Introduction

The DJI Phantom 4 Advanced is a standout in the world of aerial imaging, merging advanced flight intelligence with a powerful camera system. Designed for semiprofessional and prosumer users, this drone is engineered to deliver high-fidelity photography and videography, making it a top choice for content creators, surveyors, and enthusiasts demanding precision and reliability.

A key milestone in its commercial journey is its FCC certification under FCC ID SS3-WM332A1702. While the official FCC grant date is listed as “None,” this registration ensures that the Phantom 4 Advanced meets stringent US radiofrequency emission and interference standards, confirming its legality for sale and operation in the United States. The certification process also validates that the device operates safely within regulated RF power and spectrum limits—a crucial factor in crowded wireless environments.

In this article, we combine a deep technical analysis—spanning core specifications, wireless technologies, internal hardware, and regulatory insights—to deliver a comprehensive understanding of the Phantom 4 Advanced. We’ll also dissect its internal components through a series of teardown images, offering a rare look at the engineering excellence behind DJI’s flagship aerial platform.

Key Features & Specifications

The DJI Phantom 4 Advanced is packed with industry-leading features and robust hardware, tailored for users who demand professional-grade performance in a compact, user-friendly form factor.

Key Features

- Ranura para tarjeta MicroSD: Enables the use of high-capacity, swappable memory cards for extended video and photo capture sessions.

- Cámara aérea inteligente semiprofesional: Integrates a 1-inch, 20MP sensor, delivering exceptional clarity and low noise for both stills and 4K video.

- Modos TapFly y ActiveTrack mejorados: Intelligent flight modes via the DJI GO 4 app, allowing automated, cinematic shots and subject tracking without manual piloting.

- Sistema DJI LIGHTBRIDGE para transmisión HD en directo: Real-time HD video transmission ensures pilots receive a clear, low-latency view from the drone’s camera, critical for framing shots and avoiding obstacles.

- Estabilizador y cámara: Integrated 3-axis gimbal for ultra-smooth footage, even during aggressive maneuvers or windy conditions.

- Soporte para dispositivo móvil: Connects smartphones or tablets for live video, telemetry, and full control via the DJI GO 4 interface.

- Puerto MicroUSB: Facilitates firmware updates, data transfer, and charging.

- Botón de encendido: Simple, reliable power cycling and status management.

Technical Specifications

- Tiempo de vuelo máximo: Aproximadamente 30 minutos por carga, thanks to its high-capacity Intelligent Flight Battery (5870 mAh, 15.2 V, 89.2 Wh).

- Tamaño de imagen máximo:

- 5472×3648 (3:2)

- 4864×3648 (4:3)

- 5472×3078 (16:9)

- Obturador electrónico: 8 – 1/8000 s, enabling crisp action shots and flexible exposure control.

- Tasa de bits de almacenamiento de vídeo: Hasta 100 Mbps, ensuring high-detail 4K/60fps capture.

- Precisión de vuelo estacionario:

- Vertical: ±0,1 m (visual); ±0,5 m (GPS)

- Horizontal: ±0,3 m (visual); ±1,5 m (GPS)

- Intervalo de altitud del sistema visual: de 0 a 10 m, supporting low-altitude precision hovering.

- Velocidad máxima:

- 72 km/h (modo S)

- 58 km/h (modo A)

- 50 km/h (modo P)

- Cargador: 17,5 V, potencia nominal de 100 W, for rapid battery turnaround.

Additional Extracted Specifications

- Bluetooth: Present (details not specified), likely for device pairing and short-range communication.

- Camera Details:

- Sensor: 1” CMOS, 20MP effective pixels

- Video Recording:

- H.265: C4K (4096×2160) 24/25/30p; 4K (3840×2160) 24/25/30p; 2.7K (2720×1530) 24/25/30/48/50/60p; FHD (1920×1080) 24/25/30/48/50/60/120p; HD (1280×720) 24/25/30/48/50/60/120p

- H.264: C4K (4096×2160) 24/25/30/48/50/60p; 4K (3840×2160) 24/25/30/48/50/60p; 2.7K (2720×1530) 24/25/30/48/50/60p; FHD (1920×1080) 24/25/30/48/50/60/120p; HD (1280×720) 24/25/30/48/50/60/120p

- Battery:

- Intelligent Flight Battery (PH4-5870mAh-15.2V)

- Capacity: 5870 mAh, 15.2 V, LiPo 4S, 89.2 Wh, 468 g net weight

These specifications make the Phantom 4 Advanced a formidable tool for aerial imaging, combining speed, endurance, and image quality in a versatile, user-friendly package.

