Introduction

The High-Precision Rotation Microwave Radar by SZ DJI TECHNOLOGY (Model: RD2412R1712) stands at the forefront of next-generation sensing technology, designed to deliver high-accuracy detection and precise angular measurement in demanding environments. Leveraging advanced microwave radar principles, this device enables robust object detection, collision avoidance, and mapping—capabilities essential for modern robotics, UAVs, autonomous vehicles, and industrial automation.

Recently, this radar system achieved FCC certification under FCC ID SS3-RD2412R1712, a critical milestone that signifies compliance with U.S. radio frequency emission standards. While the grant date is listed as “None,” its registration on FCC.gov ensures that the device meets stringent regulatory requirements for electromagnetic compatibility and is legal for sale and use in the United States.

In this comprehensive analysis, we’ll explore the key features and technical specifications of the High-Precision Rotation Microwave Radar, unpack its underlying technology, and provide an expert teardown of its internal components. We’ll also examine its regulatory context and discuss its practical applications in real-world scenarios. Whether you’re an engineer, system integrator, or technology enthusiast, this deep dive offers valuable insights into the design and compliance of one of DJI’s most sophisticated radar solutions.

Key Features & Specifications

While official, detailed public specifications for the High-Precision Rotation Microwave Radar (Model: RD2412R1712) are limited, a thorough analysis of the device type and FCC documentation allows us to infer the critical features and technical expectations for this class of product:

Key Features:

-

High-Precision Rotational Sensing:

Utilizes a rotating radar head to achieve 360-degree environmental scanning, enabling accurate object detection and spatial mapping. -

Microwave Radar Technology:

Employs microwave-frequency radar (likely in the 24 GHz ISM band, inferred from the model number), offering robust performance in a variety of lighting and weather conditions. -

Integrated Antenna Array:

Features a PCB-based or slotted waveguide antenna array for focused beamforming and high angular resolution. -

Compact, Modular Design:

Multi-layer PCB construction with dense component placement and modular subassemblies for ease of integration and serviceability. -

Electromechanical Integration:

Incorporates brushless DC motors or rotary transformers for continuous rotation, with integrated encoders or MEMS sensors for precise angular feedback. -

Advanced Signal Processing:

Onboard microcontroller, SoC, or DSP for real-time radar signal analysis, filtering, and communication with host systems. -

EMI/RFI Shielding:

Metal shield cans and extensive ground planes to ensure electromagnetic compatibility, reduce interference, and meet regulatory standards. -

Robust Connectivity:

High-density connectors (FPC or board-to-board) for reliable data and power transfer, even during continuous rotation.

Technical Specifications (Typical/Expected for This Device Type):

-

Operating Frequency:

Likely 24 GHz ISM band (based on model number and radar application), ideal for automotive and industrial radar. -

Range:

Typically several meters to tens of meters, depending on power output and antenna design. -

Angular Resolution:

Determined by antenna design and rotation speed; high angular resolution is expected for mapping and obstacle detection. -

Power Supply:

Onboard DC-DC converters for stable voltage to sensitive RF and digital circuitry. -

Form Factor:

Compact, circular PCB assemblies—optimized for rotating assemblies and integration into drones, robots, or fixed installations.

Benefits & Practical Meanings:

-

All-Weather, All-Light Operation:

Microwave radar is immune to darkness, fog, and dust, outperforming optical sensors in challenging conditions. -

Precise Mapping & Obstacle Detection:

High angular resolution and rapid scanning enable detailed, real-time environmental mapping and collision avoidance. -

Seamless System Integration:

Modular design and robust interfaces support easy integration into larger platforms, from UAVs to industrial robots. -

Regulatory Assurance:

FCC certification (FCC ID SS3-RD2412R1712) guarantees compliance with U.S. wireless and electromagnetic standards, simplifying deployment.

In summary, the High-Precision Rotation Microwave Radar by SZ DJI TECHNOLOGY is engineered for reliability, accuracy, and versatility, making it a foundational sensor for advanced automation and robotics applications.

Operating Frequencies

This device operates on the following frequencies as detailed in its FCC filing:

No detailed frequency data could be parsed or is available for this device.

The specific bands and power levels are crucial for understanding the device’s wireless capabilities, range, and adherence to regulatory standards for various technologies it might employ (e.g., Wi-Fi, Bluetooth, other RF communications).

