Introduction

The DJI Mavic Mini stands as a testament to the fusion of portability and performance in the world of consumer drones. Designed for aerial photography enthusiasts and casual users alike, the Mavic Mini delivers high-quality imaging and robust flight capabilities in a remarkably lightweight frame. Weighing just 249 grams, it bypasses many regulatory hurdles while still offering features typically reserved for larger, more expensive drones. With its compact form factor, stabilized 3-axis gimbal, and intelligent flight features, the Mavic Mini is engineered for creative freedom on the go.

Critically, the Mavic Mini (models MT1SS5, MT1SD25, MR1SS5, MR1SD25) is certified under FCC ID SS3-MT1SS51905, confirming its compliance with United States regulations for radio frequency emissions and electromagnetic compatibility. This certification ensures that the device is legal to sell and operate in the US, providing assurance of both safety and performance in wireless communications.

In this article, we’ll dissect the Mavic Mini’s key specifications, wireless technology, operating frequencies, internal components, and regulatory underpinnings. Through teardown analysis and technical insight, we’ll reveal what makes the Mavic Mini a standout in its class.

Key Features & Specifications

The DJI Mavic Mini is purpose-built for high-performance aerial imaging, user-friendly operation, and regulatory compliance. Below, we break down its standout features and technical specifications, illustrating how each contributes to its market appeal.

Key Features

- 2.7K Video & 12MP Photos

Capture crisp, detailed footage with a 1/2.3” CMOS sensor, enabling cinematic video at 2.7K resolution and vibrant 12-megapixel stills. - Detachable Control Sticks

Streamlines storage and transportation, enhancing portability. - Maximum Transmission Range: 2.49 mi (4 km)

Utilizes DJI enhanced Wi-Fi technology for a robust, long-range connection between the drone and remote controller. - MicroSD Card Slot

Supports expandable storage for high-resolution media. - Obstacle Sensing & Infrared Sensing System

Provides enhanced flight safety and precision, allowing for automated landing and stable hovering. - Fully Stabilized 3-Axis Gimbal

Delivers smooth, shake-free footage even in windy conditions or during dynamic maneuvers. - Downward Vision System

Ensures accurate hovering and landing by analyzing ground patterns and altitude.

Technical Specifications

- Charging Temperature Range: 41° to 113°F (5° to 45°C)

- Maximum Flight Time: 30 minutes (in 0 wind, flying at 15.5 mph / 25 kph)

- Remote Controller Battery: 2600 mAh

- Intelligent Flight Battery Type: LiPo 2S

- Intelligent Flight Battery Capacity: 2600 mAh

- Intelligent Flight Battery Net Weight: 100 g

- Aircraft Weight: 249 g (with battery, propellers, and microSD card)

- Gimbal Controllable Range: Pitch: -100° to +20°

- Operating Frequency (Model MT1SD25): 2.4–2.4835 GHz; 5.725–5.850 GHz

Wireless Specifications

- Wi-Fi: DJI enhanced Wi-Fi technology

- MT1SS5 & MR1SS5: 5.725–5.850 GHz

- MT1SD25 & MR1SD25: 2.4–2.4835 GHz, 5.725–5.850 GHz

- Bluetooth: Present (details not specified)

- Camera:

- Sensor: 1/2.3’’ CMOS

- Effective Pixels: 12 MP

- Video: 2.7K

Practical Benefits

- Regulatory-Friendly Design: Under 250g, the Mavic Mini is exempt from FAA registration in many scenarios, maximizing convenience for hobbyists.

- Extended Flight Time: 30 minutes per charge outpaces many competitors in the sub-250g class.

- Long-Range Transmission: Up to 4 km of reliable, low-latency video and control signal transmission for expansive creative opportunities.

- Stabilized Imaging: The 3-axis gimbal and robust vision systems enable professional-quality footage, even for new pilots.

Operating Frequencies

The DJI Mavic Mini (FCC ID SS3-MT1SS51905) operates on wireless frequencies authorized under its FCC certification, ensuring optimal range, reliability, and regulatory compliance.

| Frequency Range (GHz) | Output Power (mW) | FCC Rule Part |

|---|---|---|

| 15.745–5.825 | 250 | 15ECC2.1 |

These frequency allocations and power levels are critical for both remote control and video transmission, allowing the drone to maintain a stable, long-distance connection while minimizing interference with other wireless devices.

