Introduction

The Phantom 3 SE by SZ DJI TECHNOLOGY CO., LTD. is a high-performance camera drone designed for enthusiasts and professionals seeking robust aerial imaging and precise control. Engineered for long-distance flight, high-resolution video capture, and intuitive operation, the Phantom 3 SE stands out in DJI’s renowned Phantom lineup. This model is equipped with advanced features such as a 4K camera, GPS+GLONASS navigation, and a powerful remote controller, making it a compelling choice for aerial photographers, videographers, and drone hobbyists.

A crucial aspect of the Phantom 3 SE’s market readiness is its compliance with regulatory standards. The device is certified under FCC ID SS3-W3281705, signifying that it meets stringent US regulations for radio frequency (RF) emissions and electromagnetic compatibility. While the official grant date is not listed, its registration on FCC.gov confirms its legal status for sale and use in the United States. This article delivers a comprehensive look at the Phantom 3 SE’s key features, technical specifications, wireless technologies, internal component architecture, and regulatory standing—offering expert insights for those seeking to understand its engineering and compliance profile.

Key Features & Specifications

The Phantom 3 SE is packed with high-end features and robust hardware designed to deliver exceptional performance and user experience. Here’s a breakdown of its most notable capabilities and technical specs:

Key Features

- Remote Controller Transmission Distance

- FCC compliant range: Up to 13,123 feet (4,000 m)

- SRRC compliant range: Up to 9,843 feet (3,000 m)

-

Benefit: Enables extended flight operations, critical for professional photography, surveying, and exploration.

-

Mobile Device Holder

-

Benefit: Allows real-time HD video streaming and flight telemetry display on smartphones or tablets, enhancing situational awareness.

-

Camera Performance

- Video: Records up to 4K (4096×2160 24/25p)

- Photos: 12-megapixel stills, 1/2.3” CMOS sensor

-

Benefit: Delivers ultra-high-definition footage and crisp aerial photography.

-

3-Axis Gimbal Stabilization

-

Benefit: Ensures smooth, shake-free video and precise image capture, even in dynamic flight conditions.

-

Micro SD Card Support

- Max capacity: 64GB (Class 10 or UHS-1 required)

-

Benefit: Ample onboard storage for extended missions and high-bitrate 4K video recording.

-

Interval Shot Function

-

Benefit: Enables automated time-lapse and interval photography for creative workflows.

-

Remote Controller Battery

- Type: 2,600 mAh LiPo 18650 (Rechargeable)

- Benefit: Supports long sessions without frequent recharging.

Technical Specifications

- Remote Controller Operating Temperature: 32° to 104° F (0° to 40° C)

- Max Ascent Speed: 5 m/s

- Max Video Storage Bitrate: 60 Mbps

- Aircraft Operating Temperature: 32° to 104° F (0° to 40° C)

- Battery (Aircraft):

- Capacity: 4,480 mAh, 15.2 V, 68 Wh, LiPo 4S

- Net Weight: 365 g

- Max Flight Time: ~25 minutes (real-world conditions may vary)

- GNSS Support: GPS + GLONASS

- Wireless Interfaces:

- Wi-Fi: Present (specific details not disclosed)

- Bluetooth: Present (specific details not disclosed)

Camera Video Recording Modes

- C4K: 4096×2160 @ 24/25p

- 4K UHD: 3840×2160 @ 24/25/30p

- 2.7K: 2704×1520 @ 24/25/30p

- FHD: 1920×1080 @ 24/25/30/48/50/60p

- HD: 1280×720 @ 24/25/30/48/50/60p

Operating Frequencies

The Phantom 3 SE, under FCC ID SS3-W3281705, operates across the following frequency bands, as documented in its FCC filing:

| Frequency Range (GHz) | Output Power (mW) | FCC Rule Part |

|---|---|---|

| 5.825 | 847.2 | 15E38 |

| 12.412–2.462 | 344.3 | 15CCC1.15.745 |

These allocations are critical for understanding the drone’s wireless communication capabilities. The 5.825 GHz band is commonly utilized for high-throughput, low-latency wireless links (such as video downlink or telemetry), while the 2.4 GHz range is the global standard for Wi-Fi and remote control. The specified output power ensures robust signal penetration and extended range while maintaining compliance with US radio regulations.

