Introduction

The SPARK Remote Controller by SZ DJI TECHNOLOGY CO., LTD. (Model: C2) stands as a sophisticated command center for DJI’s Spark drone, empowering pilots with robust, long-range control and real-time video transmission. Designed to extend the operational capabilities of the Spark aircraft, this controller leverages advanced wireless technologies and ergonomic engineering to deliver an intuitive, reliable, and feature-rich piloting experience.

Certified under FCC ID SS3-GL100A1704, the SPARK Remote Controller meets stringent US regulatory requirements for RF emissions, ensuring it is both legal to sell and safe to operate within the United States. While its grant date is listed as “None,” its registration with the FCC underscores its compliance with all applicable electromagnetic compatibility and interference standards.

This article provides an expert-level exploration of the SPARK Remote Controller’s key features, technical specifications, wireless technology, and internal components—supported by detailed teardown insights. We’ll also cover its regulatory context and highlight practical use scenarios for both hobbyists and professionals seeking precise, long-range drone control.

Key Features & Specifications

The SPARK Remote Controller is engineered to maximize the performance and usability of the DJI Spark drone. Its design and feature set cater specifically to pilots demanding extended range, robust connectivity, and seamless integration with mobile devices for live video feeds and advanced flight control.

Key Features

-

Amplified Wi-Fi Signal Transmission:

Utilizes a brand-new, high-powered Wi-Fi system to ensure strong, stable connections between the remote and the Spark drone, even at extended distances. -

Automatic Power-Off:

Conserves battery life by shutting down automatically after 6 minutes of inactivity—ideal for field operations where efficiency matters. -

Wireless Mobile Device Connectivity:

Connects wirelessly to smartphones or tablets, allowing pilots to view live HD video feeds and access flight telemetry via the DJI GO 4 app. -

Micro USB Charging:

Supports convenient, fast charging through a standard Micro USB port. -

Long-Distance Transmission:

Boasts a maximum transmission range of up to 1.2 miles (2 km) under FCC conditions, enabling pilots to push the boundaries of aerial exploration. -

Exclusive Spark Compatibility:

Designed specifically for the DJI Spark aircraft, ensuring optimal integration and reliability. -

Folding Mobile Device Clamp:

Features a folding clamp to securely hold a wide range of mobile devices, enhancing ergonomic comfort and flight control.

Technical Specifications

-

Operating Temperature Range:

32° – 104℉ (0° – 40℃) -

Operating Voltage:

950 mA @ 3.7 V -

Supported Mobile Device Size:

- Thickness: 6.5mm–8.5mm

-

Max Length: 160mm

-

Built-in Battery:

2970mAh (maximum remote controller battery life: approximately 2.5 hours) -

Charging Time:

Approximately 2 hours -

Max Transmission Distance (Unobstructed, Free of Interference):

- 2.4 GHz:

- 1.2 mi (2 km, FCC)

- 0.31 mi (0.5 km, CE/SRCC)

-

5.8 GHz:

- 1.2 mi (2 km, FCC)

- 0.19 mi (0.3 km, CE)

- 0.75 mi (1.2 km, SRCC)

-

Operating Frequencies:

2.412–2.462 GHz; 5.745–5.825 GHz -

Wireless Technologies:

- Wi-Fi: 2.4 GHz and 5.8 GHz bands

-

Bluetooth: Present (details not specified)

-

Other Features:

- Folding device clamp for secure smartphone/tablet attachment

- Modular design for ease of assembly and maintenance

Benefits in Practice:

These specifications translate to a controller that is durable in diverse weather conditions, offers extended operational time, and supports seamless, high-quality video streaming. The amplified Wi-Fi system and advanced antenna design ensure minimal signal dropouts, even in challenging environments. The robust battery and efficient power management make it ideal for both short and extended missions.

