Introduction

The DJI AGRAS T10 (Model: 3WWDZ-10A) represents a leap forward in agricultural drone technology, purpose-built to deliver efficient, precise, and automated aerial spraying for modern farms. As agriculture embraces digital transformation, drones like the AGRAS T10 become indispensable tools for professionals seeking to optimize crop protection and resource management. Designed for rugged field conditions, this UAV integrates advanced navigation, robust safety systems, and high-capacity spraying components—all engineered to maximize uptime and consistency.

A crucial milestone for any wireless device entering the U.S. market is FCC certification, and the AGRAS T10 bears the FCC ID SS3-T10A. This certification signifies that the device complies with strict federal regulations for radio frequency (RF) emissions, electromagnetic compatibility, and safety, making it legal for sale and operation in the United States. For agricultural operators, this assures not only regulatory compliance but also reliable performance in diverse RF environments.

In this comprehensive analysis, we’ll dive into the AGRAS T10’s standout features and technical specifications, dissect its wireless technologies and operating frequencies, and provide an expert teardown of its internal components. We’ll also highlight regulatory insights and explore real-world use cases—equipping you with a deep understanding of what sets the AGRAS T10 apart in the rapidly evolving field of agricultural drones.

Key Features & Specifications

The DJI AGRAS T10 is engineered for professional-grade agricultural operations, combining high-precision navigation, robust build quality, and smart automation to deliver efficient spraying and mapping. Below is a detailed breakdown of its features and technical specifications, each designed to address the unique challenges faced by modern growers and drone operators.

Key Features

- Automatic Bubbles Discharge Function

- Prevents clogs and ensures consistent spray quality, reducing downtime and maintenance.

- Centimeter-Level Positioning with Onboard D-RTK

- Integrates a high-precision D-RTK GNSS module, enabling precise flight paths for targeted spraying and mapping.

- Smart Controller Enterprise with OcuSync Enterprise Transmission

- Offers long-range, low-latency communication, ensuring reliable control even in complex environments.

- 5.5-inch Ultra-Bright Dedicated Screen on Remote Controller

- Provides clear, real-time data and video feeds for enhanced situational awareness, even under direct sunlight.

- Multi-Aircraft Control Mode (Up to Five Aircraft)

- Increases operational efficiency by enabling one operator to simultaneously manage multiple T10 drones.

- Forward and Backward FPV Cameras with Bright Spotlights

- Enhances safety and visibility during both day and night operations, supporting precise navigation and obstacle detection.

- Quadrilateral Folding Structure

- Streamlines transport and deployment, saving time during transitions between fields.

- Dual-Layer Protection for Core Components

- Shields vital electronics from dust, moisture, and chemical exposure, ensuring reliability in harsh agricultural environments.

Technical Specifications

- Battery

- DJI-approved flight battery (BAX501-29000mAh-51.8V)

- Hovering Time: 8.7 min (26 kg takeoff weight), 19 min (16 kg takeoff weight)

- Wireless Connectivity

- Wi-Fi: Wi-Fi Direct, Wi-Fi Display, 802.11a/g/n/ac, 2×2 MIMO

- Frequency Bands: 2.4000-2.4835 GHz, 5.150-5.250 GHz, 5.725-5.850 GHz

- Bluetooth: Bluetooth 4.2

- Nozzles

- Standard: XR11001VS

- Optional: XR110015VS, XR11002VS

- Quantity: 16

- Upward Radar

- Model: RD2414U

- Operating Frequency: 24.05-24.25 GHz

- Power Consumption: 4 W

- Transmission Power (EIRP): <13 dBm (SRRC), <20 dBm (others)

- Obstacle sensing range: 1.5–15 m; FOV: 80°

- Safety Limit Distance: 2 m

- IP Rating: IP67 (dustproof and waterproof)

- Camera

- FPV Cameras: 1280×720 resolution, 15–30 fps

- Physical Dimensions

- Max Diagonal Wheelbase: 1480 mm

- Total Weight (excluding battery): 12.2 kg

- Power

- Hovering Power Consumption: 3200W (at 26 kg takeoff weight)

- Storage Temperature

- -30° to 25° C (-22° to 77° F)

Practical Takeaway:

The AGRAS T10’s feature set is optimized for field reliability, safety, and operational scalability. Centimeter-level positioning and robust obstacle detection ensure both efficacy and safety during automated missions. The modular design and dual-layer protection make it suitable for demanding agricultural environments where uptime is critical and maintenance windows are short.

