Introduction

The Mavic 2 Zoom, engineered by SZ DJI TECHNOLOGY CO., LTD., is a flagship foldable drone celebrated for its powerful zoom lens and advanced imaging capabilities. Designed to empower aerial photographers and videographers, this UAV delivers professional-grade performance in a compact, travel-friendly form factor. With its robust flight autonomy, omnidirectional obstacle sensing, and a suite of intelligent flight modes, the Mavic 2 Zoom is tailored for both creative enthusiasts and demanding commercial applications.

A critical milestone in its journey to market is its FCC certification under FCC ID SS3-L1Z1805. This certification not only authorizes the device for legal sale and use within the United States but also affirms compliance with stringent radio frequency emission and electromagnetic interference standards. Such regulatory approval ensures that the Mavic 2 Zoom operates safely and reliably within shared wireless spectrums, minimizing the risk of disruption to other devices.

This article provides a comprehensive analysis of the Mavic 2 Zoom, including an in-depth review of its key specifications, wireless technology, internal components (teardown), and regulatory insights. Whether you are an engineer, a drone enthusiast, or an informed consumer, this teardown and specs analysis will deliver authoritative, detail-rich insights into what makes the Mavic 2 Zoom a standout in its class.

Key Features & Specifications

The Mavic 2 Zoom stands out with a feature set that merges advanced imaging, robust connectivity, and thoughtful hardware design. Below, we break down its most notable features and technical specifications:

Key Features

- Fully Stabilized 3-Axis Gimbal

- Ensures ultra-smooth video and sharp photos, even during dynamic maneuvers or in windy conditions.

- Detachable Control Sticks for Remote Controller

- Enhances portability and storage convenience, ideal for field use and travel.

- microSD Card Slot (Max Capacity: 128 GB, UHS-I Speed Grade 3 required)

- Supports high-capacity, high-speed storage for 4K video and high-resolution images.

- On-board LCD Screen on Remote Controller

- Provides real-time telemetry, battery status, and flight data for quick reference.

- 1” CMOS Sensor Camera

- Captures crisp, detailed images with superior low-light performance and greater dynamic range.

- DJI OCUSYNC 2.0 Long-Range Transmission Technology

- Delivers robust, low-latency HD video transmission up to several kilometers, with enhanced resistance to interference.

- Maximum Flight Speed: 44.7 mph (72 kph)

- Enables fast repositioning and dynamic tracking shots.

- Intelligent Flight Battery

- Offers up to 31 minutes of flight time per charge, supporting extended missions.

Technical Specifications

- Battery Type: LiPo (Lithium Polymer)

- Intelligent Flight Battery: 3850 mAh, 59.29 Wh, 17.6 V max, 15.4 V typical

- Max Flight Time: 31 minutes (no wind, 15.5 mph constant speed)

- Net Battery Weight: Approx. 297 g

- Remote Controller

- Operating Temperature: 32° to 104° F (0° to 40° C)

- Battery: 3950 mAh @ 3.83 V

- On-board LCD: For instant telemetry and status

- Charger

- Voltage: 17.6±0.1 V

- Gimbal

- Controllable Range: Pitch: -90° to +30°, Yaw: -90° to +90°

- Camera

- Sensor: 1/2.3’’ CMOS, Effective Pixels: 12M

- Max Image Size: 4000×3000 pixels

- Video Recording:

- 4K: 3840×2160 24/25/30p

- 2.7K: 2688×1512 24/25/30/48/50/60p

- FHD: 1920×1080 24/25/30/48/50/60/120p

- Flight Performance

- Max Service Ceiling (ASL): 19,685 ft (6,000 m)

- Max Speed: 44.7 mph (72 kph)

- Wireless Specs

- Operating Frequency: 2.4–2.4835 GHz; 5.725–5.850 GHz (Wi-Fi, OcuSync, and telemetry)

- Bluetooth: Supported (details not specified)

- Storage

- microSD Slot: Up to 128 GB, UHS-I Speed Grade 3 required

Benefits & Practical Implications:

These specifications translate to high reliability in complex environments, the ability to capture professional-grade footage, and seamless real-time control and feedback over long distances. The robust wireless system and advanced sensor suite make the Mavic 2 Zoom a versatile tool for aerial imaging, surveying, and autonomous operations.

