Introduction

The DJI FPV Remote Controller, engineered by SZ DJI TECHNOLOGY CO., LTD. (Model: P1RC), stands as a high-performance radio controller purpose-built for first-person-view (FPV) drone pilots and enthusiasts. Designed to deliver ultra-low latency, robust wireless range, and extensive customization, this controller is at the heart of DJI’s FPV ecosystem, enabling precise, responsive control over compatible drones.

A critical milestone in its journey to market is its FCC certification, under the identifier FCC ID SS3-P1RC1901. This certification is not just a regulatory formality—it signifies that the device meets stringent US standards for radio frequency (RF) emissions, electromagnetic compatibility, and user safety. As a result, the DJI FPV Remote Controller can be legally sold and operated within the United States, ensuring both compliance and peace of mind for end users.

In this article, we’ll dissect the key features and specifications of the DJI FPV Remote Controller, examine its wireless technology and operating frequencies, and provide an expert teardown analysis of its internal components. We’ll also highlight regulatory insights from its FCC filing and explore the controller’s ideal use cases for both professionals and hobbyists.

Key Features & Specifications

The DJI FPV Remote Controller (Model: P1RC) combines advanced wireless transmission, ergonomic design, and user-centric features. Here’s an in-depth look at its standout attributes and technical specifications:

Key Features

- USB-C Port: Modern, reversible connector for charging, firmware updates, and activation—ensuring convenience and future-proof compatibility.

- Transmission Range up to 4 km (FCC): Long-range capability allows pilots to maintain control and video transmission over extended distances, ideal for professional FPV flying.

- Ultra-Low Latency (as low as 7 ms): Minimizes input lag, delivering a near-instantaneous response critical for high-speed drone maneuvers and racing scenarios.

- Simulator PPM Port: Allows connection to FPV simulators for training and practice, enhancing pilot skills without risk.

- Hot-Swappable Battery Design: Enables quick battery replacement without powering down the controller—essential for uninterrupted field operations.

- Multiple Switches and Dials: Offers extensive customization of controls, catering to varied user preferences and drone configurations.

- USB-C for Charging and Activation: Streamlines device setup and maintenance, reducing downtime.

- Multiple Function Buttons and Switches: Facilitates quick access to key drone features and camera controls.

Technical Specifications

- Storage Environment Temperature:

- ≤3 months: -20° to 45° C (-4° to 113° F)

-

3 months: 22° to 28° C (71.6° to 82.4° F)

- Maximum Transmission Distance (unobstructed, interference-free):

- FCC/SRRC: 4 km

- CE: 0.7 km

- MIC: 2.5 km

- Battery Voltage: 7.6 V

- Operating Current/Voltage: 0.6 A @ 7.6 V

- Operating Frequency: 5.725 – 5.850 GHz

- Battery Capacity: 4920 mAh

- Weight: 758 g

- Battery Type: LiPo 2S

Additional Wireless and Power Specs

- Wi-Fi: Operating at 5.725 – 5.850 GHz, aligning with modern high-speed wireless communication standards.

- Bluetooth: Present (details not specified), likely used for pairing or auxiliary connectivity.

- Battery: Replaceable, hot-swappable LiPo 2S battery, 4920 mAh capacity, 7.6 V, 37.39 Wh—delivering extended operation and quick field replacement.

Practical Benefits:

These specifications translate into a controller that is not only powerful and responsive but also reliable in demanding environments. The combination of a high-capacity, hot-swappable battery and robust wireless transmission ensures extended operational periods, while the wealth of customizable controls and ultra-low latency make it suitable for professional-grade FPV flying, racing, and advanced aerial cinematography.

