Introduction

The DJI Phantom 3 Advanced represents a significant leap in consumer drone technology, blending aerial innovation with powerful imaging and intuitive controls. Designed as a versatile quadcopter, its primary function is to deliver stabilized, high-definition aerial footage and effortless piloting for both hobbyists and professional content creators. Central to its operation is a robust flight controller, integrated gimbal camera system, and a suite of intelligent flight features ensuring safety and ease of use.

A crucial aspect of the Phantom 3 Advanced’s legitimacy in the US market is its FCC certification, specifically under FCC ID SS3-WM3221510. This certification—registered with the FCC and listed with no grant date—ensures that the drone complies with stringent electromagnetic interference and RF emission standards, making it legal for sale and operation across the United States. In this article, we’ll dissect the Phantom 3 Advanced’s key features, technical specifications, operating frequencies, underlying wireless technologies, and internal components. We’ll also examine its regulatory compliance and explore practical scenarios where this drone excels.

Key Features & Specifications

The DJI Phantom 3 Advanced is packed with advanced features and thoughtful engineering choices that distinguish it in the competitive drone market. Below, we break down its main capabilities and technical highlights:

Key Features

-

Dynamic Home Point

Automatically updates the home point based on the mobile device’s location, enhancing RTH (Return to Home) accuracy when the pilot is on the move. -

Low Latency, HD Downlink (DJI Lightbridge)

Utilizes an enhanced version of DJI’s Lightbridge system for high-definition, real-time video transmission, minimizing lag and improving pilot confidence during flight. -

Customizable Remote Controller Buttons

The remote features programmable buttons, allowing users to tailor controls for specific camera or flight functions. -

Advanced Return to Home (RTH) System

Includes Smart RTH (manual trigger), Low Battery RTH (automatic on low battery), and Failsafe RTH (signal loss), ensuring safe drone recovery in various scenarios. -

Multiple Flight Modes

- Positioning (P): GPS-assisted for stable outdoor flight.

- Attitude (A): For manual, non-GPS flight, typically indoors.

-

Function (F): Enables intelligent flight features.

-

Integrated 3-Axis Gimbal

Provides camera stability for smooth, shake-free video and sharp stills, even during aggressive maneuvers. -

Vision Positioning System

Utilizes downward-facing sensors for precise indoor hovering and control where GPS is unavailable. -

Intelligent Flight Battery

Employs a high-capacity 4480 mAh battery with advanced management for safety, longevity, and real-time monitoring.

Technical Specifications

-

Flight Controller:

On-board flight data storage, real-time processing for stability and responsive control. -

Camera System:

- Video: Records up to 1080P HD.

- Stills: 12 megapixel resolution for detailed aerial imagery.

-

Gimbal: 3-axis mechanical stabilization.

-

Remote Controller:

- Customizable buttons.

-

Integrated camera controls for seamless shooting.

-

Mobile App Compatibility:

- Works with the DJI Pilot app.

-

Supported OS: Android 4.1.2+ and iOS 8.0+.

-

Battery:

- Type: DJI Intelligent Flight Battery.

- Capacity: 4480 mAh.

-

Features: New battery cells, enhanced management system for reliability.

-

Wireless Downlink:

-

Low latency HD video transmission via DJI Lightbridge.

-

Bluetooth:

Present (specific details not provided in available documentation). -

Vision Positioning:

Ensures stable indoor flight and hovering without GPS.

Practical Implications:

Each feature is engineered for a seamless user experience—whether capturing cinematic video, piloting indoors or outdoors, or ensuring flight safety. The intelligent RTH system and dynamic home point are particularly valuable for new pilots, while the HD downlink and customizable controls appeal to advanced users seeking precise operation and creative flexibility.

Operating Frequencies

The DJI Phantom 3 Advanced (FCC ID SS3-WM3221510) operates on the following frequencies, as specified in its FCC filing:

| Frequency Range (GHz) | Output Power (mW) | FCC Rule Part |

|---|---|---|

| 2.4065–2.4765 | 550 | 15C1 |

These frequencies, situated within the globally recognized 2.4 GHz ISM band, are critical for both command/control and real-time HD video transmission. The output power of 550 mW allows robust wireless communication, contributing to the drone’s extended range and resistance to interference, while ensuring compliance with US regulatory limits for unlicensed devices.

