Introduction

The DJI Mini 3 Pro by DJI Technology, Inc. is a compact, high-performance drone engineered for enthusiasts and professionals who demand advanced aerial capabilities in a lightweight package. Designed with portability and ease of use in mind, the Mini 3 Pro leverages cutting-edge wireless communication, intelligent flight systems, and robust safety features, making it a standout in the sub-250g drone category.

Crucially, the DJI Mini 3 Pro holds FCC certification under FCC ID SS3-MT3M3VZ, which validates its compliance with US regulations regarding radio frequency (RF) emissions and electromagnetic interference. This certification is not only a legal requirement for sale and operation in the United States but also a testament to the device’s adherence to stringent safety and performance standards set forth by the Federal Communications Commission. It assures users that the drone meets established guidelines for RF exposure, operational safety, and device reliability.

In this article, we’ll dive deep into the DJI Mini 3 Pro’s key features, technical specifications, wireless and RF technologies, and internal components through a detailed teardown analysis. Additionally, we’ll explore regulatory insights from its FCC filing and discuss practical use cases for its target audience.

Key Features & Specifications

The DJI Mini 3 Pro is engineered to deliver advanced aerial imaging and flight performance while maintaining a form factor that falls below regulatory weight limits. Below are the standout features and technical specifications, highlighting both functional benefits and underlying technology.

Key Features

- Intelligent Flight Battery (2453 mAh Capacity):

- High-density Li-ion battery (LiNiMnCoO2 chemistry) provides extended flight time and reliability.

-

2453 mAh capacity at 7.38 V ensures efficient power delivery for sustained operations.

-

Ultra-Lightweight Design (<249 g Takeoff Weight):

-

Weighs less than 249 grams, exempting it from certain aviation regulations and making it easier to transport and deploy.

-

Bluetooth 5.2 (Aircraft) & Bluetooth 4.2 (Remote Controller):

-

Enables fast, stable connectivity for device pairing, firmware updates, and auxiliary controls.

-

Advanced Charging Support:

-

Compatible with DJI 30W USB-C Charger and other USB Power Delivery (PD) chargers, ensuring rapid and flexible charging options.

-

Wi-Fi 802.11a/b/g/n/ac:

-

Dual-band Wi-Fi on the aircraft for high-speed data transfer, video streaming, and extended control range.

-

O3 Transmission System:

-

DJI’s proprietary OcuSync 3.0 system delivers low-latency, high-definition video transmission, crucial for real-time piloting and content capture.

-

Remote Controller with Integrated Screen (DJI RC):

- Features a built-in display for direct viewing, reducing dependency on smartphones and enhancing user experience.

Technical Specifications

- Takeoff Weight: <249 g

- Transmitter Power (EIRP) 5.8 GHz: <26 dBm (FCC/SRRC), <14 dBm (CE)

- Wi-Fi Operating Frequency (Aircraft): 2.400–2.4835 GHz, 5.725–5.850 GHz

- Remote Controller Wi-Fi Operating Frequency: 2.400–2.4835 GHz, 5.150–5.250 GHz, 5.725–5.850 GHz

- Remote Controller Wi-Fi Protocol: 802.11a/b/g/n

- Remote Controller Wi-Fi Transmitter Power (EIRP):

- 2.4 GHz: <23 dBm (FCC), <20 dBm (CE/SRRC/MIC)

- 5.1 GHz: <23 dBm (FCC/CE/SRRC/MIC)

- 5.8 GHz: <23 dBm (FCC/SRRC), <14 dBm (CE)

- Bluetooth Operating Frequency: 2.400–2.4835 GHz

Additional Extracted Specifications

- Wi-Fi Standards:

- Aircraft: 802.11a/b/g/n/ac

- Remote Controller: 802.11a/b/g/n

- Supported Wi-Fi Frequency Bands:

- 2.400–2.4835 GHz

- 5.725–5.850 GHz

- 5.150–5.250 GHz (Remote Controller only, some regions)

- Bluetooth Versions:

- Aircraft: Bluetooth 5.2

- Remote Controller: Bluetooth 4.2

- Battery:

- Type: Li-ion (LiNiMnCoO2)

- Capacity: 2453 mAh

- Standard Voltage: 7.38 V

Benefits & Practical Implications

- Portability: Sub-249g weight makes it ideal for travel and allows operation in more locations without registration.

- Flight Endurance: Intelligent battery management maximizes flight time and safety.

- Robust Connectivity: Dual-band Wi-Fi and advanced OcuSync 3.0 ensure reliable control and HD video, even in challenging RF environments.