Technology Deep Dive

The Phantom 3 SE leverages a suite of wireless technologies to deliver seamless control, real-time video transmission, and reliable telemetry. The presence of both Wi-Fi and Bluetooth interfaces allows for flexible connectivity with mobile devices and accessories, while the primary control and video downlink are likely managed over the 2.4 GHz and 5.8 GHz ISM bands.

Operating within these frequency ranges provides several advantages: the 2.4 GHz band offers strong obstacle penetration and range, making it ideal for remote control and telemetry, while the 5.8 GHz band is used for high-speed video transmission with reduced interference in crowded environments. The carefully managed output power, as specified in the FCC documentation, balances range, battery life, and compliance with RF exposure limits.

The Phantom 3 SE’s robust wireless architecture ensures low-latency command response and stable HD video streaming, even at extended distances. The integration of GNSS (GPS + GLONASS) further enhances positional accuracy and flight reliability. While detailed test report data is not included here, the device’s adherence to FCC emissions standards under FCC ID SS3-W3281705 confirms that its RF emissions and susceptibility are within acceptable limits, ensuring safe operation in diverse environments.

In-Depth Internal Component Analysis / Teardown

Internal-Photos-3468964_page10_img1.jpeg

A close examination reveals a PCB antenna module engineered for optimal RF performance. Labeled ‘P03170.02’, this single-sided, black soldermask PCB is mounted within the drone’s plastic arm, a strategic location to maximize signal exposure and minimize interference. The design—a thin, elongated strip—suggests an IFA or monopole trace antenna, finely tuned for 2.4GHz or 5.8GHz operation, critical for Wi-Fi or telemetry. The absence of ICs, shielding, or power components highlights its purely passive nature, while the direct soldered wire ensures minimal signal loss. This robust, lightweight antenna is essential for the Phantom 3 SE’s reliable long-range wireless communication.

Internal-Photos-3468964_page11_img1.jpeg

This passive antenna board features a long, narrow FR4 PCB with precisely etched traces, optimized for 2.4GHz or 5.8GHz frequencies. Designed for integration within the drone’s arm or body, its mounting holes ensure secure placement and consistent RF characteristics. The absence of active components and shielding is typical for such elements, as any metallic enclosure would impede signal transmission. The robust construction and exacting trace layout reflect intentional RF engineering, essential for maintaining strong, interference-resistant links for control, telemetry, or video transmission over significant distances.

Internal-Photos-3468964_page11_img2.jpeg

Here, a slim black PCB antenna assembly is connected to the main board via a coaxial cable, ensuring efficient RF signal transfer. Markings such as PO3170.02 and KB 1713 aid manufacturing traceability, while the absence of ICs confirms its passive antenna function. The board’s dimensions and layout indicate tuning for ISM bands, supporting Wi-Fi, Bluetooth, or control channels. The clean soldering and robust mounting provisions highlight DJI’s attention to production quality and reliability—crucial for consistent drone performance in both control and video transmission.

