Introduction

The Phantom 4 Pro V2.0, engineered by SZ DJI TECHNOLOGY CO., LTD, stands as a flagship in the realm of prosumer drones. Designed for aerial imaging enthusiasts and professional creators alike, this drone merges advanced flight technology with cutting-edge photography capabilities. Its primary function is to deliver high-quality, stabilized 4K video and 20-megapixel stills, all while ensuring robust flight performance and safety through intelligent obstacle avoidance systems and streamlined controls.

A crucial aspect of the Phantom 4 Pro V2.0’s legitimacy and performance in the United States is its FCC certification under ID SS3-WM331S1801. This certification, granted by the FCC (Federal Communications Commission), attests that the device adheres to stringent RF emission standards, ensuring both legal market access and safe, interference-free operation within regulated frequency bands.

In this in-depth analysis, we’ll explore the Phantom 4 Pro V2.0’s standout features, detailed technical specifications, wireless capabilities, internal components, and regulatory context. We’ll also present a teardown-based look at its core hardware and discuss its practical use cases for today’s demanding aerial imaging landscape.

Key Features & Specifications

The Phantom 4 Pro V2.0 is loaded with features that position it at the forefront of aerial imaging technology. Here’s a detailed breakdown of its capabilities and what they mean in practice:

Key Features

- Remote Controller with 4.3 mi (7 km) Transmission Range

- Enables long-distance flights and reliable signal strength, ideal for expansive landscape or infrastructure surveys.

- Physical Buttons and Dials on Remote Controller

- Dedicated controls for exposure, camera tilt, photo capture, and video recording allow for precise, on-the-fly adjustments without needing to navigate touch menus.

- 4K Video at 60fps, Up to 100 Mbps

- Delivers ultra-high-definition footage with smooth motion and rich detail, supporting professional-grade video production.

- Upgraded TapFly™ and ActiveTrack™ via DJI GO™ 4 App

- Simplifies flight path planning and intelligent subject tracking, making complex shots accessible even to intermediate pilots.

- Smart Prosumer Flying Camera

- Designed for creators who demand both ease-of-use and advanced imaging performance.

- Dual Frequency Support for More Stable HD Video Downlink

- Utilizes both 2.4GHz and 5.8GHz bands to minimize interference and provide a robust, low-latency video feed.

- 1-inch CMOS Sensor

- Offers unprecedented clarity, lower noise, and superior image quality, even in challenging lighting conditions.

Technical Specifications

- Camera

- 1-inch CMOS sensor

- 20-megapixel stills

- 4K video at 60fps, up to 100 Mbps bit rate

- Remote Controller

- Model: GL300L

- Transmission range: Up to 4.3 mi (7 km)

- Dual frequency support (2.4GHz/5.8GHz)

- Flight & Imaging

- 4 directions of obstacle avoidance (forward, backward, left, right)

- Intelligent flight modes via DJI GO™ 4 app

- Noise Reduction

- Noise power reduced by 60%, overall noise reduced by 4dB compared to previous generations, enabling quieter operation and improved flight efficiency.

- Wireless & Connectivity

- Bluetooth present (details unspecified in documentation)

- Build Quality

- Robust, modular design with high-quality internal components for durability and ease of maintenance.

These features and specifications combine to create a drone that excels in aerial imaging, offering both the technical prowess for professionals and the intelligent automation desired by enthusiasts.

Operating Frequencies

The Phantom 4 Pro V2.0 (FCC ID SS3-WM331S1801) operates across multiple frequency bands, as detailed in its FCC filings. These frequencies are critical for its wireless communication, video downlink, and control systems:

| Frequency Range (GHz) | Output Power (mW) | FCC Rule Part |

|---|---|---|

| 2.4725 | 131 | 15CCC2.35.7285 |

| 2.4775 | 125 | 15CCC2.22.4105 |

| 5.8465 | 19 | 15E38 |

| 12.4035-2.4775 | 22 | 15CCC2.12.4055 |

| 15.7305-5.8445 | 175 | 15E38 |

| 25.7355-5.8395 | 168 | 15E38 |

Why this matters:

These specified frequency ranges and output powers underscore the drone’s compliance with FCC regulations and its ability to operate robustly in crowded RF environments. Dual-band operation (2.4GHz and 5.8GHz) is especially beneficial for maintaining a stable HD video link, even in areas with heavy Wi-Fi congestion or potential interference.

