometers—vital for professional applications.

Operating across these bands enables the Cendence to maintain stable links even in challenging RF conditions, while also conforming to regulatory power limits for safety and legal operation. The use of modular, shielded RF hardware and PCB-integrated antennas further enhances signal integrity and reduces susceptibility to external interference. Overall, the technology stack reflects DJI’s focus on reliability, range, and regulatory compliance for mission-critical drone operations.

In-Depth Internal Component Analysis / Teardown

Rotary Encoder and User Input Sub-Board

A compact sub-board houses a prominent blue rectangular component marked ‘1038 703C’, which functions as a potentiometer or rotary encoder—essential for precise analog user input such as dial or knob control. The board’s clean, black FR4 construction, flat flexible cable interface, and minimal component count suggest a low-power, high-reliability design focused on user interface functionality. No RF, power, or processing components are present, reinforcing its role as a modular input assembly. The robust mounting and straightforward layout facilitate easy replacement and long-term durability, aligning with the professional build standards expected in the Cendence Remote Controller.

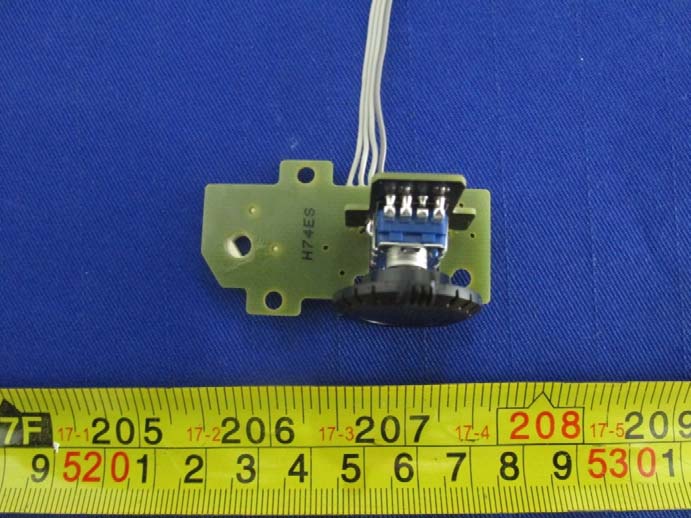

Simple Rotary Encoder Subassembly

This subassembly consists of a green, single-sided PCB supporting a mechanical rotary encoder or potentiometer, with minimal trace routing and a bundle of connecting wires. Its straightforward design—lacking complex ICs or RF components—reflects its role as a dedicated user interface element, likely for adjusting gimbal or camera parameters. Through-hole mounting ensures mechanical stability, while the modular wiring enables straightforward integration and maintenance. The design prioritizes reliability and ease of service, making it a vital yet uncomplicated part of the controller’s overall user input system.

Modular Switch Assemblies

A collection of small, single-sided PCBs populated with tactile switches and lever actuators forms the backbone of the Cendence’s customizable button interface. The green FR4 boards, connected via flat ribbon cables, are optimized for high-cycle reliability and ease of replacement. Their wide traces and basic grounding reflect low-speed, low-frequency operation, suitable for direct user input rather than signal processing or RF communication. The modular design ensures that individual switch assemblies can be serviced independently, supporting the controller’s field-repairable architecture.

Indicator and Toggle Switch Modules

This set of internal modules features small black PCBs equipped with tactile pushbuttons, toggle switches, and likely indicator LEDs. Connected via flat flexible cables and labeled for specific functions (e.g., ‘FOCUS-R’, ‘HL-ASS’), these subassemblies handle critical user interface roles such as mode selection and input feedback. The minimal component density and absence of complex ICs or RF elements highlight their dedicated function as reliable, modular user input and status indicator units, further contributing to the controller’s customizable and serviceable design ethos.

Shielded RF/Digital Module

Dominating the internal architecture is a high-density, multi-layer PCB module enveloped in extensive EMI/RFI shielding. The presence of a coaxial RF connector, gold-finger edge connector, and robust grounding points signifies its central role in wireless communication—likely integrating RF transceivers, digital processing, and power management ICs beneath the shields. The modular, serviceable construction allows for future upgrades or repairs, while the heavy shielding and careful partitioning ensure optimal RF performance and minimal interference—critical for long-range, high-reliability drone control.

