Introduction

The Mavic Air 2 by SZ DJI TECHNOLOGY CO., LTD. represents a significant leap in consumer drone technology, blending advanced imaging, intelligent automation, and robust wireless communication in a compact, foldable form factor. Designed for both aerial photography enthusiasts and demanding professionals, the Mavic Air 2 excels in capturing high-resolution imagery while delivering an intuitive, safe, and extended flight experience.

A crucial aspect of the Mavic Air 2’s market readiness is its FCC certification under FCC ID SS3-MA2UE1N1911. This designation confirms that the device adheres to stringent US regulations for radio frequency (RF) emissions and electromagnetic compatibility, ensuring it is both legal to sell and safe to operate within the United States. The certification process validates that the drone meets all necessary wireless and safety standards, a vital requirement for any RF-emitting device.

In this article, we’ll take an in-depth look at the Mavic Air 2’s key features, technical specifications, and wireless capabilities. We’ll explore its internal components through detailed teardown analysis, offer insights from regulatory documentation, and discuss its practical applications—providing a comprehensive reference for engineers, tech enthusiasts, and discerning drone users.

Key Features & Specifications

The Mavic Air 2 stands out in the crowded drone market with a blend of powerful hardware, intelligent software, and advanced wireless technology. Here’s a breakdown of its standout features and technical specifications:

Key Features

- DJI OCUSYNC 2.0 Transmission

Utilizes DJI’s proprietary long-range transmission technology, OCUSYNC 2.0, for reliable, low-latency video streaming and control at distances up to 5 miles (8 km). This ensures robust connectivity, even in challenging RF environments. - 4K Video & 48 MP Photos

Equipped with a high-performance camera capable of shooting stunning 4K video and capturing ultra-detailed 48-megapixel stills—ideal for aerial content creators. - Maximum Transmission Range: 5 mi (8 km)

With OCUSYNC 2.0, pilots enjoy a maximum range of up to 5 miles, enabling expansive exploration and creative flexibility. - Intelligent Flight Modes

Features advanced flight automation, including: - ActiveTrack 3.0 for sophisticated subject tracking.

- Point of Interest (POI) 3.0 for smooth, dynamic orbiting shots.

- QuickShot modes for cinematic, automated maneuvers.

- Advanced Pilot Assistance Systems (APAS) 2.0 for obstacle avoidance and safer flight.

- Maximum Flight Time: 34 Minutes

Achieves up to 34 minutes of continuous flight on a single charge, extending shooting sessions and minimizing downtime. - 1080p Video Transmission to Mobile Device

Delivers crisp, real-time video feeds at up to 1080p resolution directly to your mobile device for precise framing and control. - Folding Design

The drone’s compact, foldable design enhances portability without sacrificing performance or durability.

Technical Specifications

- Aircraft Model: MA2UE1N

- Battery:

- Type: LiPo 3S (Lithium Polymer, 3 cells)

- Voltage: 11.55 V

- Capacity: 3500 mAh

- Energy: 40.4 Wh

- Maximum Flight Time: 34 minutes

- Wireless Transmission:

- OCUSYNC 2.0, Wi-Fi, and Bluetooth (Bluetooth present, details not specified)

- Video transmission up to 1080p

- Transmitter Power:

- 2.4 GHz: ≤20 dBm (FCC, CE, SRRC, MIC)

- 5.8 GHz: ≤23.5 dBm (FCC), ≤14 dBm (CE), ≤26 dBm (SRRC)

- Remote Controller (2.4 GHz): ≤24.5 dBm (FCC), ≤20 dBm (others)

- Operating Temperature: 0° to 40°C

- Wi-Fi Bands: 2.4-2.4835 GHz, 5.725-5.850 GHz

Practical Benefits

- Extended Range & Stability: OCUSYNC 2.0 and carefully tuned transmitter power ensure strong, interference-resistant connections for both control and video transmission, even in congested environments.

- High-Quality Imagery: 4K video and 48 MP stills enable professional-grade content creation.

- Smart Automation: Advanced flight modes allow for creative shots and safer operation, even for less-experienced pilots.

- Portability: The folding design and lightweight construction make the Mavic Air 2 easy to transport, supporting on-the-go aerial photography.