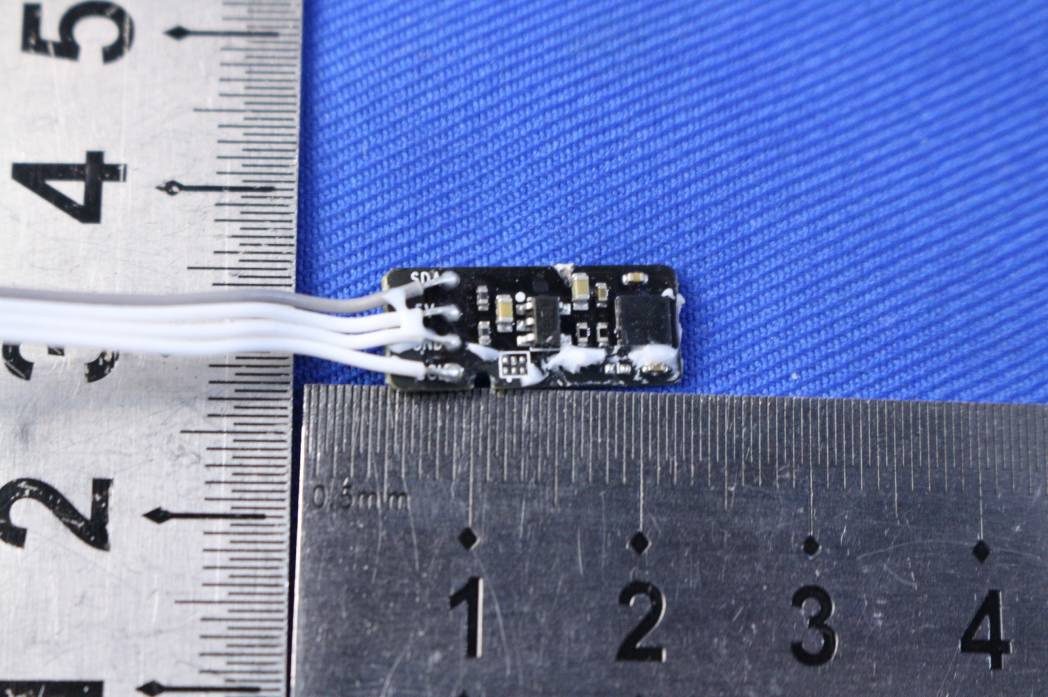

Internal-Photos-3468964_page12_img1.jpeg

This compact PCB module, measuring roughly 2 cm by 0.7 cm, is populated with several surface-mount components, including a central IC likely serving as a sensor interface or signal conditioner. The presence of four directly soldered white wires suggests integration with other drone subsystems, possibly for sensor data acquisition (e.g., IMU, compass, or barometer). Ground pours and stitching vias indicate effective EMI management, while local power filtering components support stable, noise-free operation. The overall design prioritizes low noise, modularity, and minimal weight, reflecting DJI’s meticulous engineering for flight-critical sensor integration.

Internal-Photos-3468964_page14_img1.jpeg

This densely populated, multi-layer PCB represents the heart of the Phantom 3 SE’s flight control or camera interface system. Visible are major ICs—likely memory and processing units—and a high-density connector for gimbal or camera data. Differential pair routing and numerous ground stitching vias demonstrate advanced signal integrity and EMI control. The robust power section, with inductors and capacitors, supports multiple voltage domains for digital and analog subsystems. Test points and clear silkscreen labels facilitate manufacturing and troubleshooting, while the overall compactness and modularity showcase DJI’s expertise in drone electronics integration.

