Introduction

The Agras MG-1P and MG-1P RTK, developed by SZ DJI TECHNOLOGY CO., LTD., represent the cutting edge in agricultural drone technology. Designed for professional operators, these drones offer advanced features for crop spraying, field mapping, and precision agriculture. With their robust construction, intelligent flight planning, and high-precision navigation, they are tailored for efficiency and reliability in demanding farming environments.

A crucial aspect of the MG-1P / MG-1P RTK’s market presence is its FCC certification under FCC ID SS3-GL300N1801 (grant date: None, registered by FCC.gov). This certification confirms that the device complies with strict US standards for radio frequency (RF) emissions and electromagnetic compatibility, ensuring it is legal for sale and operation in the United States.

In this article, we’ll provide an in-depth analysis of the Agras MG-1P / MG-1P RTK: highlighting its key features, technical specifications, wireless technologies, and a detailed teardown of its internal components. We’ll also offer regulatory insights based on the FCC filing and explore real-world use cases for professional agricultural drone operators.

Key Features & Specifications

The Agras MG-1P / MG-1P RTK is engineered for demanding agricultural tasks, blending rugged hardware with sophisticated software and wireless capabilities. Below are the standout features and detailed technical specifications that set this system apart.

Key Features

- Obstacle Avoidance Radar Module:

Advanced radar technology enables real-time terrain following and obstacle avoidance, ensuring safe navigation even in complex environments. - Remote Controller with Dedicated Bright Screen:

The controller features a high-brightness integrated display running the DJI MG app, offering an intuitive, sunlight-readable interface for mission planning and monitoring. - Wide-Angle FPV Camera:

Mounted at the front of the aircraft, this camera provides real-time observation of the operational area, enhancing situational awareness and safety. - Second-Generation DJI OcuSync Dual-Band Video Downlink:

The controller utilizes DJI’s OcuSync technology to deliver robust, low-latency video and telemetry over both 2.4 GHz and 5.8 GHz bands, supporting long-range, interference-resistant communication. - IP67-Rated Radar Module:

The radar assembly is sealed against dust and water ingress, ensuring reliable performance in harsh field conditions. - Intelligent Operation Planning System:

Features include waypoint and route planning, enabling automated, efficient spraying and surveying missions with minimal manual intervention. - Rugged Aircraft Body:

The airframe is IP43-rated for dust and water resistance and is constructed from anti-corrosive materials to withstand agricultural chemicals and challenging weather.

Technical Specifications

- Charging Hub Operating Temperature:

41° to 104° F (5° to 40° C) - Remote Controller Battery Energy:

37.39 Wh - AC Power Adapter Rated Power:

57 W - Remote Controller Operating Frequency:

- 2.400 GHz to 2.483 GHz

- 5.725 GHz to 5.850 GHz (not supported in Japan)

- Charging Hub Input Voltage:

17.3 – 26.2 V - MG-1P RTK Dimensions (Arms Unfolded, Propellers Removed):

1460 mm × 1460 mm × 616 mm - Diagonal Wheelbase:

1500 mm - Wireless Connectivity:

- Wi-Fi: 2.400 GHz to 2.483 GHz, 5.725 GHz to 5.850 GHz (excludes Japan)

- Bluetooth: Present (details not specified)

- Camera:

Wide-angle FPV (First Person View) camera for live flight monitoring. - Battery and Flight Time:

- Hovering Time:

- 22 minutes (Takeoff weight: 14 kg with 12,000 mAh battery)

- 20 minutes (Takeoff weight: 13.7 kg with 12,000 mAh battery)

- 9 minutes (Takeoff weight: 23.7 kg with 12,000 mAh battery)

- Battery Model: DJI MG-12000P (DJI approved)

These specifications and features collectively enable the Agras MG-1P / MG-1P RTK to deliver precise, efficient, and safe agricultural operations, even in challenging environments.