Technology Deep Dive

At the heart of the Phantom 4 Pro V2.0 is a suite of sophisticated wireless technologies. The drone’s primary communications rely on dual-band RF (2.4GHz and 5.8GHz), supporting both remote control and real-time HD video downlink. This dual-frequency capability allows the system to dynamically switch bands for optimal performance, reducing interference and maintaining a reliable connection at extended ranges.

Bluetooth is present, likely facilitating device pairing and auxiliary functions, although the specific implementation details are not detailed in the available documentation.

Operating within the regulated frequency bands ensures not only compliance but also efficient spectrum utilization. The use of moderate to high output power (up to 175 mW) in certain bands enables long-range, low-latency video and telemetry transmission, which is vital for professional aerial imaging and complex flight operations. Lower power levels in other bands help to minimize interference and conserve battery life, striking a balance between performance and efficiency.

The absence of cellular connectivity—typical for most drones—focuses the device on dedicated RF links for direct pilot-to-drone communication, minimizing external dependencies and potential security risks.

Overall, the selection and management of these wireless technologies in the Phantom 4 Pro V2.0 reflect a mature, highly optimized approach to real-time aerial data transmission and command/control reliability.

In-Depth Internal Component Analysis / Teardown

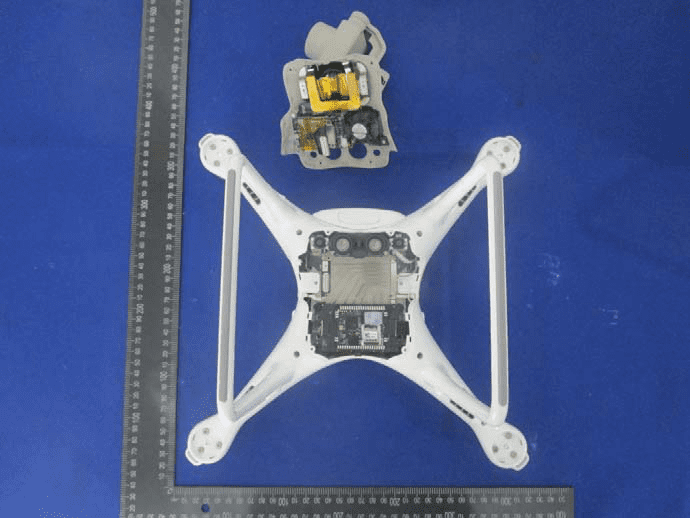

Main Chassis and Central PCB

Upon opening the main chassis of the Phantom 4 Pro V2.0, the central PCB is immediately apparent, densely populated with high-performance integrated circuits. The largest chip, situated beneath a substantial metal heatsink, is likely the main system-on-chip or flight controller, tasked with real-time video processing and flight calculations. Surrounding this are memory modules, power management ICs, and RF transceivers that handle the drone’s multifaceted communication tasks. The high layer count of the PCB (estimated at six or more) supports the complex routing for high-speed data and robust power distribution. Embedded antenna traces and slots along the drone’s arms, though not immediately obvious, suggest a sophisticated internal antenna design for multi-band operation. The presence of extensive shielding and modular connectors highlights DJI’s focus on EMI control, thermal management, and serviceability—a testament to the drone’s professional-grade engineering.