Operating Frequencies

The DJI Phantom 4 Advanced (FCC ID SS3-WM332A1702) operates on the following wireless frequencies, as documented in its FCC filing:

| Frequency Range (GHz) | Output Power (mW) | FCC Rule Part |

|---|---|---|

| 2.4065–2.4765 | 164.4 | 15C1.1 |

This range covers the 2.4 GHz ISM band, which is widely used for Wi-Fi, Bluetooth, and proprietary RF communications. The specified output power (164.4 mW) ensures robust signal transmission while remaining within regulatory limits for unlicensed wireless devices in the US.

Technology Deep Dive

The Phantom 4 Advanced leverages multiple wireless technologies to deliver seamless control, telemetry, and real-time video transmission. With its primary operation in the 2.4 GHz ISM band, the drone utilizes Wi-Fi and potentially proprietary RF protocols (such as DJI’s Lightbridge system) to ensure reliable, low-latency communication between the aircraft and its remote controller. Bluetooth, while present, is typically reserved for close-range device pairing or configuration tasks.

Operating within this spectrum allows the Phantom 4 Advanced to achieve a balance between range, data throughput, and resilience to interference. The 2.4 GHz band is known for its robust propagation characteristics but can be crowded in urban environments, making DJI’s emphasis on RF design and interference mitigation especially important. The output power of 164.4 mW is sufficient for several kilometers of range under ideal conditions, supporting both control signals and HD video downlink.

The internal test reports referenced in the FCC documentation confirm that the Phantom 4 Advanced maintains compliance with strict RF emission and immunity standards, ensuring both user safety and minimal impact on other devices. DJI’s engineering addresses power consumption and heat dissipation—key concerns for airborne electronics—by optimizing signal integrity, shielding, and efficient power regulation throughout the system.