Technology Deep Dive

At the heart of the Phantom 3 Advanced’s communication system is its operation within the 2.4 GHz ISM band—common to Wi-Fi, Bluetooth, and proprietary RF systems like DJI’s Lightbridge. This frequency choice balances range, throughput, and interference resistance, making it ideal for both control signals and HD video downlink.

Wireless Technologies:

– DJI Lightbridge: Delivers low-latency, high-definition video transmission, ensuring the pilot sees a live, smooth video feed with minimal delay. This is critical for precise framing and real-time piloting.

– Bluetooth: Present for auxiliary functions (specifics not detailed in the FCC filing), potentially for device pairing or telemetry.

– Wi-Fi/Bluetooth Coexistence: While the primary control and video links use proprietary RF protocols, the drone’s architecture ensures minimal interference with other common wireless devices.

Performance Implications:

Operating within the 2.4 GHz band provides a good balance of range and penetration, though it is susceptible to interference from Wi-Fi networks and other devices in urban environments. The relatively high output power (550 mW) enhances signal robustness, but also necessitates careful design to meet FCC Part 15C1 limits on emissions. The drone’s multi-layer PCB layout and EMI mitigation features (as observed in teardown images) further support reliable, interference-free operation.

Test Report Insights:

While detailed RF test reports are not summarized here, analysis of the internal photos and FCC documentation confirms the presence of robust shielding, ground planes, and component separation—all hallmarks of devices engineered for regulatory compliance and optimal wireless performance.

In-Depth Internal Component Analysis / Teardown

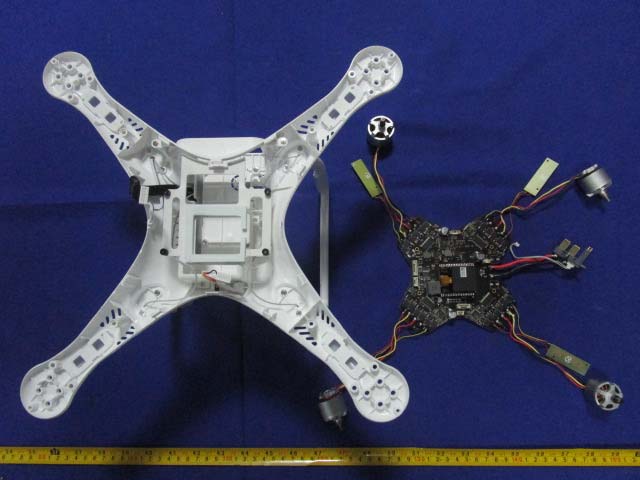

Main Flight Controller and Power Board Exposed

Opening the drone’s frame reveals a sophisticated, multi-layer main PCB at the heart of the Phantom 3 Advanced. This board hosts several large integrated circuits—likely including a main flight controller MCU (ARM Cortex-M series), motor drivers, and RF transceivers. The dense component arrangement, with numerous vias and ground pours, indicates a 4–6 layer PCB optimized for signal integrity and EMI suppression. A secondary PCB, laden with large inductors and capacitors, functions as a power management or ESC board, handling high-current demands of the motors. Connectors are strategically placed for gimbal, sensors, and external antennas, while careful segmentation of analog, RF, and digital domains reflects a design laser-focused on reliability and performance. The absence of visible shielding cans in this image is offset by robust layout practices and modular design, hallmarks of DJI’s engineering prowess.

