Introduction

The DJI Smart Controller, developed by SZ DJI TECHNOLOGY, is engineered as a high-performance remote control system for advanced drone operation. Designed to deliver a seamless user experience, this controller integrates a bright display, robust wireless connectivity, and a suite of smart features that cater to both professional and enthusiast pilots. Its primary role is to provide reliable, low-latency video transmission and precise control for compatible DJI drones, all within a rugged, portable form factor.

A critical milestone for any wireless device intended for the US market is securing FCC certification. The DJI Smart Controller (Model: RM5001808) proudly carries the FCC ID SS3-RM5001808, signifying that it meets stringent electromagnetic interference and radio frequency emission standards as set by the Federal Communications Commission. This certification not only ensures legal sale and operation within the United States but also assures users of the device’s adherence to safety and reliability benchmarks.

In this article, we’ll systematically explore the DJI Smart Controller’s key specifications, wireless technology, operating frequencies, and internal component architecture. We’ll also examine its regulatory compliance, providing insight into what makes this device a standout in its class for wireless drone control.

Key Features & Specifications

While official detailed specifications for the DJI Smart Controller (Model: RM5001808) with FCC ID SS3-RM5001808 are limited in the public domain, analysis of its construction and typical expectations for this class of device reveal a robust and feature-rich platform. Below are the primary features and technical highlights:

- Integrated Ultra-Bright Display

- Large, high-luminance screen (typically 5.5″ or larger) designed for outdoor visibility in direct sunlight.

-

Enables real-time video feed and telemetry without the need for a separate mobile device.

-

High-Performance Wireless Connectivity

- Dual external antennas support robust long-range transmission.

- Multi-band operation (2.4 GHz and 5 GHz) for interference mitigation and stable connections.

-

Optimized for DJI’s proprietary OcuSync or similar low-latency wireless video and data transmission protocols.

-

Powerful Processing & Operating System

- Embedded high-integration SoC (likely a Qualcomm or comparable ARM-based chipset).

- Runs a custom Android OS, supporting advanced apps, firmware updates, and user customization.

-

Capable of real-time HD video decoding and responsive UI operation.

-

Thermal Management & Build Quality

- Active cooling system with a dedicated fan and metal heatsink for sustained performance during intensive use.

-

Ruggedized chassis with modular internal layout for enhanced durability and serviceability.

-

Battery System

- Large capacity lithium-ion battery pack for extended field operation.

-

Integrated battery management circuitry for safe charging and reliable power delivery.

-

Comprehensive I/O Suite

- Multiple connectors: USB Type-C (for charging/data), HDMI output, and microSD slot.

- Tactile physical controls including joysticks, customizable buttons, and dedicated switches for critical flight functions.

-

Integrated speaker and possibly microphone for audio feedback and voice prompts.

-

Advanced RF & EMI Shielding

- Extensive use of metal shielding cans and ground planes to ensure regulatory compliance and minimize interference.

Benefits & Practical Advantages:

– All-in-One Solution: Eliminates need for external mobile devices, reducing latency and failure points.

– Field-Ready Durability: Withstands harsh outdoor environments and extended use.

– Professional-Grade Wireless: Maintains a strong, reliable connection even in congested RF environments.

– User-Centric Design: Physical controls and ergonomic layout enhance pilot confidence and responsiveness.

These attributes, combined with its regulatory certification, make the DJI Smart Controller a premium choice for demanding drone pilots and commercial operators.