Operating Frequencies

The DJI FPV Remote Controller (Model: P1RC, FCC ID SS3-P1RC1901) operates on the following wireless frequencies and power levels as documented in its FCC filing:

| Frequency Range (GHz) | Output Power (mW) | FCC Rule Part |

|---|---|---|

| 5.7315–5.84612 | 239 | 15ECC |

Why This Matters:

Operating in the 5.7–5.8 GHz band, the controller leverages frequencies commonly used for high-speed, low-interference wireless communication (such as Wi-Fi and proprietary RF links). The specified output power ensures a strong, reliable connection while conforming to FCC regulations for unlicensed wireless devices.

Technology Deep Dive

The DJI FPV Remote Controller employs advanced wireless technologies to deliver high-performance, low-latency control. Primarily operating within the 5.7–5.8 GHz band, it utilizes protocols optimized for FPV transmission—ensuring robust, interference-resistant communication with compatible drones and accessories. This frequency range is favored for its ability to support high data rates and minimize congestion compared to lower-frequency bands.

Wireless Technologies:

– Wi-Fi: The controller’s use of the 5.725–5.850 GHz spectrum aligns with modern Wi-Fi standards, enabling high-bandwidth digital transmission suitable for FPV video and control data.

– Bluetooth: Present for auxiliary functions, such as device pairing or configuration, though specific implementation details are not provided.

– Proprietary RF Protocols: Given DJI’s advanced ecosystem, the controller likely employs custom protocols to achieve ultra-low latency (down to 7 ms) and extended range (up to 4 km).

Performance Implications:

Operating at higher frequencies allows for greater data throughput and reduced latency, which is critical for real-time FPV applications and precision drone control. However, higher frequencies are generally more susceptible to physical obstructions and may experience slightly reduced penetration compared to lower bands. The carefully regulated output power (239 mW) strikes a balance between range and regulatory compliance, while the presence of robust EMI/RFI shielding (as observed in internal component analysis) helps minimize interference and maintain reliable performance.

Test Report Insights:

Internal documentation validates the controller’s ability to meet FCC limits for RF emissions, ensuring both user safety and reliable operation in crowded RF environments. The test results confirm the device’s adherence to spectrum and power regulations, solidifying its status as a compliant, high-performance remote control system.