Operating Frequencies

A clear understanding of the AGRAS T10’s wireless spectrum usage is essential for evaluating its performance, regulatory compliance, and operational range. According to its FCC ID SS3-T10A filing, the device operates on the following frequency bands and power levels:

| Frequency Range (GHz) | Output Power (mW) | FCC Rule Part |

|---|---|---|

| 2.4035–2.4775 | 53 | 15CCC1.12.4055 |

| 2.4625 | 26.6 | 15CCC1.55.7285 |

| 2.4715 | 231.7 | 15CCC1.42.4205 |

| 2.4745 | 53.2 | 15CCC1.22.4055 |

| 2.4755 | 489.8 | 15CCC1.32.4105 |

| 5.8295 | 257.6 | 15ECC2.5 |

| 5.8395 | 308.3 | 15ECC2.45.7455 |

| 5.8445 | 60.4 | 15ECC2.25.7305 |

| 5.8445 | 311.9 | 15ECC2.35.7355 |

| 5.8465 | 59.8 | 15ECC2.15.7305 |

These bands are primarily used for Wi-Fi, Bluetooth, and proprietary RF communications. Output power levels are tuned for optimal range and regulatory compliance, balancing robust connectivity with minimal risk of interference to other devices in the ISM (Industrial, Scientific, and Medical) bands.

Technology Deep Dive

The AGRAS T10 leverages a sophisticated suite of wireless technologies to support its advanced operational requirements. Its Wi-Fi implementation (supporting 802.11a/g/n/ac with 2×2 MIMO) enables high-throughput, robust communication between the drone and its remote controller, especially beneficial for real-time video streaming and telemetry. Bluetooth 4.2 is included for device pairing, configuration, and potentially for short-range data transfer or diagnostics.

Operating across both the 2.4 GHz and 5.8 GHz bands allows the AGRAS T10 to dynamically select the optimal frequency for minimal interference, essential in rural and semi-urban environments with variable RF noise. The presence of multiple power levels across these frequencies, as detailed in the FCC documentation, indicates careful engineering to maximize communication range while adhering to regulatory emission limits.

The adoption of OcuSync Enterprise transmission technology further enhances the reliability and range of communications, vital for safe multi-aircraft control and large-field operations. The integration of advanced radar modules and external GNSS antennas (for D-RTK) demonstrates DJI’s commitment to precise navigation and obstacle avoidance, both of which are crucial for automated agricultural workflows.

The internal documentation and test reports confirm the device’s compliance with RF emission and safety standards, while also highlighting its strong resistance to magnetic interference—a critical factor for consistent, accurate spraying near high-voltage lines or metallic infrastructure.

In-Depth Internal Component Analysis / Teardown

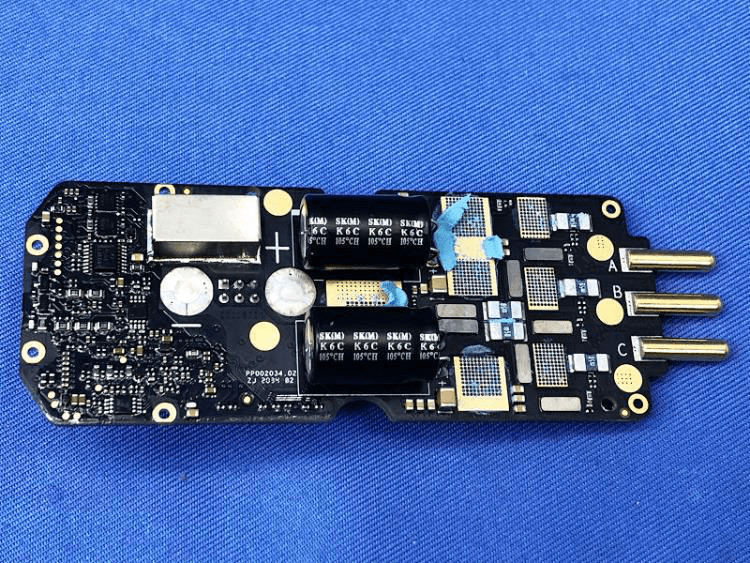

Precision Power Electronics and Motor Control

A densely populated black PCB reveals a highly sophisticated electronic speed controller (ESC) or power distribution module. The left side features a cluster of microcontrollers, gate drivers, and analog/digital ICs, protected by a large metal shield to suppress EMI. Thick copper pours and large gold-plated connectors on the right indicate high-current motor phase outputs, while robust electrolytic capacitors and MOSFETs provide power filtering and switching. Blue conformal coating and ground stitching vias signal environmental protection and EMI control. This board exemplifies DJI’s commitment to reliability and high-performance motor control, forming the heart of the AGRAS T10’s propulsion system.