Operating Frequencies

The Agras MG-1P / MG-1P RTK (FCC ID SS3-GL300N1801) operates across multiple frequency bands and power levels, as documented in its FCC filing:

| Frequency Range (GHz) | Output Power (mW) | FCC Rule Part |

|---|---|---|

| 2.462 | 46 | 15CCC |

| 2.4775 | 68 | 15CCC2.22.412 |

| 12.4035-2.4775 | 60 | 15CCC2.12.4055 |

| 15.7305-5.8445 | 85 | 15E38 |

| 25.745-5.825 | 39 | 15E38 |

| 35.7285-5.8465 | 87 | 15E38 |

These frequency allocations are crucial for understanding the drone’s wireless reach, range, and regulatory compliance. The dual-band operation (2.4 GHz and 5.8 GHz) supports both control and real-time video downlink, while output power levels ensure reliable connectivity in large agricultural areas.

Technology Deep Dive

The Agras MG-1P / MG-1P RTK leverages a robust suite of wireless technologies to support its demanding operational requirements. The system primarily utilizes Wi-Fi and proprietary RF protocols over both 2.4 GHz and 5.8 GHz bands, which are standard for industrial drone communications. Bluetooth capability is present for close-range device pairing or maintenance, though details are not specified.

Operating within these frequency bands enables the controller to maintain high-bandwidth, low-latency links for both command/control and video downlink, even in environments with potential RF interference. The use of dual-band OcuSync technology provides added resilience, allowing the system to dynamically switch between frequencies for optimal performance and minimal dropout.

Output power levels (ranging from 39 mW to 87 mW) are balanced to maximize communication range while maintaining compliance with FCC Part 15 regulations, minimizing the risk of interference with other wireless devices. The integration of patch antennas and advanced RF shielding, as seen in the teardown, further enhances signal integrity and reduces susceptibility to external noise.

Test reports and design documentation highlight careful attention to electromagnetic compatibility (EMC), with extensive shielding, filtering, and modular PCB architecture. These engineering choices ensure robust, reliable wireless performance—critical for safe and efficient operation in vast, interference-prone agricultural fields.

In-Depth Internal Component Analysis / Teardown

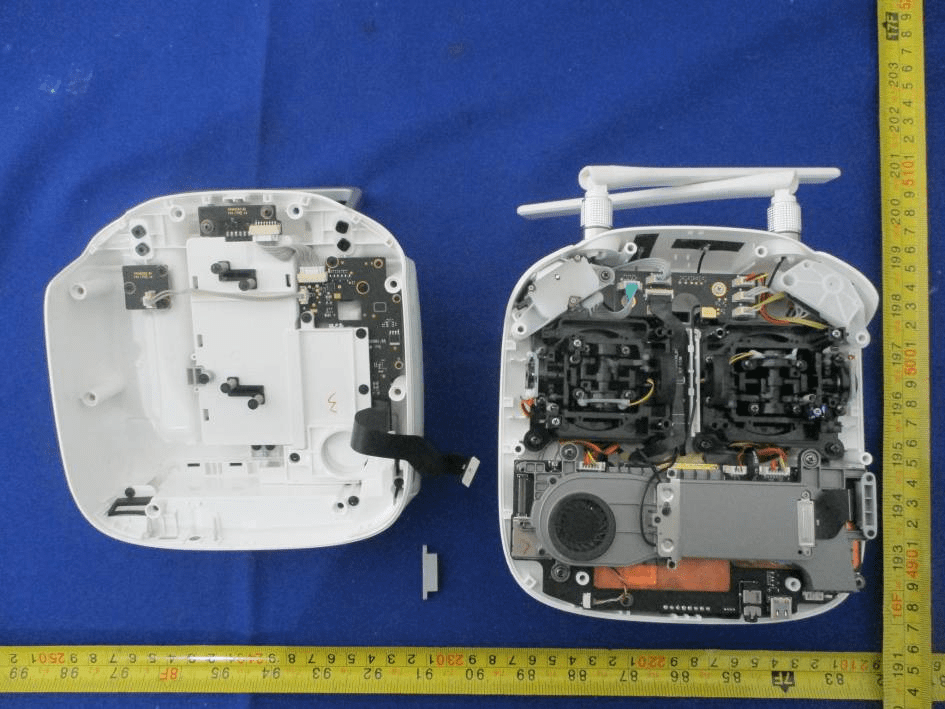

Remote Controller Main PCB and Assemblies

A high-resolution view of the remote controller’s internals reveals the heart of the MG-1P’s communication and control logic. The main PCB is densely populated, featuring multiple connectors, robust EMI/RFI shielding, and high-quality FR4 substrate. Dual external antennas, connected via coaxial cables, are engineered for optimal 2.4 GHz and 5.8 GHz RF performance, ensuring strong, interference-resistant links. The presence of multiple control stick gimbal assemblies, tactile switches, and a dedicated speaker/buzzer highlight the controller’s ergonomic and functional design. Power management circuits, large capacitors, and modular connectors indicate a focus on reliability and serviceability. The overall build quality and layout reflect DJI’s commitment to professional-grade, long-range UAV control.