- Flexible Charging: USB PD compatibility streamlines charging with widely available adapters.

- Integrated Remote Controller: On-screen telemetry and video feeds enhance usability and reduce setup time.

Operating Frequencies

The DJI Mini 3 Pro operates across multiple wireless frequency bands, as validated by its FCC filing under FCC ID SS3-MT3M3VZ. These frequencies enable robust communication, control, and data transmission capabilities:

| Frequency Range (GHz) | Output Power (mW) | FCC Rule Part |

|---|---|---|

| 2.402–2.48 | 2.4 | 15CCC2.12.4035 |

| 2.462 | 146.2 | 15CCC2.25.7275 |

| 2.4712 | 155.6 | 15CCC2.32.412 |

| 5.825 | 28.4 | 15ECC1.1 |

| 5.84812 | 154.5 | 15ECC1.25.745 |

These bands and power levels are pivotal for supporting Wi-Fi (2.4 GHz, 5 GHz), Bluetooth, and proprietary RF communications, optimizing both range and throughput while ensuring compliance with regulatory standards.

Technology Deep Dive

The DJI Mini 3 Pro leverages a sophisticated suite of wireless technologies, including dual-band Wi-Fi (2.4 GHz and 5 GHz) and Bluetooth (5.2 for the aircraft, 4.2 for the controller). The O3 transmission system, DJI’s proprietary OcuSync 3.0, is central to its real-time HD video downlink and low-latency control, providing reliable connectivity over significant distances while minimizing susceptibility to interference.

The selected operating frequencies strike a balance between range, bandwidth, and regulatory compliance. The 2.4 GHz band is favored for its extended range and obstacle penetration, while the 5 GHz band offers higher data rates and reduced congestion, ideal for high-definition video streaming. Bluetooth is employed for device pairing and auxiliary connections, benefiting from the low power consumption and robust interoperability of Bluetooth 5.2.

The output power levels, as registered with the FCC, ensure the device delivers sufficient signal strength for stable operation without exceeding safe RF exposure limits. The combination of multi-band Wi-Fi, advanced RF front-end design, and dynamic power management enables the Mini 3 Pro to maintain reliable connections in diverse environments, from urban landscapes to open fields. Overall, these technologies collectively underpin the drone’s exceptional control responsiveness, video quality, and operational safety.