Technology Deep Dive

The Mavic Mini leverages a blend of advanced wireless technologies to deliver a seamless user experience. Its primary communications rely on enhanced Wi-Fi operating in both the 2.4 GHz and 5.8 GHz bands, depending on the specific model and regulatory environment. These bands are well-suited for high-bandwidth, low-latency connections—essential for real-time video streaming and responsive flight control. Bluetooth is also present for device pairing and auxiliary functions, though detailed specifications are not provided.

Operating within these bands allows the Mavic Mini to achieve its impressive 4 km transmission range while maintaining robust performance, even in environments with potential interference from other Wi-Fi and RF sources. The specified output power (250 mW) strikes a balance between maximizing range and adhering to FCC emissions limits, ensuring both user safety and minimal impact on nearby wireless networks.

Internally, the drone’s RF architecture is supported by sophisticated shielding and power management, as seen in the teardown analysis. These design choices minimize electromagnetic interference, preserve signal integrity, and support the Mavic Mini’s reliable connectivity and flight stability. The integration of high-speed video processing and wireless transmission is further enabled by advanced SoCs, memory, and robust PCB design, all orchestrated to deliver smooth, real-time aerial imaging.

In-Depth Internal Component Analysis / Teardown

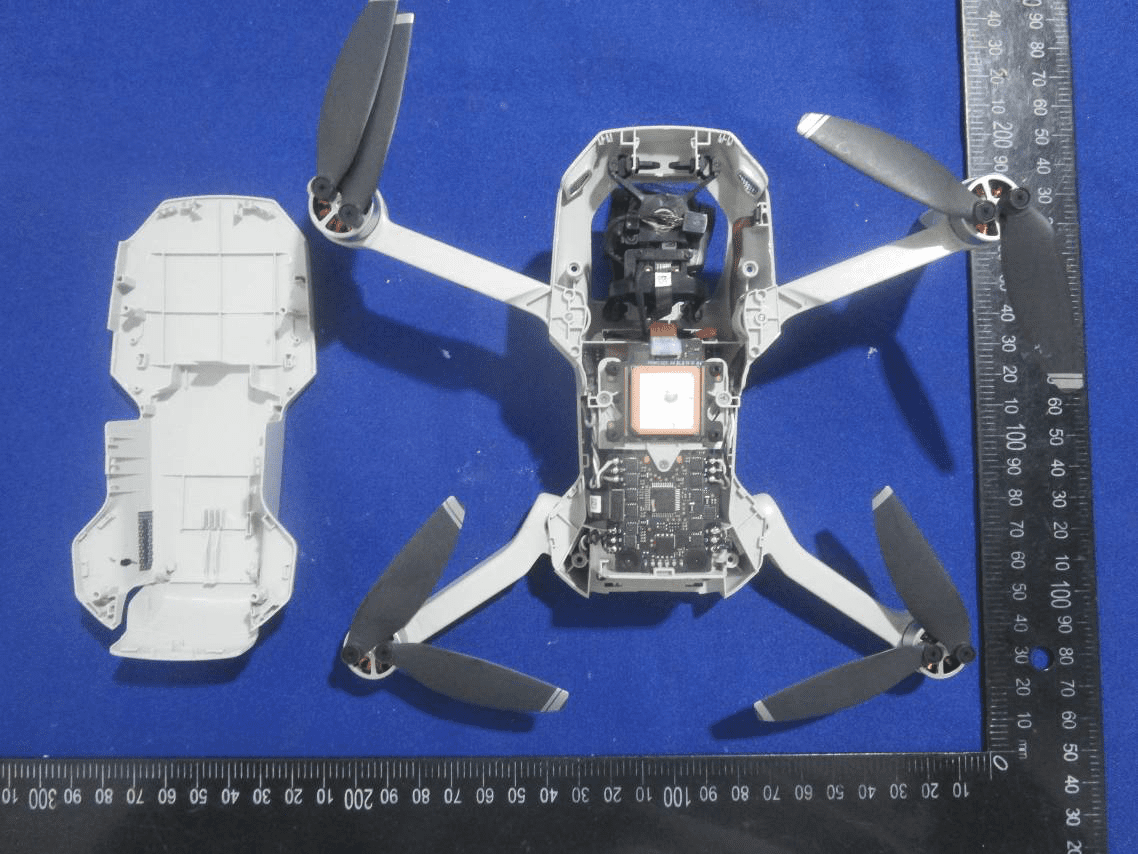

Main PCB, Gimbal Assembly, and Core Electronics

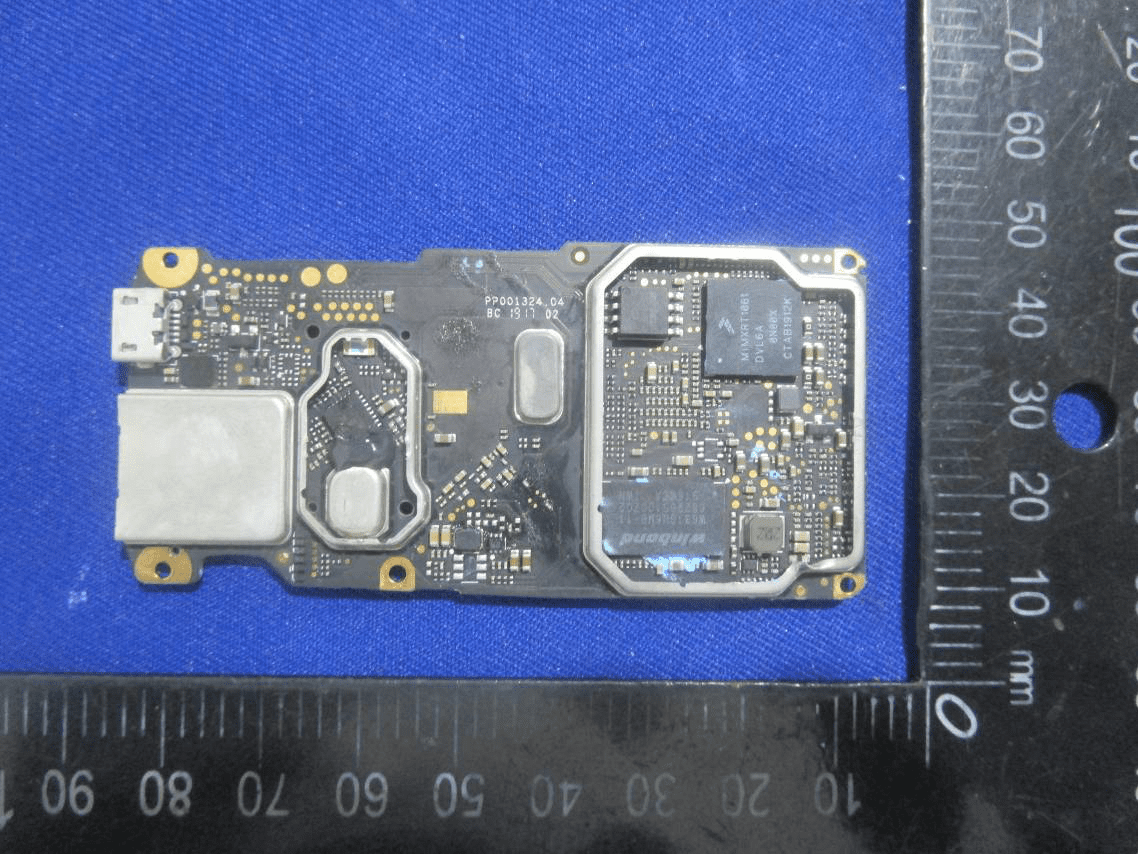

With the drone’s top casing removed, the main PCB dominates the internal landscape, densely packed with critical components. At the heart lies a large, centrally located SoC—likely ARM-based—responsible for flight control and real-time video processing. Surrounding this are flash memory modules, RF transceivers, and dedicated power management ICs, orchestrating the drone’s core functions. A shielded ceramic GPS antenna is integrated near the center, ensuring precise navigation. Numerous FPC connectors link the PCB to the gimbal, sensors, and battery, reflecting a modular, serviceable design. The use of robust copper pours and stitching vias underscores a commitment to EMI mitigation and reliable power distribution, while the compact, high-density layout exemplifies DJI’s expertise in miniaturized electronics for UAVs.