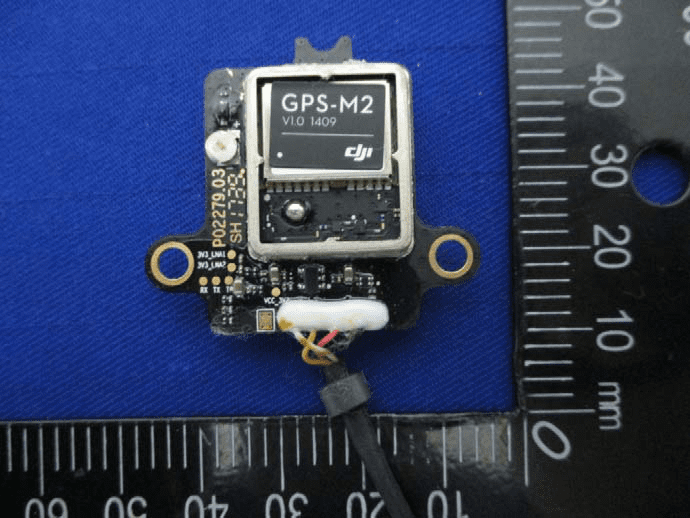

GPS Module

A close-up view of the GPS module reveals a compact PCB crowned by a shielded enclosure labeled ‘GPS-M2 V1.0 1409 DJI’. This custom module integrates a GPS receiver SoC with a dedicated RF front-end, all carefully shielded to prevent interference from the drone’s other electronics. The robust grounding strategy, evidenced by gold-plated mounting holes and stitching vias, ensures stable signal reception. A coaxial cable provides a low-loss connection to the drone’s external GPS antenna. Local power regulation and signal conditioning components are neatly arranged, and the presence of test points supports efficient debugging and maintenance. The module’s design prioritizes reliable navigation and flight stability, critical for both autonomous and manual flight operations.

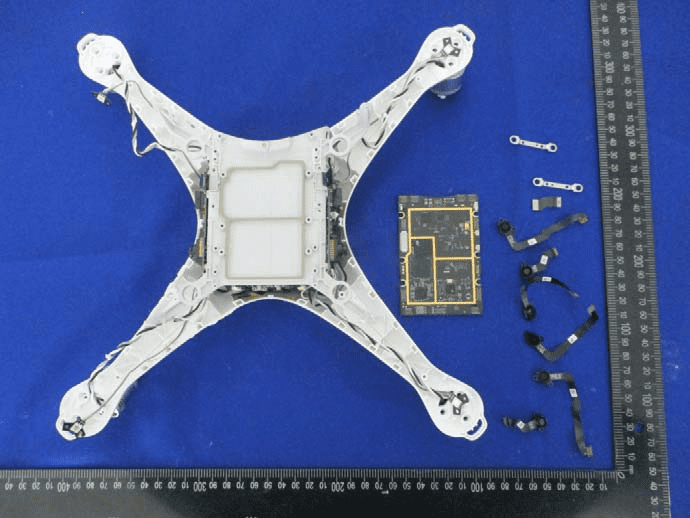

Main Frame and PCB Layout

Examining the internal structure further, the main PCB is positioned to the right of the drone’s frame, densely populated with large ICs likely responsible for flight control, sensor fusion, and data management. The board’s multi-layer construction, fine-pitch routing, and extensive ground pours are all indicative of high-speed data paths and meticulous EMI management. Multiple coaxial and flex cables connect to various antennas and sensors, ensuring modularity and ease of repair. FPC/FFC connectors facilitate connections to cameras and gimbals, while larger connectors handle power distribution. Clearly marked shield outlines on the PCB demonstrate a proactive approach to minimizing RF interference, an essential factor in a drone designed for both imaging and precise navigation.

