Introduction

The DJI Mini 2 (Model: MT2PD) stands as a compact yet powerful camera drone, engineered for aerial photography enthusiasts and professionals alike. As an evolution of DJI’s acclaimed consumer drone lineup, the Mini 2 delivers robust imaging, advanced flight features, and impressive wireless connectivity—all within a lightweight, ultraportable frame.

A significant milestone in its journey to market is its FCC certification under FCC ID SS3-MT2PD2007. This official approval not only confirms the Mini 2’s compliance with stringent US regulations for RF emissions and electromagnetic compatibility, but also authorizes its legal sale and operation in the United States. The certification process ensures the drone meets all necessary safety and interference standards, offering peace of mind to both consumers and commercial operators.

In this article, we’ll dive deep into the DJI Mini 2’s key specifications, wireless technologies, and internal components, supported by expert analysis of detailed teardown photographs. We’ll also examine its regulatory compliance, offering a comprehensive view of what makes the Mini 2 a standout in its class.

Key Features & Specifications

The DJI Mini 2 packs an impressive suite of features and capabilities into a remarkably small package, balancing performance, portability, and ease of use. Below, we break down the most critical aspects of its design and functionality.

Key Features

-

12-megapixel Photos

Capture high-resolution stills perfect for both casual and creative photography. -

Obstacle Sensing & Infrared Sensing System

Built-in sensors enhance flight safety, aiding in obstacle avoidance and precise hovering. -

DJI OCUSYNC™ 2.0 Long-Range Transmission

Industry-leading wireless technology ensures reliable control and video feed even at extended distances. -

Maximum Transmission Range of 5 mi (8 km)

Offers expansive operational reach, ideal for landscape photography and exploration. -

Fully Stabilized 3-Axis Gimbal

Mechanical stabilization delivers smooth, shake-free video and crisp photos, even in windy conditions. -

Remote Controller with Customizable Button & Gimbal Dial

Ergonomic controls with user-programmable functions for efficient, intuitive piloting.

Technical Specifications

-

Aircraft Weight: 241 g

Ultralight design allows for greater flexibility in regulatory environments and easier transport. -

Operating Temperature: 32° to 104°F (0° to 40°C)

Ensures reliable operation across a range of outdoor conditions. -

Camera Sensor: 1/2.3” CMOS; Effective Pixels: 12M

Delivers high-quality images and 4K video recording capabilities. -

35mm Format Equivalent: 24 mm

Wide-angle field of view suitable for sweeping landscapes and immersive footage. -

Focus: 1 m to ∞

Versatile focusing range for both close-ups and distant subjects. -

ISO Range: 100-3200

Supports low-light shooting and flexible exposure control. -

Max Flight Time: 30 minutes

(Based on 0 wind and consistent 15.5 mph (25 kph) flight)

Extended airtime per charge for longer creative sessions. -

Intelligent Flight Battery Capacity: 2250 mAh

High-density battery ensures optimal power-to-weight ratio. -

Bluetooth: Present (Details N/A)

Enables seamless device pairing and potential integration with companion apps. -

Video Resolution: 4K

Professional-grade video capture in a portable form factor.

Benefits & Practical Implications

The Mini 2’s combination of a stabilized gimbal, advanced wireless transmission, and robust camera sensor enables high-quality aerial imaging in virtually any environment. Its lightweight build not only eases regulatory burdens but also makes it exceptionally travel-friendly. The inclusion of obstacle sensing and a customizable controller further enhances user confidence and creative flexibility, while the long-range OCUSYNC™ 2.0 system ensures stable connections for both control and real-time video streaming.