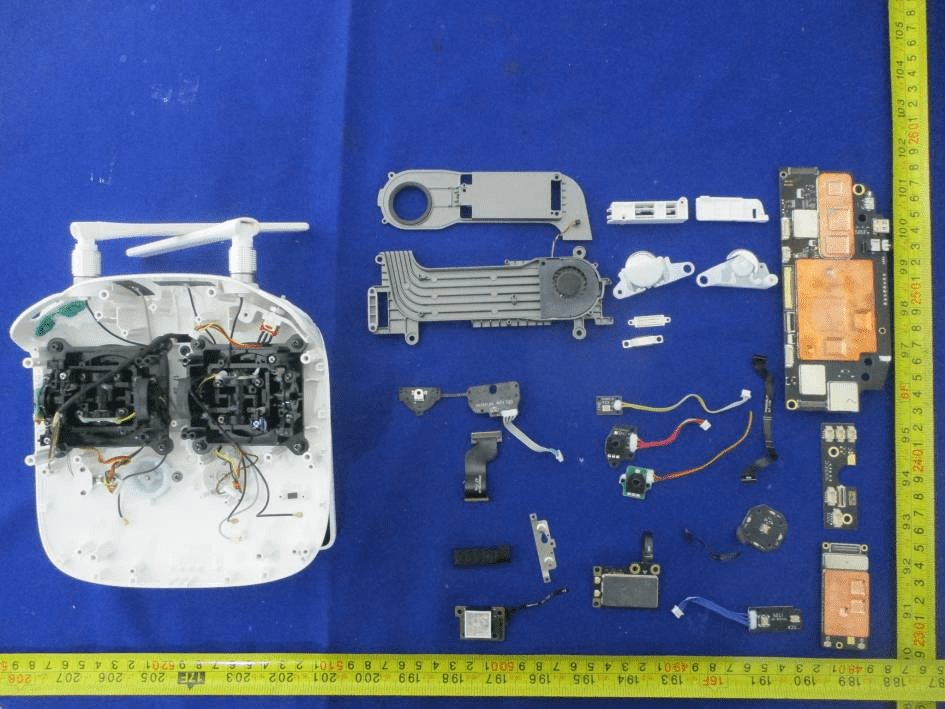

High-Density PCB with Shielded SoC and RF Sections

This teardown image exposes the controller’s main PCB, showcasing several large ICs beneath copper-colored EMI shields. These shielded domains likely house the main SoC, RF transceivers, and memory, each compartmentalized for optimal signal integrity. The extensive use of modular FPC/FFC and wire-to-board connectors allows for easy interfacing with joysticks, displays, and peripheral modules. External dual-band antennas, robust power regulation circuits, and the presence of microSD and USB ports underscore the controller’s modularity and upgradeability. The high layer count and careful grounding strategies contribute to EMI suppression and reliable high-speed operation, affirming the sophistication of DJI’s RF design.

Main controller PCB with shielded RF and SoC sections, external antennas.

Modular Subassemblies and Power Management

A detailed layout of internal modules highlights the controller’s modular architecture. Multiple PCBs, each connected via ribbon cables and board-to-board connectors, facilitate streamlined assembly and maintenance. The main board houses a microcontroller or SoC, surrounded by supporting logic and power management ICs. The inclusion of a sizable lithium polymer battery ensures extended operational endurance. The use of gold-plated pads, differential trace routing, and robust grounding underscores a design optimized for high-speed data and RF communication. The modular approach, combined with high-quality materials and careful EMI suppression, ensures reliability and longevity in professional use.

Modular PCB assemblies with battery, power management, and ribbon cable interconnects.