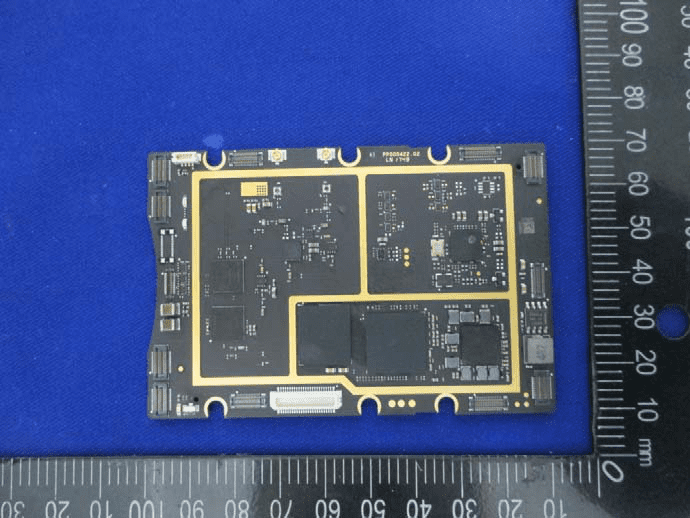

Densely Populated PCB

A focused look at one of the internal PCBs uncovers a black, ENIG-finished board populated with large BGA and QFP packages. These likely include the main application processor and memory, with high-speed differential pair routing supporting fast interfaces for video and telemetry. Multiple FPC/FFC connectors along the edges connect to cameras, sensors, or daughterboards, while a prominent white connector serves as a major interconnect. The gold-bordered regions anticipate the installation of EMI shields, and the presence of numerous test points and power management components further underscores the board’s complexity. The design speaks to DJI’s commitment to modularity, real-time processing, and robust RF communication.

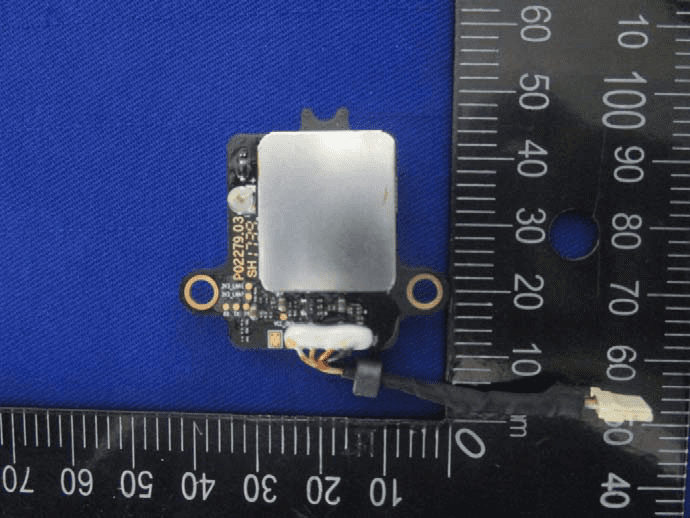

Compact Shielded Module

A small, square PCB module stands out for its dense layout and robust metal shielding. While the main ICs are hidden beneath the shield, the presence of a coaxial cable and multipin connector suggests this module is dedicated to RF communication or telemetry. The cable construction and connector type point to high-frequency signal use, such as Wi-Fi or GPS. The use of adhesive or thermal interface materials highlights attention to mechanical stability and heat management. The compact, modular design and EMI suppression measures are emblematic of DJI’s engineering standards, ensuring reliable operation in the drone’s demanding RF environment.