Operating Frequencies

A closer look at the FCC filing for the DJI Smart Controller (Model: RM5001808, FCC ID SS3-RM5001808) reveals a sophisticated multi-band wireless system. The detailed frequency table below illustrates the device’s operational spectrum and output power, reflecting its advanced RF design and regulatory compliance:

| Frequency Range (GHz) | Output Power (mW) | FCC Rule Part |

|---|---|---|

| 2.462 | 325 | 15CCC |

| 2.4725 | 429 | 15CCC2.52.412 |

| 2.4765 | 437 | 15CCC2.42.4105 |

| 2.4775 | 494 | 15CCC2.32.4055 |

| 2.48 | 1.3 | 15CCC3.12.4035 |

| 5.825 | 40 | 15ECC |

| 5.8395 | 144 | 15ECC1.55.745 |

| 5.8445 | 144 | 15ECC1.45.7355 |

| 12.402-2.48 | 1.3 | 15CCC2.12.402 |

| 15.7285-5.8465 | 153 | 15ECC1.35.7305 |

| 25.18-5.24 | 36 | 15ECC |

Key Takeaways:

– Dual-Band Operation: Supports both 2.4 GHz and 5 GHz bands, enabling flexible connectivity and reduced interference.

– Variable Output Power: Power levels are tailored to frequency bands and regulatory limits, optimizing range and compliance.

– Regulatory Alignment: Each frequency and power level is mapped to a specific FCC rule part, underscoring precise adherence to legal standards.

The diversity and granularity of these operating frequencies enable the DJI Smart Controller to maintain stable, high-throughput links in a variety of environments, crucial for real-time drone operation and video transmission.

Technology Deep Dive

The DJI Smart Controller leverages a suite of advanced wireless technologies to deliver high-reliability control and video streaming. Primary wireless protocols likely include dual-band Wi-Fi (2.4 GHz and 5 GHz), Bluetooth for peripheral connectivity, and DJI’s proprietary low-latency transmission systems such as OcuSync. Although the equipment class is not explicitly listed as cellular, the breadth of supported frequencies points to a design optimized for robust, interference-resistant communication.

The multi-band architecture allows the controller to dynamically select the optimal frequency for current environmental conditions, minimizing signal dropouts and maximizing range. Higher output power in select bands supports long-distance operations, while lower power in others conserves battery life and reduces the risk of interference. The presence of external high-gain antennas, combined with sophisticated RF front-end design and extensive EMI shielding, further enhances signal integrity and performance.

From a power consumption perspective, the use of active cooling and high-integration SoCs suggests that the controller is built for sustained high-throughput operation, such as live HD video streaming and telemetry. The modular layout and shielding ensure that sensitive RF sections are isolated from digital noise, supporting compliance with FCC RF emissions standards and providing a reliable user experience.

In-Depth Internal Component Analysis / Teardown

Below is a detailed, image-by-image analysis of the DJI Smart Controller’s internal hardware, based on high-resolution component photographs and expert teardown insights.