Operating Frequencies

The Mavic Air 2 (Model: MA2UE1N, FCC ID SS3-MA2UE1N1911) is certified to operate on the following frequency bands and power levels, as detailed in its FCC filing:

| Frequency Range (GHz) | Output Power (mW) | FCC Rule Part |

|---|---|---|

| 2.4055–2.4765 | 94.8 | 15CCC1.42.4075 |

| 2.4565 | 50.2 | 15CCC1.35.7285 |

| 2.4655 | 45.6 | 15CCC1.12.40912 |

| 2.46712 | 42.4 | 15CCC1.22.4105 |

| 2.4725 | 91.8 | 15CCC1.52.4175 |

| 5.8395 | 212.3 | 15ECC2.5 |

| 5.8445 | 30.4 | 15ECC2.15.73012 |

| 5.8445 | 30.5 | 15ECC2.35.7325 |

| 5.8445 | 220.3 | 15ECC2.45.7355 |

| 5.84612 | 29.3 | 15ECC2.25.7305 |

These frequency allocations and power outputs enable reliable, long-range wireless control and high-quality video transmission, while ensuring compliance with US regulatory standards for unlicensed wireless devices.

Technology Deep Dive

The Mavic Air 2 leverages a suite of wireless technologies to deliver robust connectivity and advanced control. Its primary communication systems operate over the 2.4 GHz and 5.8 GHz ISM bands, supporting both DJI’s proprietary OCUSYNC 2.0 protocol and standard Wi-Fi connectivity. This dual-band approach enables flexible adaptation to local RF environments, minimizing interference and optimizing range and signal clarity.

Wi-Fi is utilized for direct communication between the drone and mobile devices, particularly for video streaming and control. The inclusion of Bluetooth, while not detailed in the available documentation, likely supports device pairing and auxiliary functions.

The certified frequency bands are carefully selected to balance transmission range, data throughput, and regulatory compliance. Lower-frequency 2.4 GHz channels offer superior range and wall penetration, making them ideal for control and telemetry, while the higher 5.8 GHz bands deliver higher data rates for real-time HD video transmission at shorter distances.

Transmitter power levels are tuned to maximize range while adhering to FCC limits, reducing the risk of interference with other wireless devices. These design choices ensure stable communication in environments crowded with competing RF signals, such as urban areas or large public spaces. The internal test reports referenced in FCC documentation confirm that the Mavic Air 2 maintains safe RF emission levels, supporting both user safety and device reliability.

In-Depth Internal Component Analysis / Teardown

A closer look at the Mavic Air 2’s internal hardware reveals the meticulous engineering underpinning its advanced capabilities. Each subsystem is optimized for performance, reliability, and integration within the drone’s compact frame.