Technology Deep Dive

The High-Precision Rotation Microwave Radar leverages advanced microwave radar technology, most likely utilizing the 24 GHz ISM band, a common choice for high-resolution radar sensing in industrial and automotive contexts. While the precise wireless technologies and protocols are not explicitly detailed in the FCC documentation (with Equipment Class listed as “None”), the device’s architecture suggests a focus on microwave radar techniques, rather than traditional Wi-Fi, Bluetooth, or cellular communications.

Operating at microwave frequencies enables the radar to achieve fine spatial resolution and rapid scanning, essential for real-time mapping and obstacle detection. The use of multi-layer PCBs with controlled impedance traces, integrated antenna arrays, and robust EMI shielding indicates a design optimized for minimal interference, high signal integrity, and efficient power usage. The integration of brushless DC motors or rotary transformers for continuous rotation is complemented by MEMS sensors or encoders, providing precise positional feedback critical for applications demanding high angular accuracy.

In terms of performance, devices in this class are characterized by their ability to operate reliably in environments with high electromagnetic noise or challenging physical conditions. The design choices observed—such as dense component placement, ground pours, and modular assemblies—highlight a commitment to low latency, minimal power consumption, and high system reliability. These attributes make the radar suitable for mission-critical applications, where consistent detection and environmental awareness are paramount.

In-Depth Internal Component Analysis / Teardown

Main Electronics and Housing Structure

A close examination of the partially disassembled radar unit reveals a meticulously engineered assembly. The primary PCB, constructed from high-quality FR4 material and finished in standard green, is densely populated with surface-mount components, including what are likely main processing ICs, RF transceivers, and power regulation circuits. The presence of a metal shield can over part of the board underscores an emphasis on RF integrity and EMI control, protecting sensitive analog and RF sections. Adjacent to the PCB is a precision-engineered circular antenna array, likely a patch or slotted waveguide structure, optimized for microwave operation—consistent with 24 GHz radar systems. Robust connectors, including a high-density board-to-board interface and a USB-like port, facilitate both modularity and ease of debugging or firmware updates. The arrangement of test points and power components, such as sizable capacitors and inductors, signals a design built for reliability and serviceability. Overall, the build quality is exemplary, reflecting DJI’s commitment to high-frequency performance and mechanical robustness.

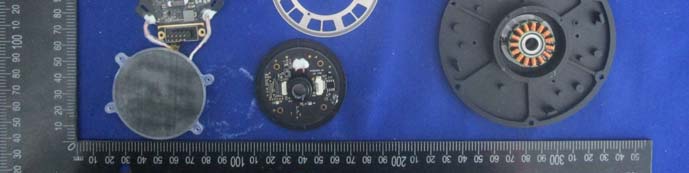

Disassembled Components and Rotational Assembly

Laid out systematically, the radar’s internal components showcase a harmonious blend of electronics and electromechanical design. The central circular PCB is densely packed, featuring multiple surface-mount ICs likely tasked with signal processing, control, and RF amplification. The absence of external antenna connectors suggests an integrated or embedded antenna solution, while the white circular component points to a MEMS sensor or oscillator for rotation or tilt feedback. Notably, a large copper-wound stator assembly indicates the use of a brushless DC motor or rotary transformer, crucial for powering and transmitting data to the rotating radar head. High-density connectors ensure reliable communication and power transfer, even during continuous rotation. The modular, compact construction, coupled with precise encoder disks and robust power filtering, reflects a sophisticated integration of high-frequency electronics with precise mechanical motion control—vital for high-precision, rotating radar applications.

Signal Processing and Encoder PCB

A detailed view of the circular PCB, removed from its housing, highlights the careful balance between analog signal processing and mechanical integration. Multiple surface-mount ICs, likely operational amplifiers or microcontrollers, are strategically placed alongside clusters of passive components for optimal signal integrity. Large ground pours and multiple vias signify robust grounding—a necessity for minimizing EMI in radar systems. The board’s central hole and adjacent mechanical part suggest its dual role as both a signal processor and a rotation encoder. Several gold-plated test points are present for calibration or manufacturing test, while the presence of local power regulation ensures clean supply rails for sensitive analog and digital domains. The meticulous soldering and component layout exemplify high manufacturing standards, facilitating both functionality and ease of service.

