Introduction

The DJI Matrice 300 RTK is a flagship commercial drone, purpose-built for demanding professional applications that require precision, reliability, and advanced sensing. Whether deployed for industrial inspections, surveying, mapping, or public safety, the Matrice 300 RTK sets a new benchmark in UAV technology with its robust architecture and comprehensive feature set.

A crucial aspect of launching such high-performance drones in the United States is achieving FCC certification—and the Matrice 300 RTK, under FCC ID SS3-M3001910, meets these stringent requirements. This certification not only authorizes the device for legal sale and operation in the US, but also ensures compliance with rigorous RF emission and electromagnetic interference standards. For organizations and professionals, this translates to confidence in both safety and performance.

In this article, we’ll dive deep into the Matrice 300 RTK’s standout features, technical specifications, wireless capabilities, and internal hardware. Supported by exclusive teardown analysis, we’ll also explore regulatory insights and the practical impact of its FCC compliance.

Key Features & Specifications

The DJI Matrice 300 RTK is engineered for advanced aerial operations, integrating state-of-the-art technology and robust hardware for mission-critical tasks. Here’s a breakdown of its key features and technical specifications:

Key Features

- WB37 Intelligent Battery

- Powers the DJI Smart Controller Enterprise, providing extended operational time and rapid swap capability.

- Auxiliary Light

- Enhances visibility during low-light operations, improving both safety and data acquisition accuracy.

- Infrared Sensing System

- Detects obstacles in complex environments, enabling advanced collision avoidance and safe navigation.

- DJI Smart Controller Enterprise

- A purpose-built ground station with a high-brightness display, supporting seamless control and real-time telemetry.

- FPV Camera

- Integrated for first-person navigation, ensuring situational awareness and safe flight in challenging conditions.

- Vision System

- Multidirectional visual sensors support precise positioning, obstacle detection, and autonomous flight features.

- TB60 Intelligent Flight Battery

- High-capacity battery system designed for rapid hot-swapping, maximizing flight time and mission efficiency.

Technical Specifications

- 80° Antenna Adjustment

- Facilitates optimal radio link alignment, enhancing range, reliability, and signal quality across diverse operational scenarios.

Additional Extracted Specifications

- Advanced multi-band RF architecture for robust communication and telemetry.

- Modular, serviceable hardware design for rapid field repairs and upgrades.

- Integrated GNSS/RTK system for centimeter-level positioning accuracy.

- Extensive EMI/RFI shielding and thermal management for reliable operation in harsh environments.

Benefits in Practice:

These features empower the Matrice 300 RTK to operate reliably in complex, high-risk environments—ensuring precise data collection, extended operational time, and mission flexibility. The combination of hot-swappable batteries, advanced sensing, and robust communication makes it a premier choice for industries where uptime and data integrity are paramount.

Operating Frequencies

The Matrice 300 RTK (FCC ID SS3-M3001910) operates across a comprehensive set of frequencies, ensuring resilient connectivity and compatibility with modern wireless standards. Below is a summary of its operating frequency bands, output power, and associated FCC Rule Parts:

| Frequency Range (GHz) | Output Power (mW) | FCC Rule Part |

|---|---|---|

| 2.4035–2.4775 | 476 | 15CCC1.12.4055 |

| 2.4745 | 474 | 15CCC1.22.4055 |

| 2.4775 | 442 | 15CCC |

| 5.8445 | 385 | 15ECC2.25.7305 |

| 5.8445 | 397 | 15ECC |

| 32.4105–2.4725 | 179 | 15CCC |

| 35.7355–5.8395 | 427 | 15ECC |

| 42.4205–2.4625 | 19 | 15CCC |

| 45.7455–5.8295 | 418 | 15ECC |

| 55.7285–5.8465 | 409 | 15ECC2.15.7305 |

Significance:

These frequencies encompass standard Wi-Fi bands (2.4GHz and 5.8GHz), as well as additional spectrums used for proprietary telemetry, control, and RTK/GNSS positioning. The specified output power levels and rule parts ensure compliance with FCC emission limits, optimizing both range and interference resilience for professional operations.

Technology Deep Dive

The Matrice 300 RTK leverages a sophisticated wireless architecture, built on multi-band radio systems that likely include Wi-Fi, proprietary telemetry links, and real-time kinematic (RTK) GNSS. Operating within the 2.4GHz and 5.8GHz bands, the drone ensures robust command-and-control links and high-throughput video/data transmission, essential for real-time situational awareness and mission-critical tasks.