In-Depth Internal Component Analysis / Teardown

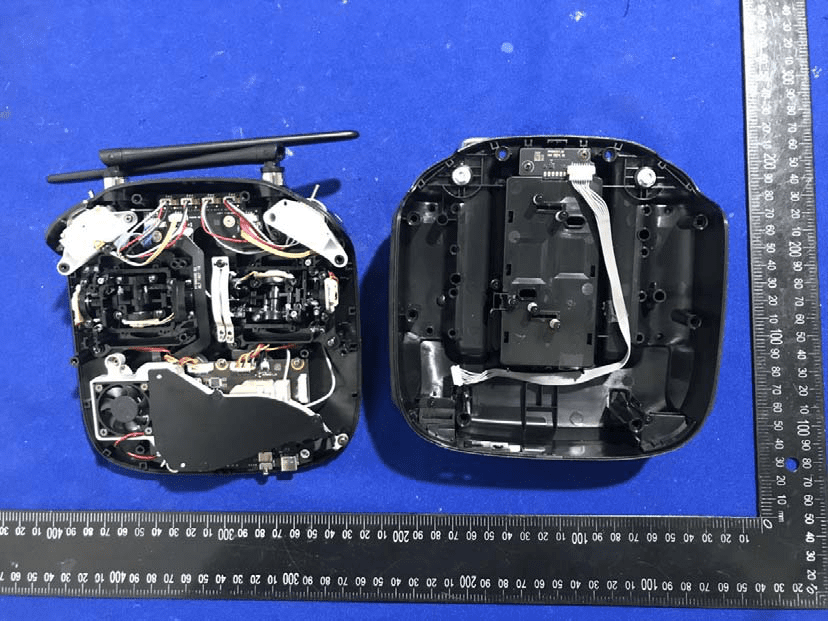

Main Internal Layout and Shielding

Within the opened controller, the left section reveals the densely populated main PCB, while the right houses the battery compartment and associated wiring. The main PCB is dominated by a large black EMI/RFI shield, a hallmark of sophisticated RF design. This shielded region likely conceals the central SoC or MCU, RF transceivers, and memory, ensuring minimal interference and optimal signal integrity. Around the periphery, smaller ICs—possibly power management or interface controllers—are visible. The PCB’s multi-layer construction, evidenced by numerous vias and careful trace routing, supports robust RF and power delivery. The external antenna, connected via coaxial cable, is optimized for 2.4/5.8 GHz operation. Modular connectors enable straightforward assembly and servicing, while the dual gimbal assemblies and tactile switches provide precise, reliable user input. Overall, the internal design reflects high build quality, with comprehensive shielding, thoughtful grounding, and a clear separation of RF and user interface domains.

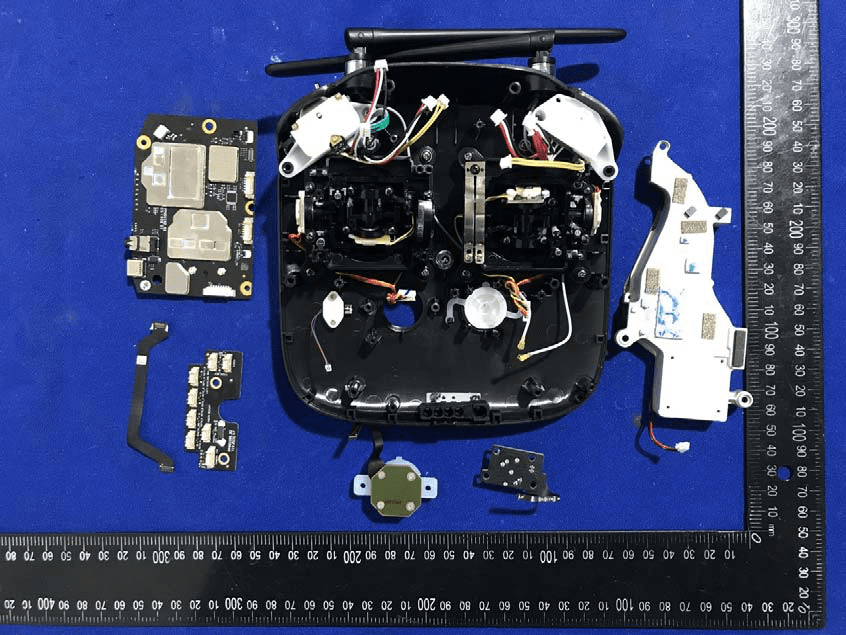

Full Disassembly and Subsystems

A fully disassembled view exposes the main PCB, sub-boards, and mechanical assemblies in detail. The principal board, finished in black solder mask, features multiple shielded zones—indicating discrete RF and digital domains. Large ICs beneath the shields are likely SoCs, RF transceivers, and power management chips, while smaller edge components handle signal conditioning and interfaces. The presence of two external antennas, attached via micro-coaxial connectors, underscores the device’s advanced wireless architecture. Numerous FPC and JST-style connectors link gimbals, buttons, and LEDs, supporting modularity and ease of repair. Mechanical assemblies, including precise gimbals with Hall sensors or potentiometers, ensure accurate stick input. Power delivery is managed by surface-mount inductors and capacitors, while soldered EMI shields and extensive via stitching reinforce RF integrity. The overall architecture balances compactness, RF performance, and user ergonomics—consistent with a professional-grade FPV controller.