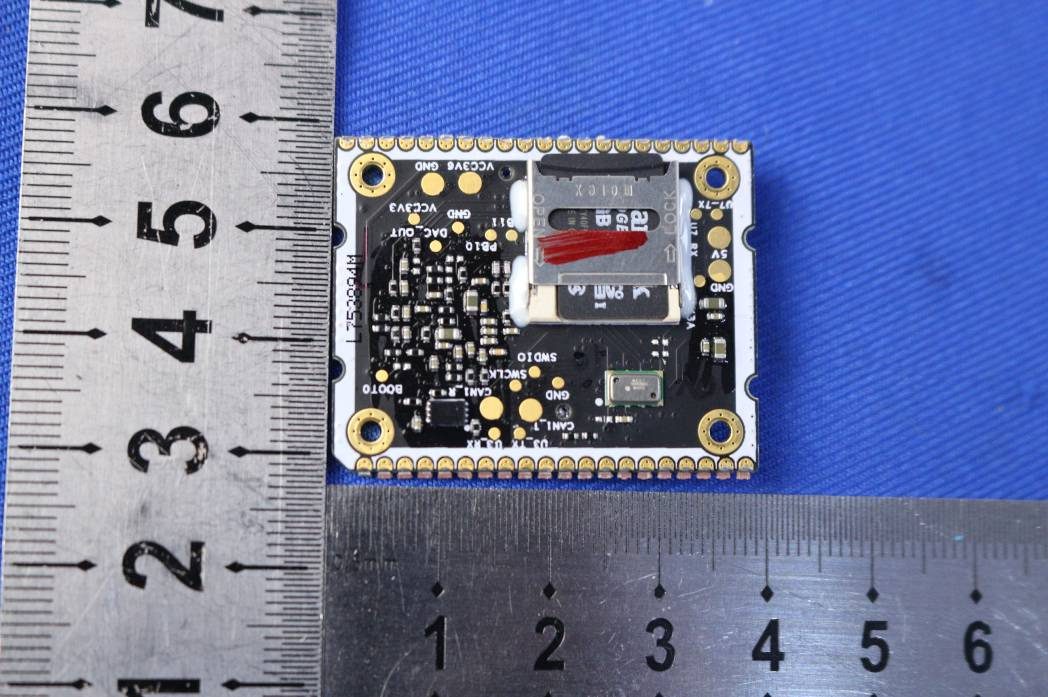

Internal-Photos-3468964_page3_img2.jpeg

This compact module features a microSD slot, several SMD ICs, and a crystal oscillator, all on a high-quality black PCB with castellated edges for integration. The layout suggests a data logging or GPS subassembly, with robust power regulation and EMI mitigation via dense ground vias. Test points for key signals indicate ease of debugging and firmware updates. The modular, well-labeled design enhances reliability and maintainability, reflecting best practices for embedded drone electronics.

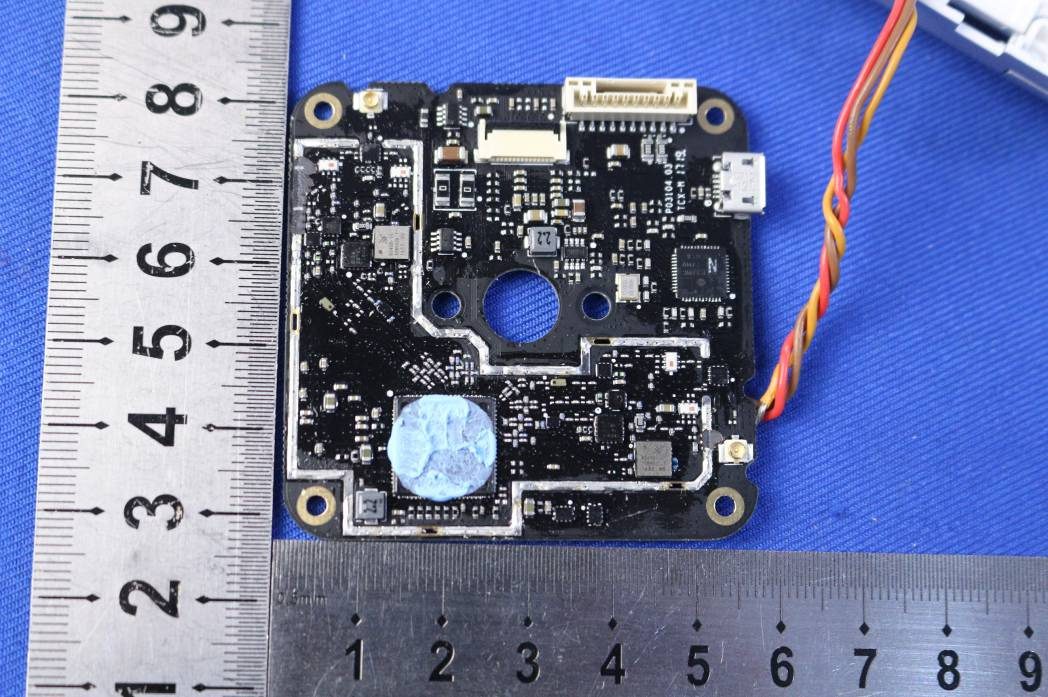

Internal-Photos-3468964_page15_img1.jpeg

This advanced PCB is likely a flight controller or gimbal interface, featuring a large MCU or SoC, multiple power management ICs, and connectors for peripherals. The dense SMT assembly, central cutout, and conformal coating demonstrate attention to thermal management and vibration resistance. Power integrity is ensured by large inductors and capacitors, while modular cabling and multiple interface connectors simplify assembly and servicing. The high integration level and robust design are hallmarks of DJI’s engineering excellence.