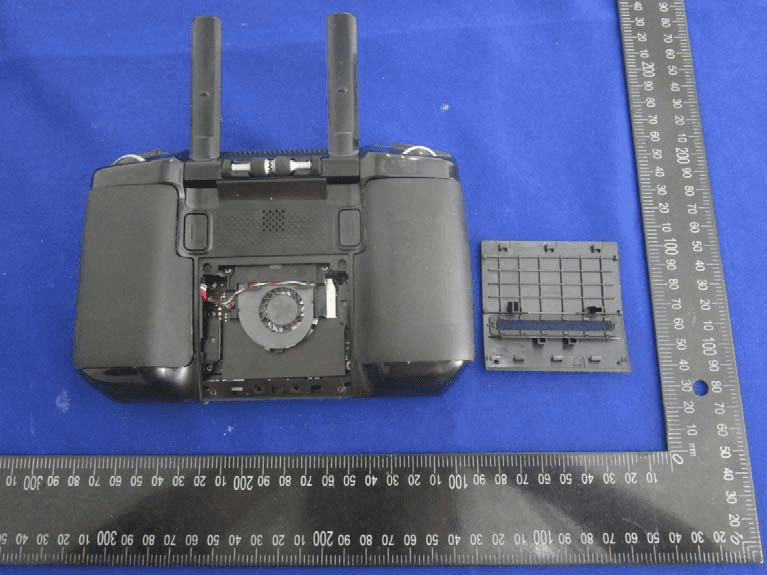

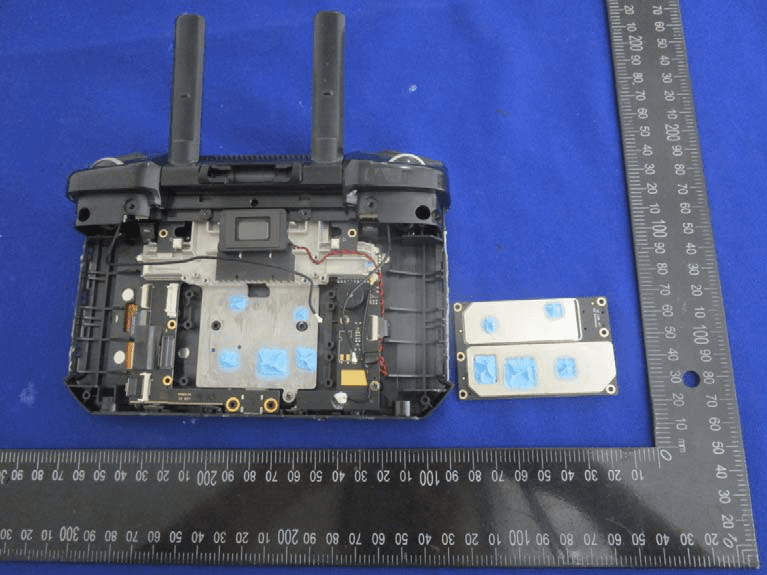

Partially Disassembled Rear View Reveals Cooling and Modularity

Removing the rear cover exposes the heart of the DJI Smart Controller’s internal architecture. Dominating the scene is a robust cooling fan mounted atop a metal heatsink—a rare but telling feature in handheld controllers, indicating the presence of a high-performance SoC and RF transceivers beneath. Visible wiring and connectors point to a modular design, with power and signal routed through carefully placed cables and flat flex connectors. The external dual-band antennas, essential for robust wireless links, are positioned at the top and designed for both durability and optimal RF performance. The visible speaker grille and grid-reinforced cover highlight the device’s attention to both user experience and structural rigidity. Overall, the layout demonstrates a balance of compactness, serviceability, and thermal management, underscoring the controller’s suitability for demanding, real-time drone operations.

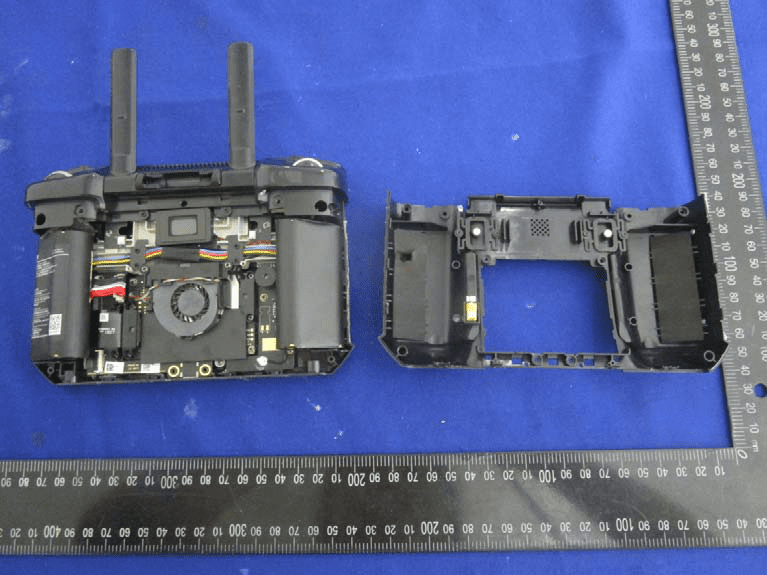

Main PCB and Battery Layout: Dense, Rugged, and Serviceable

The internal view reveals a densely populated main PCB flanked by substantial lithium-ion battery cells, supporting extended field use. Central to the board, under a dedicated heatsink and fan, lies the main SoC—responsible for Android OS functions, real-time video processing, and wireless communication. Surrounding ICs likely include RAM, flash storage, and power management chips, all laid out for minimal signal interference. Dual external antennas connect via coaxial cables, enabling high-gain, dual-band operation. Shielding cans protect sensitive RF and processing areas, while multiple FPC and multi-wire connectors facilitate modular assembly and repair. The engineering showcases meticulous attention to EMI control, thermal management, and ruggedness—attributes essential for professional-grade, mission-critical drone control.