In-Depth Internal Component Analysis / Teardown

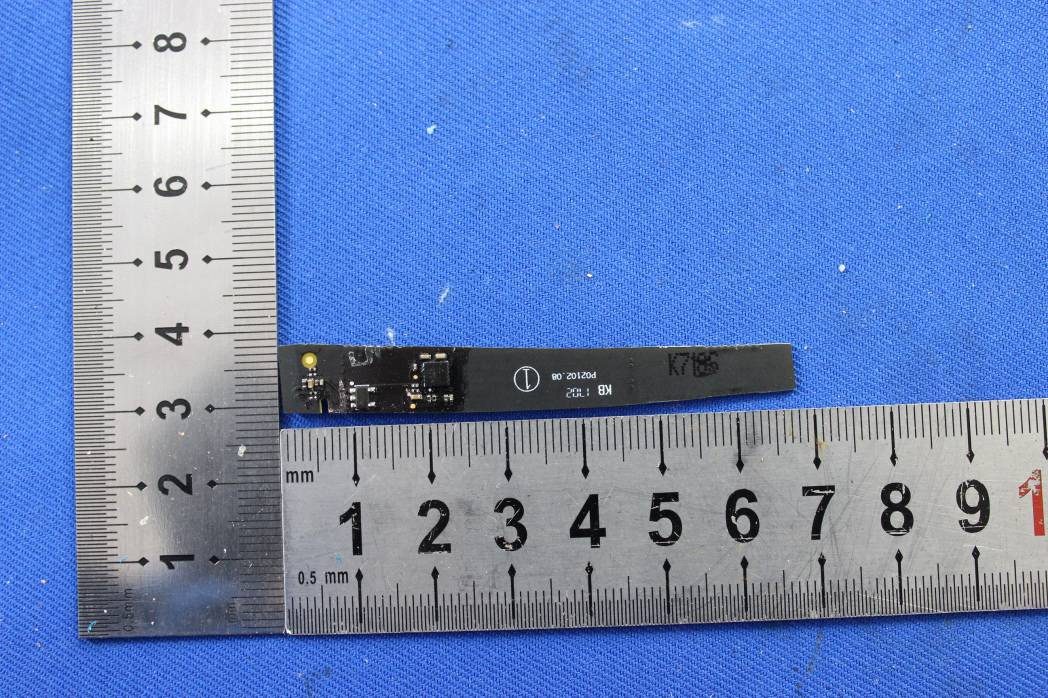

Compact Flexible PCB Module for Antenna or Sensor Interface

This slim, elongated black PCB exemplifies DJI’s attention to lightweight, modular design. Housing a single small IC—likely a sensor interface, amplifier, or microcontroller—alongside a handful of surface-mount passives, the module is built on a flexible substrate ideal for tight integration within the airframe. The lack of extensive ground pours and the presence of a gold pad at one end suggest it functions as a PCB antenna, perhaps for 2.4 GHz wireless or GPS, or as a sensor strip. The minimal component count, absence of shielding, and clean SMT assembly underscore its role as a low-power, signal-oriented board, optimized for weight and reliability in flight-critical systems.

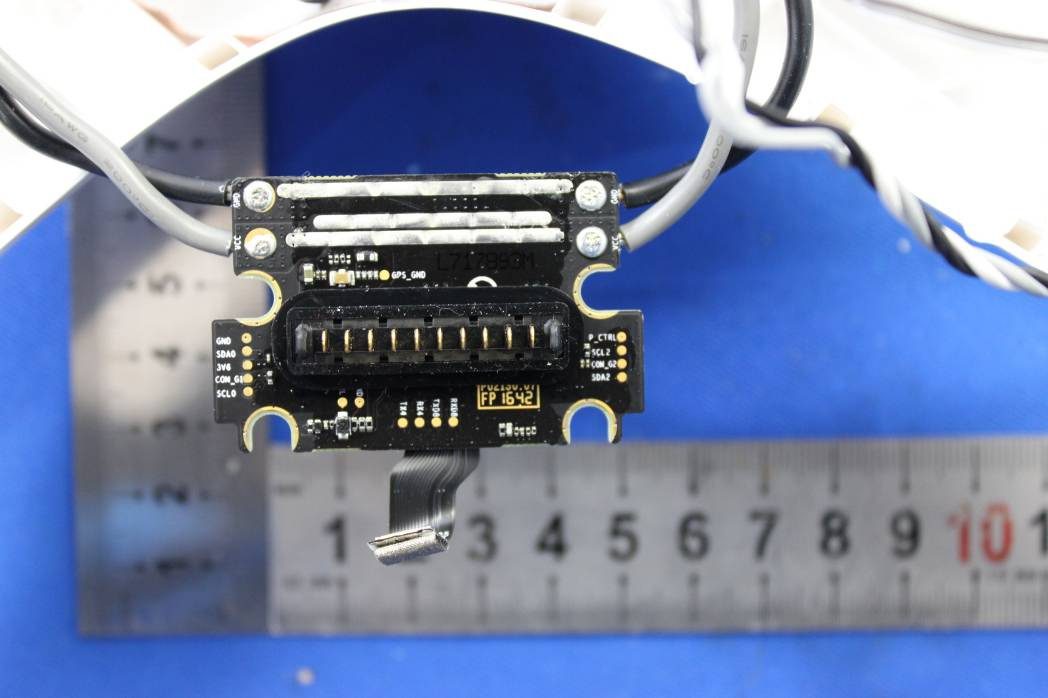

Modular PCB Assembly for Signal Interfacing

This compact, black multilayer PCB is densely populated with passive components and features a prominent multi-pin connector, multiple silkscreened signal identifiers, and a flex cable connector. Robust ground labeling and via placement indicate careful EMI management, while the array of labeled signals—such as I2C lines, power, and control—point to its role as an interface or breakout board for GPS, sensors, or other critical subsystems. The absence of major ICs and the presence of numerous test points reflect a design focused on reliable interconnection and maintainability, hallmarks of DJI’s modular engineering philosophy.