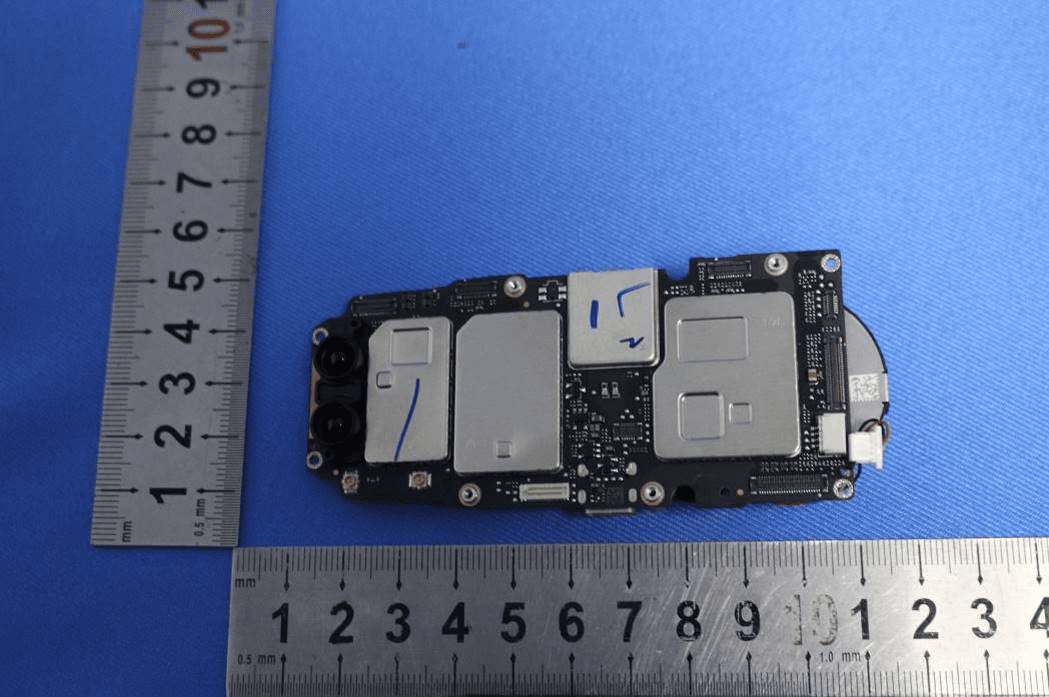

The main PCB at the heart of the Mavic Air 2 demonstrates a sophisticated, high-density design typical of modern drones. Multiple shielded sections dominate the board, protecting critical SoCs, RF transceivers, and power management ICs from electromagnetic interference. These shields are essential for maintaining precise sensor readings and robust wireless communication—key to stable flight and high-quality video transmission. The board’s densely populated layout, likely comprising six or more layers, supports the routing of high-speed signals and power distribution in a limited footprint. Numerous FPC connectors facilitate modular connections to the camera, gimbal, and sensors, while heavy-duty inductors and capacitors provide the power regulation demanded by motors and onboard electronics. Extensive via stitching and ground planes underscore the importance of EMI control in such a high-frequency environment. Overall, the component selection and build quality reflect DJI’s commitment to reliability and RF performance, ensuring the Mavic Air 2’s seamless operation even in challenging conditions.