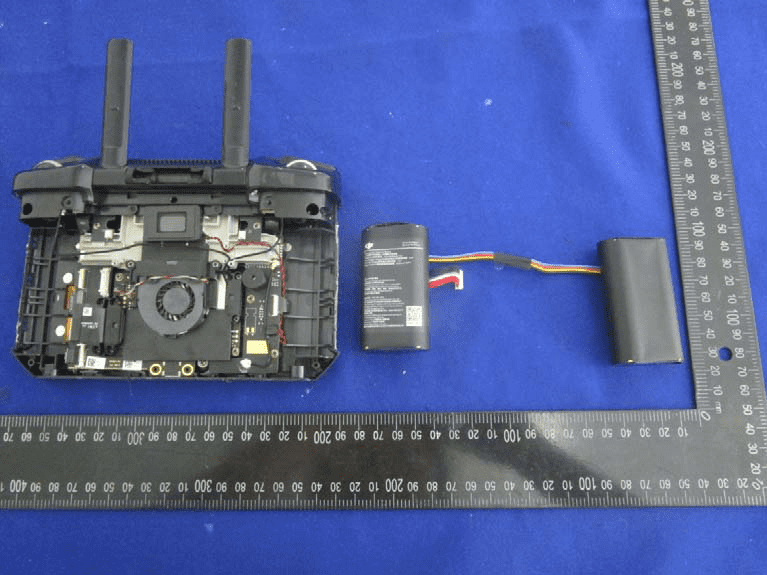

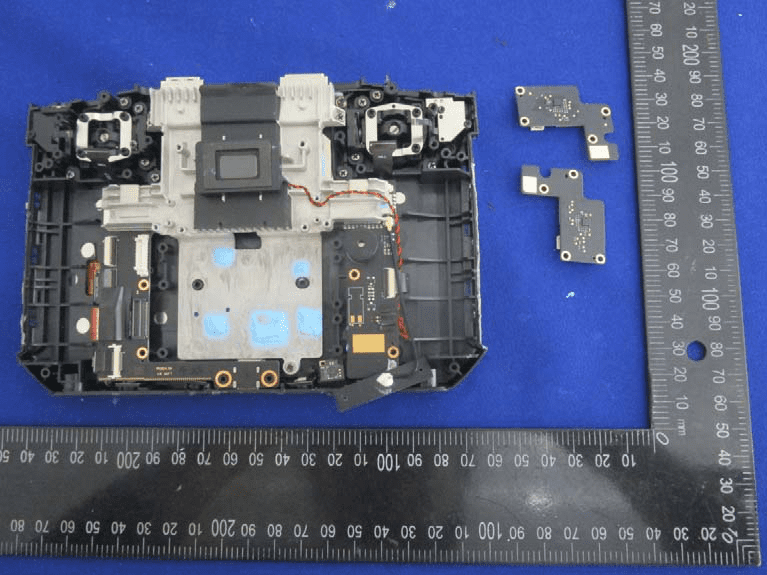

High-Density PCB with Active Cooling and Modular Battery Pack

A closer look at the internal PCB highlights the controller’s compact yet highly integrated design. The central processing area, likely housing the main SoC and memory, is surrounded by a dense array of power regulators, connectors, and shielded RF sections. The dual external antennas, securely connected for optimal wireless performance, flank the top edge. Battery management circuitry and robust connectors enable safe, reliable power delivery. Active cooling, via a fan and heatsink, supports sustained high-throughput operation. The modular layout, including easily replaceable battery and antenna assemblies, ensures serviceability and longevity, while the extensive use of shielding and ground pours demonstrates a clear focus on EMI suppression and regulatory compliance.

