Introduction

The PHANTOM VISION by DJI Innovations (Model: FC200) stands as a pioneering aerial imaging solution, integrating advanced camera technology with robust wireless connectivity and intelligent flight features. Designed for aerial photography and real-time video transmission, this device caters to enthusiasts and professionals seeking high-quality imaging from above. The PHANTOM VISION is certified under FCC ID SS3-FC2001307, confirming its compliance with stringent United States RF emission and interference standards. While the grant date is not specified, this FCC certification ensures the device is legal for sale and operation within the U.S., having met all required electromagnetic compatibility and safety benchmarks.

Targeted at users aged 18 and above, the PHANTOM VISION blends innovative flight control, GPS-based stabilization, and Wi-Fi-enabled camera streaming, making it a versatile tool for demanding aerial imaging tasks. In this article, we will dive into its key features, technical specifications, wireless capabilities, internal hardware revealed through teardown analysis, and regulatory insights—providing a comprehensive, expert-level overview for anyone interested in the technology and compliance behind this flagship DJI device.

Key Features & Specifications

The PHANTOM VISION by DJI Innovations (Model: FC200) is engineered for high performance, reliability, and user-friendly operation. Below are its standout features and an in-depth breakdown of its technical specifications:

Key Features

-

USB Interface (in Battery Compartment):

Allows direct connectivity for firmware updates, data transfer, and device maintenance, ensuring ease of use and streamlined operations. -

ATTI./GPS ATTI. Mode:

Offers both Attitude (ATTI) and GPS Attitude modes, enabling stable flight in various conditions. GPS ATTI enhances position hold and automatic return-to-home, critical for aerial photography. -

Intelligent Orientation Control:

Simplifies flight control by maintaining consistent orientation relative to the pilot, even as the drone rotates, reducing pilot workload and improving safety. -

GPS & Compass Module:

Provides precise location tracking and heading information, crucial for navigation, waypoint flight, and geotagging of captured imagery. -

LED Indicator:

Multi-color LEDs offer real-time status updates for power, GPS lock, error states, and flight mode, enhancing operational awareness. -

Camera with Wi-Fi Connectivity:

The integrated camera supports high-resolution stills and HD video, streaming live footage via Wi-Fi to the DJI VISION App. This enables real-time framing, settings adjustment, and media download. -

Range Extender:

Increases the effective Wi-Fi range, allowing for greater operational distance and more flexible flight paths during live video transmission or remote camera control. -

Camera Gimbal Control:

Users can adjust the camera angle remotely using the app or device gyroscope, providing dynamic control over framing and perspective during flight.

Technical Specifications

- White Balance:

-

AWB (Auto), Sunny, Cloudy, Indoor

Enables optimal color accuracy across diverse lighting conditions. -

Charge Circuit:

-

1A / 2A / 3A Selectable

Offers flexible charging speeds for the LiPo battery, balancing quick turnaround with battery longevity. -

Battery:

-

3S LiPo, 2200mAh, 20C, 11.1V

Delivers reliable power for extended flight times and stable voltage for sensitive electronics. -

Transmitter Working Frequency:

-

5.8GHz ISM Band

Reduces interference from common 2.4GHz Wi-Fi devices, providing a dedicated channel for flight control. -

Camera Photo Sizes:

- Large: 4608 x 3456 (16MP)

- Sub-large: 4384 x 3288 (14.4MP)

- Medium: 4384 x 2922 (12.8MP)

-

Small: 4384 x 2466 (10.8MP)

Supports multiple resolutions for flexible storage and post-processing options. -

Charger AC Input:

-

100-240V

Global compatibility for charging in multiple regions. -

Sharpness:

-

Standard, Hard, Soft

Customizable image sharpness to suit different shooting styles. -

ISO:

-

AUTO, 100, 200, 400, 800

Adjustable ISO for optimal exposure in varying lighting environments. -

Wi-Fi:

-

SSID: PHANTOM_xxxxxx

Enables secure remote control and live video via the DJI VISION App. -

Bluetooth:

-

Present (detailed specs not available)

Facilitates device pairing and potential future feature expansion. -

Camera Video & Photo Resolutions:

- Video:

- 1920×1080 30p (16:9)

- 1920×1080 60i (16:9)

- 1280×720 30p/60p (16:9)

- 1280×960 30p (4:3)

- 640×480 30p (4:3, VGA)

- Photo:

- Large: 4608 x 3456 (16MP, 4:3)

- Sub-large: 4384 x 3288 (14.4MP, 4:3)

- Medium: 4384 x 2922 (12.8MP, 3:2)

- Small: 4384 x 2466 (10.8MP, 16:9)

These features and specs underscore the PHANTOM VISION’s versatility, combining robust flight control, advanced imaging, and seamless wireless connectivity—making it a standout choice for aerial imaging professionals and enthusiasts alike.

Operating Frequencies

The PHANTOM VISION (FCC ID SS3-FC2001307) operates on the following frequencies, as detailed in its FCC documentation:

| Frequency Range (GHz) | Output Power (mW) | FCC Rule Part |

|---|---|---|

| 2.412–2.462 | 11 | 15CMO2.12.412 |

| 2.462 | 31 | 15C1.1 |

These frequency bands are primarily used for Wi-Fi (2.4GHz ISM band), supporting high-speed wireless data transmission between the drone, camera, and remote devices. The specified output power levels ensure compliance with regulatory limits, balancing range and safety while minimizing interference with other wireless technologies.

Technology Deep Dive

The PHANTOM VISION leverages multiple wireless technologies to deliver seamless control and real-time media transmission. Its primary communication channels include 2.4GHz Wi-Fi for live video streaming and camera control, and 5.8GHz for flight command telemetry. Wi-Fi enables the DJI VISION App to connect to the drone’s onboard camera, facilitating high-resolution image and video downloads, remote framing, and real-time status monitoring.

Operating within the 2.4GHz ISM band, the device achieves robust signal penetration and adequate range, while the moderate output power (up to 31mW) ensures compliance with FCC regulations and minimizes interference with other devices. The presence of Bluetooth (details unspecified) suggests potential for device pairing or future feature upgrades, though its role is secondary to Wi-Fi in the current configuration.

The use of dual-band operation (2.4GHz for camera, 5.8GHz for control) helps segregate control and media channels, reducing the risk of interference and enhancing reliability during flight. The device’s RF circuitry, as revealed in internal analysis, is engineered for low-latency, high-integrity signal transmission—vital for real-time video and responsive flight control. Power management components further optimize energy use, supporting longer missions without compromising performance.