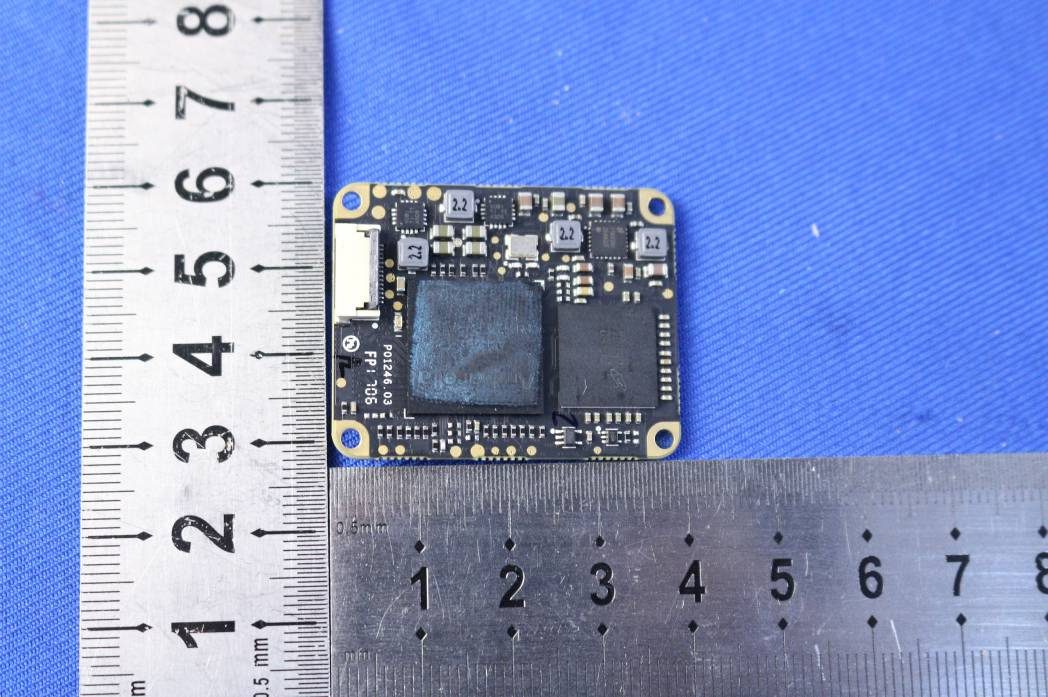

Internal-Photos-3468964_page16_img2.jpeg

This small, high-density PCB integrates a main processor, memory chip, power management, and interface circuits, likely supporting flight control or wireless communication. The gold ENIG finish, multi-layer construction, and impedance-controlled traces ensure durability and high-speed signal fidelity. A single FPC/FFC connector enables modular integration, while the absence of large power components points to its role as a logic or communication board. The build quality and layout are consistent with DJI’s standards for reliable, compact drone electronics.