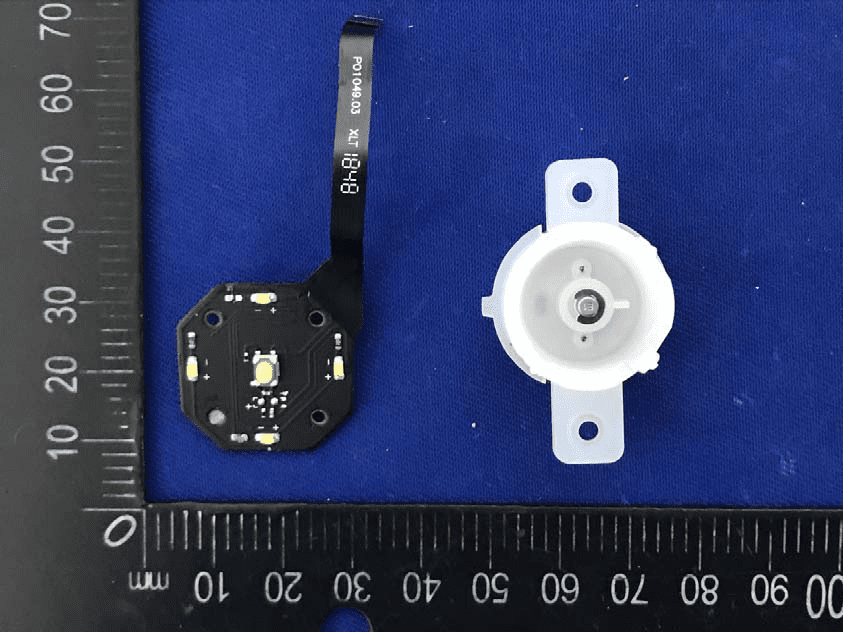

Illuminated Button or Joystick Module

A close-up of a small PCB subassembly reveals a tactile switch or Hall effect sensor at its center, surrounded by four yellowish LEDs. This board, compact and black, is likely part of a user interface element—such as an illuminated button or joystick module. The surface-mount passive components support the primary sensor or switch, while the flexible flat cable (FPC) enables seamless integration with the main controller PCB. The absence of complex ICs and EMI shielding is appropriate for this low-frequency, user-facing circuit. Clean soldering and modular design facilitate replacement of high-wear components, reflecting DJI’s attention to serviceability and user experience.

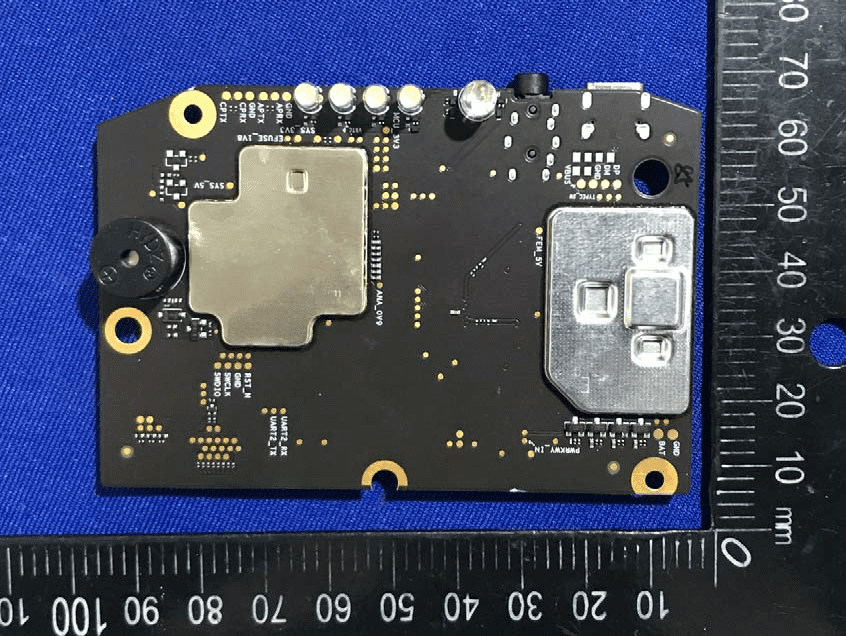

RF and Power Section PCB

Examining a high-resolution image of an internal PCB, two substantial metal shields dominate the landscape, protecting sensitive RF transceivers or SoCs. The black, multi-layer board features numerous vias and test points, indicative of a design focused on signal integrity and manufacturing testability. Decoupling capacitors and inductors near the shielded regions ensure clean power delivery to high-frequency circuits. Traces leading from the shielded areas suggest connections to external antennas for high-bandwidth wireless communication. The overall layout, with its compact footprint and strategic shielding, is emblematic of advanced RF engineering aimed at minimizing interference and maximizing wireless range and reliability.