In-Depth Internal Component Analysis / Teardown

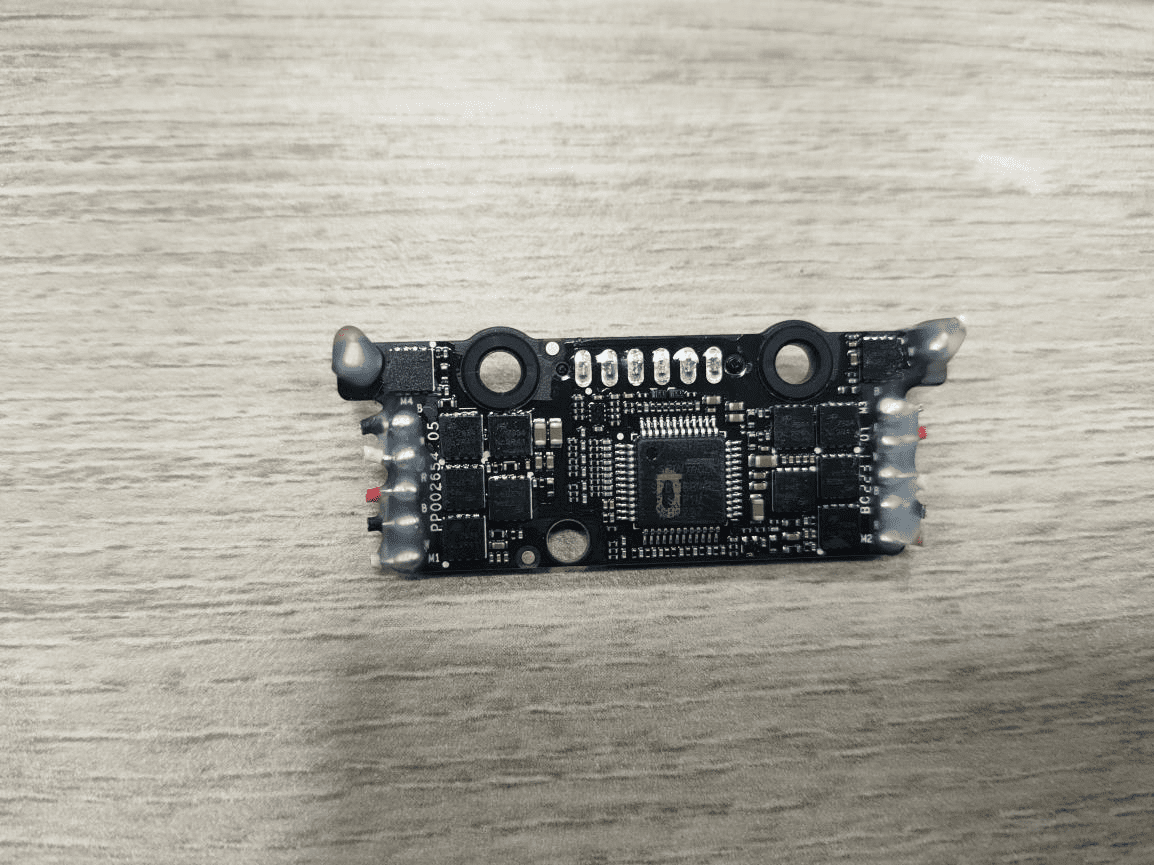

Main PCB with Central Microcontroller and Power Drivers

A close examination of the main internal PCB reveals a meticulously engineered board at the heart of the DJI Mini 3 Pro. Dominating the center is a quad flat package (QFP) microcontroller or ASIC, likely responsible for critical flight operations such as motor control or sensor data processing. Surrounding this are multiple MOSFETs or power drivers, strategically positioned near edge connectors labeled with motor and sensor designations—indicative of their role in controlling brushless motors or actuators.

The black ENIG-finished PCB showcases high build quality with at least four layers, supporting robust power and signal routing. Extensive ground pours, via stitching, and reinforced connectors (secured with epoxy for vibration resistance) ensure both electromagnetic compatibility and durability in the drone’s high-vibration environment. The presence of large ceramic capacitors for power smoothing and a clear separation of analog and digital domains further highlight the thoughtful design. This board exemplifies the modularity and reliability essential for safe, stable flight and seamless integration with the drone’s broader control and sensor systems.