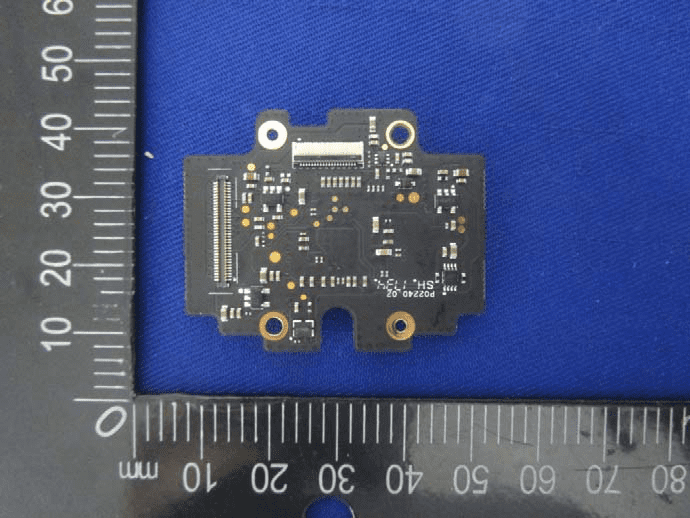

Secondary Component PCB

Another internal PCB, measuring roughly 35mm x 40mm, is populated primarily with passive components and fine-pitch connectors. The board’s black soldermask and dense via structure indicate a multi-layer design focused on signal integrity and grounding. Two FPC/FFC connectors suggest this board serves as an interface or sensor module, rather than the main flight controller. Multiple test points and reinforced mounting holes ensure the board can be securely installed and easily tested during manufacturing. The absence of large power handling components or antennas denotes its specialized, supporting role within the drone’s electronic ecosystem.

Regulatory Insights & FCC Filing

The FCC ID SS3-WM331S1801 is more than just a regulatory label—it’s a testament to the Phantom 4 Pro V2.0’s compliance with U.S. electromagnetic interference (EMI) and RF emission standards. This certification, registered on FCC.gov, signifies that the drone has undergone rigorous testing to ensure its wireless transmissions do not cause harmful interference with other devices and are safe for public operation.

FCC filings typically encompass a comprehensive suite of documents, including RF exposure and EMC test reports, internal and external photographs, technical manuals, schematics, and block diagrams. These materials collectively verify that the device meets all relevant safety and performance criteria.

Insights from the user manual and internal documentation further highlight the Phantom 4 Pro V2.0’s strengths: advanced imaging capabilities, intelligent flight modes, and significant noise reduction improvements. The remote controller’s extended range and dual-frequency operation are crucial for both signal reliability and regulatory adherence. Internal documentation also reflects a strong emphasis on EMI management and modularity—key factors in passing stringent FCC testing.

In summary, the Phantom 4 Pro V2.0’s FCC certification under SS3-WM331S1801 underpins its legality, interoperability, and technical robustness in the U.S. market.

Potential Use Cases & Target Audience

The advanced capabilities of the Phantom 4 Pro V2.0 make it a versatile tool across several demanding scenarios:

- Professional Aerial Photography & Cinematography

- With its 1-inch 20MP sensor and 4K/60fps video, the drone is ideal for filmmakers, photographers, and content creators seeking broadcast-quality aerial footage and images.

- Surveying, Mapping, and Inspection

- The long-range transmission, precise GPS, and multi-directional obstacle avoidance suit commercial applications such as land surveying, infrastructure inspection, and agricultural monitoring, where clarity and reliability are paramount.

- High-End Enthusiast Use

- Tech-savvy hobbyists and prosumers who value both ease-of-use and advanced imaging will appreciate the intelligent flight modes, reduced noise, and robust wireless connectivity—enabling creative exploration with professional results.

The Phantom 4 Pro V2.0 is engineered for users who demand unprecedented clarity, lower operational noise, and superior image quality—whether for creative, commercial, or advanced recreational applications.

Conclusion

The Phantom 4 Pro V2.0 by SZ DJI TECHNOLOGY CO., LTD (FCC ID SS3-WM331S1801) exemplifies the pinnacle of prosumer drone design, seamlessly integrating high-resolution imaging, advanced flight intelligence, and robust wireless technology. Its FCC certification ensures legal compliance and reliable operation in the U.S., while its modular, expertly engineered internals support both performance and maintainability. Whether deployed for professional aerial imaging, commercial inspection, or advanced recreation, the Phantom 4 Pro V2.0 stands out as a versatile, future-ready flying camera, setting a high bar for the next generation of unmanned aerial systems.