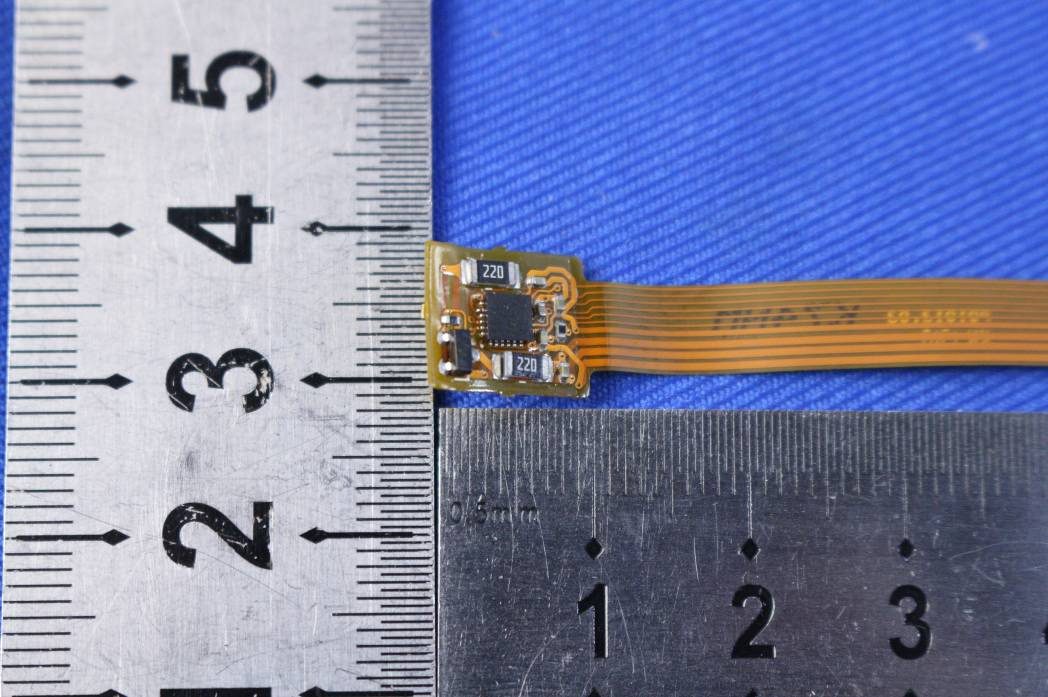

Internal-Photos-3468964_page9_img2.jpeg

This flexible printed circuit (FPC) assembly demonstrates precision engineering for space-constrained applications. The central QFN IC, flanked by passives, likely provides sensor interface or signal conditioning functions—possibly for a gimbal, camera, or IMU. The FPC format enables lightweight, flexible routing within the drone, while clean component placement and trace routing ensure reliability. Designed for low-power, low-noise operation, this module exemplifies how DJI achieves high integration without sacrificing performance or maintainability.

Regulatory Insights & FCC Filing

Certification under FCC ID SS3-W3281705 confirms that the Phantom 3 SE by SZ DJI TECHNOLOGY CO., LTD. meets all US standards for electromagnetic interference (EMI) and radio frequency (RF) emissions. This compliance is essential for legal sale and operation within the United States, ensuring that the device does not cause harmful interference to other wireless systems and operates safely within regulated power and frequency constraints. The device’s registration (grant date: None) is recorded with the FCC, providing transparency and accountability.

FCC filings typically include a wealth of technical documentation—RF exposure and EMC test reports, internal and external photographs, user manuals, schematics, and block diagrams. These documents collectively demonstrate the device’s adherence to technical and safety requirements. According to the user manual, the Phantom 3 SE is engineered for extended-range flight, high-resolution imaging, and user-friendly operation, with built-in safety guidelines and robust wireless architecture. The FCC documents substantiate its engineering quality and regulatory fitness.

Potential Use Cases & Target Audience

With its powerful feature set and robust wireless capabilities, the Phantom 3 SE appeals to a wide range of users:

-

Aerial Photographers & Videographers: The 4K camera, stabilized gimbal, and long-range remote controller make the Phantom 3 SE ideal for capturing cinematic landscapes, real estate, or event footage from unique aerial perspectives.

-

Surveyors & Mapping Professionals: The drone’s extended flight range, GPS+GLONASS navigation, and high-resolution imaging enable precise surveying, mapping, and inspection of large areas, infrastructure, or agricultural fields.

-

Tech Enthusiasts & Hobbyists: Drone enthusiasts seeking advanced capabilities—such as interval shooting, real-time HD video streaming to mobile devices, and customizable flight parameters—will appreciate the Phantom 3 SE’s blend of performance and user-friendly features.

Built-in safety mechanisms, intuitive controls, and mobile device integration further broaden its appeal, making it suitable for both seasoned professionals and ambitious beginners aiming to explore aerial technology.

Conclusion

The Phantom 3 SE by SZ DJI TECHNOLOGY CO., LTD. (Model: Phantom 3 SE, FCC ID SS3-W3281705) stands as a testament to DJI’s expertise in drone engineering. Its combination of long-range wireless capability, 4K camera performance, and integrated safety features make it a versatile tool for aerial imaging and exploration. The device’s FCC certification validates its compliance with US RF emission standards, affirming its readiness for the American market. Whether for professional imaging, mapping, or advanced hobbyist use, the Phantom 3 SE offers a compelling mix of innovation, reliability, and regulatory assurance.