Introduction

The Mavic 2 Pro by SZ DJI TECHNOLOGY CO., LTD. stands as a flagship in the world of professional and enthusiast aerial photography drones. Designed for high-end imaging and robust flight performance, this quadcopter is engineered to deliver stunning 20MP stills and 4K video, all supported by advanced autonomous features. Whether you’re a seasoned drone operator, an aerial cinematographer, or a tech enthusiast eager for the latest in UAV innovation, the Mavic 2 Pro offers a compelling blend of power, precision, and portability.

Of particular note is the Mavic 2 Pro’s FCC certification under FCC ID SS3-L1P1805. This regulatory approval is vital: it confirms that the device meets stringent US standards for radio frequency (RF) emissions and electromagnetic compatibility, ensuring both legal market access and reliable wireless operation. In this article, we’ll dissect the Mavic 2 Pro’s key specifications, wireless technologies, internal hardware, and regulatory context—culminating in an expert-level teardown analysis of its internal components.

Key Features & Specifications

The Mavic 2 Pro is packed with cutting-edge features and robust technical specifications, making it one of the most capable drones in its class.

Key Features

- Maximum Flight Speed: 44.7 mph (72 kph), enabling rapid deployment and agile maneuvers for dynamic shots or swift navigation.

- Omnidirectional Obstacle Sensing: Sensors on all sides provide comprehensive collision avoidance, greatly enhancing safety in complex environments.

- Fully Stabilized 3-Axis Gimbal: Delivers ultra-smooth footage and sharp photos, compensating for drone movement and wind.

- 20-Megapixel Still Photos: The large sensor captures detailed, high-dynamic-range images suitable for professional use.

- Remote Controller with On-Board LCD and Detachable Control Sticks: Real-time flight data display and customizable ergonomics for portability and control.

- Intelligent Flight Modes: Includes ActiveTrack, Hyperlapse, and advanced waypoint navigation for creative and automated shooting scenarios.

- Obstacle Avoidance: Reduces crash risk, making it suitable for both advanced users and cautious beginners.

Technical Specifications

- Max Transmission Distance:

- FCC: 8 km

- CE/SRRC: 5 km

This extended range ensures reliable control and video downlink in open environments. - Battery Type: LiPo (Lithium Polymer), balancing high energy density with lightweight construction.

- Net Weight (Battery): Approx. 297 g

- Remote Controller Operating Temperature: 32° to 104° F (0° to 40° C)

- Charger Voltage: 17.6±0.1 V

- Still Photography Modes:

- Single shot

- Burst shooting (3/5 frames)

- Auto Exposure Bracketing (AEB): 3/5 frames at 0.7 EV Bias

- Interval capture

- Gimbal Controllable Range:

- Pitch: -90° to +30°

- Yaw: -90° to +90°

- Wi-Fi:

- Operating Frequency: 2.4–2.4835 GHz; 5.725–5.850 GHz

These dual bands provide flexibility and resilience against interference. - Bluetooth: Present (details not specified)

- Camera Info:

- Sensor: 1″ CMOS; 20MP effective pixels

- Max Image Size: 5472×3648

- Video Recording Modes:

- 4K: 3840×2160 24/25/30p

- 2.7K: 2688×1512 24/25/30/48/50/60p

- FHD: 1920×1080 24/25/30/48/50/60/120p

- Battery (Drone):

- Intelligent Flight Battery Capacity: 3850 mAh

- Max Flight Time: 31 minutes (no wind, steady 15.5 mph/25 kph)

- Battery (Remote Controller):

- Capacity: 3950 mAh

- Max Run Time: 2 hours 15 minutes

Benefits in Practice:

These specifications translate to longer missions, superior image quality, and greater reliability in challenging conditions. The integration of advanced sensors and gimbal stabilization ensures that both amateurs and professionals can capture cinematic footage with minimal manual intervention.