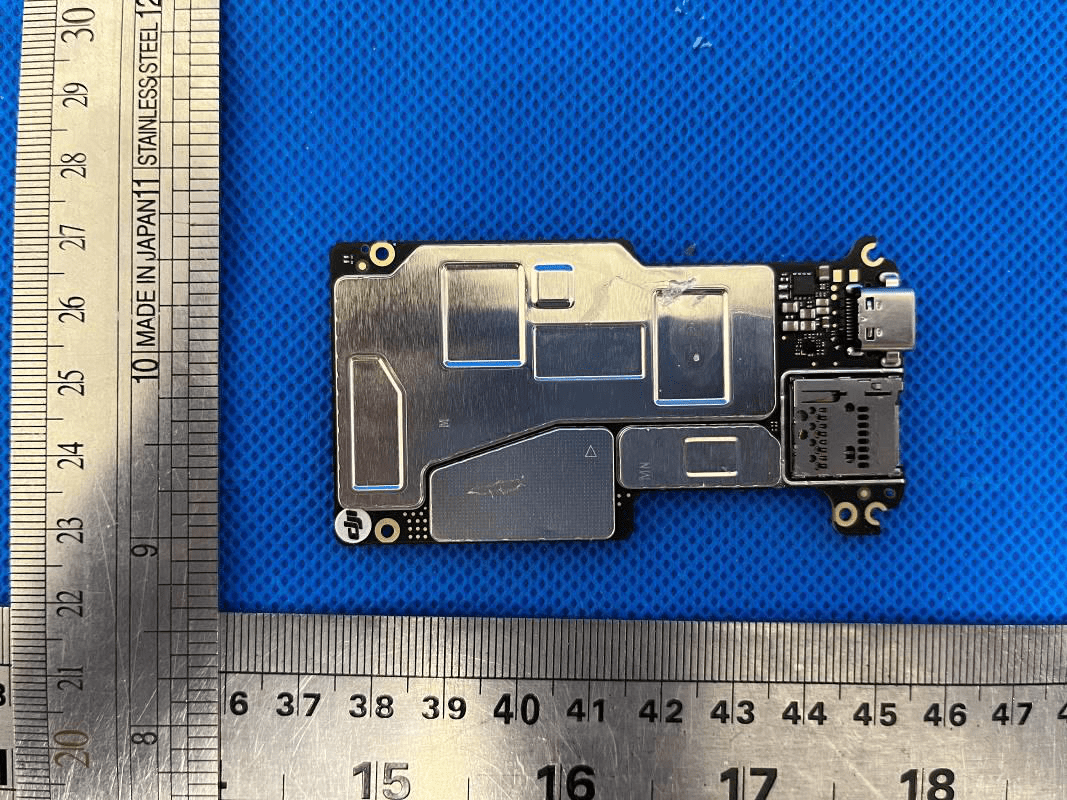

Densely Populated PCB with Extensive EMI/RFI Shielding

Another internal assembly features a high-density PCB, heavily shielded with multiple metal EMI/RFI cans. These shields likely cover the main system-on-chip (SoC), memory, and RF transceivers, safeguarding sensitive circuits from electromagnetic interference while facilitating high-speed data processing and robust wireless communication. The presence of a USB-C connector and microSD slot suggests this board manages data transfer, storage, and perhaps direct firmware updates.

The black, multi-layer PCB employs careful signal integrity strategies, including via-in-pad and stitching vias, to support high-frequency digital and RF signals. Several FPC/FFC connectors indicate modular interfacing with the camera, gimbal, and sensors. The extensive shielding and compact layout underscore DJI’s commitment to performance and reliability, ensuring the drone can handle complex video, telemetry, and wireless tasks without compromise.