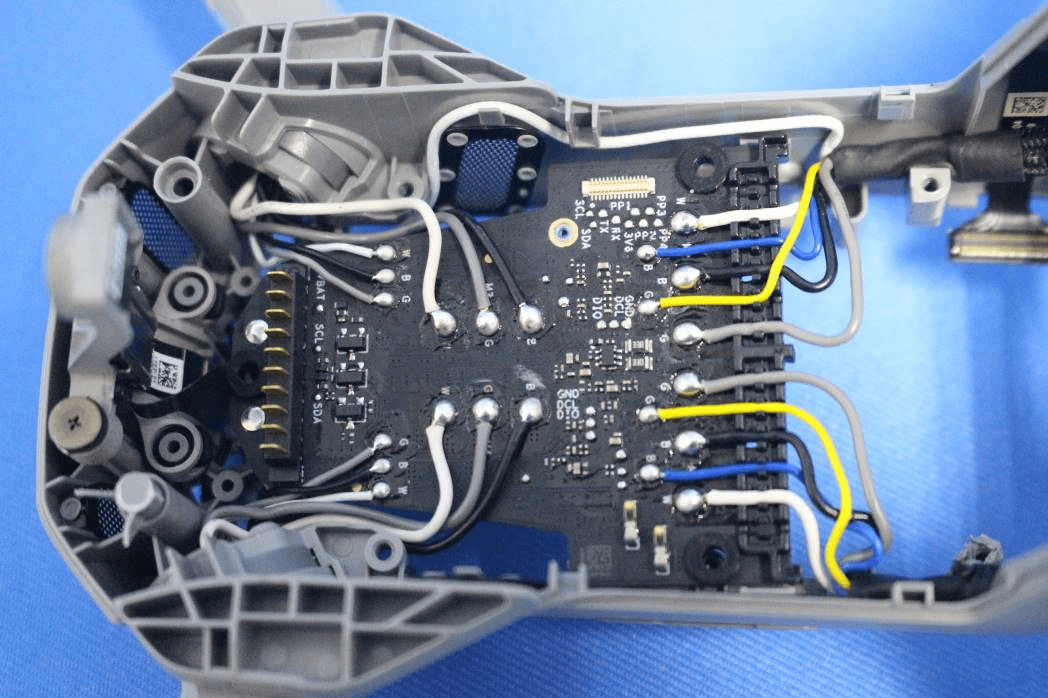

The electronic assembly associated with the drone’s arm or motor controller section is a testament to the design required for high-performance brushless motor control. The PCB features a suite of MOSFETs or gate drivers, positioned near thick, high-current traces and wires—indicative of its role as an electronic speed controller (ESC). The board’s multi-layer construction, coupled with extensive ground pours and stitching vias, ensures both power delivery and signal integrity. Gold-finger edge connectors and FPC interfaces support modularity, while heavy-gauge wires provide direct, reliable connections for three-phase motor outputs. The lack of metal shielding here is typical for power boards, as EMI is managed through layout and grounding rather than shielding. The presence of I2C lines hints at smart ESC features, enabling telemetry and integrated feedback. This assembly exemplifies the rugged, reliable engineering required to withstand the mechanical stresses and electrical demands of drone flight.

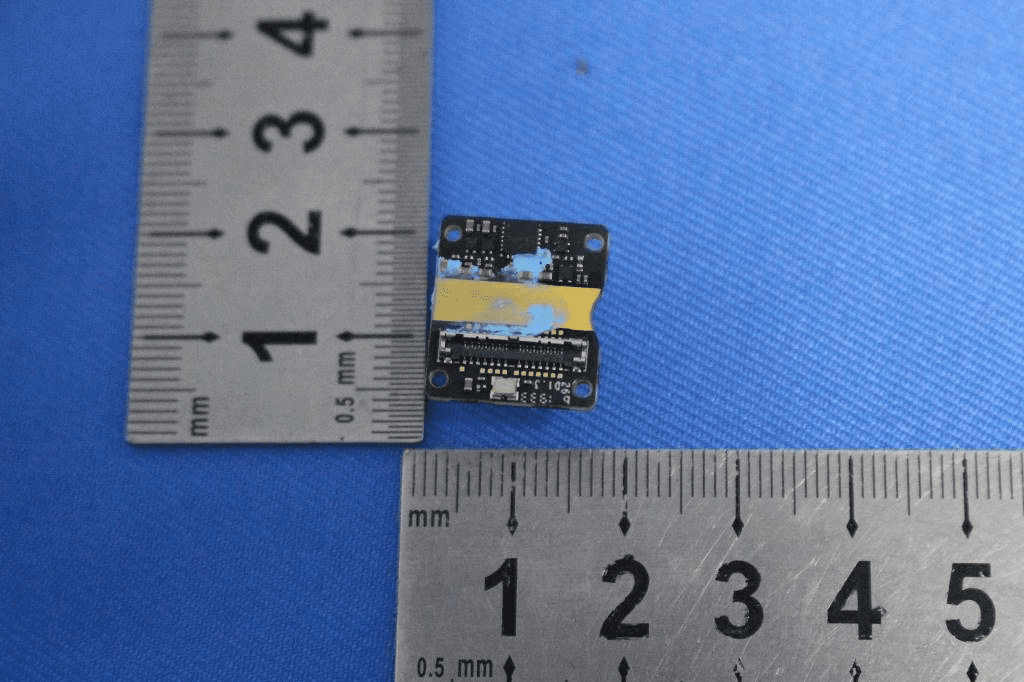

A compact PCB module, likely serving as a sensor or control interface, highlights the Mavic Air 2’s emphasis on precision and stability. With its small footprint and high-density SMT assembly, this board is engineered for integration into tight spaces while maintaining high performance. The presence of small QFN and WLCSP ICs, potentially sensor fusion or power management chips, aligns with the critical role of such modules in flight stabilization—possibly as an IMU (Inertial Measurement Unit). Mounting holes and thermal compound application suggest careful mechanical and thermal management, vital for accuracy in sensitive sensor systems. The board’s single fine-pitch connector streamlines data and power transfer to the main system, ensuring minimal latency and noise. This module is a clear example of DJI’s attention to detail in ensuring reliable, high-precision flight control.