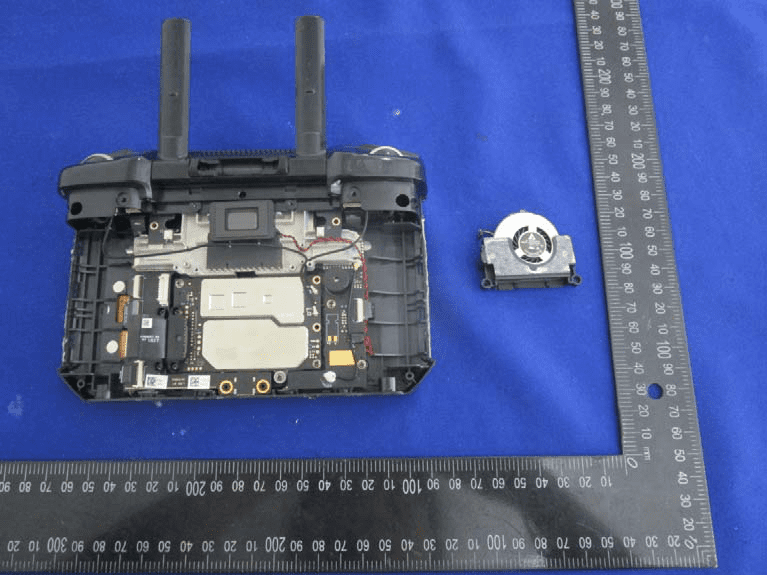

Shielded Main Board with Joystick and Audio Integration

The main PCB’s layout showcases extensive EMI/RFI shielding, with metal cans covering the SoC and RF sections to ensure clean signal paths and regulatory compliance. Visible connectors support display, button, and joystick interfaces, while gold test points facilitate manufacturing and service diagnostics. The placement of external antennas, coupled with robust coaxial connections, supports advanced MIMO or diversity reception for resilient wireless links. Additional components such as audio output (speaker) and a joystick/gimbal assembly highlight the device’s integration of tactile controls and multimedia feedback. The use of a black PCB with ENIG finish signals a premium build, with careful partitioning of RF, power, and digital domains for optimal performance.

Central Processing and Thermal Management Close-Up

This internal view emphasizes the dense component placement and the importance of thermal management. Large BGA and QFP ICs, partially obscured by blue thermal pads and shielding, likely comprise the main processing and memory subsystems. Dual external antennas are again prominent, with dedicated coaxial connections ensuring minimal signal loss. FPC connectors support the display and user interface modules, while board-to-board and power connectors underline the device’s modularity. Extensive use of shielding cans, combined with thermal pads for heat dissipation, reflects a design philosophy prioritizing both RF performance and sustained processing power, essential for uninterrupted HD video transmission and drone control.