Operating Frequencies

The Mavic 2 Pro (Model L1P, FCC ID SS3-L1P1805) operates across multiple wireless frequency bands, as detailed in its FCC filing:

| Frequency Range (GHz) | Output Power (mW) | FCC Rule Part |

|---|---|---|

| 2.4035–2.4775 | 129.1 | 15CCC1.12.4055 |

| 2.4725 | 67 | 15CCC1.35.7285 |

| 2.4775 | 64.6 | 15CCC1.22.4105 |

| 5.8395 | 161.8 | 15ECC2.3 |

| 5.8445 | 208 | 15ECC2.25.7355 |

| 5.8465 | 164.1 | 15ECC2.15.7305 |

Significance:

These bands support robust wireless video transmission, remote control, and possibly telemetry, ensuring strong performance in diverse environments. The output powers are carefully selected to balance range, data rate, and regulatory compliance.

Technology Deep Dive

The Mavic 2 Pro leverages advanced wireless technologies to deliver seamless connectivity and control. Utilizing dual-band Wi-Fi (2.4 GHz and 5.8 GHz), the drone achieves high data throughput for real-time HD video streaming and responsive command input. These frequencies are industry standards for minimizing interference and maximizing range, especially important in crowded RF environments.

Bluetooth is also present, likely supporting peripheral connectivity or simplified setup, though detailed implementation specifics are not available. The absence of cellular connectivity aligns with its primary use cases, focusing on direct wireless links between drone and controller.

Operating across multiple frequency bands allows the Mavic 2 Pro to adapt dynamically to RF congestion, reduce the risk of signal dropouts, and maintain low-latency video feeds. The device’s moderate-to-high output power levels enhance range while remaining within safe RF exposure limits, as confirmed by regulatory test reports. Internal documentation highlights the importance of EMI shielding and robust power management, both critical for maintaining signal integrity and minimizing interference between subsystems. Collectively, these technologies underpin the Mavic 2 Pro’s reputation for reliable, long-distance operation and professional-grade wireless performance.

In-Depth Internal Component Analysis / Teardown

Main PCB and Processing Core

The internal architecture of the Mavic 2 Pro reveals a densely populated main PCB, showcasing the hallmarks of advanced drone engineering. Under extensive metal shielding, large integrated circuits act as the system’s brain—likely comprising the main SoC, flight controller MCU, and RF transceivers. The multi-layer PCB design, with visible ground planes and numerous vias, ensures high-speed data integrity and effective EMI suppression. Robust coaxial antenna connections support omnidirectional RF coverage, vital for both control and HD video transmission. The presence of large inductors and capacitors indicates sophisticated power management, while multiple FPC connectors facilitate modular assembly and vibration resistance. This layout demonstrates a meticulous focus on reliability, performance, and RF compliance.

Power Distribution and Motor Control Board

A closer look at the power distribution module reveals a PCB optimized for high-current delivery. Thick solder joints and heavy-gauge wires are routed directly to motor windings, indicating this is the electronic speed controller (ESC) board. While major ICs are not visible on this side—likely shielded or located on the reverse—the presence of large SMD capacitors and MOSFETs suggests active power switching and filtering. The modularity is evident in the use of edge connectors and labeled test points, supporting both manufacturing efficiency and serviceability. This board exemplifies careful management of high-power circuits and robust grounding, essential for reliable flight and motor response.

Internal Structure and Motor Interface

The partially disassembled view exposes the integration of power, control, and mechanical subsystems. The black ENIG-finished PCB supports both motor control and sensor interfacing, with visible QFP and QFN packages likely serving as MOSFET drivers and microcontrollers. Wide traces accommodate motor currents, while fine differential pairs suggest high-speed data or sensor connections. A white coaxial cable hints at internal antenna routing, supporting RF communication. Modular connectors and compact wiring facilitate both assembly and repair. This architecture balances dense integration with modularity, ensuring the drone’s core systems remain both lightweight and serviceable.