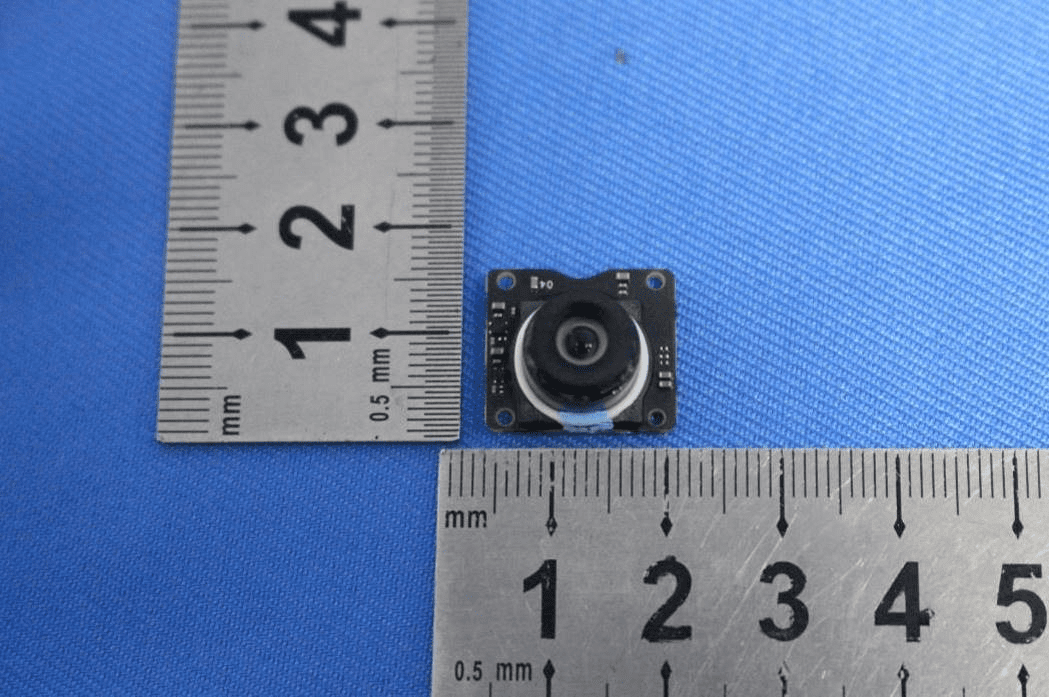

The camera module is a marvel of miniaturization, designed to deliver high-resolution imaging within a lightweight, durable package. Its square PCB supports a centrally mounted lens assembly, with passive components positioned around the periphery for signal conditioning and decoupling. The absence of large power components or shielding reflects the module’s reliance on the main board for power regulation and EMI control. Standard mounting holes and likely FPC connectivity facilitate secure attachment and high-speed data transfer to the drone’s processing systems. The module’s compact design ensures minimal impact on drone weight and balance, while the robust construction enables reliable operation during flight maneuvers and landings. This camera module is foundational to the Mavic Air 2’s ability to capture 4K video and 48 MP stills, underpinning its appeal to aerial photographers and content creators.