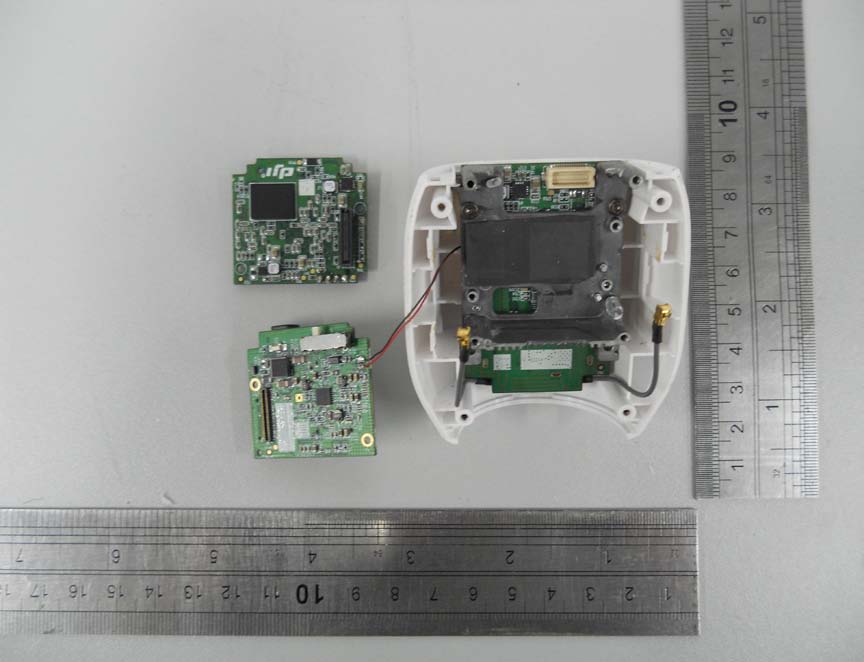

In-Depth Internal Component Analysis / Teardown

Camera Module PCB: High-Integration Design for Real-Time Video

The internal camera module features a densely populated PCB with a highly integrated image processing system. Two prominent integrated circuits dominate the board: one likely serving as the main image processor (potentially an Ambarella or similar SoC), and the other as a high-capacity memory chip (DDR or NAND flash), supporting fast image capture and buffering. The presence of multiple smaller ICs, assumed to be power management and logic support, ensures stable operation under varying power conditions. Differential pair routing and numerous vias point to a multi-layer board optimized for high-speed data and power delivery, while ground pours and stitching vias provide EMI control. Dual coaxial cables connect to RF interfaces for robust Wi-Fi or video transmission. Flex connectors streamline sensor and control integration, and large capacitors and inductors facilitate efficient power regulation. The overall construction is modular and robust, characteristic of DJI’s engineering focus on reliability and serviceability in demanding drone applications.

Modular PCB Assemblies: Advanced RF and Control Integration

The device’s main electronic assemblies reveal multiple green FR4 PCBs, each densely populated with a mix of DJI-branded SoCs, memory, and support ICs. The primary PCB houses a large central chip for image processing or flight control, surrounded by memory and power management devices. Adjacent boards feature RF transceivers and sensor interfaces, protected by metallic shields for EMI suppression. The inclusion of PCB trace antennas and coaxial connectors enables reliable dual-band wireless communication, while modular FPC/FFC connectors support flexible assembly and maintenance. Power handling is robust, with thick traces and sizable capacitors and inductors. Crystals provide precise clocking, and test points facilitate manufacturing and service diagnostics. The design is compact yet sophisticated, balancing performance, EMI resilience, and manufacturability—key for real-time video, telemetry, and control in aerial platforms.

Wireless & Processing PCB: Integrated Antenna and Storage

Another critical assembly showcases a PCB with several key ICs, including a main microcontroller or SoC (in QFP/QFN package) for image or wireless processing, complemented by smaller power management and memory chips. The board’s layout is divided for analog/RF and digital domains, optimized through ground pours and careful via placement. A patch antenna, likely for GPS or Wi-Fi, is mounted within the plastic housing, connected via a dedicated wire. The PCB also integrates a microSD slot for local storage or firmware updates, multiple connectors for sensor and power integration, and visible test points for quality assurance. Absence of visible shielding is compensated by rigorous PCB-level EMI strategies. The assembly reflects DJI’s commitment to modularity, RF performance, and ease of manufacturing.

Video Processing Board: TI DaVinci SoC and High-Speed Memory

The densely populated PCB dedicated to video capture and streaming features a Texas Instruments DM368 DaVinci SoC, a high-performance processor combining ARM and DSP cores for real-time HD video handling. Paired with closely located DDR or NAND flash memory, this setup ensures smooth data flow and minimal latency. Decoupling capacitors and local power inductors provide noise suppression and voltage stability, while controlled impedance traces guarantee signal integrity for high-speed interfaces. A fine-pitch FPC connector allows for direct connection to the camera sensor or main system board. Ground pours and multiple test points underscore the board’s focus on EMI mitigation and serviceability. The layout and component choices confirm a sophisticated video pipeline, essential for the PHANTOM VISION’s HD imaging and wireless streaming features.