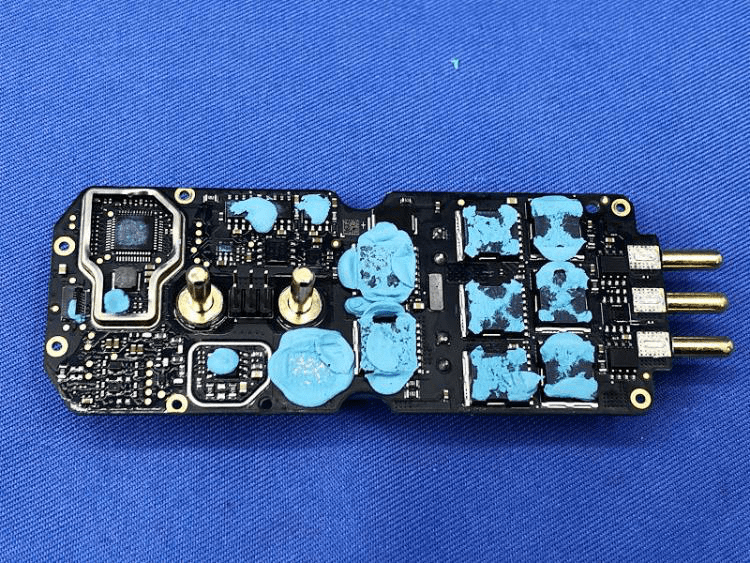

Integrated Motor Control and Thermal Management

Another high-density PCB showcases a large microcontroller or motor control SoC, flanked by gate drivers and op-amps for precise motor actuation. The right side, covered with blue thermal pads, houses MOSFETs or power stages that manage significant current for brushless motors. The presence of a metal shield frame and ENIG finish reflects EMI mitigation and durability. Robust board-to-board connectors and modular layout ensure serviceability. This design is critical for precise, efficient, and reliable motor control under the demanding conditions faced by agricultural drones.

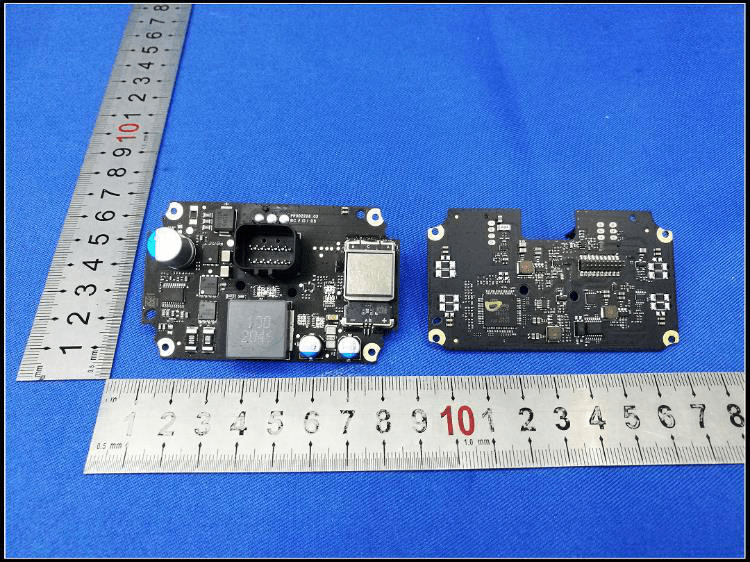

Central Processing and RF Communication Modules

Two compact black PCBs feature a mix of microcontrollers, RF transceivers, and power management ICs. The left PCB’s shielded section likely houses the main wireless communication module, with a large multi-pin connector facilitating subsystem integration. Onboard power regulation components ensure stable operation, while external antenna connectors suggest robust RF performance. These boards handle real-time control, telemetry, and possibly sensor fusion, essential for autonomous mission execution and live video streaming.