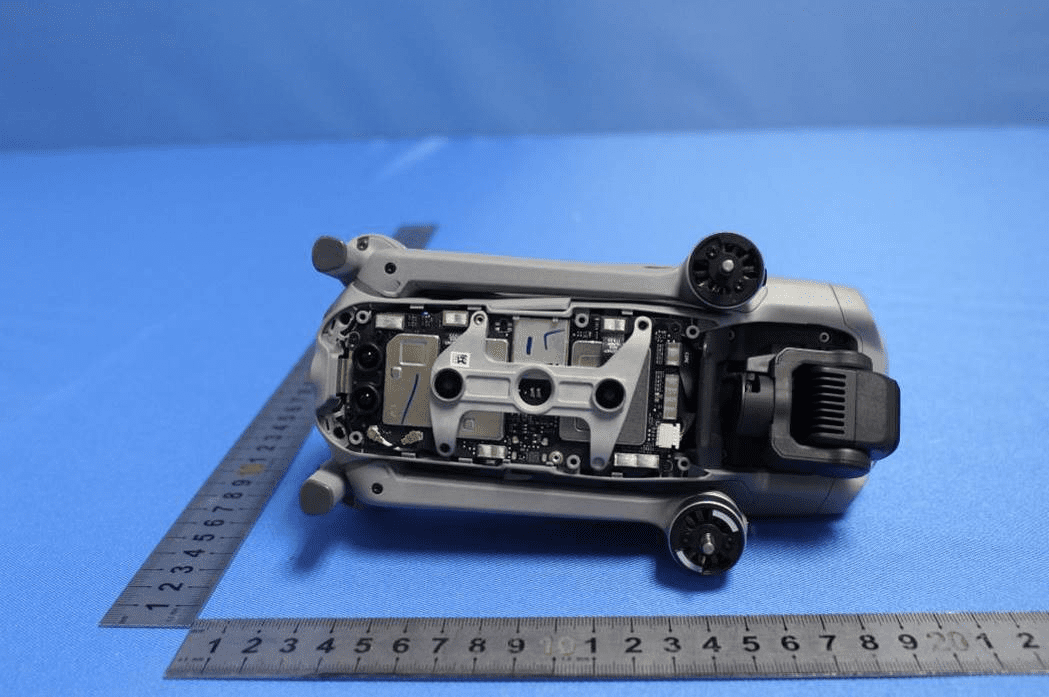

The main logic board is a dense, multi-functional hub integrating flight control, imaging, and wireless communication subsystems. Multiple large metal shields cover high-performance SoCs, RF transceivers, and power management circuits, ensuring electromagnetic compatibility and thermal stability. The board’s multi-layer construction supports the routing of high-speed data for cameras and sensors, while robust connectors enable integration with the drone’s motors, battery, and external modules. The visible stereo camera modules indicate advanced obstacle sensing capabilities, vital for safe and autonomous flight. Extensive use of ground vias, high-quality capacitors, and inductors underscores the focus on power integrity and EMI suppression. The modular layout, with separate shielded domains and numerous FPC connectors, simplifies assembly and maintenance. This logic board exemplifies the state-of-the-art electronics that empower the Mavic Air 2’s advanced automation, imaging, and communication features.

Regulatory Insights & FCC Filing

The Mavic Air 2’s FCC ID SS3-MA2UE1N1911 certification is a hallmark of its compliance with US electromagnetic interference and RF emission standards. This certification, registered with FCC.gov, is essential for the device’s legal sale and operation in the United States, affirming that it meets stringent requirements for wireless safety and performance.

FCC filings for the Mavic Air 2 encompass a wealth of technical documentation—including user manuals, test reports, internal photographs, and block diagrams. These documents verify that the drone’s radio systems operate within prescribed power limits, exhibit safe RF exposure levels, and do not cause harmful interference with other devices.

Key insights from the documentation highlight the device’s folding design, advanced 3-axis gimbal camera, and integration of safety technologies. The user manual outlines setup procedures and operational guidelines, while test reports confirm that the device’s wireless systems conform to all relevant FCC rules. Internal documentation also provides a detailed look at the device’s modular construction, shielding strategies, and power management—underscoring the engineering rigor behind its market approval.

Potential Use Cases & Target Audience

The Mavic Air 2’s combination of advanced imaging, intelligent automation, and robust wireless capabilities makes it ideal for a variety of users and scenarios:

- Aerial Content Creators:

Photographers and videographers seeking professional-grade imagery will benefit from the drone’s 4K video, 48 MP photos, and intelligent flight modes. The long flight time and extended transmission range support complex, cinematic shots with minimal interruption. - Outdoor Adventurers and Travel Enthusiasts:

The foldable design and lightweight construction make the Mavic Air 2 perfect for on-the-go exploration. Users can capture stunning landscapes and dynamic action footage with confidence, thanks to obstacle avoidance and advanced pilot assistance. - Tech Enthusiasts and Engineers:

Those interested in drone technology, wireless systems, or robotics will appreciate the sophisticated internal components, high-density PCB design, and regulatory compliance. The device serves as an excellent platform for learning about RF engineering and aerial robotics.

Conclusion

The Mavic Air 2 by SZ DJI TECHNOLOGY CO., LTD. (Model: MA2UE1N, FCC ID SS3-MA2UE1N1911) is a standout in the consumer drone landscape, offering a compelling mix of high-performance imaging, intelligent automation, and robust wireless communication. Its FCC certification ensures legal compliance and user safety, while its meticulously engineered internal components enable reliable, feature-rich operation. Whether for creative pursuits, technical exploration, or professional use, the Mavic Air 2 sets a high standard for aerial platforms—demonstrating DJI’s leadership in drone innovation and regulatory adherence.