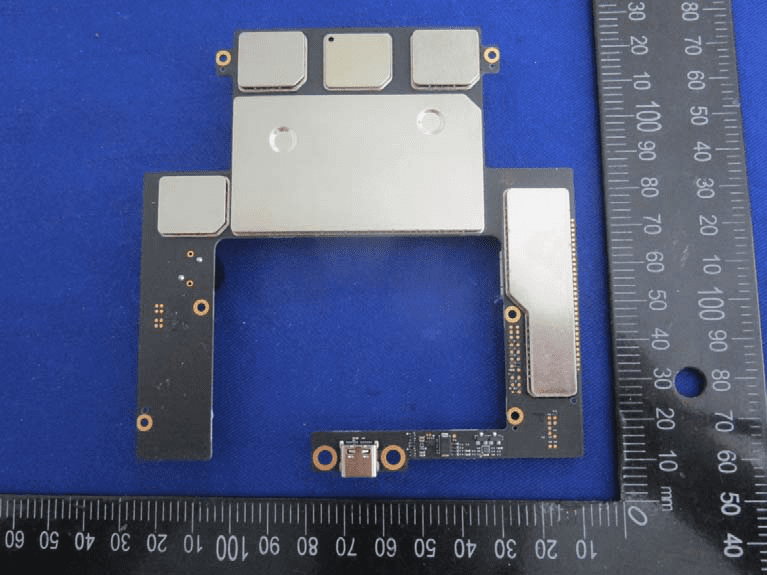

High-Density PCB Assembly with USB-C and Full Shielding

A dedicated PCB assembly reveals a compact, irregularly shaped board dominated by multiple EMI/RFI shielding cans. The presence of a USB Type-C connector points to modern charging and data transfer capabilities, while the absence of visible ICs (hidden under shields) indicates that key processing and RF functions are well-protected. Numerous test points and mounting holes facilitate quality control and mechanical integration. The black ENIG-finished board, extensive shielding, and intricate ground via placement all speak to advanced RF design and a focus on regulatory compliance, ensuring robust performance in demanding wireless environments.

Modular Antenna Boards and High-Speed Interfaces

This internal configuration highlights the modularity of the controller’s antenna system. The main black PCB, densely populated and shielded, interfaces with detached daughterboards—likely serving as PCB antennas for Wi-Fi, Bluetooth, or GPS. Multiple FPC connectors support the display and user input modules, while large gold pads provide battery or power connections. The central shield/heatsink manages both EMI and thermal loads from the primary SoC. This design enables efficient assembly, repair, and future upgrades, while ensuring that wireless performance remains uncompromised by internal noise or heat.