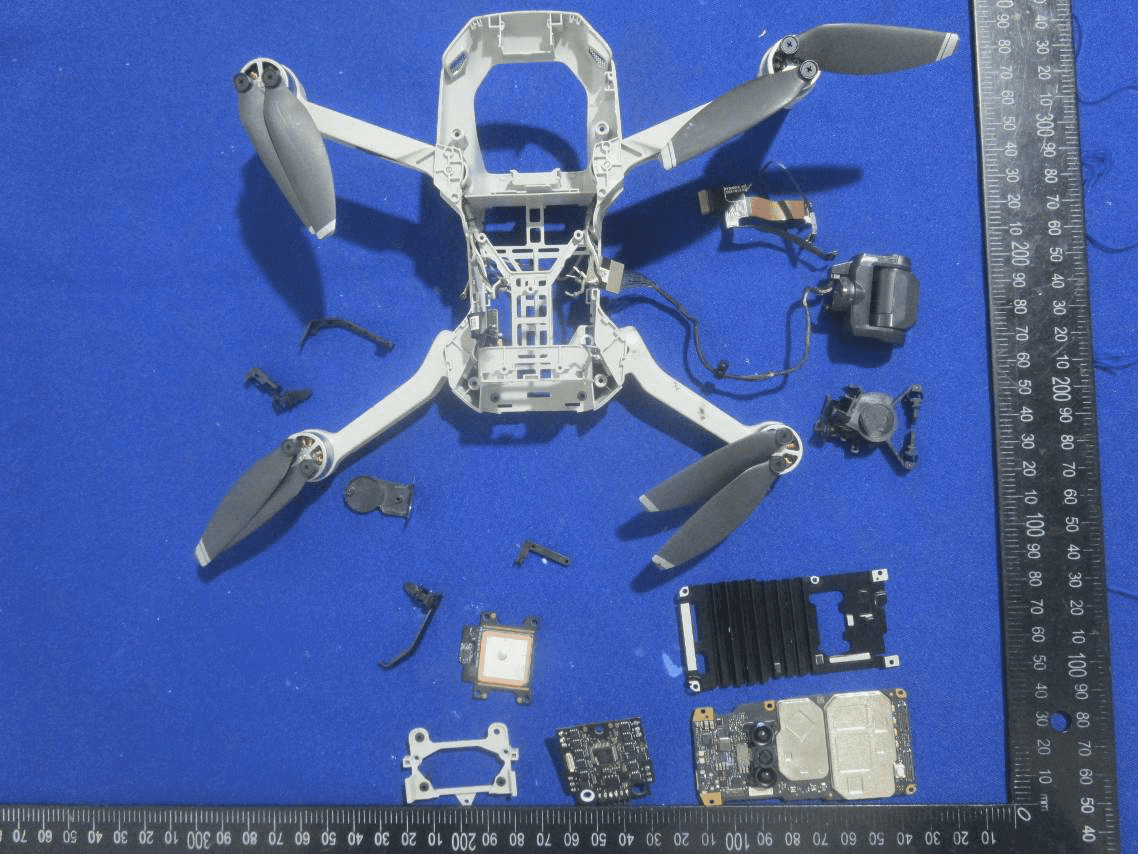

Modular PCB Assemblies and Shielded Subsystems

A comprehensive teardown reveals a meticulously organized internal structure, with two primary PCBs densely populated and extensively shielded. The larger board houses multiple RF and digital domains under metal cans, likely encompassing the main Ambarella video SoC, RF transceivers, and power management. The adjacent smaller board serves as a hub for motor control, IMU, and possibly a dedicated microcontroller for flight logic. Notably, a ceramic GPS patch antenna is situated for optimal signal reception, while camera modules and gimbal assemblies are connected via FPCs. The modularity of these subsystems not only enhances repairability but also supports robust manufacturing quality control. Extensive use of test points, thick power traces for motors, and dedicated heatsinking for the processor highlight a design optimized for both performance and longevity.