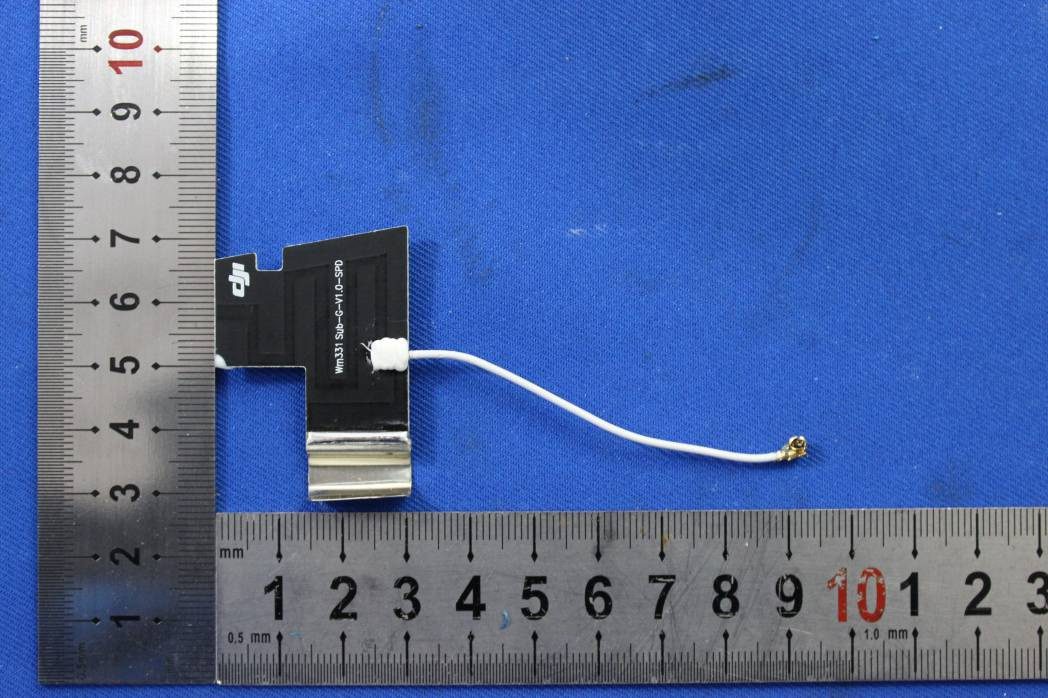

High-Performance PCB Antenna Module

This elongated PCB, precision-fabricated with controlled impedance traces, is purpose-built for high-frequency RF performance. The prominent copper trace and U.FL connector confirm its identity as a PCB antenna, most likely supporting 2.4 GHz or 5.8 GHz operation for Wi-Fi, Bluetooth, or drone control links. No active components are present, and the layout is meticulously optimized for minimal loss and maximum radiation efficiency. The use of a detachable U.FL connector allows for modular assembly and straightforward replacement, reflecting DJI’s commitment to maintainability and robust wireless performance.

Compact PCB Trace Antenna with Ground Plane

This small, black PCB is engineered as a trace antenna module, featuring a white coaxial cable terminated with a U.FL connector for high-frequency RF connections. The metallic section at one end likely serves as a ground plane or reflector, optimizing radiation efficiency. Silkscreen labeling and the DJI logo aid in assembly and identification. The absence of active components and the tailored form factor highlight DJI’s focus on performance, weight savings, and integration, ensuring reliable RF communication in the Phantom 4 Advanced’s compact chassis.

Main Flight Controller and Gimbal/Camera Electronics

The open airframe reveals the heart of the Phantom 4 Advanced: a high-density, multi-layer main PCB with a large BGA SoC, wireless transceiver or GPS module, and numerous memory and sensor interface chips. Extensive EMI shielding, robust FPC connectors, and careful partitioning of analog, digital, and RF domains illustrate DJI’s commitment to signal integrity and reliability. The secondary module, likely the gimbal/camera assembly, features its own power and control electronics, including large inductors and capacitors for motor drive. The integration of ultrasonic sensors, oscillators, and IMUs reflects advanced flight capabilities and sensor fusion, all executed with clean, serviceable assembly.

