Introduction

The DJI MATRICE by SZ DJI TECHNOLOGY has emerged as a versatile and powerful drone platform, designed to meet the rigorous demands of professional aerial operations. Known for its advanced flight capabilities, modular design, and robust communication systems, the MATRICE caters to industries ranging from filmmaking and agriculture to infrastructure inspection and emergency response.

Recently certified by the FCC under FCC ID SS3-TP14061504, this certification ensures that the DJI MATRICE complies with stringent US electromagnetic interference and RF emission standards, making it legally available for sale and operation within the United States. Although the FCC filing currently lists no specific grant date, the device’s presence in the FCC database confirms its adherence to essential regulatory guidelines.

In this comprehensive analysis, we delve into the DJI MATRICE’s key technical specifications, explore its wireless technologies, perform an authoritative teardown of its internal components, and discuss its practical use cases and regulatory insights.

Key Features & Specifications

Official detailed specifications are relatively sparse, but based on typical DJI MATRICE models, users can expect the following features and performance characteristics:

- Robust Flight Performance:

- Long flight duration capabilities (typically 30-40 minutes per charge depending on payload).

-

Advanced stabilization and precise hover accuracy.

-

Modular Payload Support:

- Compatible with various payloads including high-resolution cameras, thermal imaging sensors, and LiDAR systems.

-

Quick-release mechanisms for swift payload interchangeability.

-

Advanced Navigation:

- Integrated GPS and GLONASS modules ensuring precise geolocation and stable flight paths.

-

Obstacle avoidance systems leveraging ultrasonic and visual sensors.

-

Reliable Communication:

- Robust wireless communication in the 2.4065-2.4765 GHz frequency range, outputting up to 603 mW of RF power.

-

Supports real-time video transmission, telemetry data, and payload control.

-

High-Quality Build & Design:

- Multi-layered PCB designs for optimal signal integrity and power efficiency.

- Modular construction for streamlined maintenance and component upgrades.

Given its professional-grade classification, the DJI MATRICE is likely to feature advanced processing capabilities, significant onboard storage, and power management systems designed to handle intensive operational scenarios.

Operating Frequencies

The DJI MATRICE certified under FCC ID SS3-TP14061504 operates within the following frequency parameters:

| Frequency Range (GHz) | Output Power (mW) | FCC Rule Part |

|---|---|---|

| 2.4065-2.4765 | 603 | 15CMO1 |

These frequencies fall within the standard ISM band, commonly utilized for technologies such as Wi-Fi and other RF communication protocols, ensuring compatibility and minimal interference during flight operations.

Technology Deep Dive

The DJI MATRICE notably operates in the widely used 2.4 GHz ISM band—ideal for drone communication and control systems due to its balance between range, bandwidth, and power consumption. Typically, drones operating in this spectrum benefit from stable connections over moderate distances (up to several kilometers under optimal conditions), making it suitable for real-time telemetry, video streaming, and control commands.

The output power of 603 mW aligns with professional drone applications, providing reliable command and control signals even in environments with moderate interference. The presence of U.FL connectors for external antennas further enhances the drone’s flexibility, allowing customized antenna configurations to optimize range and signal integrity.

In-Depth Internal Component Analysis / Teardown

The internal construction of the DJI MATRICE reveals meticulous engineering aimed at performance, reliability, and modularity. Below is a detailed analysis based on internal component imagery.

The PCB exhibits high-density component placement with several large ICs suggesting processing and memory functionalities. Smaller ICs likely serve power management or RF transceiver roles. The multi-layer black PCB design, typical for high-performance electronics, utilizes differential pair routing and impedance-controlled traces to accommodate high-speed data signals and RF requirements. Capacitors and inductors visible indicate robust power regulation and noise filtering mechanisms, essential for stable drone operation. A metal shield present provides EMI/RFI protection, critical for sensitive RF and processing circuits. The presence of test points indicates ease of debugging and quality assurance during manufacturing.

This section of the PCB highlights a large central IC—likely the primary SoC or microcontroller—positioned strategically for efficient signal routing. Surrounding ICs probably include PMICs and memory chips to support the primary processor. Three gold-colored U.FL connectors suggest external antennas, enhancing RF communication capabilities. The extensive metal shielding demonstrates DJI’s focus on minimizing electromagnetic interference, vital for reliable drone operations. Power regulation components such as inductors and capacitors ensure stable voltage delivery to critical circuits.