Integrated Display and Antenna Array

Opening the display module reveals a densely populated PCB with a prominent shielded area, likely protecting the main processor or RF circuitry. A flat, white antenna array connects via coaxial cables, supporting strong, directional wireless links. The use of multiple FPC/FFC connectors enables seamless integration of the display, touch panel, and control interfaces. The layout prioritizes EMI containment, robust power regulation, and modularity—enabling reliable long-range communication and straightforward field servicing. The engineering reflects a careful balance of performance, integration, and user experience.

Display module PCB with shielded RF section and integrated antenna array.

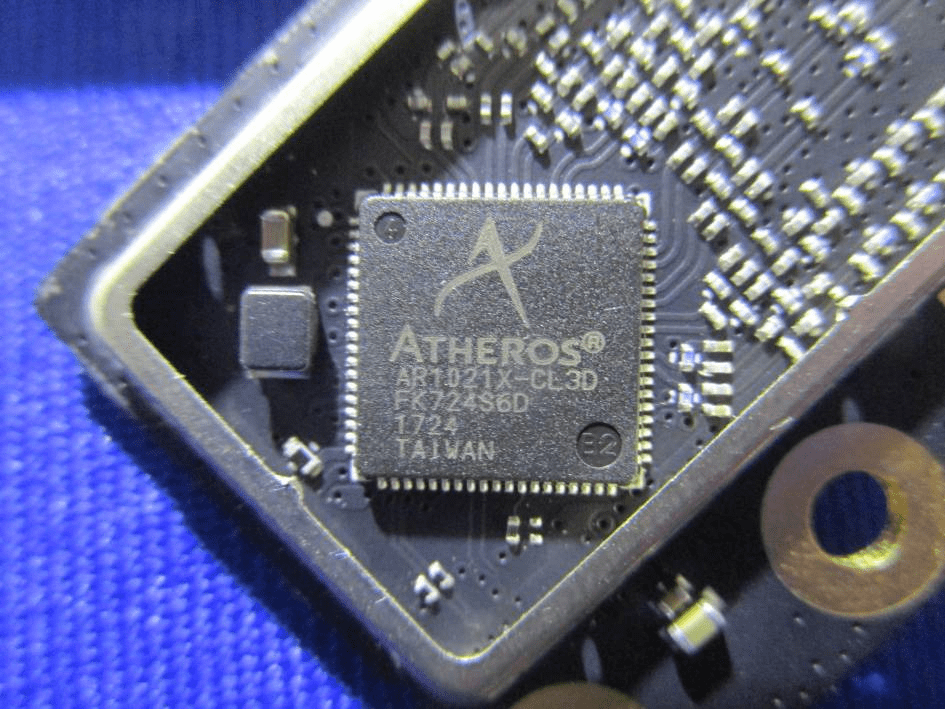

Capacitive Touchscreen Controller PCB

A close-up of the PCB reveals the Atheros AR1021X-CL3D, a dedicated capacitive touchscreen controller, surrounded by dense passive components and enclosed within a metallic shield frame. This IC is responsible for processing user touch inputs, ensuring responsive and accurate interface interactions. The high-density, multi-layer PCB and robust grounding strategy support signal integrity and EMI immunity, vital for reliable operation in environments with strong RF activity. The precision and quality of component placement affirm the controller’s suitability for demanding field applications.

Atheros touchscreen controller IC with robust EMI shielding.