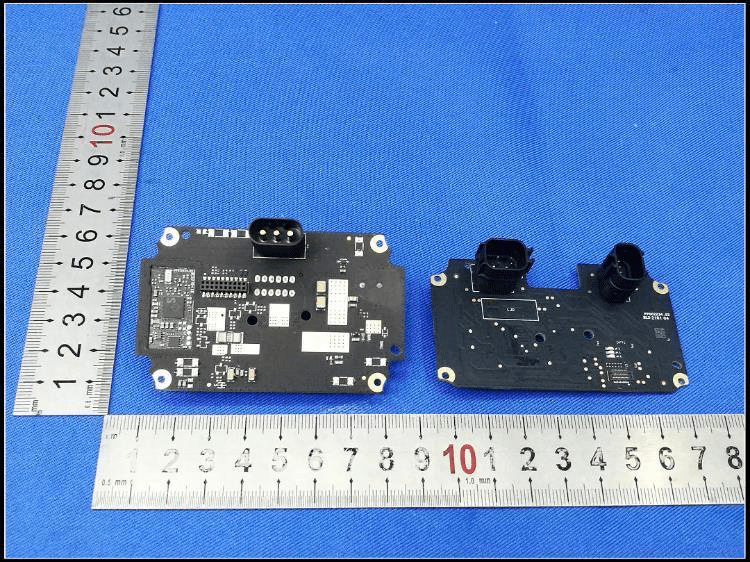

Sensor and Actuator Interface Boards

Viewed from both sides, these PCBs demonstrate meticulous layout for sensor or actuator interfacing, featuring a prominent microcontroller and power regulation circuitry. Robust connectors support reliable integration with the drone’s harness, while ground pours and differential pair routing ensure signal integrity. The absence of RF shielding and antennas implies these boards manage navigation sensors or payload control, contributing to the AGRAS T10’s precise flight and spraying operations.

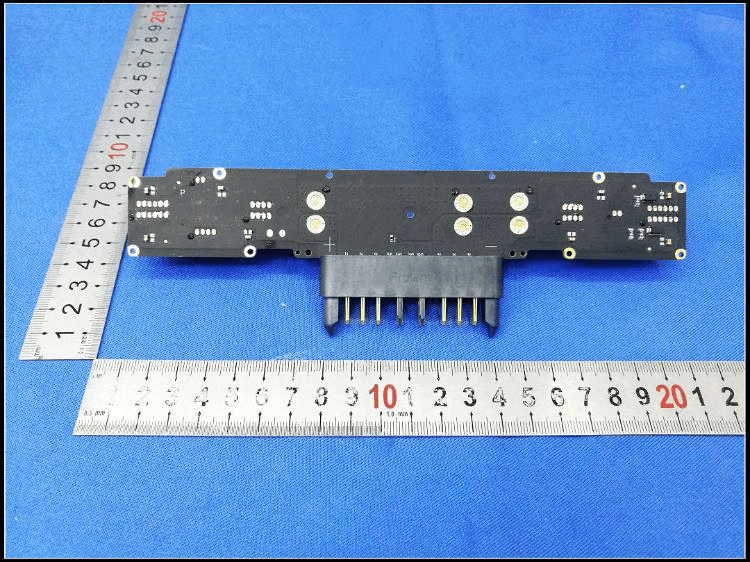

Power Distribution and System Connectivity

A large, black, multi-layer PCB is dominated by a substantial multi-pin connector, optimized for high-current or multi-signal interfacing. This side of the board is populated mainly with passive components, test points, and plated-through holes, reflecting its role as a power distribution or sensor interface module. The design prioritizes durability, modularity, and reliable connectivity—attributes vital for the AGRAS T10’s field serviceability and robust system integration.