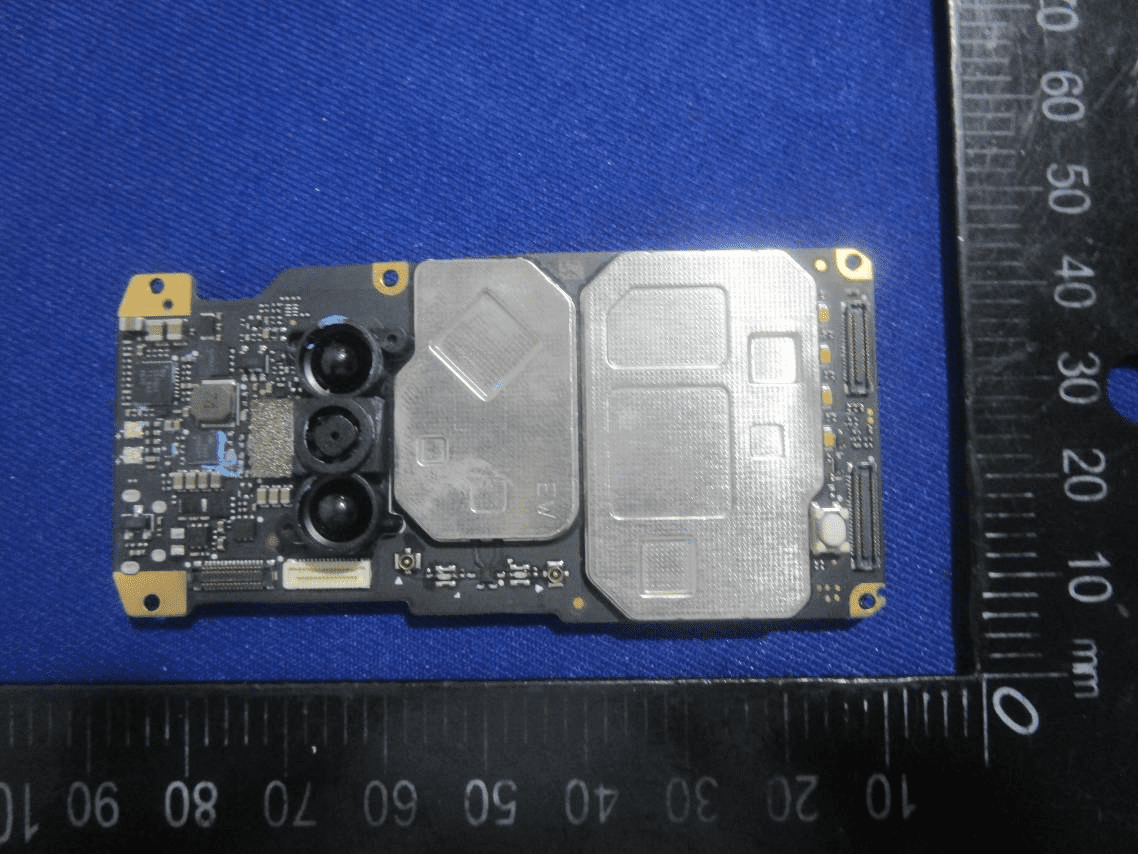

High-Density PCB with EMI Shielding and Sensor Integration

A close-up of a key internal PCB underscores the engineering precision behind the Mavic Mini. Major ICs, including power management and possibly microcontrollers, are strategically placed for optimal signal integrity. Two substantial EMI shields house the main SoC and RF transceivers, segregating high-frequency circuits and minimizing cross-talk. Peripheral connectors facilitate communication with the camera, gimbal, and antennas, while robust ground stitching and multi-layer construction ensure both EMI control and mechanical resilience. Integrated vision positioning modules hint at the downward vision system, essential for stable hovering and automated landing. The overall design balances miniaturization with modularity, supporting both advanced flight features and efficient assembly.