Gimbal/Camera Assembly with Cooling Fan

This section showcases a high-density PCB dedicated to the gimbal and camera system. Multiple ICs—potentially including a microcontroller, memory, and motor drivers—are supported by local power regulation and a dedicated cooling fan, indicating significant processing and thermal loads. The presence of a large FPC connector and robust metallic structures highlights the focus on precise, stable operation and EMI management. This assembly is crucial for delivering smooth, high-quality imagery, even during demanding flight conditions.

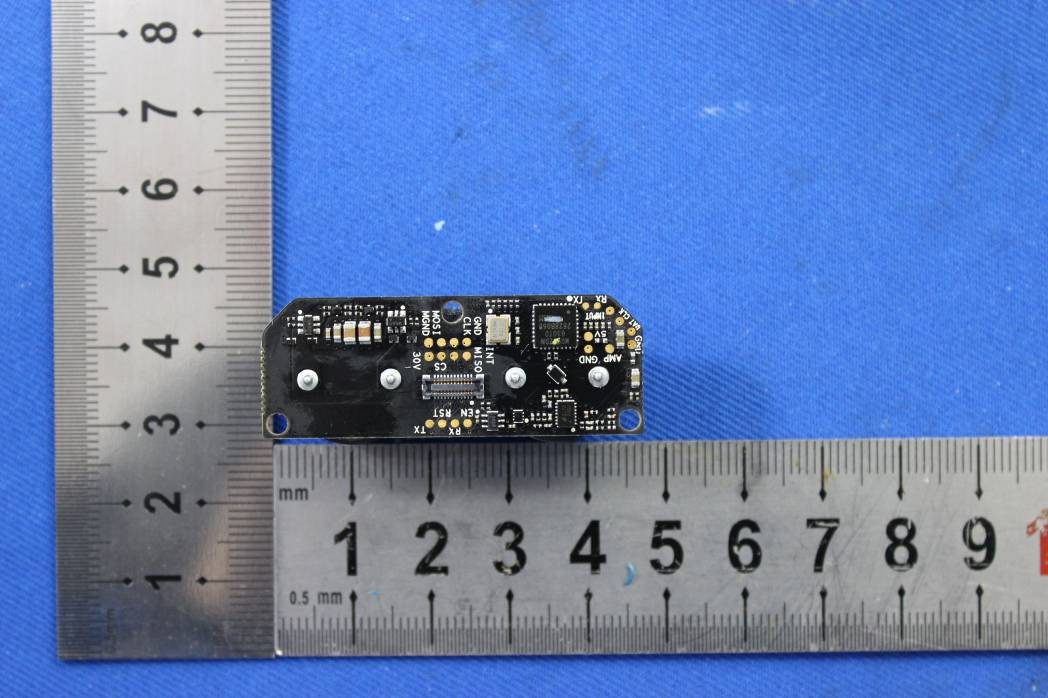

Sensor or Interface PCB with Multiple Debug Interfaces

This densely populated black PCB features a central microcontroller or interface IC, multiple labeled test points, and clear evidence of SPI and UART interfaces for programming and debugging. Robust power regulation and careful signal routing, including differential pairs, underscore the board’s role in managing sensor data or subsystem communications. The absence of antennas and the focus on signal integrity and testability are consistent with a design tailored for reliability within the Phantom 4 Advanced’s complex electronic ecosystem.