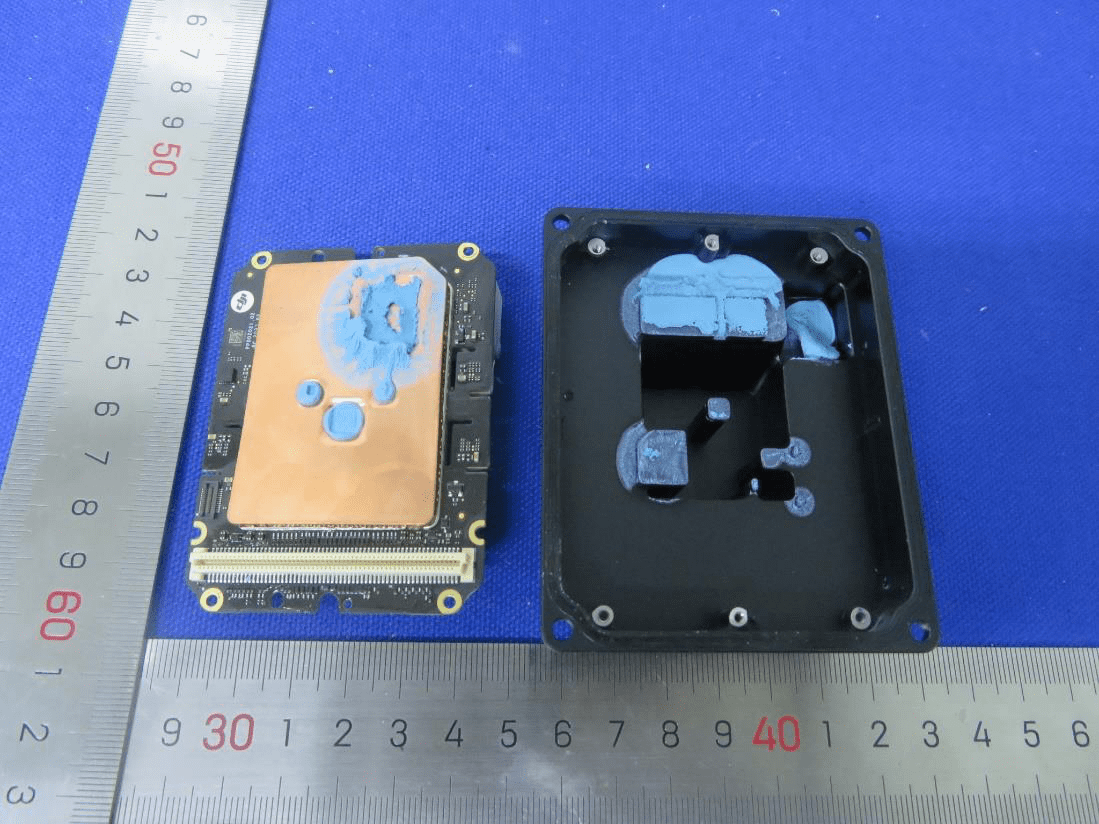

Advanced Heat Management and EMI Shielding

A high-density PCB is partially covered by a copper heat spreader and blue thermal interface material, indicating the presence of high-power or heat-sensitive components beneath. The large edge connector supports modular integration, while mounting holes ensure secure mechanical and electrical grounding. The design reflects a focus on thermal management, EMI shielding, and mechanical robustness—key for the high-performance processing or sensor fusion tasks required by the AGRAS T10.