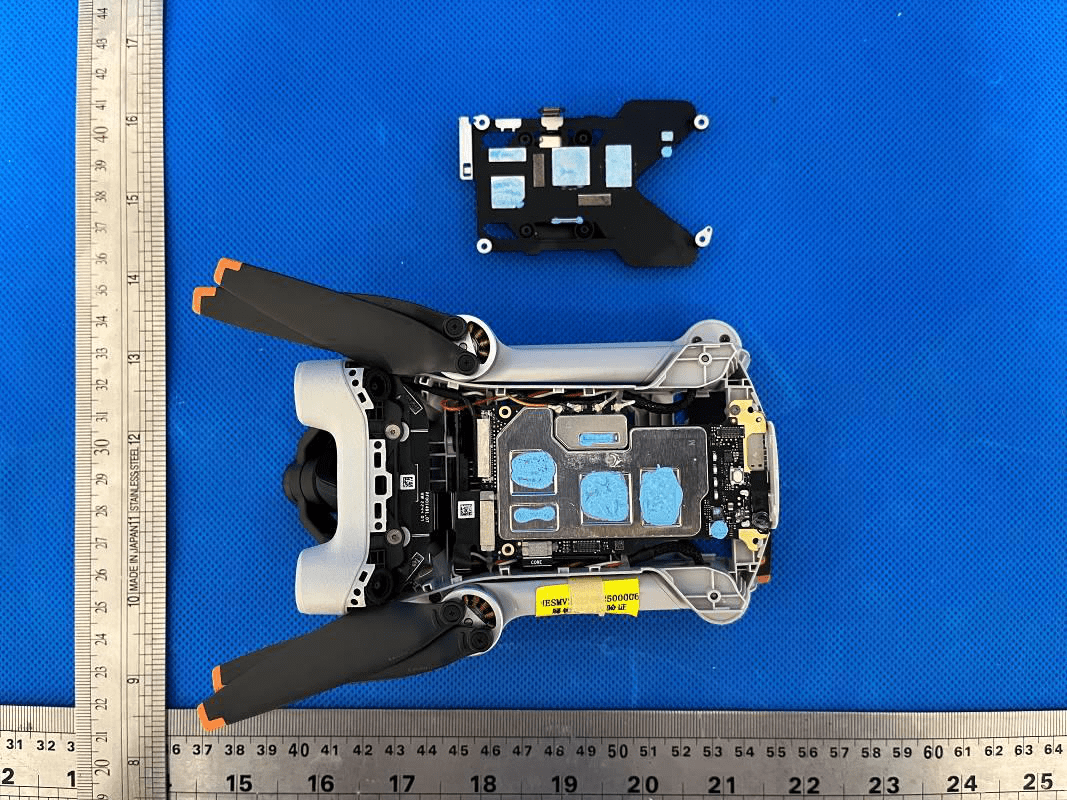

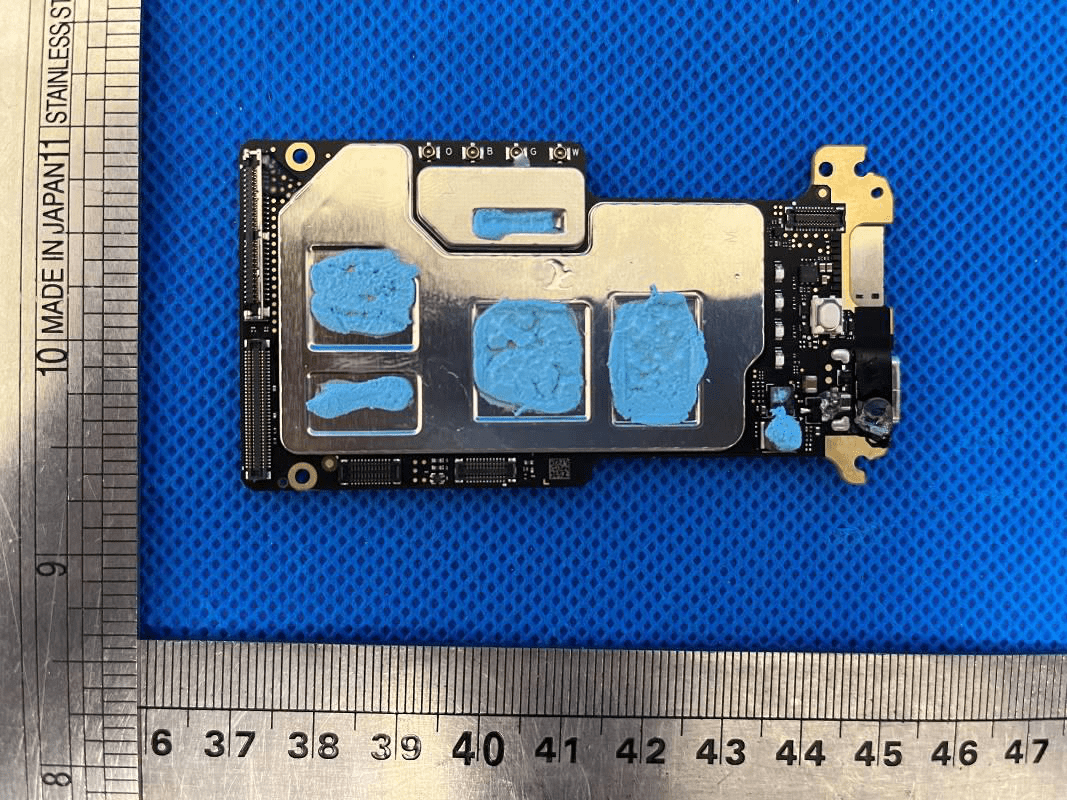

Mainboard Assembly with Shielded ICs and Integrated Power Management

Within the mainboard, several large ICs are shielded with thermal pads, signifying high-performance components such as the primary SoC, memory, and RF transceivers. These central chips are likely responsible for flight control, image processing, and wireless connectivity. The periphery hosts power management ICs, motor drivers, and sensor interfaces, all densely arranged to maximize functionality within the compact form factor.

Coaxial cables and connectors at the board’s edges suggest the use of PCB-embedded or FPC antennas for Wi-Fi and GPS, routed for optimal signal propagation. The use of blue thermal pads atop shields demonstrates a dual focus on heat dissipation and electromagnetic containment. Robust power regulation components, including large inductors and capacitors, are positioned near the battery connector to handle the high currents required by motors and onboard electronics. The overall modularity, high-density layout, and meticulous shielding reflect the engineering rigor that allows the Mini 3 Pro to deliver real-time flight control, high-bandwidth video, and reliable wireless operation within a lightweight and efficient package.