Operating Frequencies

The SPARK Remote Controller (FCC ID SS3-GL100A1704) operates across multiple frequency bands and output power levels, as documented in its FCC filing. These parameters are crucial for understanding its wireless range, regulatory compliance, and resistance to interference.

| Frequency Range (GHz) | Output Power (mW) | FCC Rule Part |

|---|---|---|

| 2.412–2.462 | 4 | 15CCC1.12.412 |

| 2.462 | 234 | 15CCC |

| 15.745–5.825 | 181 | 15E38 |

| 25.745–5.825 | 4 | 15E38 |

- 2.4 GHz and 5.8 GHz Bands: These are standard for Wi-Fi and many proprietary drone communication protocols, chosen for their balance of range, bandwidth, and resistance to interference.

- Output Power: Higher output at specific points (e.g., 234 mW at 2.462 GHz) enables the controller to maintain strong, reliable connections over longer distances and through potential obstacles.

These frequency and power settings ensure the controller delivers robust communication, while complying with FCC Part 15 rules for unlicensed wireless devices.

Technology Deep Dive

The SPARK Remote Controller employs advanced wireless technologies, primarily leveraging Wi-Fi in both the 2.4 GHz and 5.8 GHz ISM bands. This dual-band approach allows the controller to dynamically select the optimal frequency for minimal interference and maximum range—a critical feature for drone operation in RF-congested environments.

Wi-Fi is the backbone of the controller’s communication with the Spark aircraft, providing high-throughput, low-latency links necessary for real-time video transmission and responsive flight control. The use of an amplified Wi-Fi system, as indicated in both the product documentation and teardown analysis, suggests the integration of robust RF amplifiers and carefully engineered antenna systems. This ensures stable connections at distances up to 2 km under ideal conditions.

Bluetooth support (details unspecified) may be present for pairing or auxiliary device connectivity, but the primary data and video link is handled over Wi-Fi. The absence of cellular modules (as per equipment class) confirms a focus on direct, device-to-device RF communication.

The controller’s operating frequencies are chosen for their proven reliability in consumer electronics. The 2.4 GHz band offers longer range and better penetration through obstacles, while 5.8 GHz provides higher bandwidth and less congestion in some environments. Output power and antenna design are carefully balanced to maximize range without exceeding regulatory limits or causing undue interference.

Test reports from the FCC filing (notably, test report summaries) confirm the device meets all required standards for RF emissions and electromagnetic compatibility, ensuring both user safety and minimal impact on other wireless devices.