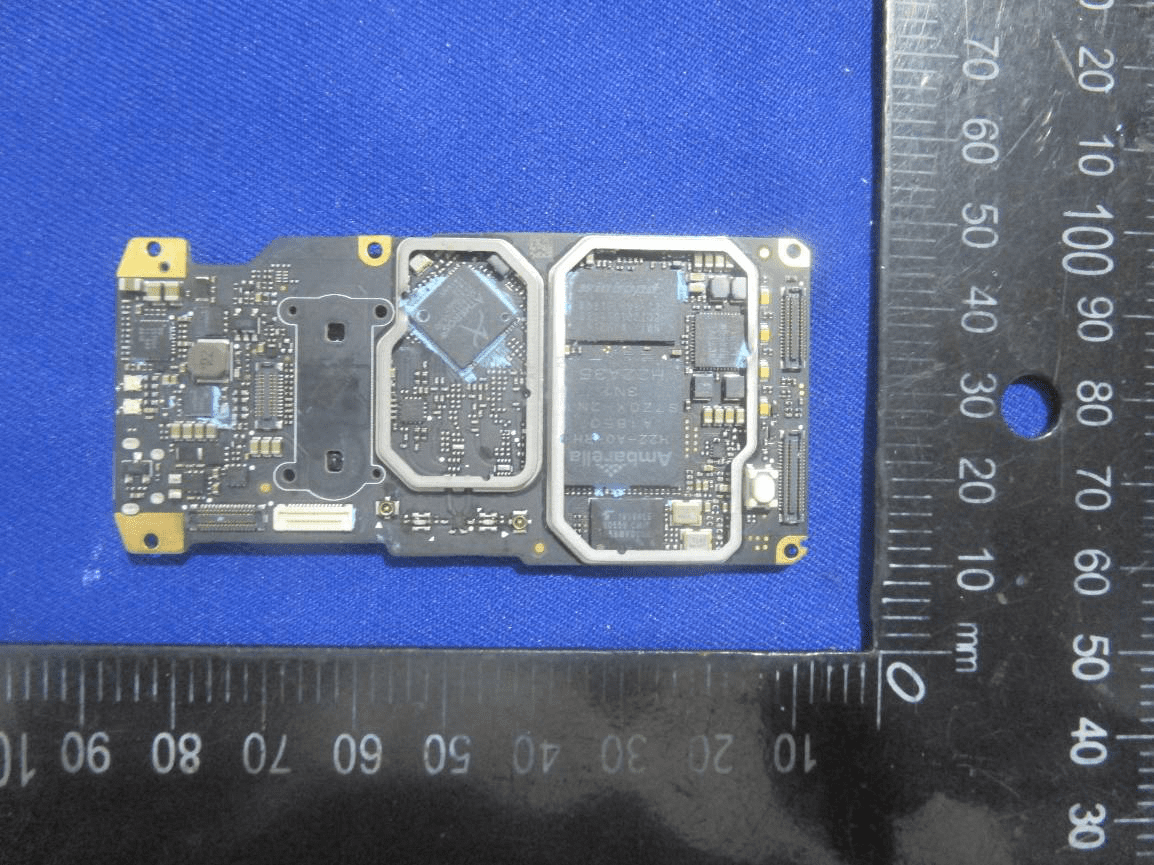

Ambarella Video SoC and Memory Subsystem

Dominating the next board is an Ambarella SoC, a powerhouse for real-time video encoding and flight control. Flanked by DDR and flash memory chips, this subsystem orchestrates high-speed image processing and data storage. Surrounding power supply circuits, including large inductors and capacitors, provide stable, noise-free power essential for digital and RF performance. Multiple connectors along the PCB edge enable integration with other subsystems—camera, gimbal, sensors—while a partially removed metal shield reveals the tightly packed IC layout. The presence of precise clock oscillators and robust ground planes further illustrates the sophistication required for seamless flight and imaging.

Multi-Layer PCB with Ambarella SoC and Flash Memory

This densely populated PCB exemplifies DJI’s approach to compact, high-performance electronics. The prominent Ambarella SoC, paired with Winbond flash memory, handles critical functions such as video capture, encoding, and flight control. Multiple shielded sections isolate RF and digital circuits, reducing EMI and supporting multi-band wireless operation. Gold-plated connectors and numerous test points facilitate both manufacturing and modular upgrades. The layout, employing advanced HDI techniques, underscores a careful balance between miniaturization, power management, and signal integrity—key to delivering the Mavic Mini’s extended range and stable flight characteristics.

