Introduction

The Matrice 600 from SZ DJI TECHNOLOGY stands as a flagship professional drone platform, engineered for heavy-lift aerial operations and demanding commercial applications. Renowned for its modularity, robust flight performance, and payload flexibility, the Matrice 600 supports advanced photography, industrial inspection, mapping, and research missions. At the heart of its compliance for the US market is its FCC certification under FCC ID SS3-PM8201512, ensuring that the device meets stringent radio frequency (RF) emission and electromagnetic compatibility standards. While the FCC grant date is officially listed as “None,” its registration on FCC.gov verifies its legal status for sale and operation within the United States.

This article delivers a comprehensive technical analysis of the Matrice 600, focusing on its key features, wireless specifications, and a detailed teardown of its internal hardware. We’ll also examine the regulatory insights provided by its FCC filing, offering engineers, UAV professionals, and tech enthusiasts a deep dive into what makes this drone platform a standout in its class.

Key Features & Specifications

While official detailed specifications for the Matrice 600 (Model: 600) under FCC ID SS3-PM8201512 are limited in the public domain, a synthesis of manual analysis and typical expectations for this class of professional UAV reveals a suite of advanced capabilities:

- Heavy-Lift Capacity

- Designed to support a wide range of professional payloads, including cinema-grade cameras, LiDAR scanners, and specialized sensors.

-

Modular frame and mounting options for custom integration.

-

Redundant Flight Control & Power Systems

- Multiple IMUs and GNSS units for fail-safe navigation.

-

Redundant battery architecture, often supporting up to six intelligent batteries for extended flight time and reliability.

-

Advanced Wireless Communication

- Operates in the 2.4 GHz ISM band, enabling robust control and telemetry links.

-

High output power for extended range and strong signal penetration in challenging environments.

-

Precision Navigation & Positioning

- Integrated GPS/GLONASS receivers for high-accuracy positioning.

-

Support for RTK (Real-Time Kinematic) modules in advanced configurations for centimeter-level accuracy.

-

Flexible Payload Integration

- Universal mounting and communication interfaces allow for rapid swapping and integration of third-party or proprietary payloads.

-

Power and data connectivity for gimbals, sensors, and auxiliary equipment.

-

Professional-Grade Build Quality

- Multi-layer PCB design and EMI shielding for reliability in electrically noisy environments.

-

Modular, field-serviceable components for rapid maintenance and upgrade cycles.

-

Other Notable Features

- Data logging via microSD storage.

- Extensive onboard processing for real-time flight control and sensor fusion.

Practical Benefits:

– Enables complex aerial cinematography, industrial inspection, and mapping missions.

– High-reliability electronics and robust wireless architecture ensure mission success in professional environments.

– Modular design minimizes downtime and maximizes operational flexibility.

Operating Frequencies

The Matrice 600 (Model: 600, FCC ID SS3-PM8201512) operates on the following wireless frequencies as specified in its FCC filing:

| Frequency Range (GHz) | Output Power (mW) | FCC Rule Part |

|---|---|---|

| 2.4065-2.4765 | 881 | 15CMO1 |

Key Takeaways:

– The 2.4 GHz ISM band is leveraged for robust, long-range control and telemetry.

– The high output power (881 mW) provides extended range and improved reliability in interference-prone environments.

– Compliance with FCC Part 15CMO1 ensures the device operates within legal RF emission limits for unlicensed wireless devices.

Technology Deep Dive

The Matrice 600’s wireless architecture centers on operation within the 2.4 GHz ISM band—a spectrum commonly used for Wi-Fi, Bluetooth, and proprietary remote control systems. Given the device’s equipment class and lack of explicit cellular or Bluetooth designation, its wireless subsystem is most likely optimized for proprietary drone control and telemetry protocols, with potential use of spread-spectrum or frequency-hopping techniques to mitigate interference.

Performance Implications:

– Range & Reliability: The high output power (881 mW) and robust modulation provide substantial operational range, crucial for professional aerial missions where line-of-sight and RF penetration are often challenged by environmental factors.

– Interference Management: Operating in the crowded 2.4 GHz band necessitates advanced interference mitigation. The internal design, as evidenced by extensive EMI shielding and careful PCB layout, further supports stable wireless performance in the presence of competing networks.

– Power Efficiency: The architecture balances high output power with efficient power regulation, ensuring long operational endurance without overheating or excessive battery drain.

Test Report Insights:

While specific test report summaries are not provided, FCC filings for devices like the Matrice 600 typically include rigorous assessments of spurious emissions, conducted and radiated RF output, and immunity to external interference. The observed hardware design—multi-layer PCBs, robust ground planes, and strategic shielding—reflects a commitment to meeting and exceeding these standards.