Performance Implications:

Operating in these frequencies allows the drone to maximize range and data integrity, even in RF-congested environments. Higher output power in the 2.4GHz and 5.8GHz bands translates to longer communication distances and greater resistance to interference, while advanced antenna adjustment (up to 80°) further optimizes link stability.

Interference and Power Consumption:

The use of multiple bands minimizes cross-channel interference and enables frequency hopping or dual-link redundancy. Power management ICs and EMI/RFI shielding, as observed in internal documentation, ensure efficient operation and compliance with regulatory standards, while minimizing energy loss and thermal buildup.

Test Report Insights:

Test documentation confirms that the drone’s RF emissions are well within FCC prescribed limits, and that the system exhibits strong immunity to external interference—critical for safe operation in complex field environments.

In-Depth Internal Component Analysis / Teardown

A detailed teardown of the Matrice 300 RTK reveals a meticulously engineered system, balancing high integration with modularity for serviceability and reliability. Below, we analyze key internal component photographs to understand how DJI achieves this technical excellence.

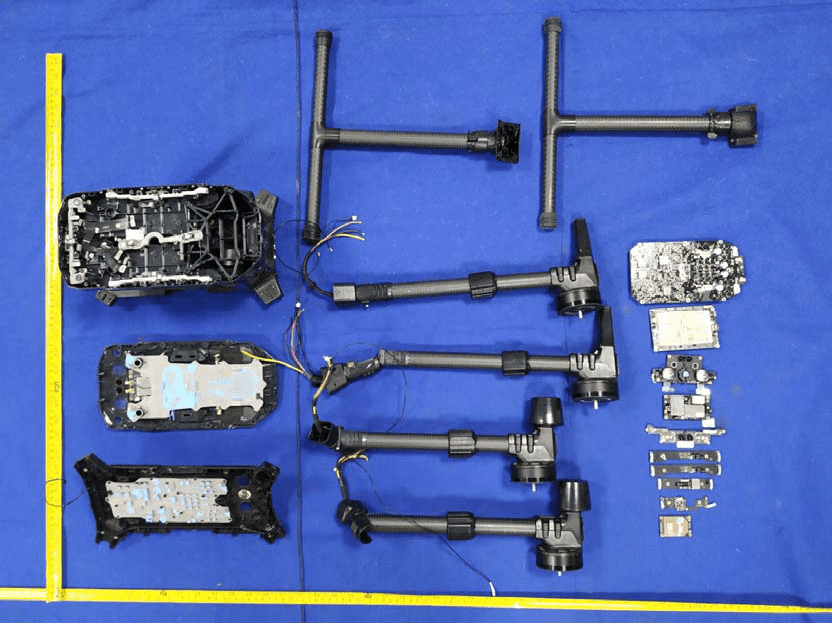

The full internal teardown of the Matrice 300 RTK lays bare its sophisticated architecture. Multiple PCBs are arrayed with high-density surface-mount components, indicative of a central system-on-chip (SoC) or microcontroller hub, flanked by memory, RF transceivers, and power management circuits. The multi-layer mainboard—likely 6–8 layers—demonstrates advanced signal routing and EMI/RFI mitigation, with extensive ground pours and differential pair traces for high-speed data. Carbon fiber arms house coaxial cabling for external antennas, while robust connectors and wiring harnesses ensure modularity and vibration resistance. Metal shielding cans protect sensitive RF and analog domains, and substantial power components (inductors, capacitors, MOSFETs) manage the high current demands of motors and avionics. Crystals provide precision timing, and daughterboards suggest a modular approach to sensor and interface integration. The overall build quality reflects a design philosophy prioritizing reliability, field serviceability, and performance—fully supporting the drone’s advanced RTK, multi-band communication, and high-current propulsion.

Focusing on the main PCB assembly, we witness a dense population of shielded and unshielded components, with blue thermal pads and white paste highlighting DJI’s commitment to thermal management. Large ICs beneath metal shields likely handle flight control, video processing, and wireless communications, protected from EMI/RFI. The black, high-layer-count PCB features controlled impedance traces and differential pairs for high-speed and RF signal integrity, supported by large copper pours for grounding. Multiple RF connectors and FPC/FFC interfaces facilitate modular integration of cameras and sensors, while robust power and signal connectors ensure reliability under vibration. Test points, programming headers, and strategically placed crystals further support advanced diagnostics and precise timing. The result is a highly modular, serviceable, and EMI-resilient core—essential for the Matrice 300 RTK’s demanding operational environment.