Operating Frequencies

The Mavic 2 Zoom (FCC ID SS3-L1Z1805) operates across multiple RF bands, as detailed in its FCC filing. These frequencies and output powers are central to understanding its wireless communication capabilities and regulatory compliance:

| Frequency Range (GHz) | Output Power (mW) | FCC Rule Part |

|---|---|---|

| 2.4035–2.4775 | 127.4 | 15CCC1.12.4055 |

| 2.4725 | 65.9 | 15CCC1.35.7285 |

| 2.4775 | 63.4 | 15CCC1.22.4105 |

| 5.8395 | 180.3 | 15ECC2.3 |

| 5.8445 | 178.6 | 15ECC2.25.7355 |

| 5.8465 | 175.8 | 15ECC2.15.7305 |

These bands enable robust dual-frequency operation, supporting both long-range HD video transmission and low-latency control, while adhering to U.S. FCC Part 15 regulations for unlicensed wireless devices.

Technology Deep Dive

The Mavic 2 Zoom leverages cutting-edge wireless technologies, including dual-band Wi-Fi and proprietary DJI OcuSync 2.0, to deliver reliable, long-range HD video and telemetry links. The device’s ability to operate in both the 2.4 GHz and 5.8 GHz bands offers flexibility in crowded RF environments, optimizing range and minimizing interference from other devices. Bluetooth support further enhances connectivity with mobile devices and accessories, streamlining setup and firmware updates.

The specific frequency allocations and output power profiles ensure the drone can maintain a strong, interference-resistant link even in challenging environments. Higher output powers in the 5.8 GHz band facilitate improved penetration and reliability for video transmission, while the 2.4 GHz band offers superior range under optimal conditions. These wireless systems are engineered to balance performance and power efficiency—crucial for maximizing flight time and ensuring dependable communication for both recreational and professional operations.

Test reports in the FCC documentation confirm that the Mavic 2 Zoom meets strict limits on RF emissions and electromagnetic compatibility, ensuring both user safety and coexistence with other wireless equipment.