In-Depth Internal Component Analysis / Teardown

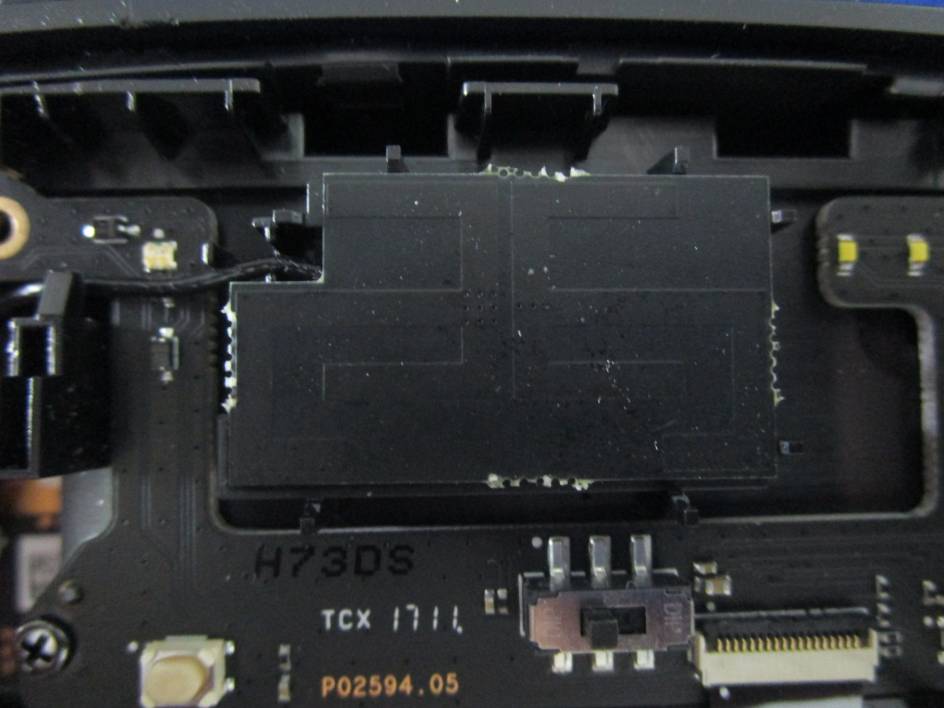

Main PCB with RF Shielding and Antenna Connection

The main circuit board of the SPARK Remote Controller showcases a meticulous design prioritizing RF performance and electromagnetic compatibility. Dominating the layout is a substantial RF shield can, soldered securely to the PCB, which likely encapsulates the critical transceiver, power amplifier, and possibly a Wi-Fi/Bluetooth SoC. The presence of a coaxial cable routed into the shielded section indicates a dedicated antenna interface, crucial for reliable 2.4 GHz and 5.8 GHz operation. The black PCB, with multiple vias and complex routing, suggests a multi-layer design aimed at optimizing signal integrity and grounding. A flat flex connector and tactile switch highlight the device’s modular assembly, while robust grounding and EMI mitigation reflect a high standard of build quality. This section underscores DJI’s commitment to low-latency, high-reliability wireless communication in their remote controllers.