High-Density Motor Driver and Power Board

A densely populated PCB reveals a sophisticated array of motor driver ICs, power management chips, and memory controllers. Large microcontrollers and MOSFETs are symmetrically arranged to optimize motor control and power distribution. White coaxial cables routed from the board underscore the importance of robust RF connectivity, likely supporting video and telemetry links. The presence of numerous test points and debug pads facilitates factory programming and diagnostics. The build quality—marked by clean soldering, precise placement, and modular connectors—reflects a mature engineering approach, optimized for real-time control and high-bandwidth communication.

Internal Metal Strip Antenna

A detailed view of the metal strip antenna highlights the drone’s RF sophistication. The stamped metal design, paired with a coaxial cable, is tuned for optimal efficiency in the 2.4/5.8 GHz bands. This robust construction ensures durability and consistent performance, even in challenging flight conditions. The etched patterns and mounting holes speak to precision engineering for minimal signal loss and reliable omnidirectional coverage—key for both remote control and video downlink.

Stereo Vision and Obstacle Detection Module

This compact sensor module is central to the drone’s omnidirectional obstacle sensing. Featuring dual lens assemblies, high-intensity LEDs, and a shielded processing IC, this board enables real-time depth mapping and navigation. The dense layout and robust EMI shielding minimize interference, ensuring accurate data acquisition even in electromagnetically noisy environments. The presence of local power regulation and precise clocking components underlines the sophistication required for stereo vision and active sensing.

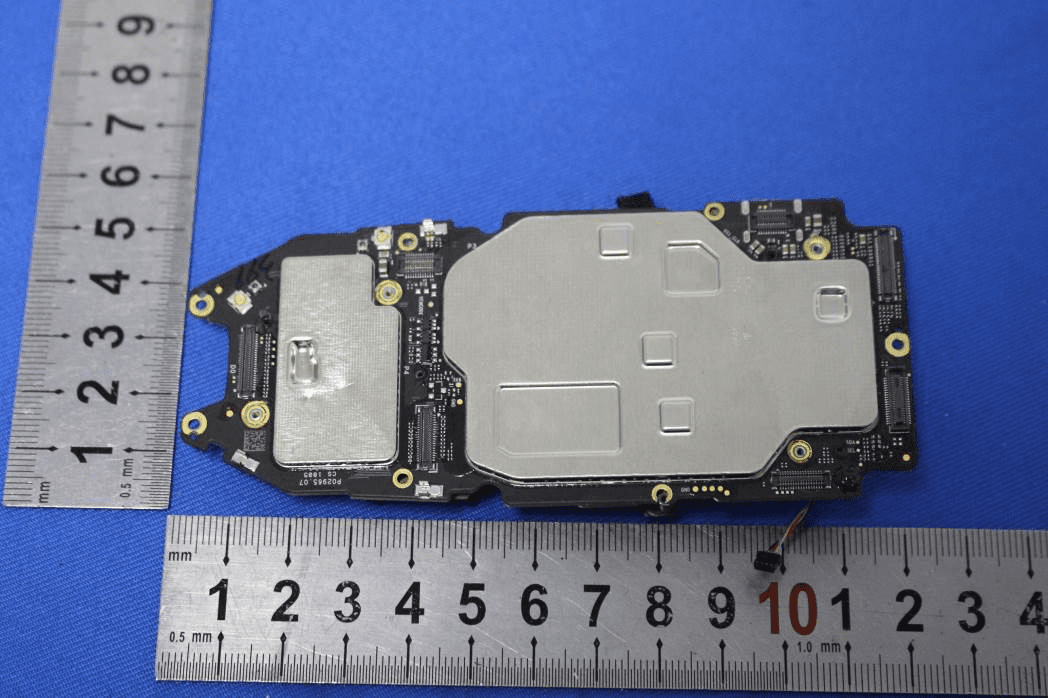

Flight Controller and RF Mainboard

A densely populated, multi-layer PCB houses the drone’s core flight controller and wireless subsystems. Under substantial EMI shielding, large BGA and QFP ICs likely serve as the main processor, memory, and RF transceivers. The presence of multiple FPC connectors and test points supports modular integration and diagnostics. Extensive power filtering and thermal management (evidenced by blue thermal pads) ensure stable operation under demanding conditions. This board exemplifies the integration of real-time flight control, image processing, and multi-band wireless communication.