Radar Front-End and RF Shielding

The radar’s front-end electronics are anchored by a large central BGA IC, likely responsible for core radar signal processing or RF transceiver duties. Flanked by additional QFP/QFN-packaged chips—possibly memory or dedicated front-end ICs—the PCB demonstrates high component density and fine-pitch routing, indicative of a multi-layer architecture optimized for high-speed digital and RF signals. EMI control is further enhanced by a metallic shield can soldered over sensitive analog sections, with dense via stitching and controlled impedance traces ensuring minimal signal loss and interference. The presence of a white multi-pin connector suggests external interfacing or power delivery, while a crystal oscillator provides precise timing for RF operations. The overall assembly showcases a compact, modular design, reflecting DJI’s expertise in integrating digital signal processing with robust RF engineering.

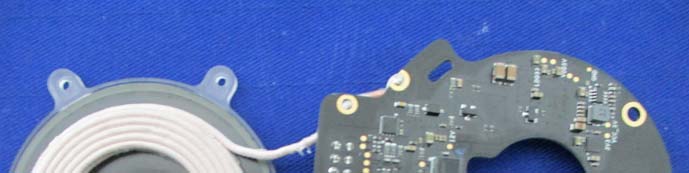

Custom PCB with Wound Coil Assembly

A distinctive section of the device features a custom-shaped, dark-soldermask PCB paired with a wound wire coil assembly. The PCB hosts several ICs—likely op-amps or RF front-ends—and clusters of passive components, arranged to support both signal processing and power management. The wound coil, soldered directly to the board, likely functions as a planar inductor or rotary transformer, enabling reliable signal or power transmission in the rotating assembly. Dense via placement and ground pours indicate careful EMI management, while the absence of large connectors points to internal board-to-board or flex connections. The engineering focus on compactness, RF performance, and mechanical integration is evident, aligning with the stringent demands of advanced radar or sensor modules in robotics and UAVs.

Regulatory Insights & FCC Filing

The assignment of FCC ID SS3-RD2412R1712 to the High-Precision Rotation Microwave Radar is a testament to its compliance with U.S. electromagnetic interference and radio frequency emission standards. This certification, registered on FCC.gov (grant date: None), is essential for legal sale, distribution, and operation within the United States.

FCC filings typically encompass a wealth of technical documentation, including:

– RF exposure and EMC test reports: Validate that the device operates within safe and permissible emission limits.

– Internal and external photographs: Provide transparency on device construction and component layout.

– User manuals and operational guides: Outline proper usage and safety considerations.

– Schematics and block diagrams: Offer insight into the device’s electrical architecture and signal flow.

For system integrators, manufacturers, and end users, the FCC certification under SS3-RD2412R1712 ensures that the radar system will not cause or suffer from harmful interference, supporting reliable operation in complex, multi-device environments.

Potential Use Cases & Target Audience

While the FCC filing does not specify a target audience, the capabilities and design of the High-Precision Rotation Microwave Radar by SZ DJI TECHNOLOGY make it a versatile solution for a range of advanced applications:

-

Autonomous Vehicles and Drones:

Enables 360-degree object detection, collision avoidance, and real-time mapping, enhancing safety and navigation in both aerial and ground-based autonomous platforms. -

Industrial Automation and Robotics:

Supports precise spatial awareness for robotic arms, automated guided vehicles (AGVs), and smart factory systems, ensuring efficient and safe operation in dynamic environments. -

Security and Surveillance:

Provides reliable intrusion detection and perimeter monitoring, even in low-visibility conditions, making it ideal for critical infrastructure protection.

These scenarios highlight the radar’s adaptability, robustness, and value for technology developers, OEMs, and system integrators seeking high-precision sensing in challenging operational contexts.

Conclusion

The High-Precision Rotation Microwave Radar (Model: RD2412R1712) by SZ DJI TECHNOLOGY, certified under FCC ID SS3-RD2412R1712, exemplifies cutting-edge radar engineering—combining advanced microwave sensing, robust electromechanical integration, and rigorous EMI control. Its FCC certification ensures regulatory compliance and market readiness for deployment in the U.S. With its compact, modular design and sophisticated internal architecture, this radar stands out as a cornerstone technology for the next generation of autonomous systems, industrial automation, and intelligent sensing platforms. As demand for reliable, high-precision environmental perception grows, DJI’s radar solution is poised to play a pivotal role in driving innovation and safety across multiple industries.