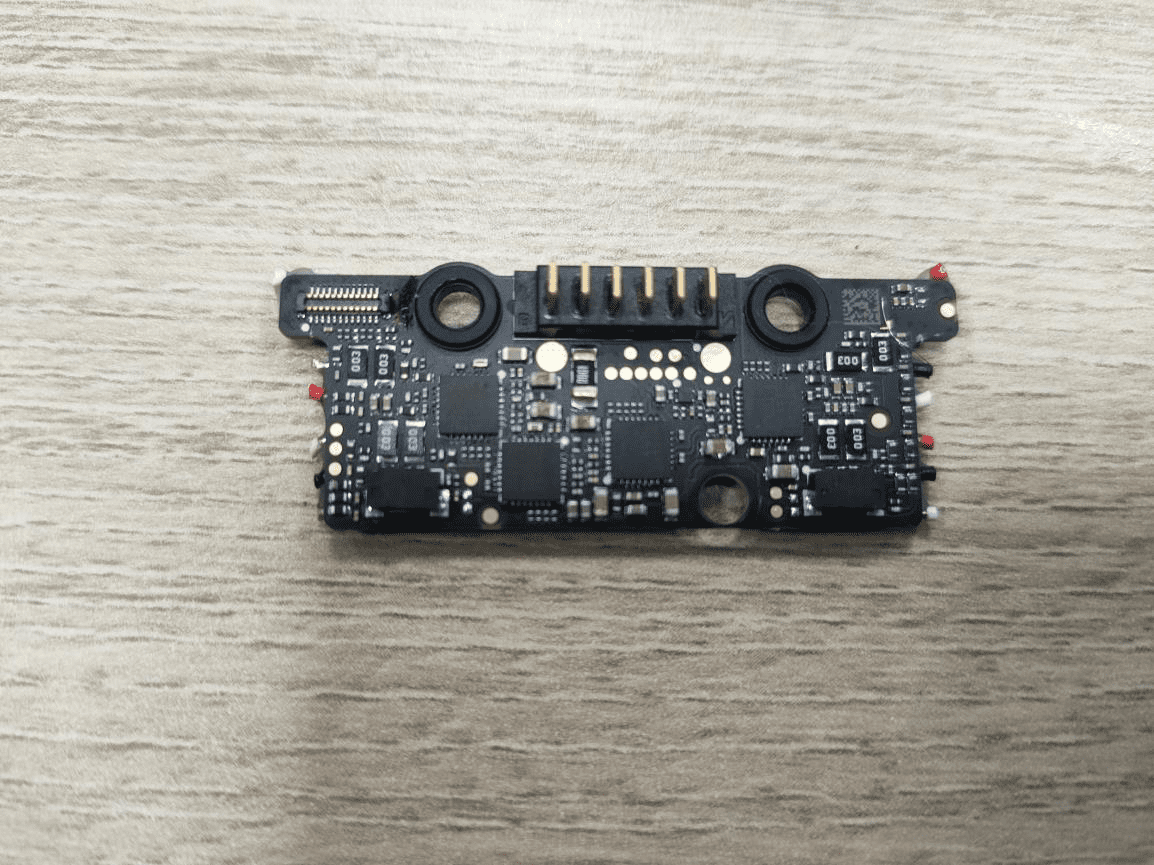

Sensor Interface or Power Management Board

This compact PCB exhibits a sophisticated layout, populated with several QFN/BGA integrated circuits likely serving as sensor processors, MCUs, or power management chips. The board employs a black ENIG finish and at least four layers, with numerous vias and ground pours to ensure robust signal integrity and electromagnetic compatibility. A prominent gold finger edge connector and fine-pitch FPC connector facilitate modular integration with other subsystems—potentially linking the board to the battery, main logic, or sensor arrays.

The careful distribution of large inductors and capacitors indicates localized power regulation, essential for supporting sensitive analog and digital circuits. No explicit antennas are visible, but gold pads and edge connectors may serve as RF interfaces for Wi-Fi, GPS, or proprietary control links. The high-density layout, reliable connectors, and extensive grounding strategies exemplify DJI’s commitment to modularity, reliability, and performance in the drone’s demanding operational environment.

PCB Assembly with Shielded Processor and RF Modules

A compact, densely populated PCB features a large metal EMI/RFI shield with blue thermal interface material, protecting the main processor, wireless communication ICs, and memory. Multiple fine-pitch FPC connectors and a coaxial RF connector support the integration of antennas, cameras, and additional sensors. The board’s high layer count and robust grounding ensure the integrity of high-speed data and RF signals.

Large capacitors and inductors near the edges provide local power regulation, while a tactile switch and test points facilitate diagnostics and manufacturing. The use of thermal pads and shielding underscores the emphasis on heat management and RF performance. This board is likely central to flight control and real-time communication, underpinning the Mini 3 Pro’s advanced features and reliability.