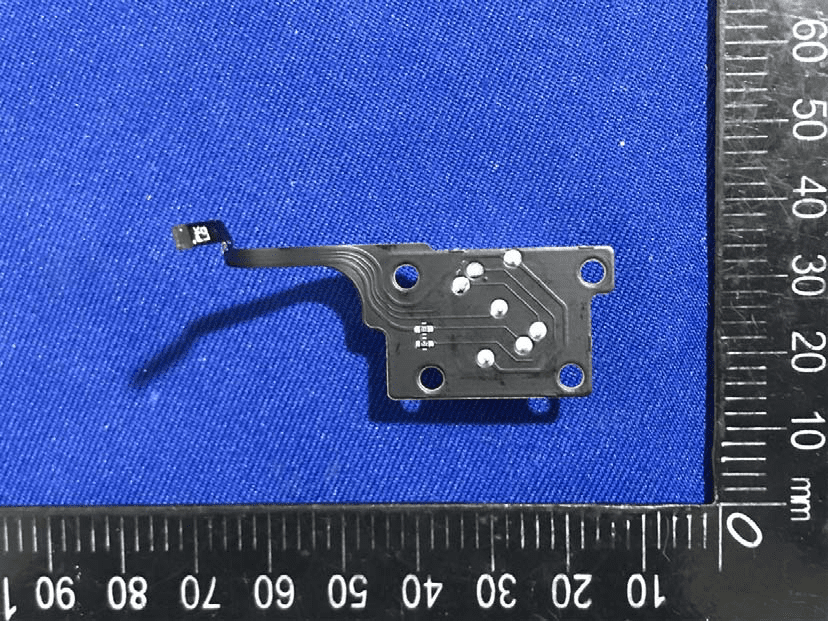

Simple Button or Interface Board

A small, irregularly shaped PCB connected via a flex cable showcases a straightforward design, likely serving as a button or sensor interface. The board features wide traces and a few through-hole pads, with minimal surface-mount components—suggesting low-speed, low-frequency operation. The absence of complex circuitry or shielding is consistent with its probable function as a mechanical switch or sensor input within the controller’s ergonomic controls. The use of a flex cable allows for integration into tight or moving spaces, supporting the controller’s modular, user-friendly assembly.