Operating Frequencies

The DJI Mini 2 (FCC ID SS3-MT2PD2007) operates across a range of frequencies, as detailed in its official FCC filing:

| Frequency Range (GHz) | Output Power (mW) | FCC Rule Part |

|---|---|---|

| 2.402–2.48 | 2 | 15CCC1.12.4055 |

| 2.452 | 241 | 15CCC1.35.7285 |

| 2.4565 | 255 | 15CCC1.62.422 |

| 2.462 | 220 | 15CCC1.22.4175 |

| 2.4655 | 162 | 15CCC1.42.40912 |

| 2.46712 | 196 | 15CCC1.52.4105 |

| 2.4725 | 766 | 15CCC1.82.412 |

| 2.4765 | 612 | 15CCC1.72.4075 |

| 5.825 | 65 | 15ECC2.6 |

| 5.8395 | 256 | 15ECC2.55.745 |

| 5.8445 | 36 | 15ECC2.15.73012 |

| 5.8445 | 38 | 15ECC2.35.7325 |

| 5.8445 | 269 | 15ECC2.45.7355 |

| 5.84612 | 37 | 15ECC2.25.7305 |

These frequencies support robust communications for remote piloting, video transmission, and telemetry, leveraging both 2.4GHz and 5.8GHz ISM bands—common in Wi-Fi, Bluetooth, and proprietary drone control systems.

Technology Deep Dive

The DJI Mini 2’s advanced wireless architecture is built on a foundation of proven RF technologies, including Wi-Fi, Bluetooth, and custom long-range transmission protocols. The integration of both 2.4GHz and 5.8GHz frequency bands enables dynamic channel selection, minimizing interference and maximizing range. The adoption of OCUSYNC™ 2.0, DJI’s proprietary technology, further enhances signal stability and reduces latency, crucial for real-time HD video feeds and responsive control.

Operating in these ISM bands provides several advantages:

– Performance & Range: Higher output power at select frequencies ensures reliable connections even at extended distances, supporting the Mini 2’s 5-mile (8 km) maximum range.

– Interference Management: Dual-band operation allows the drone to switch frequencies to avoid congested channels, a key benefit in urban or crowded environments.

– Power Efficiency: Intelligent power scaling, as evident in the varied output levels, helps balance transmission strength with battery life—critical for maximizing flight time.

– Regulatory Compliance: The defined power levels and frequency usage are tailored to comply with FCC regulations, reducing the risk of interference with other devices and ensuring safe operation.

Test reports referenced in the FCC filing confirm the Mini 2’s adherence to strict RF exposure and electromagnetic compatibility standards, validating both its performance claims and its safety for consumer use.

In-Depth Internal Component Analysis / Teardown

Right Arm Antenna Module

Embedded within the right arm of the Mini 2, a dedicated PCB functions as a high-performance antenna module. The board’s design is characterized by wide, meandering traces forming a printed antenna—likely an inverted-F configuration—optimized for operation in the 2.4GHz and 5.8GHz bands. Minimal passive components and the absence of major ICs confirm its exclusive focus on RF signal transmission and reception. The lack of traditional connectors and the use of edge contacts suggest a seamless integration with the drone’s main circuitry, maximizing spatial diversity and minimizing interference. This modular, lightweight approach is indicative of DJI’s commitment to reliable, long-range wireless performance in a compact aerial platform.

Full System Teardown Overview

A comprehensive view of the Mini 2’s internal architecture reveals multiple densely-packed PCBs, precision wiring, and robust structural components. The main logic board features advanced BGA and QFN ICs, including a powerful SoC for video processing, a dedicated flight controller, and RF transceivers—all protected by metal EMI shields. Multi-layer PCB construction, extensive use of ground planes, and modular FPC/FFC connectors underscore the drone’s sophisticated design. High-capacity power management circuits, embedded antennas, and modular camera/gimbal interfaces further highlight DJI’s engineering prowess. This meticulous integration ensures stable flight, long-range connectivity, and high-fidelity imaging, all while minimizing weight and maximizing reliability.