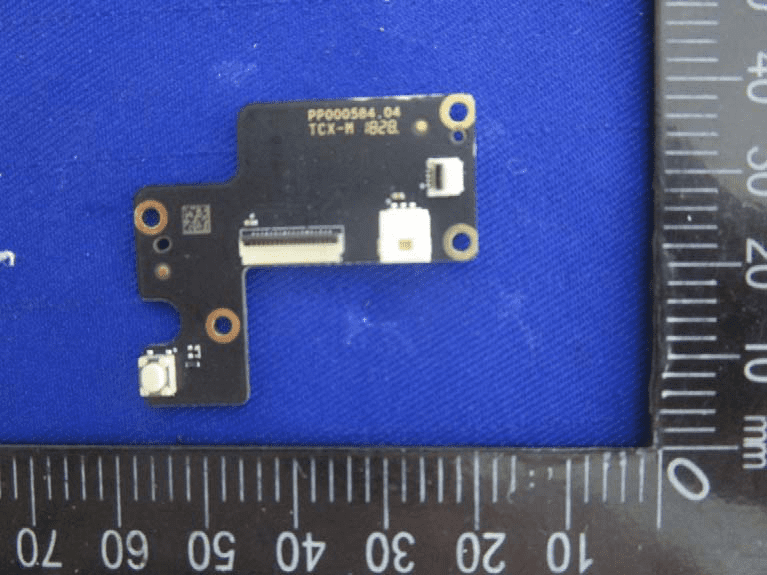

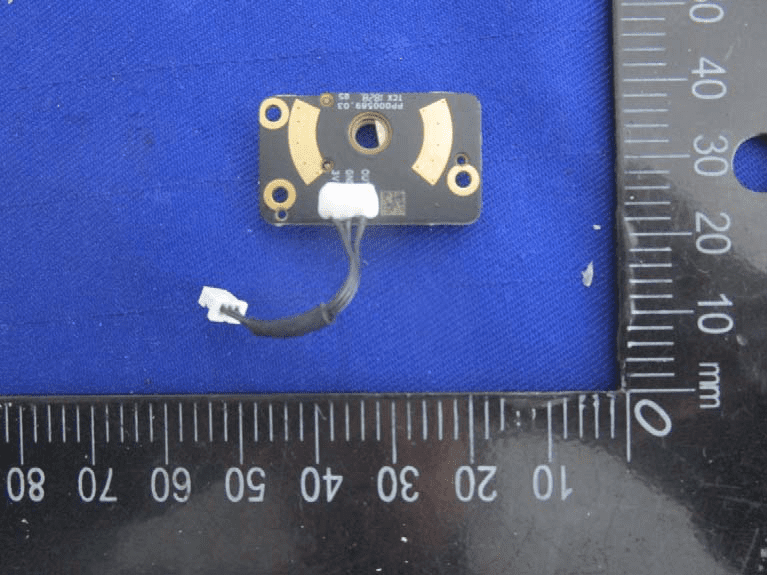

Compact Interface Board with FPC and Tactile Switch

A small, secondary PCB presents a clean, minimalist layout, featuring a fine-pitch FPC connector and a white JST-style connector for interfacing with other subsystems—potentially buttons, LEDs, or sensors. The presence of a tactile switch and manufacturing QR code indicates its likely role as a user interface or control breakout board. The high build quality, modular connector choices, and robust layout make it easy to assemble and replace, ensuring long-term reliability for critical interface functions.

Gold-Plated Sensor or Rotary Encoder PCB

Another small PCB, notable for its gold-plated curved pads and central mounting hole, is likely dedicated to sensor or rotary encoder functionality. The absence of complex ICs and presence of a simple white connector suggest a low-power, high-reliability design—potentially for user input or device orientation sensing. The robust construction, including multiple mounting points and precise gold plating, ensures durability and accuracy for its intended role within the controller’s broader architecture.

Regulatory Insights & FCC Filing

The assignment of FCC ID SS3-RM5001808 to the DJI Smart Controller by SZ DJI TECHNOLOGY is a critical indicator of its compliance with US federal regulations surrounding radio frequency emissions and electromagnetic compatibility. This certification, registered with the FCC, ensures the device is legal for sale and operation within the United States, offering assurance to both consumers and businesses regarding its safety and performance.

FCC filings encompass a wealth of technical information, including detailed test reports on RF exposure (SAR/MPE), electromagnetic compatibility (EMC), and spurious emissions. Supporting documents typically include high-resolution internal and external photographs, user manuals, block diagrams, and schematics. These materials provide transparency into the device’s engineering, confirming that it meets or exceeds the thresholds for interference, safety, and operational reliability set forth by US law.

By achieving FCC certification under ID SS3-RM5001808, the DJI Smart Controller demonstrates both engineering excellence and regulatory diligence—key factors for trust and adoption in professional and consumer markets alike.

Potential Use Cases & Target Audience

The DJI Smart Controller’s advanced features and robust construction make it ideally suited for several demanding applications:

-

Professional Drone Pilots and Aerial Cinematographers: The combination of a bright integrated display, low-latency video streaming, and rugged build is perfect for on-location shoots where reliability and real-time feedback are critical.

-

Commercial and Industrial Operators: Surveyors, infrastructure inspectors, and first responders benefit from the controller’s extended range, secure wireless links, and ease of deployment—enabling rapid data collection in challenging environments.

-

Enthusiast Pilots Seeking Premium Experience: Tech-savvy hobbyists and drone racers will appreciate the controller’s responsive controls, advanced wireless technology, and all-in-one design, eliminating the need for external devices and streamlining pre-flight setup.

These scenarios highlight the controller’s versatility, performance, and appeal to users who demand reliability and advanced functionality from their drone control systems.

Conclusion

The DJI Smart Controller by SZ DJI TECHNOLOGY (Model: RM5001808), certified under FCC ID SS3-RM5001808, stands out as a meticulously engineered, high-performance remote control solution for advanced drone operation. Its sophisticated wireless architecture, robust thermal management, and modular design reflect a deep understanding of the demands faced by professional and enthusiast pilots alike. The device’s FCC certification not only affirms its legal status but also underscores its technical merit and reliability. In a rapidly evolving market, the DJI Smart Controller remains a benchmark for integration, performance, and regulatory compliance in wireless drone control technology.