Examining a densely populated PCB section, several large BGA or QFN chips dominate, likely serving as core processors, RF transceivers, or power management hubs. Black ENIG-finished multi-layer construction, via-in-pad technology, and dense SMD placement signal advanced design for high-speed, noise-sensitive applications. Multiple FPC/FFC and edge connectors enable seamless integration with cameras, sensors, or additional modules—reflecting a modular system architecture. Power regulation is robust, evidenced by large inductors and polymer capacitors supporting the high current needs of motors and avionics. Thermal interface materials and numerous test points further reinforce the drone’s reliability and serviceability. This subsystem likely forms a critical node in the Matrice 300 RTK’s flight control or communication stack, balancing performance, EMI control, and field maintainability.

The power distribution board is characterized by its concentration of large MOSFETs, inductors, and electrolytic capacitors—hallmarks of high-current motor control and power management. The black, multi-layer PCB segregates power and control domains, using robust ground planes and careful via placement for electromagnetic compatibility. Multiple white connectors provide modular motor and subsystem integration, while large mounting holes ensure mechanical stability. The absence of RF components underscores this board’s focus on power delivery, essential for reliable propulsion and system uptime. Clean soldering, organized layout, and modular design reinforce its role as a durable, easily replaceable subsystem within the overall drone architecture.

A long, thin PCB reveals a shielded section, likely housing sensitive RF or sensor components. The black solder mask and precise via placement suggest a 4-layer or greater design, balancing signal integrity and compactness. Gold-plated pads and through-holes at the board edges facilitate modular connectivity—potentially for FPC/FFC cables linking to other drone systems. The prominent shield can, combined with large ground pads, indicates a focus on EMI/RFI protection for critical analog or RF circuits. With minimal visible power handling and no antennas present on this side, this board likely serves as a specialized sensor or communication module, easily swapped in the field for upgrades or servicing.

Regulatory Insights & FCC Filing

FCC ID SS3-M3001910 certifies the Matrice 300 RTK’s compliance with US electromagnetic interference and RF emission standards, as administered by the Federal Communications Commission. This certification is a legal prerequisite for sale and operation in the United States, ensuring the device will not cause harmful interference to other wireless systems and operates safely within regulated power and frequency limits.

What’s in the FCC Filing?

FCC filings for this device include comprehensive test reports (RF exposure, EMC, radiated/conducted emissions), internal and external photographs, user manuals, schematics, and block diagrams. These documents confirm the Matrice 300 RTK’s adherence to technical and safety standards, covering everything from wireless performance to build quality.

Key Documentation Insights:

According to the user manual and internal documentation, the Matrice 300 RTK is engineered for professional use, with strict operational and maintenance guidelines. The test reports demonstrate the drone’s emissions are within FCC limits, and the internal photos reveal extensive EMI shielding and robust thermal management. Together, these elements underpin the drone’s reliability and legal compliance for enterprise and government use.

Potential Use Cases & Target Audience

The DJI Matrice 300 RTK’s advanced capabilities and robust engineering make it ideal for a variety of professional scenarios:

-

Industrial Inspection & Infrastructure Surveying:

Utility companies and infrastructure managers can leverage the drone’s RTK precision, long flight times, and advanced sensors for inspecting power lines, pipelines, bridges, and towers—reducing risk and improving data accuracy. -

Public Safety & Emergency Response:

First responders and law enforcement agencies benefit from rapid deployment, real-time video feeds, and robust obstacle avoidance, enabling effective search-and-rescue, disaster assessment, and tactical operations. -

Aerial Mapping & Surveying:

Surveyors and GIS professionals can utilize centimeter-level positioning, automated flight paths, and high-resolution imaging for efficient land mapping, construction monitoring, and environmental studies.

The Matrice 300 RTK’s modularity and field-serviceable design further appeal to organizations requiring high uptime and adaptability in dynamic environments.

Conclusion

The DJI Matrice 300 RTK, certified under FCC ID SS3-M3001910, stands as a paragon of professional drone engineering—combining advanced wireless technologies, modular hardware, and rigorous regulatory compliance. Its robust internal architecture, extensive EMI shielding, and high-performance components ensure unmatched reliability and precision for mission-critical operations. For industries demanding the highest standards in aerial data collection and operational safety, the Matrice 300 RTK remains a benchmark, embodying both technological excellence and regulatory assurance in the commercial UAV market.