In-Depth Internal Component Analysis / Teardown

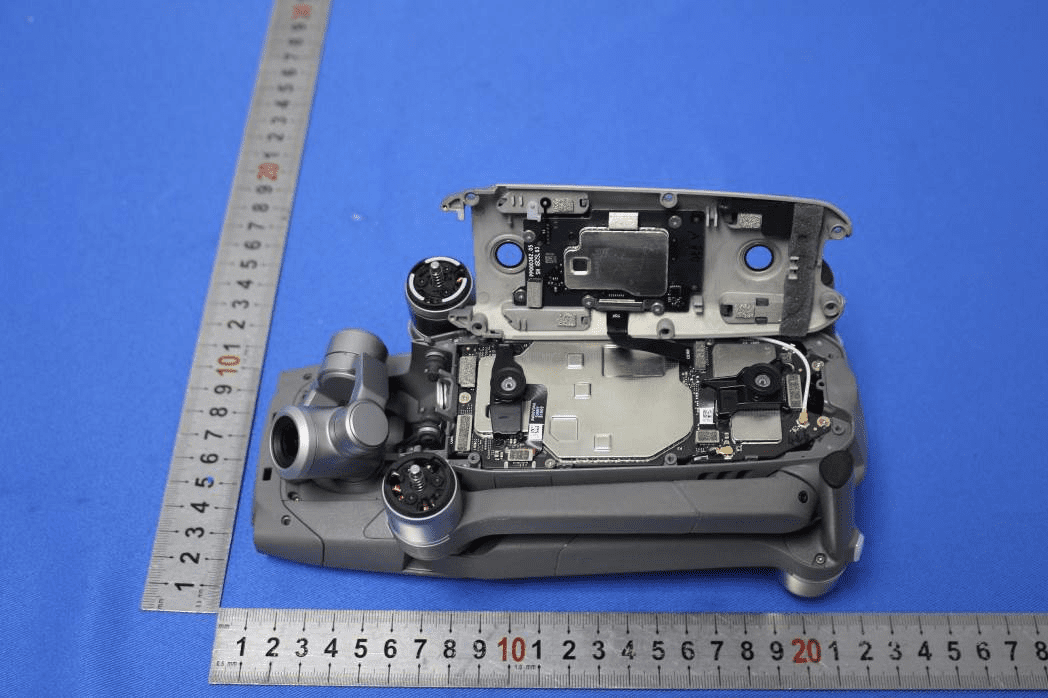

Main PCB, Shielding, and Gimbal/Camera Assembly

Examining the primary internal assembly reveals a sophisticated main PCB, partially cloaked by metal shielding cans that safeguard high-speed digital and RF circuits. The board’s multi-layer design supports dense integration of critical components, likely including a central SoC for image processing, memory modules, and RF transceivers. Extensive use of ground planes and stitching vias underscores a commitment to signal integrity and EMI resilience. Coaxial connectors route RF signals to external or embedded antennas, while robust FPC/FFC connectors facilitate modular integration of the camera, gimbal, and sensor subsystems. Power regulation is handled by sizable inductors and capacitors, ensuring stable operation across demanding load conditions. The visible portion of the gimbal/camera interface and presence of multiple test points further highlight the design’s serviceability and engineering sophistication.

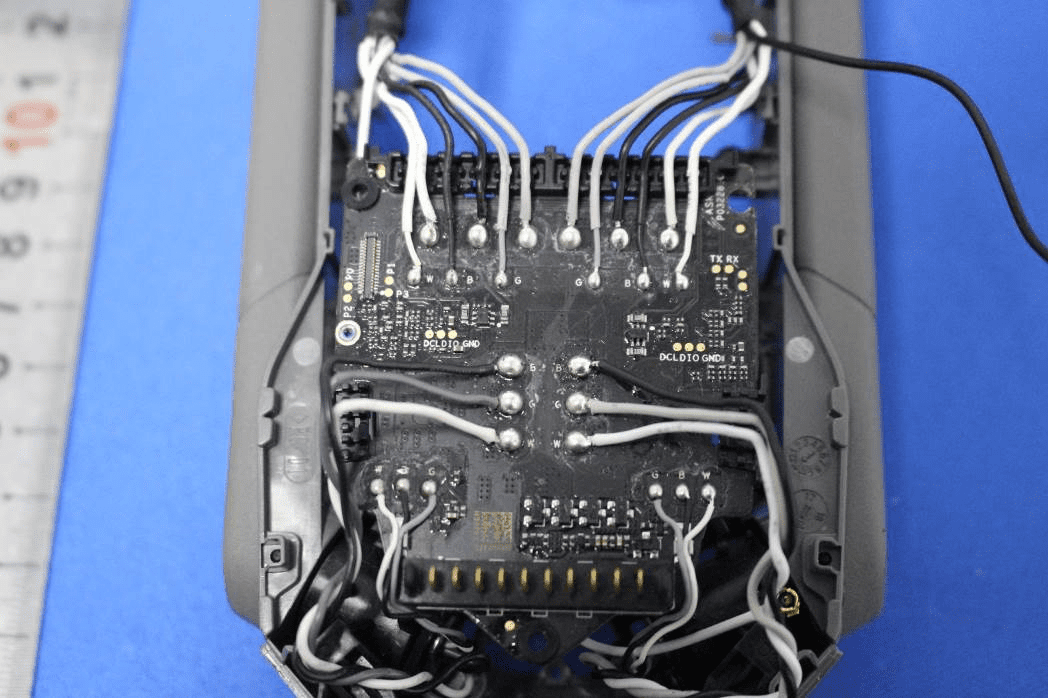

Motor Controller/ESC PCB

A closer look at the motor control subsystem reveals a compact, high-density PCB dedicated to brushless motor management. The presence of multiple MOSFETs, gate drivers, and logic-level ICs supports precise, high-current motor control—essential for agile flight and stability. Thick power traces and direct-soldered wires minimize losses and enhance reliability under vibration. Robust grounding and clear labeling of test points and pads facilitate both EMI mitigation and streamlined manufacturing or service processes. The overall layout reflects DJI’s focus on modularity, durability, and high power efficiency in drone ESC design.