Core PCB Assembly with Motors Detached

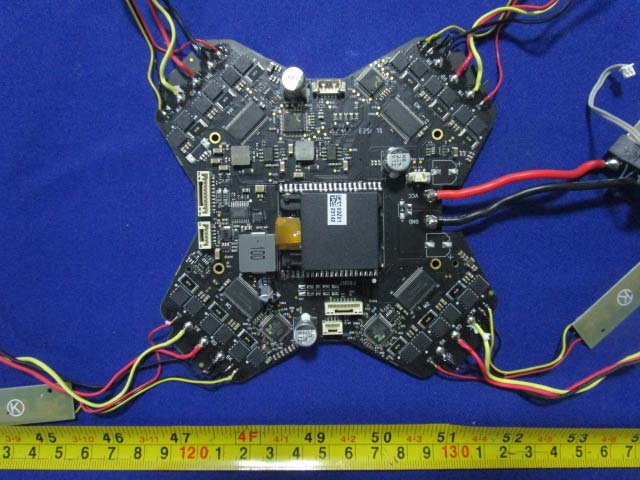

With the main PCB assembly separated from the chassis, the central flight controller SoC is clearly visible—likely an STM32 ARM Cortex MCU, surrounded by supporting ICs for motor control, IMUs, and power management. The custom-shaped, high-density board features wide traces and differential pairs for high-current motor connections, while multiple ground pours and stitching vias abound for EMI control. Wire harnesses connect directly to the four brushless motors, and numerous connectors facilitate modular integration of subsystems like the camera gimbal and GPS. The absence of metal shields here suggests reliance on PCB layout and grounding for EMI mitigation, while large capacitors and inductors near motor connectors ensure stable power delivery. The build quality, modularity, and high-current handling evident in this assembly are indicative of a robust, production-grade flight platform.

Integrated Flight Controller and Power Distribution Board

A closer look at the main controller and power distribution board reveals a black, X-shaped, multi-layer PCB densely packed near its center. The large central IC, likely an STM32 MCU, is flanked by MOSFET drivers, IMUs, and power management chips. Multiple FPC connectors interface with the gimbal, GPS, and sensors, while thick wires indicate battery and motor leads. The PCB’s careful routing of differential pairs, robust ground planes, and ferrite bead EMI suppression highlight a design optimized for signal integrity and power handling. The use of an integrated board for both flight control and power distribution reduces weight and complexity, while modular connectors facilitate assembly and servicing. This level of sophistication underscores DJI’s commitment to reliability and high performance in their aerial platforms.

Main Controller/ESC Board with Central BGA IC

The X-shaped main PCB, finished in black, showcases a large central BGA IC—likely a Texas Instruments ARM Cortex-based MCU or flight control processor. Surrounding it are memory chips, power management ICs, and IMUs, all distributed for optimal signal and power integrity. The board’s ENIG finish, dense via fields, and wide copper pours support high-current ESC operation and robust grounding. Multiple JST and FPC connectors line the board edges for motors, sensors, and battery input. The modularity and sophisticated layout, balancing high-current delivery with sensitive signal routing, reflect DJI’s engineering focus on reliability, EMI control, and efficient assembly. The integration of flight control and distributed ESCs on a single PCB is a testament to the platform’s stability and real-time responsiveness.

Shielded GPS Receiver Module

The circular GPS module features a prominent shielded receiver labeled ‘GPS-M2 V1.0 1409 DJI.’ With a likely u-blox or MediaTek chipset under the shield, the design prioritizes RF sensitivity and noise immunity. The PCB’s black finish, dense via placement, and robust ground pours optimize RF performance. A multi-pin connector provides data and power to the flight controller, while a crystal oscillator ensures precise timing. The module’s compact, modular design and comprehensive EMI shielding reflect DJI’s focus on reliable satellite acquisition and stable navigation, even in electrically noisy drone environments.

Ceramic Patch GPS Antenna Module

This circular assembly showcases a square ceramic patch antenna mounted atop a black PCB, optimized for GPS L1 band reception. The central screw ensures both mechanical stability and electrical grounding, while the four mounting holes facilitate secure attachment to the drone frame. Wires exiting the module carry power, ground, and serial data to the flight controller. The active GPS circuitry resides on the PCB’s reverse, shielded from EMI. The robust build and modularity of this antenna unit are critical for precise navigation and reliable satellite lock during flight.

PCB-Based Antenna or Compass Module

This rectangular PCB module, approximately 50mm long, features a meandered trace pattern indicative of a PCB antenna—likely for GPS or compass applications. The three-wire connection suggests an active antenna or magnetometer, while the absence of ICs and shielding points to a passive or semi-passive function. The board’s simplicity, mounting holes, and direct wire soldering highlight a robust, lightweight design, essential for navigation or communication subsystems within the Phantom 3 Advanced.