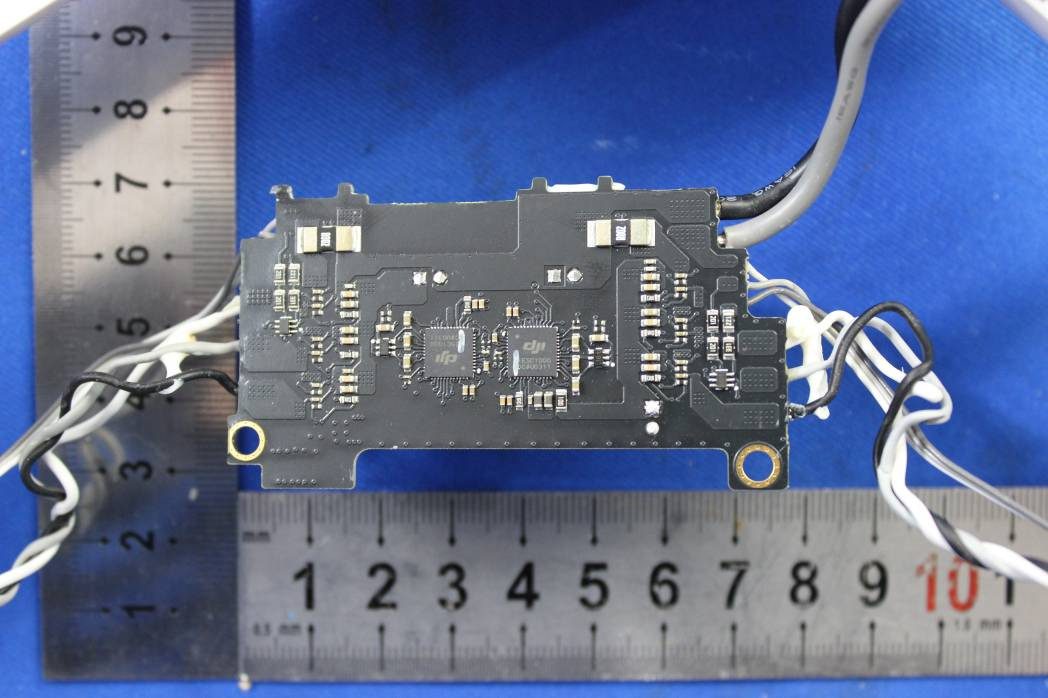

Motor or Sensor Control PCB with DJI-Branded ICs

This high-density black PCB is populated with two central DJI-branded ICs, likely custom microcontrollers or motor drivers, surrounded by a multitude of passives and local power regulation. Multiple wire harnesses suggest connections to motors, sensors, or other modules. The design balances compactness, signal integrity, and robust power/signal interfacing—critical for flight control or gimbal/motor management. The clean soldering, test points, and modular wiring reflect DJI’s high standards for quality and maintainability.