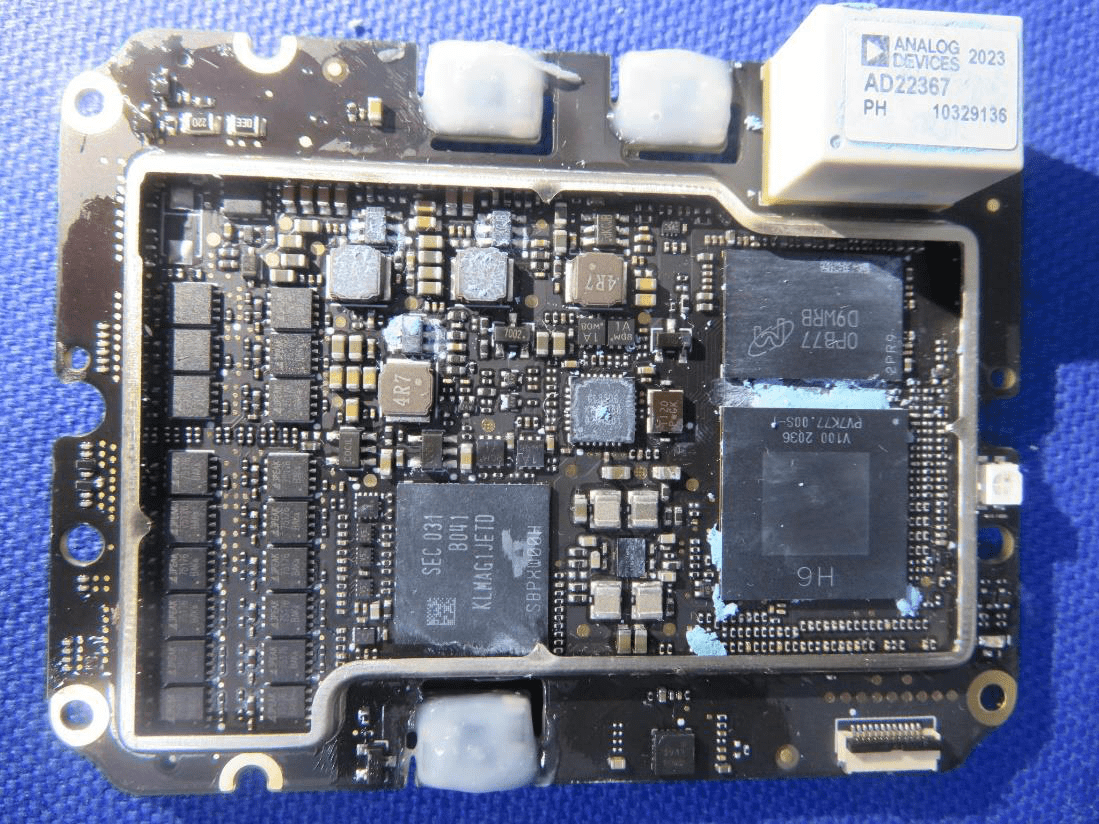

Flight Controller and Data Storage Hub

A densely packed PCB features major ICs including a high-performance Microchip MCU/SoC, a Samsung eMMC NAND flash memory for onboard data storage, and a VIA power management IC. An Analog Devices module, housed in a shielded can, likely handles precision sensor signal conditioning. The layout boasts controlled impedance traces, multiple layers, and extensive ground stitching, reflecting careful EMI management and signal integrity vital for flight control and sensor processing.

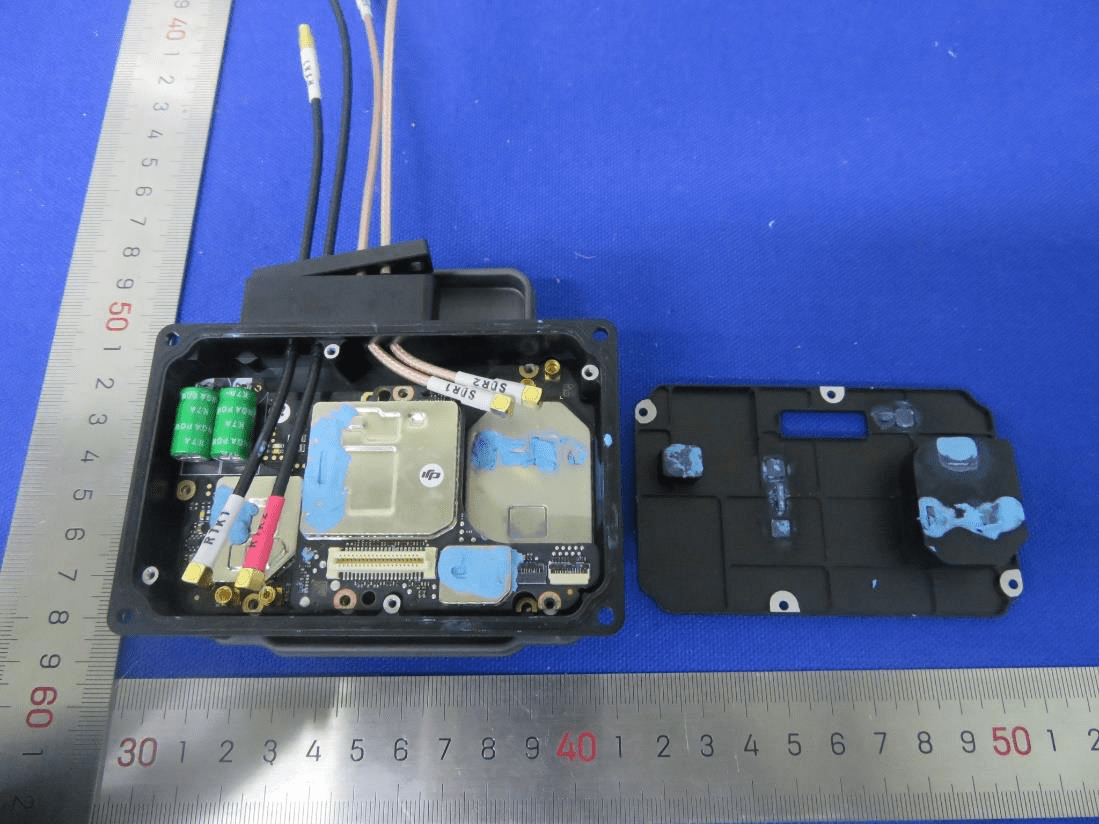

High-Power Wireless and Processing Module

This module combines two major ICs under substantial EMI shields, each with dedicated thermal interface material for heat dissipation. Coaxial RF connectors and labeled wires support modular antenna and power integration. Large capacitors and inductors provide power filtering for high-frequency or high-current loads. The robust shielding and careful layout suggest this board acts as a communication hub or high-power processing center, supporting the drone’s advanced wireless and control functions.