The densely populated PCB layout indicates sophisticated integration efforts typical of DJI’s high-end drone electronics. Large connectors visible are likely FPC types, facilitating modular connections to sensors or additional components. Absence of visible antennas suggests integration elsewhere, possibly in external modules or the drone’s housing. The compact design and precise routing underscore DJI’s commitment to balancing functionality with space efficiency.

The PCB prominently features a metal shielded IC, indicative of a high-performance processor or RF module requiring stringent EMI/RFI protection. Four external antenna connectors hint at multi-frequency or MIMO communication capabilities, enhancing signal robustness and range. Power management components strategically placed near ICs ensure operational stability, crucial during intensive drone missions.

The central processor or SoC, accompanied by smaller PMICs and memory ICs, highlights DJI’s emphasis on processing capability and reliability. Extensive shielding across sensitive components further underscores attention to interference management. The presence of large connectors indicates modularity, enabling easy integration of optional payloads or sensors.

This PCB section reveals multiple ICs, including RF transceivers and power management circuits, essential for the drone’s wireless and power distribution systems. Gold-plated antenna connectors further support robust RF capabilities. The layout, densely packed yet organized, reflects DJI’s commitment to performance and reliability.

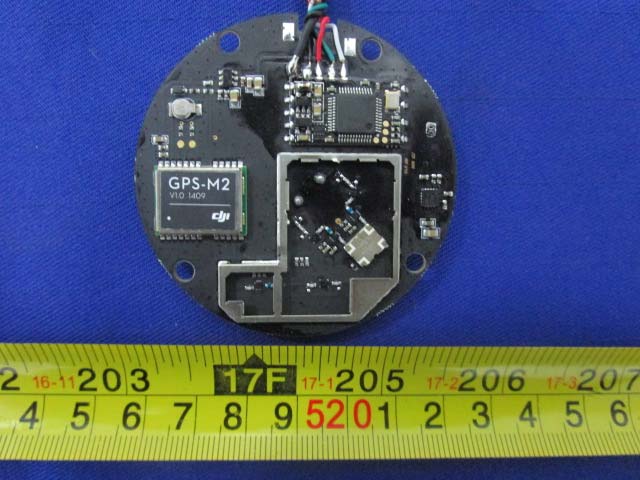

The circular PCB showcases a dedicated GPS module (“GPS-M2”), essential for precise drone navigation and geolocation. A metal shield protects sensitive RF circuits from interference, ensuring accurate GPS signal reception and processing. The multi-wire connector likely facilitates data and power transfer between the GPS module and main control systems.

Another circular PCB with GPS functionality (“GPS-M2 V10.1409”) indicates DJI’s emphasis on precise positioning. The integrated shield ensures minimal interference, critical for maintaining GPS accuracy in flight. Compact design and efficient component placement optimize space usage within the drone’s housing.

The custom DJI-branded GPS module (“GPS-M2 V1.0 1409”) signifies tailored engineering for enhanced navigation performance. The sophisticated multi-layer PCB construction supports precise timing and signal integrity, essential for reliable drone operation.

Regulatory Insights & FCC Filing

The DJI MATRICE’s FCC ID SS3-TP14061504 confirms its compliance with US electromagnetic interference standards, ensuring it is legally authorized for sale and operation within the US. FCC filings typically include detailed test reports for RF exposure, EMC compliance documentation, internal and external photographs, manuals, schematics, and block diagrams, providing comprehensive insights into the device’s regulatory adherence.

Potential Use Cases & Target Audience

Given its sophisticated features, the DJI MATRICE is ideal for professional applications such as:

- Industrial Inspection: Inspecting power lines, wind turbines, and infrastructure safely and efficiently.

- Agricultural Monitoring: Precision agriculture tasks including crop monitoring, soil analysis, and aerial spraying.

- Emergency Response: Rapid deployment for search-and-rescue operations, disaster assessment, and real-time situational awareness.

Conclusion

The DJI MATRICE (FCC ID SS3-TP14061504) exemplifies advanced drone technology designed for professional-grade applications. Its robust internal design, regulatory compliance, and versatile operational capabilities position it as a leading solution in various demanding industries, reinforcing DJI’s commitment to innovation, reliability, and performance in drone technology.