GNSS (GPS) Antenna Module

A compact PCB assembly houses a prominent ceramic patch antenna, dedicated to GPS/GNSS reception. The antenna’s central feed point and robust mechanical mounting ensure minimal signal loss and stable satellite acquisition. Careful RF design is evident in the short feed lines and the use of encapsulated flex connectors for strain relief. The modular nature of this GNSS unit allows for easy integration and serviceability, while the use of a high-quality ENIG finish and multi-layer PCB construction reflects a focus on RF integrity and durability. Such precision in GNSS design is critical for the Mini 2’s accurate positioning and autonomous flight capabilities.

High-Density Module with EMI Shielding

This compact, high-density PCB demonstrates DJI’s advanced miniaturization techniques. A large metal EMI shield dominates the board, protecting sensitive RF or high-speed digital circuits—likely a wireless transceiver or camera interface—from external interference. The presence of a robust FPC connector enables high-speed data or video transmission to other subsystems, such as the main board or gimbal assembly. Local power regulation is evident from the presence of inductors and capacitors, ensuring clean, stable voltage to critical components. The overall design prioritizes EMI suppression, signal integrity, and modularity, essential for reliable operation in the Mini 2’s compact, interference-prone environment.

Sensor or Camera Control Module

A close inspection of this module reveals a central QFN/BGA IC, likely serving as a microcontroller or sensor interface. A crystal oscillator nearby provides precise timing, crucial for imaging or inertial measurement tasks. The dense, multi-layer PCB layout, combined with extensive ground pours and via stitching, ensures strong EMI control and signal integrity. The flat flex connector facilitates high-speed communication with other drone subsystems, while robust mounting holes suggest vibration isolation—vital for accurate sensor readings or stable camera operation. This module exemplifies DJI’s focus on compact, reliable electronics tailored for demanding aerial applications.

Main Control Board with STM32 MCU

The heart of the Mini 2’s control system is a black PCB populated by a high-performance STM32F4xx ARM Cortex-M4 microcontroller. Surrounded by power management ICs, MOSFET drivers, and dense signal routing, this board orchestrates real-time flight control, sensor fusion, and communications. Differential pair traces and robust grounding strategies highlight a design optimized for high-speed data and RF signal integrity. A shielded RF section and coaxial cabling indicate careful attention to minimizing electromagnetic interference, while modular wire harnesses enable efficient assembly and maintenance. This sophisticated integration is critical for the Mini 2’s agility, stability, and responsive control.

Left Arm Antenna PCB

Mirroring the right arm, this narrow PCB is embedded within the drone’s left arm and features a prominent PCB trace antenna, likely for 2.4/5.8GHz operation. The design is streamlined, with minimal components and broad RF traces ensuring optimal signal propagation. Silkscreen markings denote part numbers and orientation, aiding in assembly and quality control. The absence of complex electronics or external connectors emphasizes its role as a dedicated antenna module, contributing to the Mini 2’s spatial diversity and robust wireless performance. This lightweight, integrated approach exemplifies DJI’s commitment to efficient, high-reliability RF engineering.