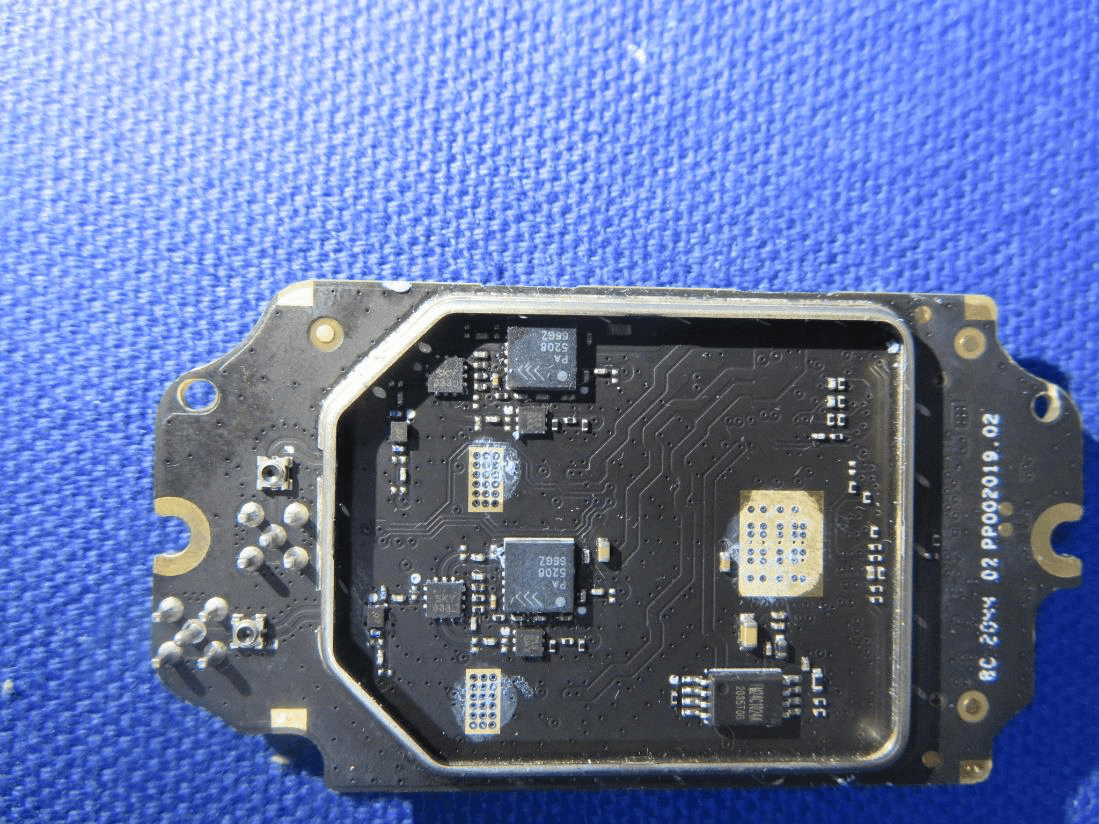

Sensor or Control Subsystem with EMI Shielding

A compact PCB features several low-profile QFN ICs, likely analog front-ends or signal conditioning chips, surrounded by a metal EMI frame. Dense routing and through-hole connectors support modular integration, while the lack of large power components or antennas points to a specialized control or sensor processing role within the drone, emphasizing robust EMI protection and signal integrity.