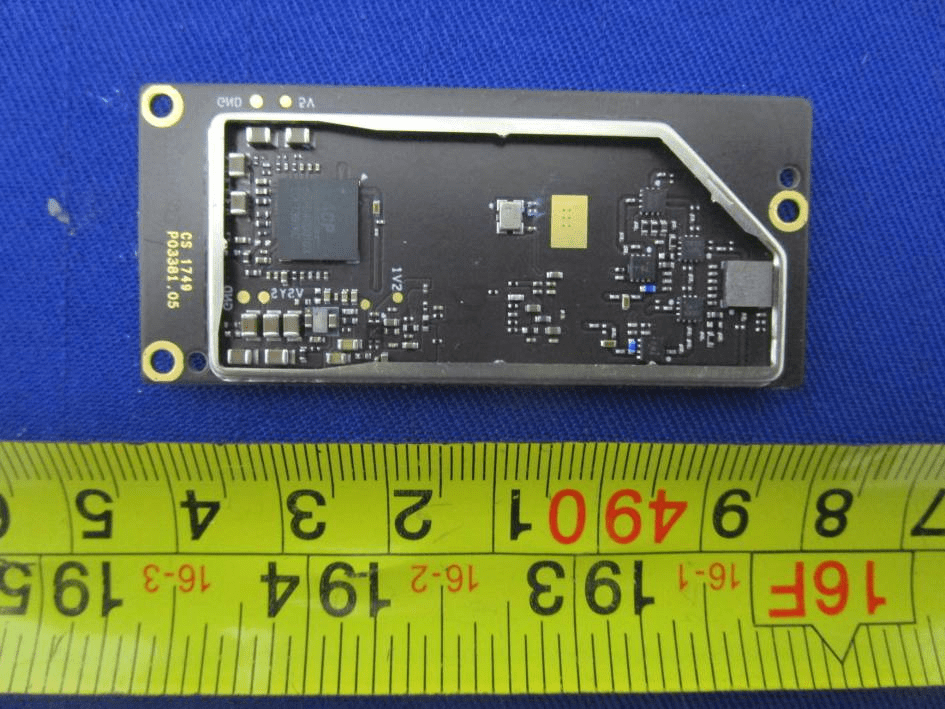

Compact RF/GNSS Module for Navigation

This compact PCB module, partially shielded with a metal can, is likely dedicated to high-frequency RF or GNSS (RTK) signal processing. The high component density, careful via placement, and presence of a crystal oscillator indicate a sophisticated RF design, essential for precise positioning and telemetry. Gold-plated test points and labeled voltage rails suggest onboard LDOs and switching regulators, while the modular form factor allows for easy integration within the drone’s avionics bay. This module is critical for providing the real-time kinematic (RTK) positioning that enables centimeter-level accuracy in agricultural operations.

Shielded RF/GNSS module for precise navigation and telemetry.

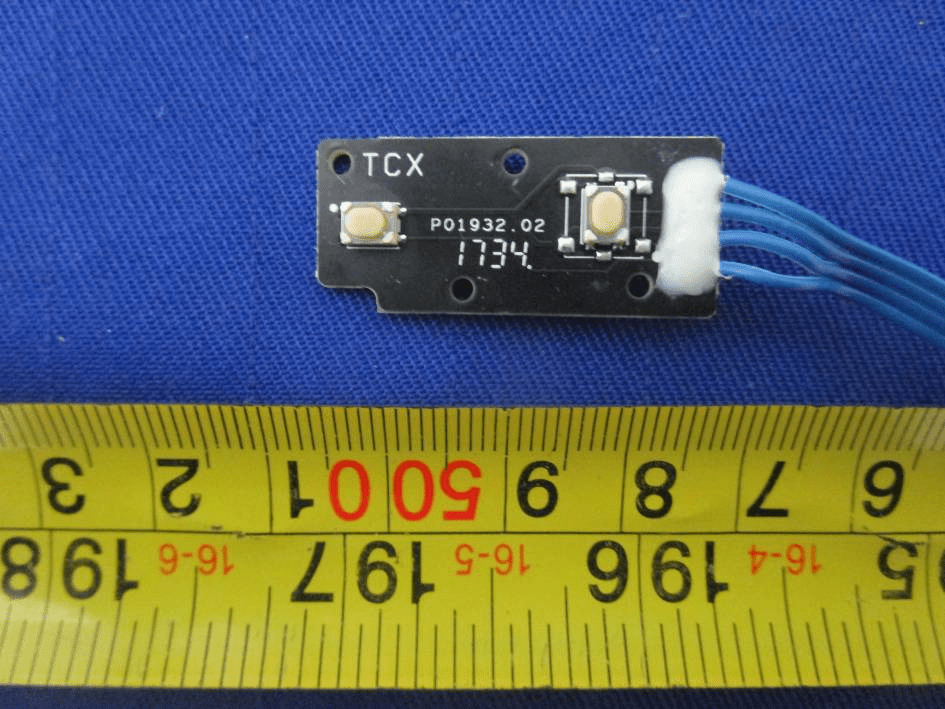

Simple User Interface Switch Board

A small, robust PCB labeled ‘TCX’ houses two tactile switches, designed for user input or calibration/reset tasks. The use of strain-relieved wiring and mounting holes ensures mechanical stability and vibration resistance, critical for drone applications. The straightforward, single-sided layout prioritizes reliability and ease of assembly, serving as a dependable interface for essential user operations within the MG-1P system.