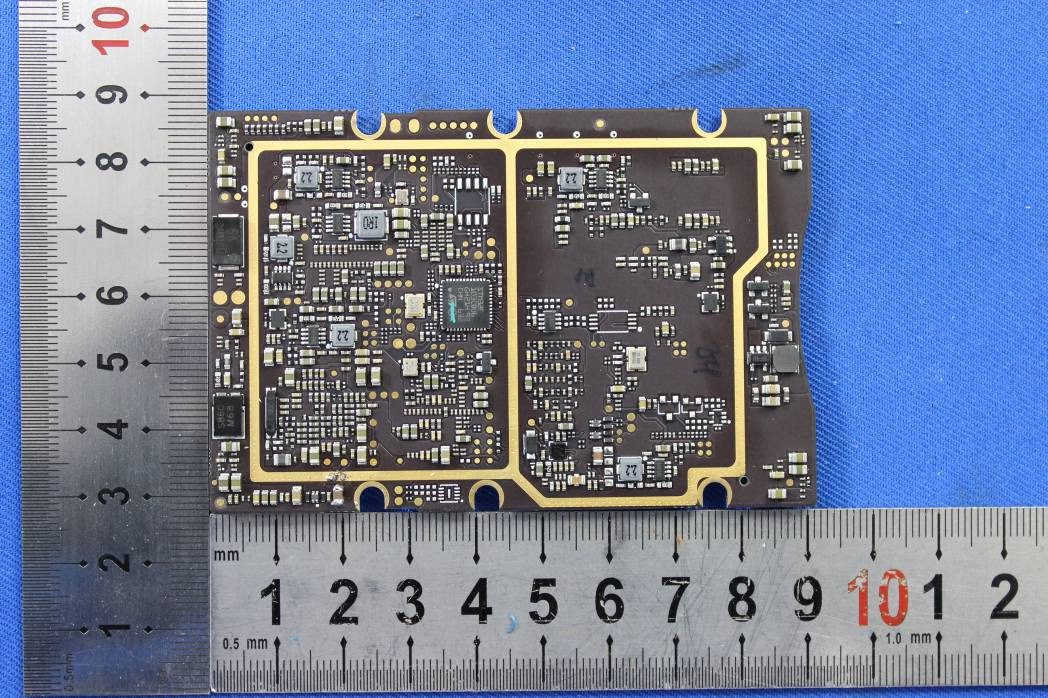

Densely Populated Multi-Layer PCB for Flight Control

This complex, dark brown PCB measures approximately 7.5 x 5.5 cm and features a central QFP/LQFP IC, likely serving as a main controller or DSP. Multiple smaller ICs, extensive power regulation, and compartmentalized gold-plated borders for EMI shielding highlight a design optimized for high-speed data processing and electromagnetic compatibility. The layout and component selection are consistent with advanced flight control, real-time telemetry, and signal processing needs of the Phantom 4 Advanced.

PCB with Integrated Trace Antennas and Vibration Dampers

The bottom side of this black PCB reveals integrated meandered PCB trace antennas, likely for 2.4 GHz or 5.8 GHz operation, within a silkscreened box. Multiple labeled test points (power, I2C, I/O) and dense via placement indicate a complex, multi-layer design. The inclusion of rubber vibration dampers at the corners suggests this module is sensitive to mechanical disturbances—potentially an IMU, gimbal controller, or RF module. The design reflects a focus on reliability, signal integrity, and ease of testing.

Regulatory Insights & FCC Filing

The FCC ID SS3-WM332A1702 serves as a testament to the Phantom 4 Advanced’s compliance with US electromagnetic interference and RF emission standards. While the official grant date is listed as “None,” the device’s presence in the FCC database (registered by FCC.gov) confirms it has undergone rigorous testing and is legally permitted for sale and use in the United States.

FCC filings for devices like the Phantom 4 Advanced typically include a wealth of technical documentation: RF exposure and EMC test reports, detailed internal and external photographs, user manuals, block diagrams, and circuit schematics. These materials collectively ensure the device meets all relevant safety, performance, and interference mitigation requirements.

From the user manuals referenced in the FCC documentation:

– The Phantom 4 Advanced is described as a smart, semiprofessional aerial camera, capable of capturing 4K video at 60fps and 20MP stills. It features advanced intelligent flight modes like TapFly and ActiveTrack, a robust remote control system, and seamless integration with the DJI GO 4 app for enhanced usability and creative flexibility.

This level of regulatory scrutiny assures users that the Phantom 4 Advanced not only meets but often exceeds industry standards for RF safety and operational reliability—a crucial consideration for both commercial and prosumer operators.

Potential Use Cases & Target Audience

With its professional imaging features and robust flight capabilities, the Phantom 4 Advanced is tailored for a discerning semiprofessional and prosumer audience. Here are key scenarios where it excels:

- Aerial Photography & Cinematography: Content creators, wedding videographers, and independent filmmakers benefit from the one-inch CMOS sensor’s clarity and low noise, capturing cinematic 4K/60fps video and stunning 20MP stills. Intelligent flight modes automate complex shots, freeing users to focus on creative composition.

- Surveying & Mapping: Professionals in construction, agriculture, and real estate leverage the drone’s precise hovering, long flight time, and high-resolution imagery for site surveys, orthomosaic mapping, and inspection tasks.

- Enthusiast Exploration: Tech-savvy hobbyists and drone enthusiasts appreciate the combination of advanced control, real-time HD camera view, and reliable flight performance, making the Phantom 4 Advanced ideal for landscape photography, travel documentation, and personal creative projects.

The device’s blend of intelligent automation, robust wireless connectivity, and industry-leading imaging positions it as a go-to tool for users seeking both power and ease of use.

Conclusion

The DJI Phantom 4 Advanced (Model: Phantom 4 Advanced, FCC ID SS3-WM332A1702) stands as a benchmark in aerial imaging, delivering exceptional performance, intelligent automation, and professional-grade image quality. Its FCC certification assures users of regulatory compliance, RF safety, and operational reliability. With a sophisticated internal architecture, advanced wireless technologies, and a wealth of smart features, the Phantom 4 Advanced is a top-tier choice for semiprofessional and prosumer users seeking to push the boundaries of creativity and productivity in the sky.