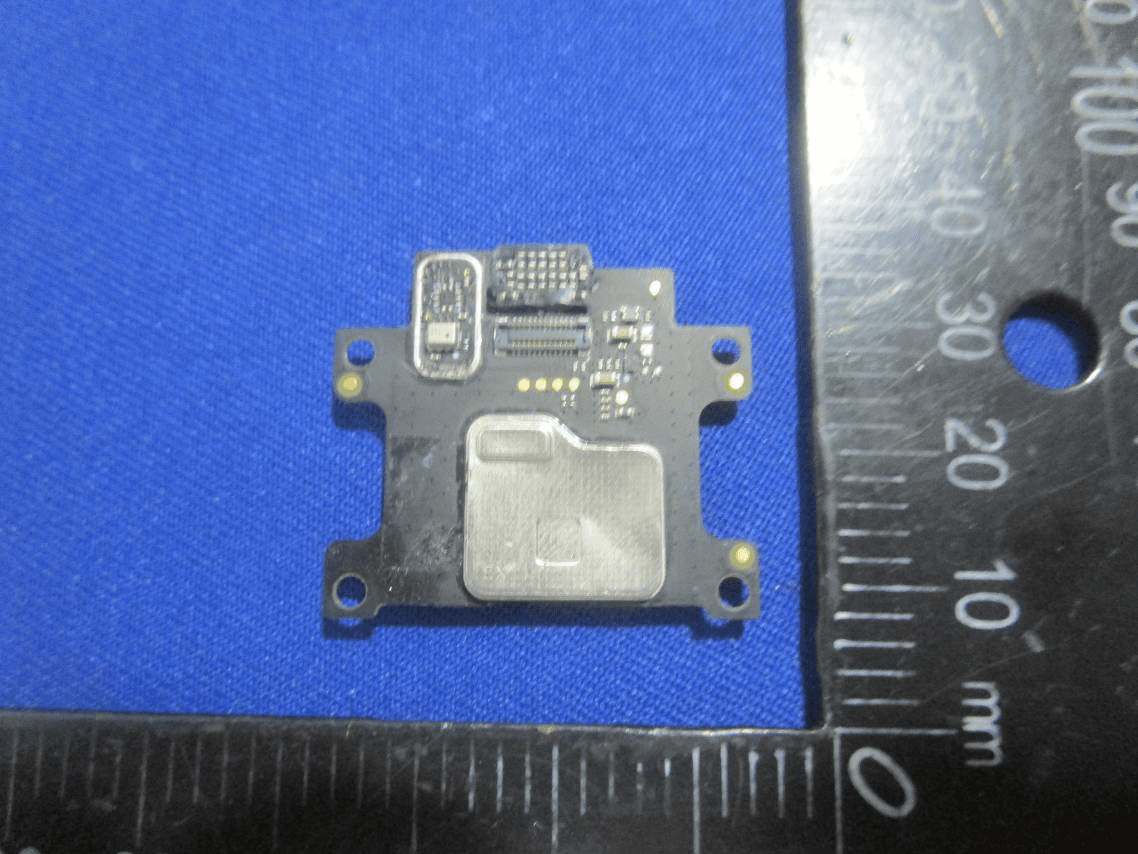

Compact RF/Wireless Module with Shielding

A smaller PCB module, approximately 25mm square, demonstrates the sophistication of the Mavic Mini’s wireless architecture. The majority of active circuitry is concealed beneath a substantial metal shield, indicative of a high-frequency RF transceiver or communication module. Visible SMD components include power management and clock oscillators, while gold-plated mounting holes and edge contacts ensure reliable board-to-board connectivity and grounding. The tight layout, multi-layer design, and test points suggest this module is integral to the drone’s Wi-Fi or Bluetooth communication, balancing RF performance with size constraints.