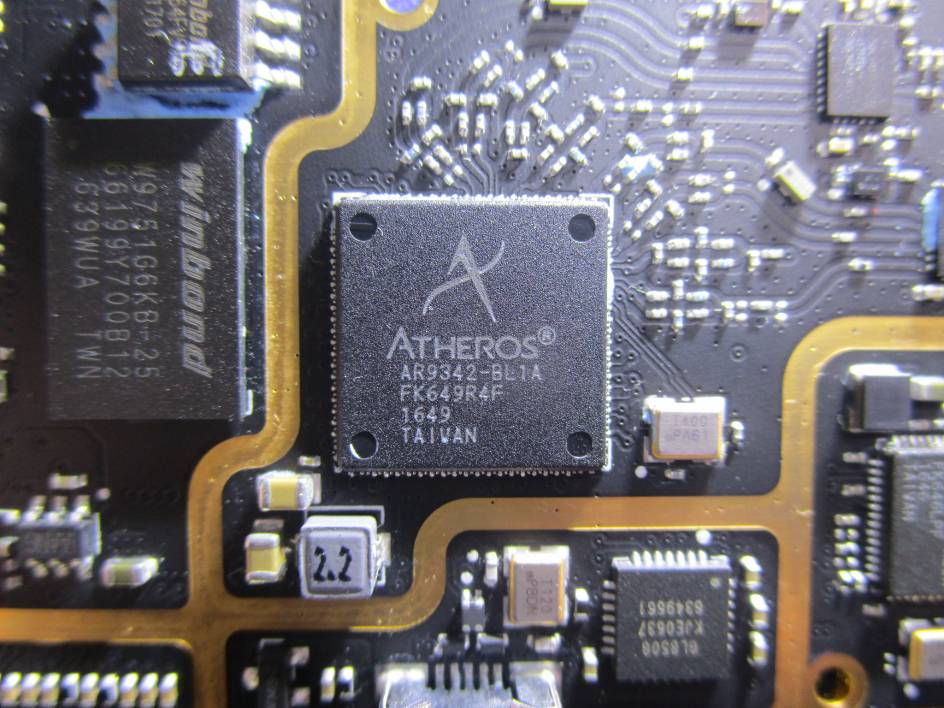

Wi-Fi SoC and Flash Memory Section

A closer examination of the main PCB reveals the powerhouse behind the controller’s wireless capabilities: the Atheros AR9342-BL1A, a highly integrated dual-band Wi-Fi SoC. This chip orchestrates all RF and baseband processing, enabling seamless, long-range communication with the Spark drone. Adjacent is a 16MB Winbond flash memory, responsible for firmware storage and updates. The meticulous PCB layout—featuring impedance-controlled traces, dense via stitching, and extensive ground pours—demonstrates a design optimized for EMI control and RF signal integrity. Power management components, including large capacitors and an inductor, ensure stable operation even during high-power transmission bursts. The integration of these components, coupled with a modular approach to antenna connectivity, underscores the controller’s capability to deliver robust, low-latency wireless performance in demanding environments.

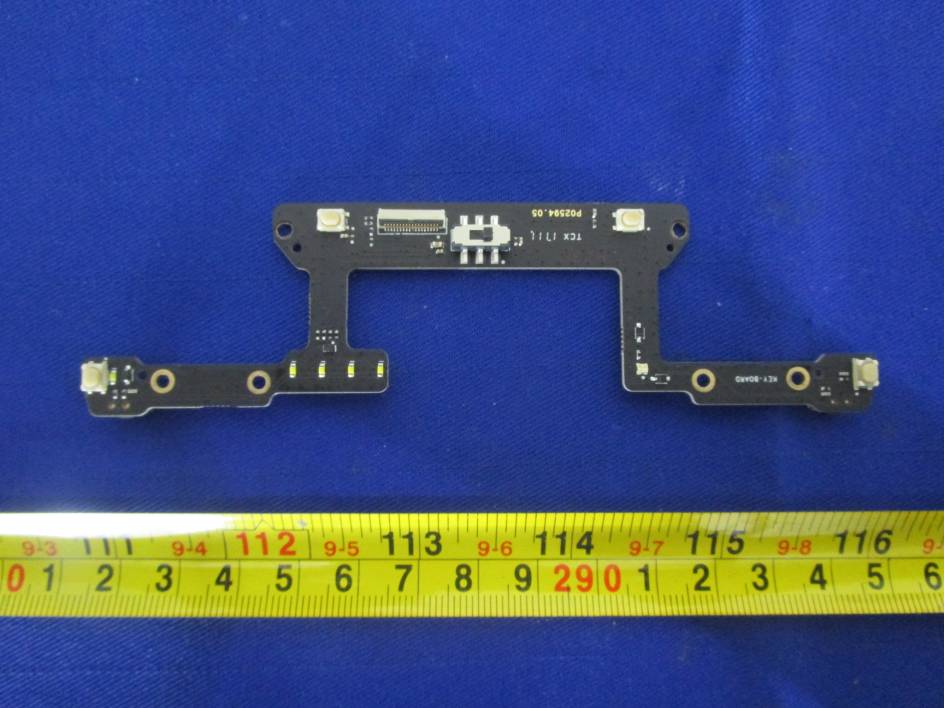

User Interface and Indicator PCB

The interior of the SPARK Remote Controller also includes a custom-shaped secondary PCB dedicated to user interface functions. This board is populated with surface-mount LEDs for visual status indication and a tactile switch—likely serving as a user input or test button. The moderate component density and absence of major ICs or RF components suggest its role is confined to interface support rather than core processing. A central FPC/FFC connector links this board to the main controller PCB, enabling modular assembly and potential ease of service. The clean soldering, custom shape, and robust mechanical integration reflect DJI’s attention to both functional and ergonomic design, ensuring user feedback and device status are clearly communicated during operation.