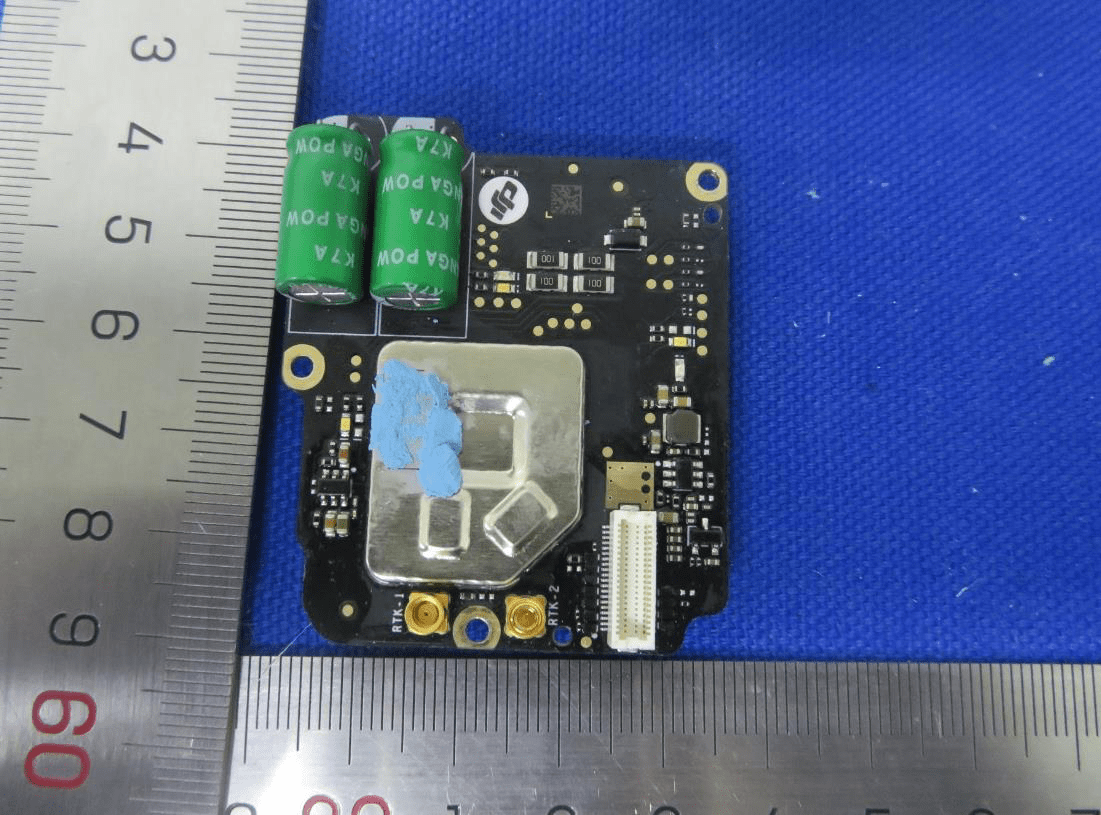

D-RTK GNSS Positioning Module

A high-density PCB features a large EMI shield protecting sensitive RF and digital circuits, with blue thermal compound for heat dissipation. Two U.FL connectors labeled for RTK antennas confirm this is a GNSS/RTK positioning module, essential for the AGRAS T10’s centimeter-level accuracy. Large capacitors support power integrity, while a white FPC/FFC connector enables system integration. This design exemplifies the precision and reliability required for high-accuracy agricultural navigation.

Regulatory Insights & FCC Filing

The FCC ID SS3-T10A confirms that the DJI AGRAS T10 meets rigorous U.S. standards for electromagnetic compatibility and RF emissions, ensuring it is legal for sale and operation nationwide. Registered through the FCC, this certification process involves comprehensive testing and documentation, including RF exposure reports, electromagnetic compatibility (EMC) assessments, internal and external photographs, user manuals, and detailed schematics.

The user manual and internal documentation reveal several key compliance features: robust EMI shielding, advanced radar and GNSS modules for precision navigation, and a dual-layer protection system for critical electronics. Test reports confirm that the AGRAS T10’s RF emissions fall well within legal limits, even when operating at maximum output in the 2.4 GHz and 5.8 GHz bands. The filing also documents the device’s strong resistance to magnetic interference, ensuring consistent performance near high-voltage lines or metallic structures—a common challenge in agricultural settings.

Overall, the FCC certification not only validates the AGRAS T10’s technical design but also provides peace of mind for operators, knowing their equipment meets stringent safety and interference standards.

Potential Use Cases & Target Audience

With its robust feature set and advanced wireless capabilities, the DJI AGRAS T10 is tailored for a variety of demanding agricultural scenarios:

- Large-Scale Crop Spraying Operations

- Operators managing extensive fields can deploy the T10’s multi-aircraft control mode, maximizing coverage and reducing labor costs. Its automatic bubble discharge and consistent spray system minimize chemical waste while ensuring even application.

- Precision Farming and Research

- Agricultural professionals and researchers benefit from the T10’s centimeter-level D-RTK positioning, enabling targeted application of pesticides or fertilizers. This precision reduces environmental impact and supports data-driven crop management strategies.

- Challenging Environments with High Magnetic Interference

- Farms located near power lines or metallic infrastructure can rely on the T10’s strong resistance to magnetic interference and advanced radar systems, ensuring safe, accurate operation where other drones might struggle.

These use cases underscore the AGRAS T10’s appeal to forward-thinking growers, agronomists, and drone service providers seeking to modernize their operations with reliable, high-performance aerial technology.

Conclusion

The DJI AGRAS T10 (Model: 3WWDZ-10A) sets a new benchmark for agricultural drones, blending advanced wireless technology, rugged engineering, and intelligent automation. Its FCC ID SS3-T10A certification not only clears it for legal operation in the U.S. but also attests to its robust RF design and regulatory compliance. With cutting-edge features like D-RTK positioning, modular construction, and comprehensive EMI protection, the AGRAS T10 is poised to lead the transformation of precision agriculture. For professionals seeking reliability, performance, and compliance, the AGRAS T10 stands out as a smart investment in the future of farming technology.