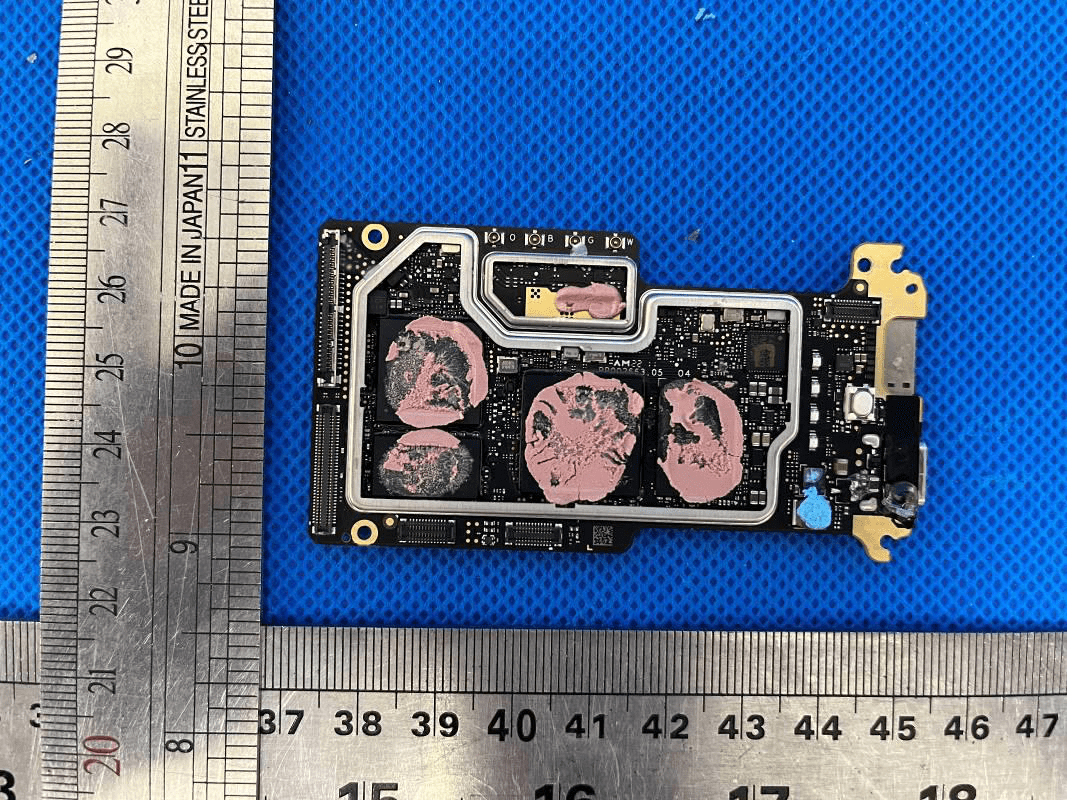

High-Density PCB with SoC and Antenna Interfaces

This internal assembly reveals a black PCB approximately 60mm x 30mm, populated with large BGA-packaged ICs partially covered by pink thermal interface material. These components likely include the main SoC for flight and video control, along with memory and RF transceivers. Multiple FPC/FFC connectors, edge connectors, and a blue-capped RF connector enable modular integration with the drone’s camera, gimbal, and wireless subsystems.

The presence of controlled impedance traces and extensive ground pours demonstrates careful attention to EMI/RFI control and signal integrity. Crystals and oscillators provide precise timing for digital and RF operations, while test points aid in manufacturing and diagnostics. Overall, the design reflects a balance between compactness, performance, and serviceability, supporting the drone’s real-time processing and robust wireless communication.