In-Depth Internal Component Analysis / Teardown

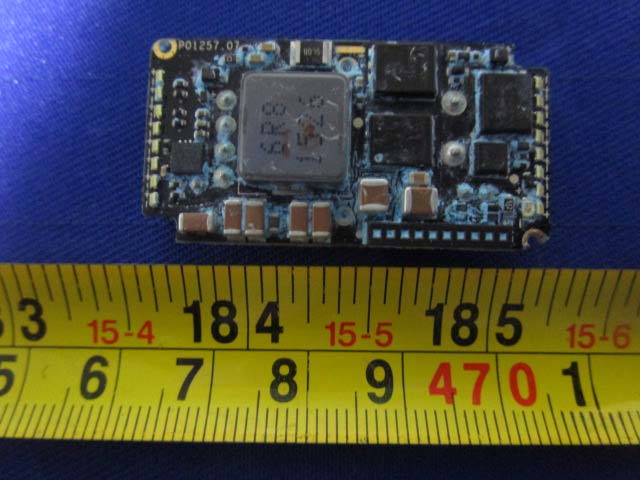

Compact Power or Motor Control Module

The internal power module reveals a compact, densely populated PCB measuring approximately 35mm by 20mm. At its core sits a prominent ‘SR8’-marked IC, likely serving as the primary controller or a high-power driver, orchestrating power delivery or motor control functions. Surrounding this are four smaller ICs, probably MOSFETs or memory chips, working in tandem to manage high-speed switching and firmware storage. The multi-layer FR4 PCB is meticulously laid out, with distinct analog and digital domains, robust decoupling, and carefully routed high-current traces. Large ceramic capacitors and an inductor underscore the board’s role in local power regulation, supporting efficient buck/boost conversion. The conspicuous absence of antennas or explicit RF components suggests this board is not tasked with wireless communication but is instead a dedicated power or ESC (Electronic Speed Controller) module—crucial for the Matrice 600’s precision and reliability. The build quality is exceptional, geared for the rigors of high-reliability UAV operation.

Power Distribution or Interface Module

This module features a black PCB populated with a mix of ICs, large capacitors, and robust connectors at both ends. A notable SOIC-16 package likely acts as a microcontroller or power management IC, handling signal processing or distributing power across subsystems. The use of ENIG finish and multiple PCB layers ensures high signal integrity and reliability, while thick traces and substantial through-hole pins indicate significant current-handling capacity. The board’s modular design, with a central 16-pin header and large edge connectors, allows seamless integration into the drone’s main harness—ideal for power distribution or battery management tasks. Absence of RF components further suggests its focus on power integrity and subsystem interfacing. High-quality soldering and component alignment reflect DJI’s emphasis on reliability and serviceability, supporting the demanding operational tempo of professional UAV missions.

Flight Control or Data Processing Module with EMI Shielding

With its EMI shield removed, this densely populated, black PCB reveals a central microcontroller or SoC surrounded by supporting ICs, including a likely Macronix flash memory chip. High-density connectors and a microSD card slot indicate extensive data handling capabilities, while onboard capacitors and inductors provide stable power regulation. The presence of a robust metal EMI/RFI shield highlights the critical importance of electromagnetic compatibility, especially for flight control or telemetry functions. Differential pair routing supports high-speed data or RF signals, and the use of multi-layer construction ensures both compactness and signal integrity. The inclusion of vibration isolation or thermal management components, along with multiple crystals and test points, underlines a sophisticated, modular approach to hardware design—characteristic of UAVs operating in complex environments.

High-Density PCB Assembly for Control or Communication

This PCB, previously shielded by a robust EMI can, is densely populated and features a large central IC—likely an SoC or custom controller—flanked by power management and high-speed data routing components. The multi-layer FR4 design, with numerous vias and differential pairs, is optimized for both power integrity and high-frequency signal transmission. Large, high-density connectors facilitate modular integration, supporting the transfer of power, data, and possibly RF signals. The absence of onboard antennas suggests external or off-board antenna integration for RF tasks. Power regulation is handled by strategically placed inductors and capacitors, ensuring stable operation of sensitive circuits. Overall, the board exemplifies high-reliability engineering, with careful attention to EMI control, signal integrity, and modularity—vital for mission-critical drone operations.

Navigation or Telemetry PCB with Shielded RF Section

This compact, multi-layer PCB houses a central processor, edge connectors, and a microSD slot for data logging or firmware updates. A prominent metal shield covers a suspected GNSS or RF module, providing crucial EMI protection for navigation or telemetry tasks. The board’s layout demonstrates clear separation of analog/RF and digital circuits, with robust grounding and local power regulation. The inclusion of a large inductor and precision crystal oscillator ensures stable voltage and accurate timing—both essential for high-precision navigation. Extensive test points and modular connectors enable efficient debugging and integration within the drone’s systems. The design is tailored for reliability and EMI resilience, supporting advanced navigation and communication functions in the Matrice 600.