Main Processing Board: RF and Power Optimization

The primary processing PCB is characterized by a central high-pin-count SoC, likely handling image processing or core device control, and a large adjacent memory chip. The board features gold-plated pads and controlled-impedance RF traces, suggesting integrated or external antenna connections for high-frequency wireless communication. The use of multiple via types and ground strategies ensures robust EMI control and signal integrity. Local power regulation is handled by ceramic capacitors and inductors, while clock stability is provided by a dedicated oscillator. The absence of large connectors on this side points to a modular assembly approach, with key interfaces located elsewhere. This board exemplifies DJI’s attention to RF performance, power efficiency, and compact integration—key for drone applications requiring reliable, high-speed data transmission.

Sensor Interface Board: Optimized for Image Quality

The sensor board presents a clean, high-quality PCB with a large FPC connector labeled ‘SENSOR’, designed for direct connection to the image sensor module. The central footprint likely accommodates a CMOS sensor, surrounded by carefully arranged SMD components for local power filtering, signal conditioning, and EMI control. Multiple vias and copper pours enhance grounding and shield sensitive analog signals. The absence of RF components or major ICs on this side points to its dedicated role in imaging, with processing and wireless handled on separate boards. Mechanical mounting points and test pads support robust assembly and streamlined manufacturing. This modular approach allows for sensor upgrades and ensures optimal imaging performance in varying flight conditions.

Regulatory Insights & FCC Filing

The PHANTOM VISION by DJI Innovations, under FCC ID SS3-FC2001307, is certified for compliance with U.S. electromagnetic interference (EMI) and radiofrequency (RF) emission standards. This certification, registered with FCC.gov, means the device has passed rigorous testing for safe operation within defined RF power and frequency limits, ensuring it will not cause harmful interference with other communications systems.

FCC filings for this device typically include detailed test reports (such as RF exposure and EMC), internal and external photographs, user manuals, block diagrams, and schematics. These documents provide transparency into the device’s design and performance, supporting regulatory review and consumer confidence.

According to the ‘User-manual-2097304.pdf’, the PHANTOM VISION User Manual offers comprehensive instructions for assembly, setup, and safe operation, highlighting features like the built-in autopilot, intelligent orientation control, and enhanced fail-safe mechanisms. The manual also outlines compliance with international standards, including CE, FCC, and RoHS certifications, reinforcing the device’s commitment to quality and legal operation across global markets.

Potential Use Cases & Target Audience

With its advanced wireless capabilities, intelligent flight control, and high-resolution imaging, the PHANTOM VISION is ideal for several demanding scenarios:

-

Aerial Photography and Videography Professionals:

Photographers and filmmakers can leverage the 16MP camera, real-time HD video streaming, and precise gimbal control to capture stunning aerial perspectives for commercial or creative projects. -

Surveying and Inspection Operations:

Industrial users can employ the drone for infrastructure inspection, land surveying, or agricultural monitoring, utilizing its GPS stabilization, range extender, and robust RF performance for reliable, data-rich missions. -

Tech Enthusiasts and Advanced Hobbyists:

Users aged 18 and above, passionate about drone technology, can explore the PHANTOM VISION’s intelligent orientation control, customizable flight modes, and modular design for both recreational flying and technical experimentation.

The device’s built-in autopilot, fail-safe features, and adherence to strict safety and quality standards make it a compelling choice for responsible, results-driven users seeking cutting-edge aerial imaging solutions.

Conclusion

The PHANTOM VISION by DJI Innovations (Model: FC200) is a testament to advanced engineering in aerial imaging, combining sophisticated wireless technology, intelligent flight control, and modular internal architecture. Its FCC certification under ID SS3-FC2001307 underscores its compliance with U.S. RF and EMI standards, affirming its safety and legality for commercial sale and use. With its robust feature set, high-quality imaging, and meticulously designed internal components, the PHANTOM VISION remains a benchmark for drone-based camera systems, serving professionals and enthusiasts who demand performance, reliability, and regulatory peace-of-mind.