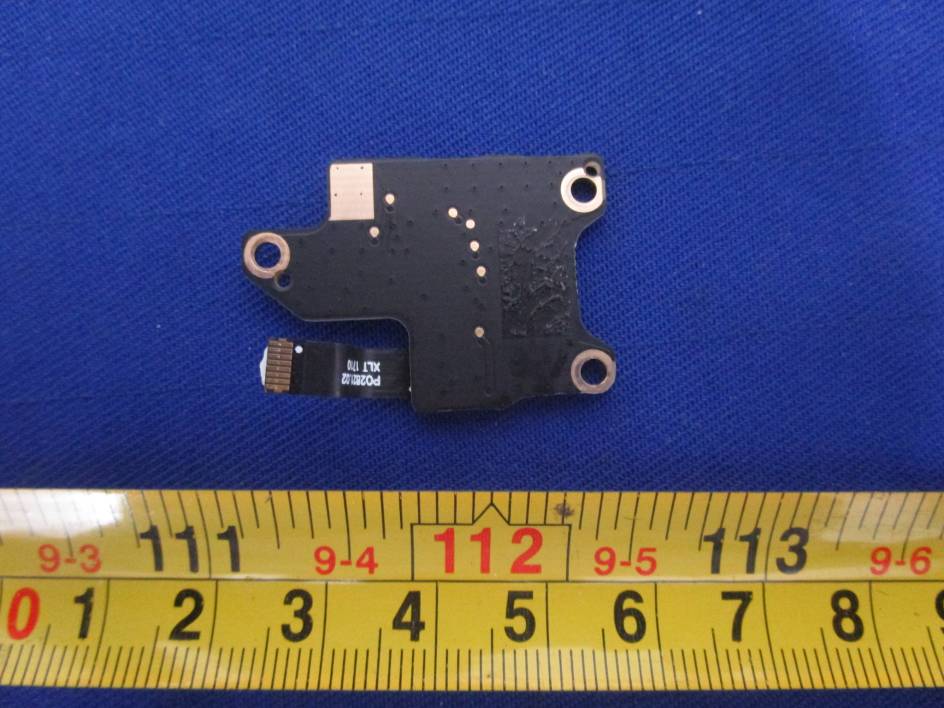

Compact PCB with Flex Cable—Potential Antenna or Module Interface

A compact PCB featuring a gold-plated ground plane and a fine-pitch flex cable stands out for its focus on EMI/RFI control. While no active components or antennas are visible on this side, the board’s design—with multiple vias and meticulous grounding—suggests it serves as an interface for an RF module or antenna. The use of a flex cable allows for flexible, space-efficient routing within the controller’s enclosure, supporting modular assembly and robust signal transmission. The high build quality, evidenced by gold-plated mounting holes and clean layout, is consistent with the demands of high-frequency RF applications in drone controllers.