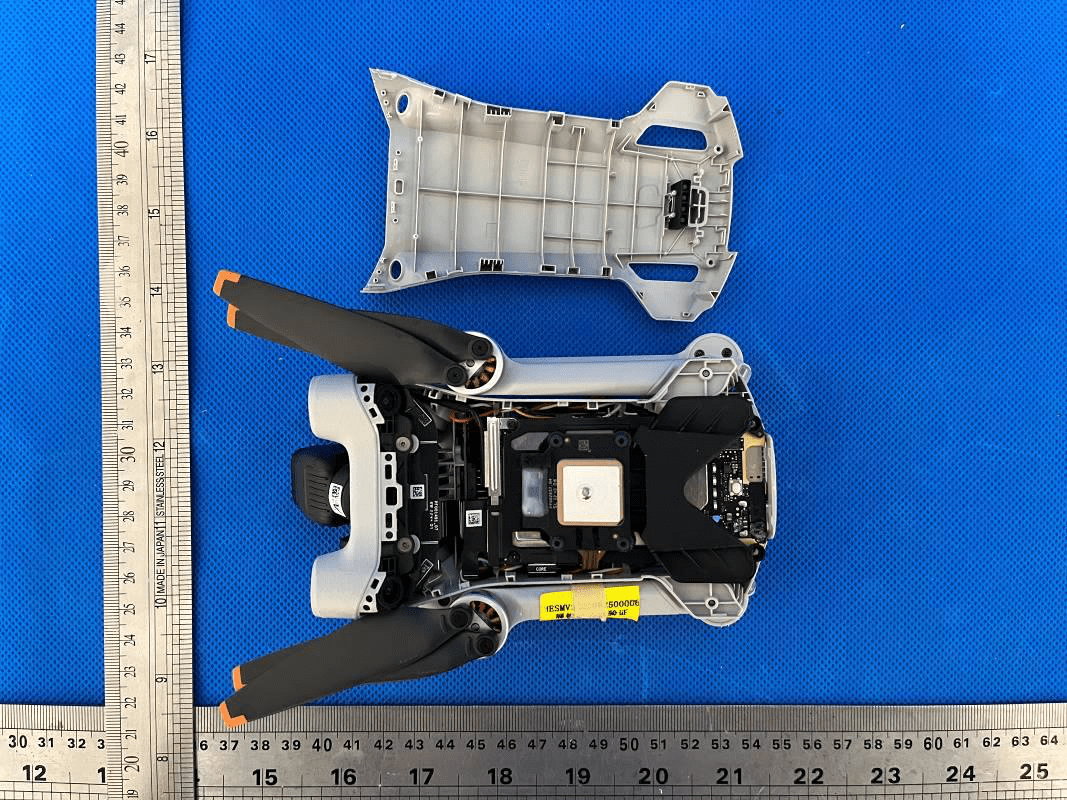

Integrated Flight Controller and GNSS Module

With the top cover removed, the Mini 3 Pro’s central electronics become visible, highlighted by a shielded processing module and a GNSS (GPS/GLONASS/BeiDou) receiver. The GNSS module’s centrally placed patch antenna is optimized for satellite reception, crucial for precise navigation and flight stability. The densely populated PCB features multiple via structures, FPC/FFC connectors for the camera and sensors, and robust wire-to-board connectors for the motors and power distribution.

Large inductors and capacitors near the edges support high-current power management, while the yellow-labeled connector handles the main battery input. Metal EMI shields protect critical analog and RF sections, ensuring both electromagnetic compatibility and thermal management. The modular, compact design exemplifies DJI’s approach to balancing integration, performance, and reliability in a lightweight drone platform.

Regulatory Insights & FCC Filing

The DJI Mini 3 Pro’s FCC ID SS3-MT3M3VZ certification is a vital assurance of its regulatory compliance and market readiness in the United States. This FCC ID, registered by FCC.gov, attests that the device has passed rigorous testing for electromagnetic compatibility and radio frequency emissions, ensuring it does not interfere with other wireless devices and operates safely within prescribed RF exposure limits.

The typical documentation included in such FCC filings encompasses comprehensive test reports for RF exposure and electromagnetic compatibility, internal and external photographs, user manuals, schematics, and block diagrams. These documents collectively provide transparency into the device’s design, safety features, and adherence to federal regulations.

Insights from the user manual highlight detailed safety guidelines and technical specifications, emphasizing safe operation in appropriate weather and environmental conditions. The documentation also outlines the drone’s wireless parameters, battery safety protocols, and specific warnings regarding RF exposure—affirming that the Mini 3 Pro is designed for use in uncontrolled environments and meets all FCC standards for portable devices. This thorough regulatory vetting not only ensures legal sale and operation but also enhances consumer confidence in the safety, reliability, and performance of the DJI Mini 3 Pro.

Potential Use Cases & Target Audience

With its advanced feature set, robust wireless connectivity, and sub-249g weight class, the DJI Mini 3 Pro caters to a diverse range of users—excluding children, as clearly indicated in its documentation.

-

Aerial Photographers and Videographers: The combination of high-definition video transmission, intelligent flight modes, and a lightweight frame makes the Mini 3 Pro ideal for content creators seeking dynamic aerial perspectives without the regulatory burden of heavier drones.

-

Professional Surveyors and Inspectors: The drone’s precise GNSS module, stable flight control, and modular design support applications in mapping, land surveying, and infrastructure inspection, where portability and quick deployment are critical.

-

Enthusiast Pilots and Tech-Savvy Hobbyists: Advanced users benefit from the drone’s customizable controls, O3 transmission, and integrated remote controller—enabling immersive first-person viewing and real-time telemetry for recreational or experimental flights.

The device’s compliance with FCC radiation exposure limits and its design for safe operation in uncontrolled environments position it as a versatile tool for responsible adult users in a variety of professional and recreational scenarios.

Conclusion

The DJI Mini 3 Pro by DJI Technology, Inc. exemplifies the convergence of high-performance engineering, regulatory compliance, and user-centric design in the ultra-light drone category. Its advanced wireless capabilities, intelligent battery system, and modular internal architecture are validated by the rigorous FCC certification under FCC ID SS3-MT3M3VZ, ensuring both legal operation and user safety.

Through deep integration of state-of-the-art components and meticulous RF design, the Mini 3 Pro sets a new standard for portable drones, serving the needs of professionals and enthusiasts alike. Its market position is reinforced by its thoughtful engineering, regulatory transparency, and adaptability across a range of demanding aerial applications.