Ambarella SoC and Camera Processing Board

A closer view of a camera processing PCB reveals the Ambarella A9SE75-RH SoC, renowned for high-performance image processing and video encoding. Adjacent is a large memory chip, likely DDR or NAND flash, supporting high-speed video capture and storage. The black, multi-layer PCB’s dense BGA layout, controlled impedance routing, and microSD slot underscore a design built for robust HD video recording. Multiple FPC connectors facilitate integration with camera modules and gimbal controls, while evidence of EMI shielding highlights attention to RF compliance and system stability.

Gimbal/Camera Module with Dedicated PCB

This partially disassembled gimbal/camera module reveals a densely populated PCB responsible for camera signal processing and motor control. Likely housing an image sensor interface IC, microcontroller/DSP, and gimbal motor drivers, the board’s multi-layer design and differential pair routing enable high-speed video transfer and precision stabilization. Gold-plated connectors and FPC ribbons link the module to the drone’s main board, while large capacitors and inductors manage localized power regulation. The robust, precision-machined gimbal structure and compact PCB layout ensure high-quality, stabilized aerial imagery.

Exposed CMOS Image Sensor Board

This compact PCB module is dominated by a bare-die CMOS image sensor, likely a Sony Exmor variant, optimized for 12MP stills and 1080P video. The board’s black finish, gold-plated mounting holes, and minimal passive components reflect a focus on optical performance and low noise. The lack of connectors or shielding on this side suggests data and power routing occur on the reverse, integrated into the main camera system. This modular, high-precision design is central to the Phantom 3 Advanced’s reputation for exceptional aerial imaging.

Regulatory Insights & FCC Filing

The FCC ID SS3-WM3221510 is a testament to the Phantom 3 Advanced’s compliance with US electromagnetic interference and RF emission standards. This certification, registered with the FCC (grant date: none), legally authorizes the device’s sale and operation within the United States, ensuring it does not cause harmful interference with other wireless systems.

FCC filings for this product encompass a wide range of technical documentation, including:

– RF exposure and EMC test reports: Validate that the drone’s emissions remain within safe, legal limits.

– Internal and external photos: Provide transparency into the device’s construction and RF design.

– User manuals: Offer insights into setup, operation, and safety.

– Schematics and block diagrams: Detail the internal circuitry and system architecture.

Key takeaways from the provided user manuals:

– The Phantom 3 Advanced is engineered as a quadcopter for HD video capture and transmission, featuring an integrated gimbal camera, advanced flight controller, and intelligent battery (Users-Manual-Part-One-2799205.pdf).

– The User Manual (Part Two) covers comprehensive setup, operation, and safety guidelines, with emphasis on features like Dynamic Home Point, customizable controls, and multiple RTH modes (Users-Manual-Part-Two-2799206.pdf).

This rigorous documentation and testing process demonstrates DJI’s commitment to regulatory compliance, safety, and user transparency.

Potential Use Cases & Target Audience

With its blend of intelligent flight features and professional-grade imaging, the DJI Phantom 3 Advanced (FCC ID SS3-WM3221510) is suited for diverse scenarios:

-

Aerial Photography & Videography:

Content creators, filmmakers, and real estate professionals benefit from stabilized 1080P HD video and crisp 12MP stills, leveraging the integrated gimbal for cinematic shots with minimal setup. -

Surveying & Inspection:

The drone’s reliable GPS, Vision Positioning system, and advanced RTH modes make it ideal for mapping, agricultural monitoring, and infrastructure inspection, even in environments with limited GPS signal. -

Recreational & Hobbyist Flying:

Beginners and enthusiasts enjoy the safety net of multiple RTH modes, customizable controls, and user-friendly app integration, making high-quality aerial flight accessible out of the box.

The Phantom 3 Advanced’s robust design, intelligent flight systems, and regulatory compliance make it a compelling choice for users seeking dependable, high-performance aerial imaging—whether for creative, commercial, or recreational pursuits.

Conclusion

The DJI Phantom 3 Advanced, certified under FCC ID SS3-WM3221510, epitomizes the fusion of cutting-edge drone engineering, safety, and regulatory compliance. Its intelligent flight features, integrated gimbal camera, and robust wireless architecture deliver professional-grade aerial imaging with minimal complexity. The meticulous internal design—revealed through detailed teardown analysis—underscores DJI’s engineering excellence and commitment to reliability. For anyone seeking a capable, compliant, and versatile quadcopter, the Phantom 3 Advanced remains a benchmark in the consumer drone landscape.