High-Resolution Camera Sensor Module

This module showcases the Mavic 2 Pro’s imaging prowess, featuring a large 1-inch CMOS sensor mounted on a compact PCB. The attached image signal processor and local power regulation components enable real-time image capture and pre-processing before data is sent to the main flight controller. The use of a high-bandwidth flex cable ensures minimal signal loss, while the dense, multi-layer PCB layout prioritizes noise reduction and signal integrity. This assembly is the cornerstone of the drone’s professional-grade imaging capabilities.

EMI-Shielded Communication and Processing Board

Another critical PCB within the Mavic 2 Pro features extensive EMI shielding over its primary RF and processing sections. Multiple FPC connectors, fine-pitch routing, and robust grounding strategies are evident, supporting high-speed data transfer and minimizing interference. The modular design, with board-to-board connections and test points, ensures ease of assembly and future servicing. This board likely handles wireless communication, flight data processing, and peripheral integration, all under strict EMI control.

Miniaturized RF and Control Module

A compact, shielded PCB exemplifies advanced miniaturization and integration. The dense layout, fine-pitch connectors, and multi-layer construction support high-speed wireless communication and sensor interfacing. The presence of a crystal oscillator and shielded IC cluster suggests this board is dedicated to RF transmission or flight control. The overall build quality, including robust soldering and modular connectors, reflects DJI’s commitment to reliability and performance in compact UAV designs.

Regulatory Insights & FCC Filing

The Mavic 2 Pro’s certification under FCC ID SS3-L1P1805 signifies that it meets all US requirements for RF emissions and electromagnetic compatibility. This approval, registered by the FCC, is essential for legal sale and operation in the United States and attests to the device’s adherence to established safety and interference standards.

FCC filings for the Mavic 2 Pro include comprehensive documentation: RF exposure and electromagnetic compatibility test reports, internal and external photographs, user manuals, and detailed block diagrams. These documents confirm that the drone operates safely within regulated power and frequency limits, and that its wireless subsystems are engineered to minimize interference with other devices.

User manual analysis highlights the drone’s advanced feature set—omnidirectional obstacle sensing, stabilized 3-axis gimbal, and a 1” CMOS camera—while test reports validate that all wireless emissions remain within prescribed limits. Internal documentation further underscores the importance of robust EMI shielding, effective power management, and modular hardware design, all contributing to the drone’s reliability and regulatory compliance.

Potential Use Cases & Target Audience

With its blend of professional imaging and intelligent flight technologies, the Mavic 2 Pro serves a diverse spectrum of users:

-

Aerial Photography and Cinematography Professionals:

The 20MP, 1-inch CMOS sensor and stabilized 3-axis gimbal make the Mavic 2 Pro a top choice for filmmakers and photographers seeking cinematic-quality footage and high-resolution stills, even in challenging lighting conditions. -

Surveyors and Mapping Specialists:

The drone’s long flight time (up to 31 minutes), extended range (up to 8 km), and precise obstacle avoidance allow operators to efficiently capture detailed aerial data for mapping, inspection, and surveying projects. -

Advanced Enthusiasts and Drone Pilots:

For hobbyists and tech-savvy users, the Mavic 2 Pro offers a platform for exploring intelligent flight modes, waypoint navigation, and real-time HD video streaming—making it an ideal tool for both creative and technical exploration.

Conclusion

The Mavic 2 Pro by SZ DJI TECHNOLOGY CO., LTD. sets a high standard in the realm of consumer and professional drones, blending powerful imaging, robust wireless performance, and intelligent flight autonomy. Its FCC certification under FCC ID SS3-L1P1805 underscores its compliance with rigorous US regulatory standards, ensuring both legal operation and reliable performance. With advanced internal engineering, extensive EMI shielding, and a suite of intelligent features, the Mavic 2 Pro remains a premier choice for anyone demanding the best in aerial imaging and technology-driven flight.