User interface board with tactile switches and strain-relief wiring.

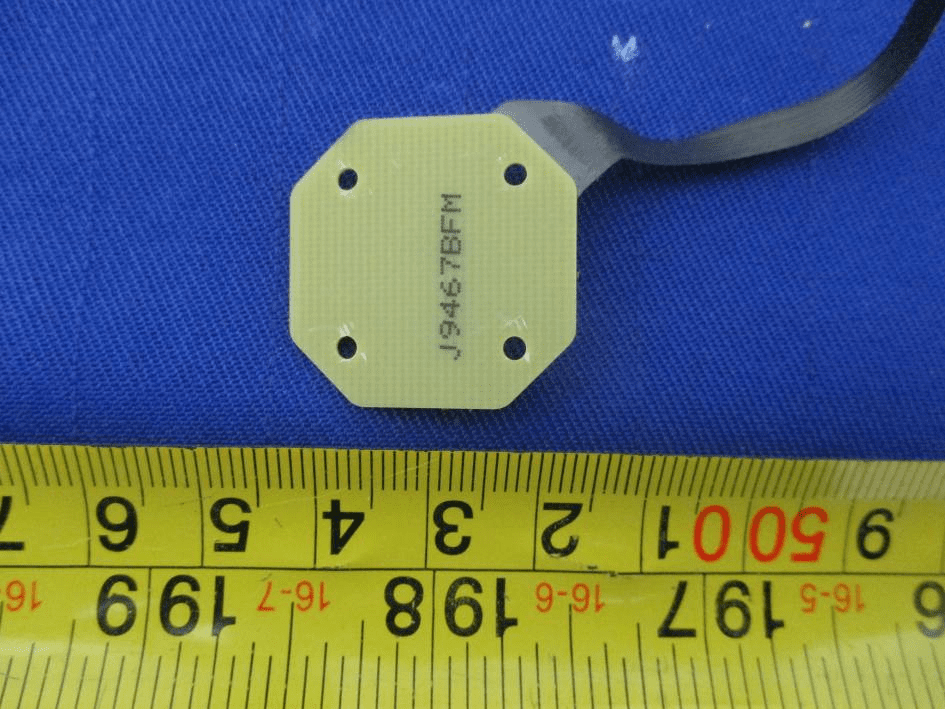

High-Precision GNSS Patch Antenna

A featureless, octagonal PCB connected via an FFC cable is identified as a passive patch antenna, likely optimized for the GNSS L1 band. The robust build, secure mounting holes, and use of flexible cabling allow for optimal placement within the drone chassis, minimizing interference and maximizing positioning accuracy. This antenna is vital for the RTK capabilities of the MG-1P RTK, enabling high-precision navigation in agricultural environments.

Octagonal GNSS patch antenna for RTK positioning.