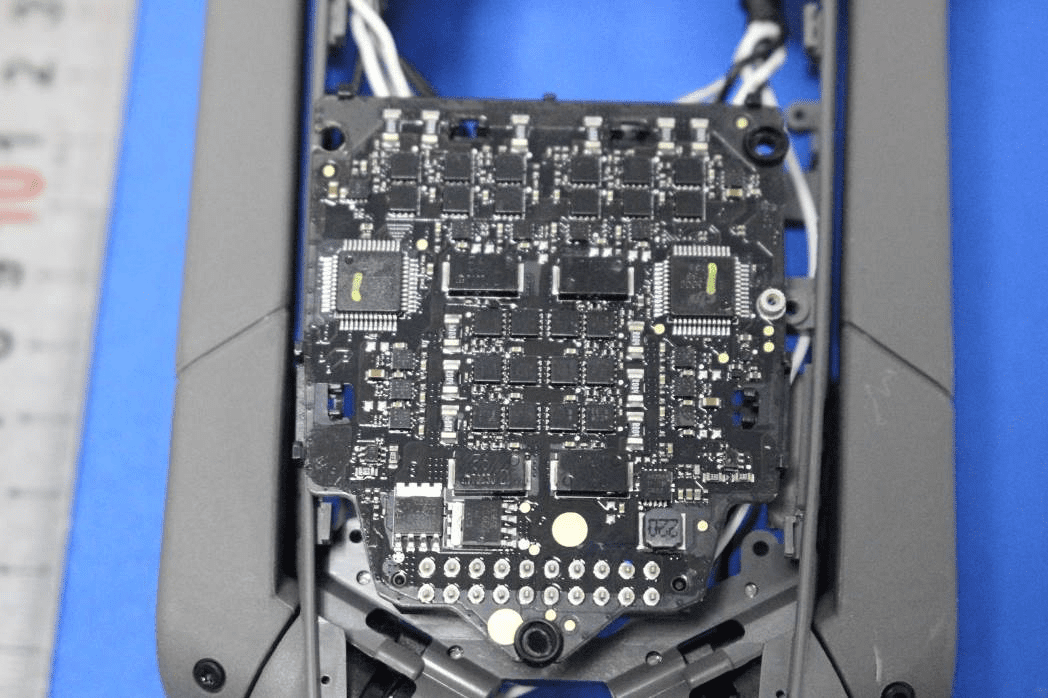

High-Density Control/ESC Board

This densely populated black PCB hosts two prominent microcontrollers or motor control ICs in QFP packages, surrounded by an array of MOSFETs and support components. The careful arrangement of wide power traces and differential signal paths enables reliable, low-noise motor operation. Bundled white wires likely route motor phases and feedback, while coaxial connectors support off-board antenna or telemetry connections. The inclusion of crystal oscillators and test/debug pads points to a design optimized for real-time control and serviceability. The mechanical mounting with standoffs and screws further emphasizes durability and vibration resistance.

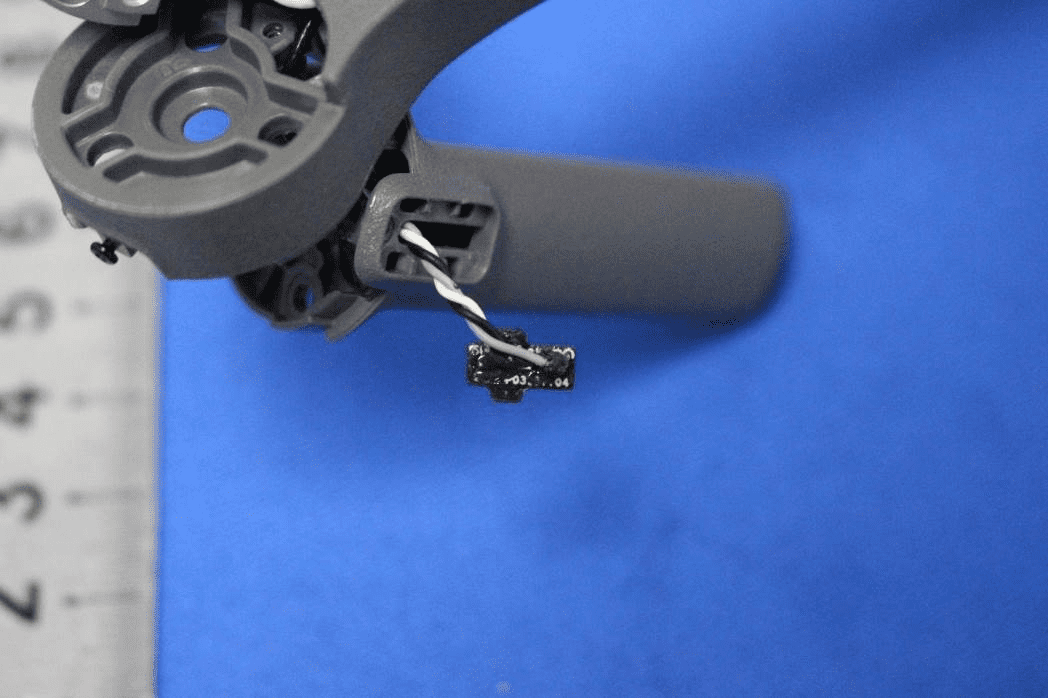

Peripheral Sensor or Indicator Board

A small, rectangular green PCB nestled within a mechanical assembly likely serves as a peripheral sensor or status indicator. Its minimal component count and use of twisted pair wiring suggest a focus on noise immunity for low-speed signals, possibly for position or landing detection. The modular design and secure cable routing highlight DJI’s attention to serviceability and electrical robustness in peripheral subsystems.