Integrated Antenna PCB and Shielding

A white PCB featuring large planar copper traces acts as the integrated antenna system, optimized for operation in the 2.4 GHz and/or 5.8 GHz ISM bands. The substantial metal plate adjacent to the board serves as both EMI/RFI shielding and mechanical reinforcement. The design leverages PCB antennas for compactness and reliability, with careful attention to trace geometry and grounding to ensure consistent, high-quality wireless performance—underscoring DJI’s expertise in RF engineering for mission-critical applications.

Main Controller PCB and Housing

The main PCB, housed within the controller’s robust chassis, features multiple high-integration ICs (likely including the main SoC, RF transceivers, and memory), dense via structures, and a modular layout with FPC/FFC connectors for joysticks, buttons, and displays. Extensive power management circuits, test points, and crystal oscillators are evident, supporting the controller’s complex RF, video, and telemetry functions. The design also accommodates coaxial connectors for external or internal antennas, with a focus on EMI/RFI control and mechanical stability. The overall construction reflects DJI’s commitment to high build quality, modularity, and serviceability in professional equipment.

Antenna Subsystem and RF Module

A pair of large, white PCB antennas and a compact black PCB module comprise the core of the Cendence’s RF front-end. The antennas, likely of IFA or similar planar design, are engineered for efficient 2.4 GHz/5.8 GHz operation, while the small module hosts RF signal processing or antenna switching ICs. Clean trace routing, modular construction, and attention to ground plane integrity ensure robust wireless communication and ease of assembly or replacement—hallmarks of a well-designed RF subsystem in a high-end controller.

Regulatory Insights & FCC Filing

FCC ID SS3-GL800A1703 certifies that the DJI Cendence Remote Controller (GL800A) meets all US regulatory requirements for RF emissions and electromagnetic compatibility. Although the grant date is listed as “None,” the device is registered with the FCC, confirming its legal status for sale and operation within the United States.

FCC filings for this device include a comprehensive set of technical documents: RF exposure and EMC test reports, internal and external photographs, user manuals, schematics, and block diagrams. These documents provide transparency into the device’s wireless operation, safety margins, and engineering practices.

Manuals referenced in the filing—such as ‘User-Manual-3555635.pdf’ and ‘Users-Manual-3405496.pdf’—highlight the controller’s use of DJI’s LIGHTBRIDGE technology, dual-frequency HD video downlink, and advanced dual-operator support. The technical data ensures the Cendence operates safely within FCC-mandated RF limits, minimizing interference with other spectrum users and guaranteeing reliable, legal operation for professional users. This regulatory compliance underscores DJI’s commitment to high standards in both engineering and market access.

Potential Use Cases & Target Audience

While the FCC documentation does not specify a target audience, the Cendence Remote Controller’s feature set and technology clearly position it for:

- Professional Aerial Cinematographers

- The customizable interface, dual-operator support, and extended transmission range make it ideal for complex film shoots where separate operators control the drone and camera, ensuring cinematic precision and safety.

- Industrial Inspectors and Surveyors

- The robust wireless links and modular design suit critical infrastructure inspection, mapping, and surveying tasks, where reliability, long-range operation, and quick field maintenance are paramount.

- Enterprise and Mission-Critical Operators

- Organizations requiring live HD video feeds, precise multi-operator control, and seamless integration with DJI’s professional ecosystem will benefit from the Cendence’s advanced capabilities.

In these scenarios, users can operate controllers up to 328 feet apart, access live HD video through DJI’s apps, and leverage the platform’s flexibility for demanding, high-stakes applications.

Conclusion

The DJI Cendence Remote Controller (Model: GL800A, FCC ID SS3-GL800A1703) exemplifies cutting-edge design in professional drone control systems. Its robust wireless architecture, modular internal construction, and extensive user interface customization deliver unmatched flexibility and reliability. FCC certification assures users of its regulatory compliance and legal marketability in the US. For enterprise, industrial, and creative professionals demanding the highest standards in control, performance, and serviceability, the Cendence stands as a benchmark in DJI’s lineup—combining engineering excellence with real-world utility.