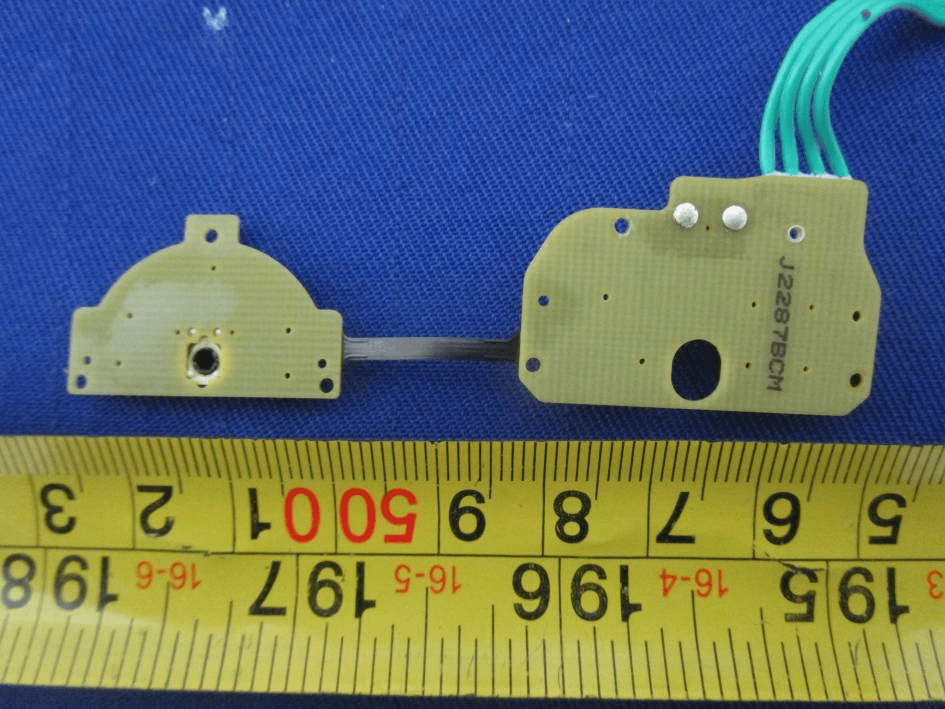

Sensor Interface or Peripheral PCB

A simple, green PCB marked ‘J2287BCM’ features direct wire connections and a metallic contact, likely serving as a sensor interface or mounting bracket. The utilitarian design, absence of active components, and straightforward routing suggest this board’s role as a peripheral or support module. Its construction prioritizes reliability and durability, reflecting DJI’s commitment to robust engineering in every subsystem.

Sensor interface or peripheral PCB with direct wire connections.

Regulatory Insights & FCC Filing

The Agras MG-1P / MG-1P RTK, under FCC ID SS3-GL300N1801, meets stringent US standards for electromagnetic compatibility and RF emissions. While the grant date is listed as ‘None’, registration by FCC.gov certifies that the device is compliant and legally marketable in the United States.

FCC filings for this model encompass a wide spectrum of documentation, including:

– Detailed test reports for RF exposure and electromagnetic compatibility

– Internal and external photos

– User manuals

– Schematics and block diagrams

Insights from the Users Manual confirm the MG-1P / MG-1P RTK’s advanced feature set: high-precision radar, integrated obstacle avoidance, terrain following, and robust environmental protection. These filings not only demonstrate the device’s regulatory compliance but also offer transparency into its engineering and operational capabilities. The presence of extensive shielding, careful frequency management, and modular design are all validated through the FCC’s rigorous certification process.

Potential Use Cases & Target Audience

The Agras MG-1P / MG-1P RTK is purpose-built for professional agricultural drone operators who demand reliability, precision, and efficiency. Key scenarios include:

- Precision Crop Spraying:

Operators can leverage the drone’s RTK navigation, obstacle avoidance, and intelligent waypoint planning to perform automated, highly accurate spraying missions. This reduces chemical usage, improves coverage, and minimizes environmental impact. - Field Mapping and Surveying:

With its wide-angle FPV camera and high-precision GNSS, the MG-1P RTK enables real-time mapping, crop monitoring, and digital field analysis—vital for precision agriculture and yield optimization. - Safe Operation in Challenging Environments:

The A3 redundancy system, with eight-rotor propulsion redundancy and advanced radar sensing, ensures safe flight even in the presence of obstacles, variable terrain, and adverse weather—ideal for large farms and rugged landscapes.

The MG-1P / MG-1P RTK’s robust build, advanced avionics, and comprehensive wireless connectivity make it an indispensable tool for modern, data-driven agriculture.

Conclusion

The Agras MG-1P / MG-1P RTK by SZ DJI TECHNOLOGY CO., LTD. stands at the forefront of agricultural drone technology. Its powerful feature set—combining robust hardware, advanced wireless systems, and intelligent automation—addresses the demanding needs of professional operators. Certification under FCC ID SS3-GL300N1801 underscores its compliance with US RF and EMC standards, ensuring both safety and legality.

With its sophisticated internal architecture, modular design, and proven reliability, the MG-1P / MG-1P RTK is a compelling choice for precision agriculture, enabling safer, more efficient, and smarter farming operations in the digital age.