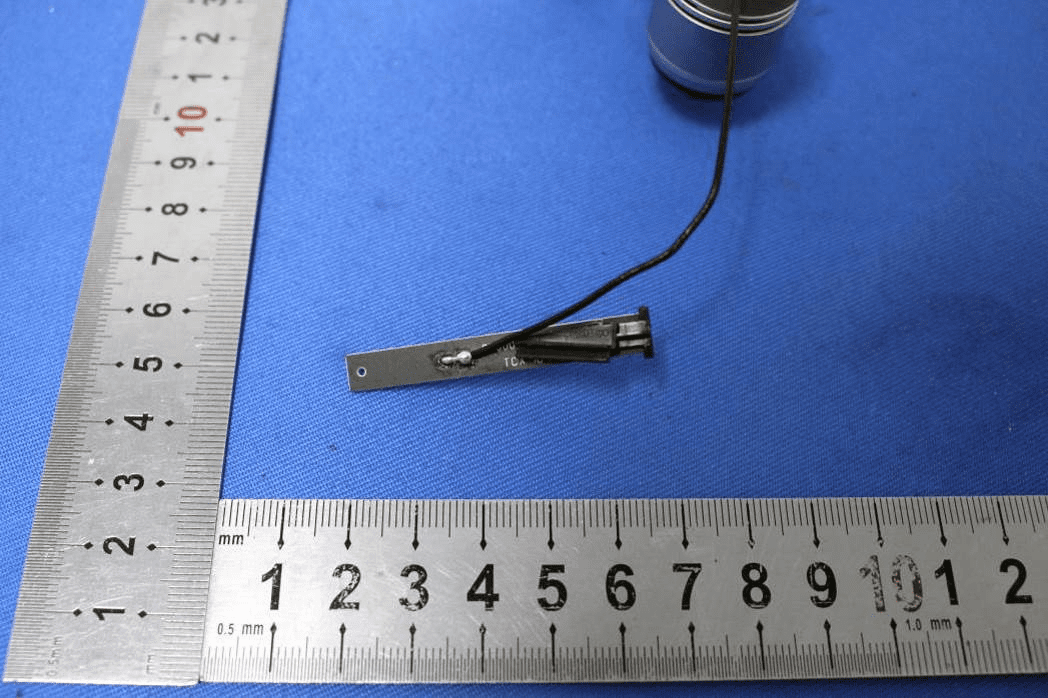

PCB Antenna Module

The elongated, narrow PCB with an attached coaxial wire is a classic example of a purpose-built drone antenna. Its minimalist construction and lack of active components are suited for high-frequency RF transmission or reception in the 2.4 GHz and 5.8 GHz bands. The design ensures precise control over the antenna’s radiation characteristics, while the modular connector enables easy replacement or assembly during manufacturing. This component is critical for the drone’s robust telemetry and video downlink performance.