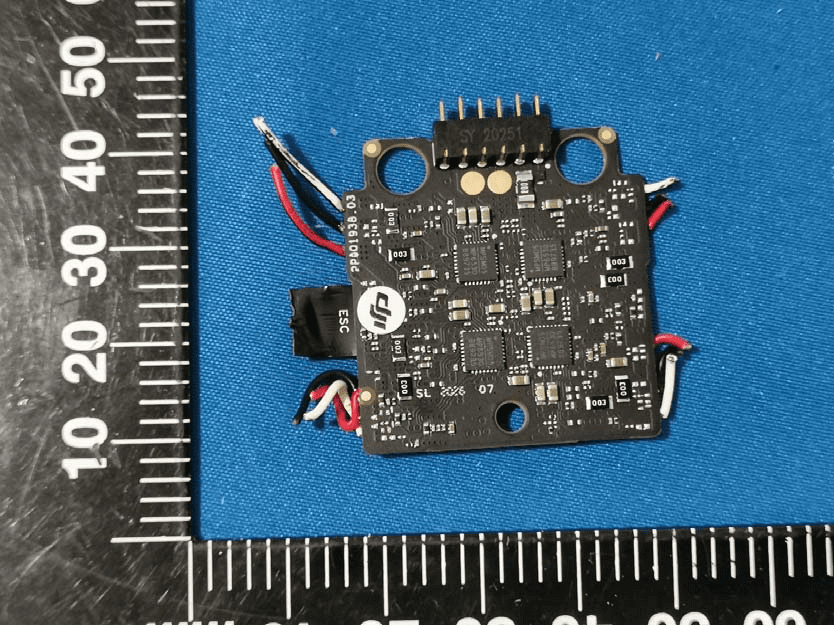

ESC/Power Distribution Board

This robust PCB serves as the Mini 2’s electronic speed controller (ESC) and power distribution hub. Four identical ICs—likely MOSFET drivers—are symmetrically arranged to manage each brushless motor independently. Multiple heavy-gauge wire pairs provide reliable power delivery, while dense surface-mount capacitors ensure noise suppression and stable operation. The multi-layer, black soldermask PCB is optimized for efficient current flow and minimal EMI, with careful separation of power and signal paths. Modular connectors facilitate integration with the flight controller, supporting telemetry and control. This design reflects DJI’s emphasis on efficiency, reliability, and serviceability—cornerstones of modern drone engineering.

Regulatory Insights & FCC Filing

The FCC ID SS3-MT2PD2007 designation for the DJI Mini 2 (Model: MT2PD) is more than just a regulatory formality—it is a testament to the device’s adherence to stringent US standards for electromagnetic compatibility and RF emissions. Registered with the FCC, this certification authorizes the Mini 2’s sale and operation within the United States, ensuring it neither causes nor suffers from harmful interference with other wireless devices.

FCC filings for the Mini 2 encompass a wealth of documentation, including RF exposure assessments, electromagnetic compatibility (EMC) test reports, internal and external photographs, user manuals, and circuit schematics. These documents confirm the drone’s compliance with all relevant FCC rules, including those governing output power, frequency usage, and device labeling.

Insights from the user manual and internal documentation reveal that the Mini 2 is engineered for both safety and performance, featuring a lightweight airframe, obstacle sensing, a stabilized 3-axis gimbal, and a high-quality camera system. FCC test reports validate the effectiveness of its shielding and power management strategies, confirming the drone’s ability to operate safely in diverse environments without exceeding permissible RF exposure limits.

Potential Use Cases & Target Audience

The DJI Mini 2 is designed to serve a broad spectrum of users, thanks to its blend of portability, advanced features, and regulatory compliance:

-

Aerial Photography & Videography Enthusiasts:

With its 4K video capability, stabilized gimbal, and long-range transmission, the Mini 2 is ideal for content creators seeking high-quality aerial footage without the bulk of larger drones. -

Travelers & Outdoor Adventurers:

The ultralight 241g design and foldable form factor make it perfect for travelers who want to document their journeys from unique perspectives, all while staying under regulatory weight limits in many regions. -

STEM Education & Drone Hobbyists:

The Mini 2’s accessible controls, programmable features, and robust safety systems make it an excellent platform for learning about drone technology, wireless communications, and aerial robotics.

Whether used for professional content creation, recreational flying, or educational exploration, the Mini 2 delivers a compelling balance of performance, reliability, and ease of use.

Conclusion

The DJI Mini 2 (Model: MT2PD, FCC ID SS3-MT2PD2007) stands as a benchmark in the realm of consumer drones, combining advanced imaging, robust wireless connectivity, and meticulous internal engineering within a remarkably compact package. Its FCC certification not only guarantees regulatory compliance and safe operation but also underscores DJI’s commitment to quality and innovation. For enthusiasts, creators, and hobbyists alike, the Mini 2 offers a versatile, reliable, and high-performance aerial platform—solidifying its place as a leader in the lightweight drone market.