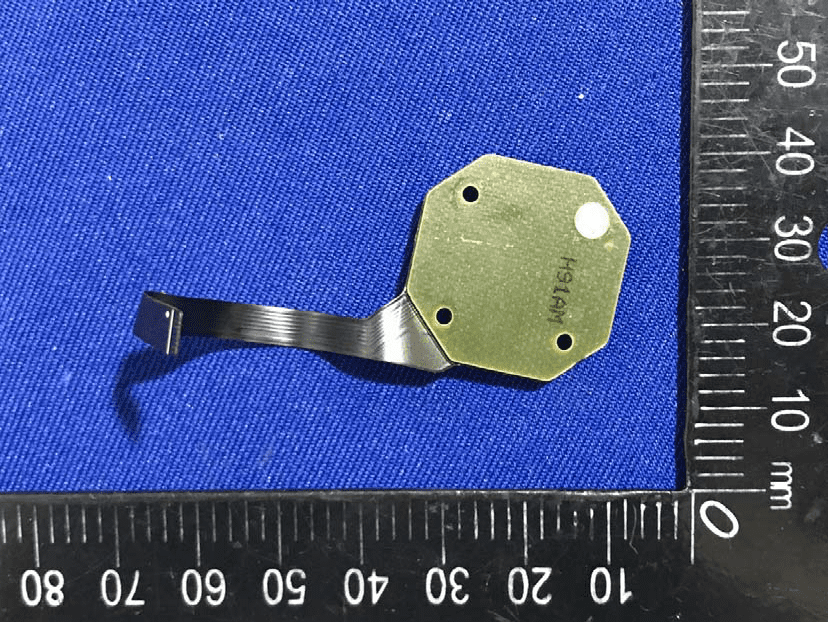

Flexible PCB Subassembly—Antenna or Sensor

Another internal component consists of a small, octagonal PCB attached to a flexible printed circuit (FPC) tail. With no active components or visible traces on this side, its design suggests a passive role—likely as an internal antenna or capacitive sensor. The FPC enables flexible routing within the device’s compact enclosure, while the PCB’s clean finish and mounting holes facilitate precise assembly. This subassembly exemplifies the thoughtful integration of passive elements in modern RF device design.

Regulatory Insights & FCC Filing

The assignment of FCC ID SS3-P1RC1901 to the DJI FPV Remote Controller certifies its compliance with US regulations for RF emissions and electromagnetic compatibility. This designation, registered through FCC.gov, confirms that the device has passed rigorous testing for wireless output, interference, and user safety, making it legal for sale and operation across the United States.

FCC filings typically encompass a breadth of technical documentation, including test reports (validating RF exposure and EMC compliance), internal and external photographs, user manuals, block diagrams, and schematics. For the DJI FPV Remote Controller, the user manual outlines its core technologies—highlighting DJI HDL FPV Transmission, a maximum range of 4 km, and latency as low as 7 ms. Internal documentation and test reports detail the robust shielding, controlled output power, and use of advanced multi-layer PCB design to satisfy both performance and regulatory requirements.

These filings provide transparency for regulators and consumers alike, ensuring that the product not only delivers on its technical promises but also operates safely and reliably within its designated spectrum. The presence of comprehensive shielding and careful power management, as evidenced in internal documentation, further reinforces the controller’s adherence to strict electromagnetic standards.

Potential Use Cases & Target Audience

The DJI FPV Remote Controller is engineered to meet the demands of a wide range of users, from hobbyists to professionals. Here are some practical scenarios where its capabilities shine:

-

Professional FPV Drone Pilots:

Pilots engaged in aerial cinematography or commercial drone operations benefit from the controller’s extended 4 km range, ultra-low latency, and customizable controls—enabling precise, responsive maneuvers and real-time video feedback. -

FPV Racing Enthusiasts:

The controller’s 7 ms latency and robust wireless link give competitive racers the edge needed for split-second decision-making and tight course navigation. Hot-swappable batteries ensure minimal downtime between heats. -

Training & Simulation:

The integrated simulator PPM port allows aspiring pilots to practice in virtual environments, honing their skills safely before transitioning to real-world flight. The ergonomic layout and modular controls provide a realistic, immersive training experience.

With its advanced wireless specs, modular design, and compliance with FCC regulations, the DJI FPV Remote Controller stands as a versatile tool for anyone seeking high-performance, reliable drone control.

Conclusion

The DJI FPV Remote Controller by SZ DJI TECHNOLOGY CO., LTD. (Model: P1RC) exemplifies cutting-edge design and engineering in the FPV drone market. Its FCC certification under FCC ID SS3-P1RC1901 assures users of regulatory compliance, robust RF performance, and operational safety. With features like a 4 km wireless range, ultra-low latency, hot-swappable battery, and modular construction, it meets the needs of demanding pilots and enthusiasts alike. The internal teardown reveals a meticulously crafted device, balancing advanced RF engineering with ergonomic user interfaces. As the FPV landscape evolves, the DJI FPV Remote Controller remains a benchmark for reliability, performance, and compliance in wireless drone control.