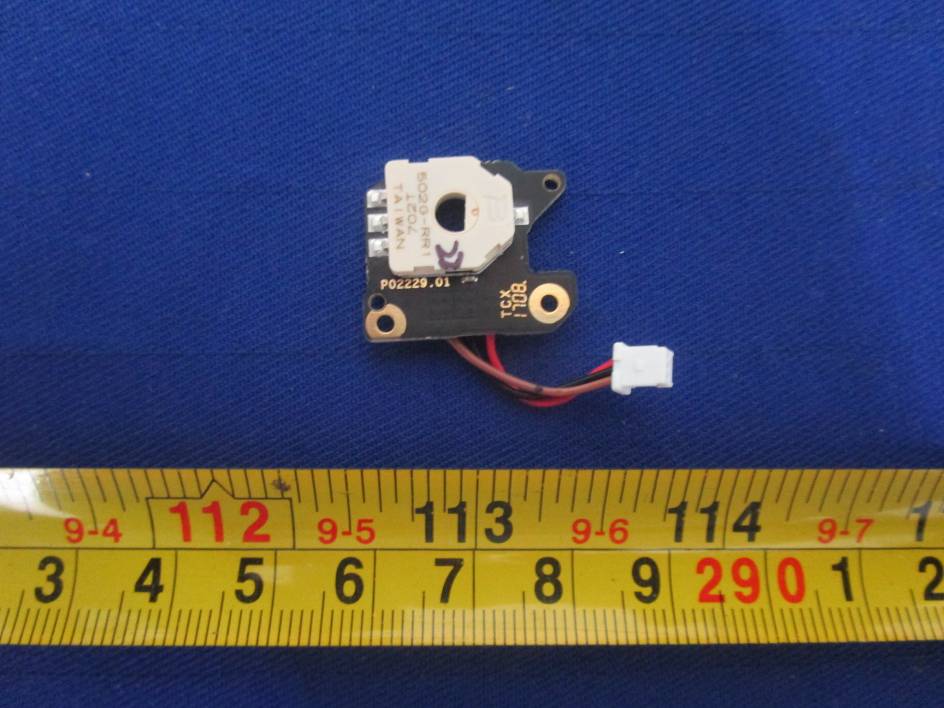

Rotary Encoder Module for Precise Analog Input

Integral to the user control experience is a dedicated PCB assembly featuring a Bourns rotary position sensor. This high-quality component is likely employed for joystick or gimbal control, translating user input into precise analog signals for the Spark aircraft. The PCB, finished in black with gold-plated contacts, is compact and robust, with a simple layout reflecting its analog sensor function. A JST-style connector provides straightforward integration with the main controller PCB, while minimal passive components ensure signal fidelity. The choice of a reputable Bourns sensor highlights DJI’s emphasis on durability and input accuracy, vital for responsive and reliable flight control.

Regulatory Insights & FCC Filing

The SPARK Remote Controller’s certification under FCC ID SS3-GL100A1704 marks its full compliance with US regulatory standards for radio frequency emissions and electromagnetic compatibility. This certification, registered by FCC.gov (grant date: None), authorizes the device for legal sale and operation within the United States, ensuring it poses no undue risk of interference with other wireless devices.

FCC filings for this device include a suite of critical compliance documents—test reports for RF exposure and EMC, detailed internal and external photographs, user manuals, block diagrams, and schematics. These materials provide transparency into the device’s design and operational safety.

Key insights from the user manual highlight the controller’s amplified Wi-Fi transmission system and its ability to control both the Spark aircraft and its gimbal camera at distances up to 2 km (FCC conditions). The manual also details user-centric features such as automatic power-off, folding device clamps, and wireless mobile device integration.

Test reports confirm that the controller’s RF emissions are well within permissible limits, and the robust shielding and PCB design observed in teardown images further support its compliance with electromagnetic interference standards. This regulatory rigor is essential not only for legal compliance but also for ensuring reliable, interference-free operation in real-world environments.

Potential Use Cases & Target Audience

The SPARK Remote Controller (FCC ID SS3-GL100A1704) is purpose-built for DJI Spark pilots who demand reliable, long-range, and intuitive control. Its feature set and robust wireless architecture make it ideal for several user profiles:

-

Aerial Photography Enthusiasts:

Photographers and videographers benefit from the controller’s extended range and live HD video feed via the DJI GO 4 app, enabling creative shots and precise gimbal control far beyond the limits of standard Wi-Fi-only operation. -

Outdoor Adventurers and Explorers:

Hikers, travelers, and drone hobbyists can confidently pilot their Spark drones in open environments, leveraging the amplified Wi-Fi system and automatic power-off function to maximize flight time and coverage during remote excursions. -

Professional and Semi-Professional Drone Operators:

For event coverage, surveying, or inspection tasks, the controller’s robust wireless link ensures uninterrupted operation, while its ergonomic design and folding device clamp support extended use and rapid deployment in the field.

By catering to these use cases, the SPARK Remote Controller extends the practical utility and enjoyment of the DJI Spark ecosystem.

Conclusion

The SPARK Remote Controller by SZ DJI TECHNOLOGY CO., LTD. (Model: C2) stands out as a meticulously engineered device, blending advanced RF technology, user-centric features, and robust regulatory compliance under FCC ID SS3-GL100A1704. Its sophisticated internal architecture and thoughtful design deliver the performance, reliability, and ease of use demanded by today’s drone pilots. Whether for creative aerial photography, adventurous exploration, or professional applications, this controller exemplifies DJI’s commitment to quality and innovation in wireless control technology.