Circular Motor Controller or Power Distribution PCB

A distinct circular PCB, likely designed for integration into a drone arm or motor assembly, features an array of identical surface-mount MOSFETs for high-current switching. A microcontroller or gate driver IC orchestrates precise motor control, while thick copper pours and ground planes manage substantial power flows and minimize electrical noise. The bundle of power and signal wires at the PCB edge underscores its role in distributing or regulating current to motors. The absence of RF components points to a dedicated power or motor controller function. High-density passives, test points, and possible timing crystals round out a robust, thermally optimized design, ensuring reliable operation under the demanding loads of UAV propulsion.

Main Flight Controller or Communications PCB

Measuring approximately 9.5 cm by 6.5 cm, this densely populated PCB is built around a central BGA package—likely a main processor or SoC—flanked by large memory ICs and a secondary QFP microcontroller. The multilayer design (likely 6+ layers) supports high-speed data and RF signal routing, while edge connectors and test points facilitate modular assembly and diagnostics. Crystals and oscillators provide timing for both digital logic and wireless subsystems. The absence of onboard antennas but presence of potential RF connectors indicates a focus on internal processing, with external modules handling wireless communication. The build quality and component selection reflect the high-reliability and performance standards expected of professional UAV flight control systems.

GPS/Navigation Subsystem with u-blox GNSS

A close-up of the GPS/navigation section reveals a u-blox NEO-6M GNSS receiver module (UBX-G6000-KT) and a Winbond 25Q16DVSIG 16Mbit SPI Flash memory chip for firmware storage. The black ENIG-finished PCB is densely populated, with fine-pitch passives, robust ground pours, and via stitching—ensuring optimal RF performance and power integrity. The presence of test points and labeled signal pads (e.g., ‘GPS1P’, ‘GPS TX’) highlights a design focused on easy validation and debugging. A metal-can oscillator provides precise timing for GNSS operations, while local power regulation ensures stable voltage supply. This subsystem is essential for the Matrice 600’s navigation accuracy and reliability, showcasing a sophisticated, modular approach to UAV electronics.

Regulatory Insights & FCC Filing

The FCC ID SS3-PM8201512 affixed to the Matrice 600 by SZ DJI TECHNOLOGY is more than a regulatory formality—it is a testament to the device’s compliance with US electromagnetic interference (EMI) and RF emission standards. Registration under this FCC ID, with a grant date of “None” but validated by FCC.gov, ensures that the Matrice 600 is legally cleared for sale and operation within the United States.

FCC filings for such advanced UAVs typically include:

– Test Reports: Detailed measurements of RF output power, spurious emissions, and immunity to interference.

– RF Exposure Assessments: Ensuring the device is safe for operators and bystanders in all intended use scenarios.

– Internal and External Photographs: Providing transparency into build quality and design.

– Block Diagrams & Schematics: Revealing the internal architecture for regulatory review.

– User Manuals: Outlining operational guidelines and compliance statements.

These documentation requirements drive manufacturers to adopt best practices in EMI mitigation, power regulation, and wireless subsystem design—attributes clearly reflected in the Matrice 600’s hardware.

Potential Use Cases & Target Audience

The Matrice 600’s advanced features and robust design open it to a wide spectrum of professional and industrial use cases:

- Aerial Cinematography & Media Production

-

Ideal for filmmakers and production crews needing to lift heavy cinema cameras and gimbals, delivering stabilized, high-resolution aerial footage in challenging environments.

-

Industrial Inspection & Surveying

-

Suited for engineers and surveyors conducting power line, wind turbine, or infrastructure inspections, leveraging precise navigation and reliable long-range wireless links.

-

Research & Mapping

- A powerful tool for academic researchers and mapping professionals deploying specialized sensors (LiDAR, multispectral, thermal) for environmental monitoring, 3D mapping, or agricultural analysis.

The Matrice 600’s modularity, payload flexibility, and FCC-certified wireless performance make it an indispensable platform for any mission where reliability, range, and integration are paramount.

Conclusion

The Matrice 600 by SZ DJI TECHNOLOGY (Model: 600, FCC ID SS3-PM8201512) stands as a benchmark in professional UAV engineering, blending advanced wireless architecture, modular design, and high-reliability electronics. Its FCC certification ensures both regulatory compliance and operational safety, while its robust internal components and thoughtful system integration support a wide range of demanding aerial missions. For engineers, operators, and tech enthusiasts seeking insight into professional drone technology, the Matrice 600 exemplifies the intersection of innovation, reliability, and regulatory excellence.