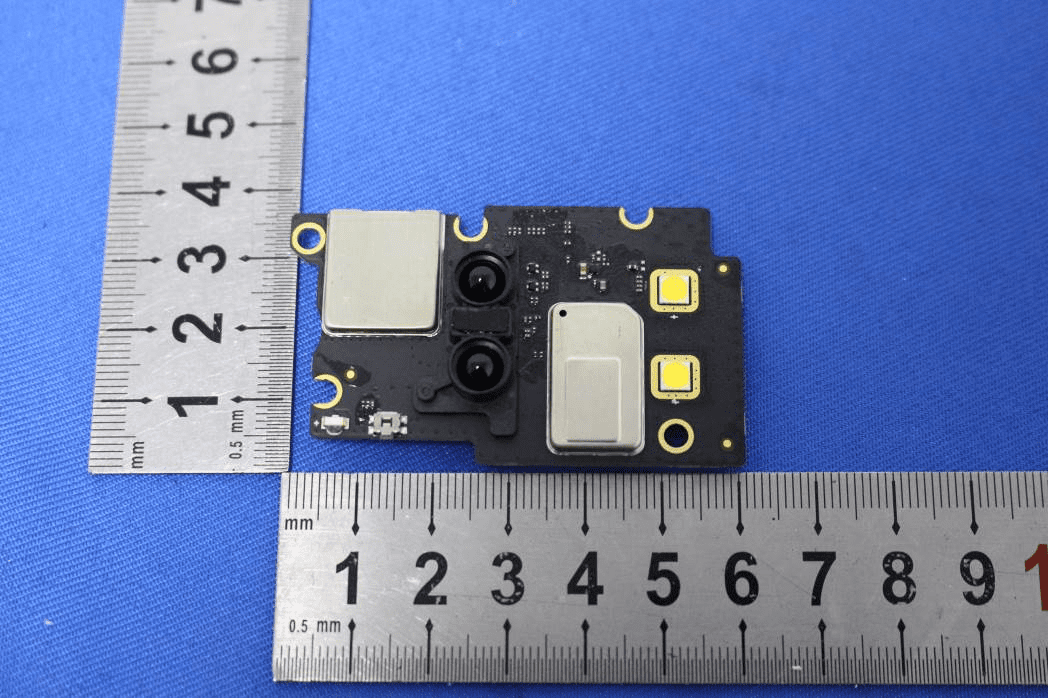

Stereo Vision/ToF Sensor Module

A compact, black PCB populated with two camera lenses and high-power LEDs serves as the drone’s stereo vision or time-of-flight (ToF) sensor. Metal shields cover sensitive ICs, likely including an image signal processor and microcontroller for real-time depth sensing and obstacle avoidance. The precise, modular construction ensures reliable operation in space-constrained environments, supporting advanced autonomous functions like obstacle detection and navigation.

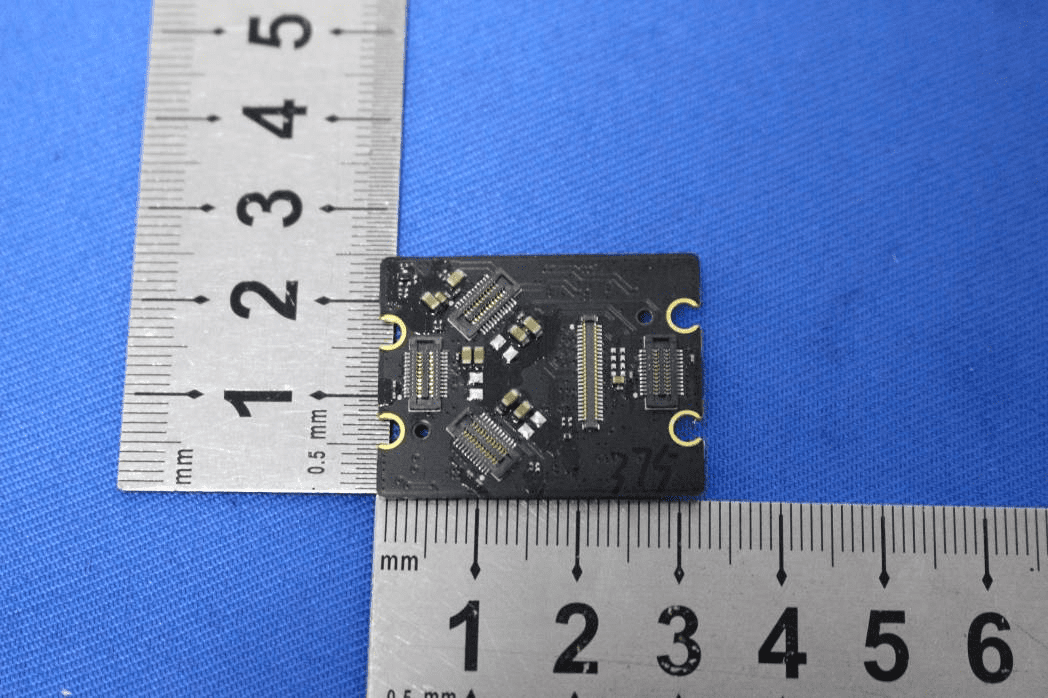

Sensor Interface/Peripheral Board

This small, high-density PCB features multiple small-outline ICs and fine-pitch connectors, likely supporting sensor signal conditioning, analog multiplexing, or data interfacing for the drone’s camera or gimbal systems. The board’s dense layout and modular connectors enable easy integration with other subsystems, while its robust grounding and power filtering ensure signal integrity in electrically noisy environments.