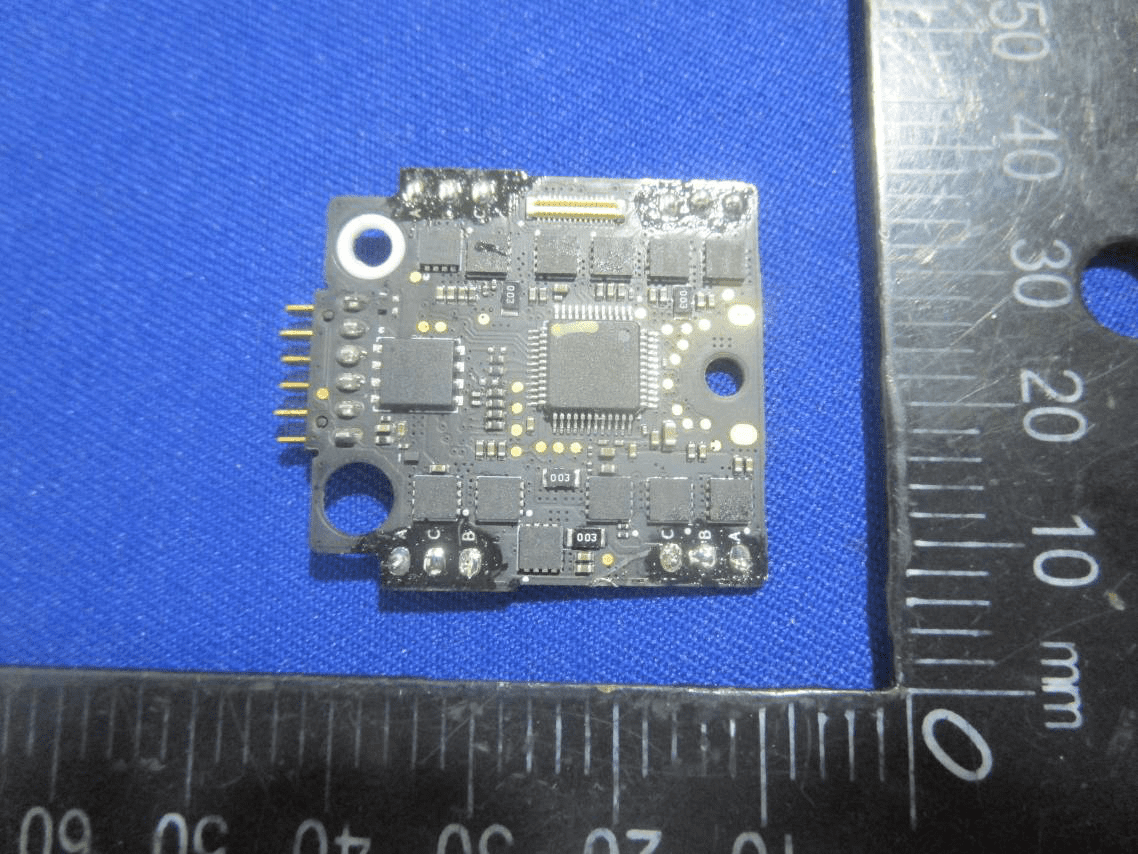

Flight Controller/Sensor Fusion Board

A compact, densely populated PCB reveals the heart of the drone’s flight control system. Central to this board is a large QFP/LQFP microcontroller, likely an STM32 or similar ARM Cortex MCU, orchestrating real-time flight logic and sensor fusion. Accompanying ICs and MEMS sensors provide critical data for stabilization and navigation. Local power regulation is evident from the presence of large capacitors and inductors, while multiple connectors enable seamless integration with the rest of the drone’s electronics. The absence of visible RF components suggests this board is dedicated to flight control rather than wireless communication, underscoring DJI’s modular, reliability-first engineering philosophy.

Regulatory Insights & FCC Filing

The FCC ID SS3-MT1SS51905, assigned to the DJI Mavic Mini, certifies its compliance with stringent US standards for electromagnetic emissions and wireless device safety. This certification, registered by FCC.gov, is mandatory for any wireless device marketed or sold in the United States. It assures users that the Mavic Mini meets established criteria for radio frequency (RF) emissions, minimizing the risk of interference with other devices and ensuring user safety.

FCC filings for the Mavic Mini encompass a wide array of documentation, including RF exposure and electromagnetic compatibility (EMC) test reports, internal and external photographs, user manuals, and detailed block diagrams. These documents provide transparency into the device’s design and performance, ensuring regulatory compliance at every stage.

Key insights from the official documentation highlight the Mavic Mini’s lightweight construction (249g), advanced obstacle and infrared sensing systems, stabilized 3-axis gimbal, and high-resolution 1/2.3” CMOS camera capable of 2.7K video and 12MP stills. The drone’s intelligent flight features and robust wireless architecture are designed to deliver reliable, long-range operation while remaining within the bounds of FCC regulations.

Potential Use Cases & Target Audience

The DJI Mavic Mini, with its blend of advanced imaging, extended range, and lightweight design, is well-suited for a variety of users and scenarios:

- Aerial Content Creators & Hobbyists:

Photographers and videographers seeking a portable, easy-to-use drone for capturing stunning landscapes, real estate, or travel footage benefit from the Mavic Mini’s stabilized 2.7K video, long flight time, and intuitive controls. - First-Time Drone Pilots:

Thanks to its sub-250g weight, obstacle sensing, and automated flight modes, the Mavic Mini is ideal for beginners who want to explore aerial photography without the complexities of registration or advanced piloting skills. - Professional Applications (Lightweight Scenarios):

Real estate agents, event planners, or surveyors needing quick, high-quality aerial shots in locations where larger drones are impractical or restricted will appreciate the Mavic Mini’s portability and regulatory advantages.

The combination of a stabilized 3-axis gimbal, robust wireless range, and intelligent sensing systems empowers users at all levels to achieve professional results with minimal setup and training.

Conclusion

The DJI Mavic Mini (FCC ID SS3-MT1SS51905) exemplifies the convergence of compact design, advanced technology, and regulatory compliance. Its lightweight frame, high-resolution camera, stabilized gimbal, and robust wireless architecture make it a standout option for both enthusiasts and professionals seeking accessible aerial imaging. FCC certification not only legitimizes its presence in the US market but also ensures users benefit from safe, reliable, and interference-free operation. As a result, the Mavic Mini secures its place as a leader in the ultralight drone segment, offering exceptional value and cutting-edge features in a remarkably portable package.