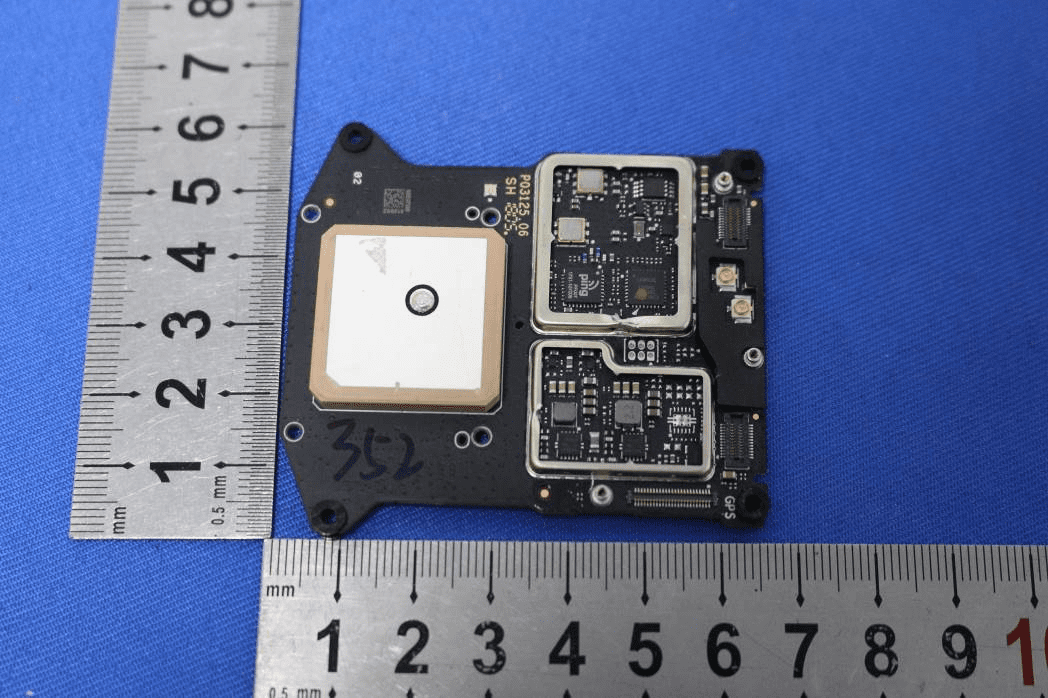

GNSS/Navigation Module

A standout RF-centric module, this PCB integrates a large ceramic patch antenna—indicative of GNSS (GPS/GLONASS) reception—alongside shielded sections protecting sensitive receiver and RF front-end ICs. The use of fine-pitch connectors and extensive power filtering ensures precise navigation data and robust EMI suppression. The module’s modularity and test points underline DJI’s commitment to reliable, high-performance navigation in demanding environments.

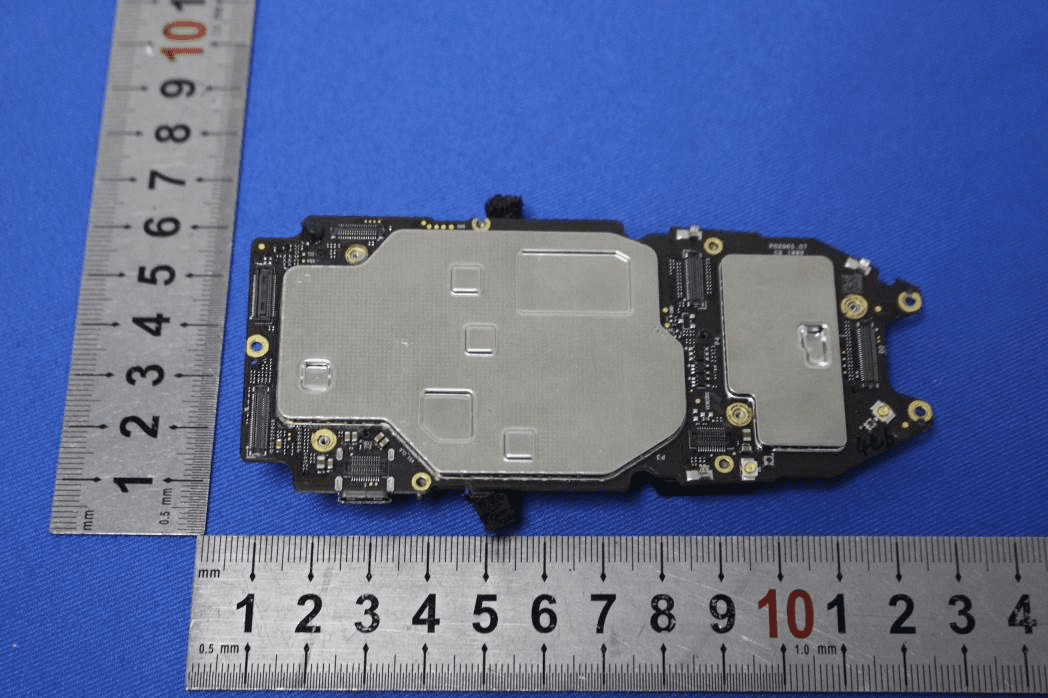

Core Logic & RF Board

The central logic board exemplifies DJI’s advanced integration, with multiple shielded domains housing the main processor, RF transceivers, and memory. Modular FPC/FFC connectors enable flexible interconnection with camera, sensor, and power subsystems. The board’s dense population, high layer count, and robust EMI shielding reflect the demands of real-time image processing, high-speed wireless communication, and flight control. Test points and modular connectors further reinforce the design’s serviceability and reliability.

Regulatory Insights & FCC Filing

The FCC certification (FCC ID SS3-L1Z1805) for the Mavic 2 Zoom is a testament to its compliance with rigorous U.S. standards for electromagnetic interference and radiofrequency emissions. This certification, registered through FCC.gov, is a legal prerequisite for the device’s sale and operation in the United States, ensuring it does not cause harmful interference to other wireless systems.

FCC filings for this device encompass a comprehensive array of documentation, including test reports for RF exposure and electromagnetic compatibility, internal and external photographs, user manuals, schematics, and block diagrams. Insights from the user manual highlight the drone’s advanced camera system, robust flight autonomy, and integrated safety features. Internal documentation further confirms the presence of sophisticated wireless technologies, stringent EMI shielding, and modular hardware design. The test reports validate that the Mavic 2 Zoom operates well within FCC-mandated limits for spurious emissions and RF output, confirming both user safety and coexistence with other wireless equipment.

This regulatory compliance not only affirms the Mavic 2 Zoom’s technical integrity but also provides assurance to consumers and professionals relying on its performance in mission-critical scenarios.

Potential Use Cases & Target Audience

With its blend of advanced optics, intelligent flight modes, and robust wireless connectivity, the Mavic 2 Zoom is designed for a spectrum of demanding aerial applications:

-

Aerial Photography & Videography:

Professional and enthusiast creators can leverage the 2x optical zoom, 4K video, and stabilized gimbal to capture dynamic perspectives, cinematic reveals, and detailed landscapes—all with minimal setup time. -

Surveying & Inspection:

Engineers and surveyors benefit from the drone’s long flight time, high-resolution imaging, and precise GPS for mapping, infrastructure inspection, and site documentation, even in challenging environments. -

Creative Content & Social Media:

Content creators and influencers can utilize intelligent flight modes—such as HyperLapse, ActiveTrack 2.0, QuickShot, and Panorama—to automate complex shots, track moving subjects, and share immersive aerial content with ease.

The Mavic 2 Zoom’s omnidirectional obstacle sensing and Advanced Pilot Assistance Systems make it accessible to both seasoned pilots and newcomers seeking reliable, safe flight in diverse scenarios.

Conclusion

The Mavic 2 Zoom by SZ DJI TECHNOLOGY CO., LTD. (Model: L1Z), certified under FCC ID SS3-L1Z1805, represents the pinnacle of compact drone engineering, seamlessly blending advanced imaging, robust wireless communication, and modular internal design. Its FCC certification underscores its adherence to strict U.S. regulatory standards, ensuring safe, interference-free operation. Packed with intelligent features and engineered for reliability, the Mavic 2 Zoom stands as a versatile, professional-grade tool for creators, surveyors, and aerial enthusiasts alike—setting a high bar for performance, innovation, and regulatory compliance in the UAV market.