Introduction

The DJI Ronin-M (Model: R-6, RONIN M-TX) emerges as a premier handheld camera stabilization system, engineered specifically for filmmaking professionals striving for cinematic perfection. At its core, the Ronin-M delivers unparalleled stabilization through advanced gimbal technology, enabling filmmakers to capture smooth, jitter-free footage even under demanding conditions. This device has received FCC certification under the ID SS3-HG800TX15, affirming its compliance with stringent US electromagnetic interference (EMI) and radio frequency (RF) emission standards. This certification means that the Ronin-M is legally authorized for sale and use within the United States, providing users with confidence in its regulatory compliance and operational safety.

In this comprehensive analysis, we’ll dissect the Ronin-M’s technical specifications, delve into its advanced internal components through a detailed teardown, and explore key insights from its FCC filing (FCC ID: SS3-HG800TX15). Whether you’re a tech enthusiast, professional filmmaker, or engineer intrigued by the intricacies of high-performance stabilization devices, this in-depth exploration will illuminate the sophisticated technology behind DJI’s renowned Ronin-M stabilizer.

Key Features & Specifications

The DJI Ronin-M offers an impressive array of advanced features and specifications designed for professional-grade stabilization:

Key Features:

- D-Bus/PPM Receiver Supported: Allows compatibility with third-party transmitters and receivers, enhancing operational flexibility.

- Built-in Independent IMU Module: Ensures precise orientation measurement and stabilization accuracy.

- USB Connection: Facilitates firmware updates, configuration, and data transfer.

- Three Operation Modes: Underslung, Upright, and Briefcase modes provide versatile filming angles and handling options.

- DJI Advanced 32-Bit DSP Processor: Delivers rapid, accurate motor control and stabilization responses.

- Motors with Encoders: Offer precise, feedback-driven motor positioning for optimal stabilization.

- 2.4GHz Receiver: Enables reliable wireless control and communication with remote controllers.

Technical Specifications:

- Accessory Power Connections: 12V regulated P-Tap x2, USB 500mW x1, DJI Lightbridge x1

- Operating Temperature: -15°C to 50°C (-5°F to 120°F)

- Mobile Assistant Software Requirements: iOS 6.1+, Android 4.3+

- Control Angle Accuracy: ±0.02°

- Working Current: Static 300mA (@16V), Dynamic 600mA (@16V), Locked Motor Max 10A (@16V)

- Maximum Control Rotation Speed: Pan 90°/sec, Tilt 100°/sec, Roll 30°/sec

- Mechanical Endpoint Range: Pan 360°, Tilt Up 105°/Down 165°, Roll ±110°

- Connections: 2.4GHz Remote Control, Bluetooth 4.0, USB 2.0

Operating Frequencies:

| Frequency Range (GHz) | Output Power (mW) | FCC Rule Part |

|---|---|---|

| 2.415-2.473 | 37 | 15CCC1.1 |

Technology Deep Dive

The Ronin-M leverages advanced wireless technologies, including Bluetooth 4.0 and a 2.4GHz receiver, optimizing seamless communication and control precision. Operating within the 2.4GHz band ensures compatibility with widely-used wireless protocols, offering robust connectivity, reduced interference, and impressive range. Given its moderate output power of 37mW, the device strikes a balance between reliable wireless communication and efficient power consumption, minimizing RF interference risks. The inclusion of Bluetooth 4.0 enhances ease of configuration and seamless interaction with mobile assistant apps, while the 2.4GHz receiver ensures responsive remote control functionality critical for professional filmmaking scenarios.

In-Depth Internal Component Analysis / Teardown

The internal architecture of the Ronin-M showcases DJI’s meticulous engineering philosophy, balancing performance with reliability:

The primary PCB is compact and densely populated, featuring multiple integrated circuits (ICs) likely including microcontrollers or motor drivers essential for precise gimbal stabilization. The careful routing of differential pairs and impedance-controlled traces indicates a design optimized for signal integrity and efficient data communication, critical for accurate motor control. High-quality capacitors and inductors suggest robust power regulation circuits, ensuring stable voltage delivery to sensitive electronics and motors.

Another PCB layer highlights three coaxial connectors, indicative of external antenna connections for high-frequency RF communication, likely within the 2.4GHz band. The gold-plated traces and dense component arrangement underscore DJI’s dedication to reliability and durability, essential attributes for professional filming equipment.

Further internal examination reveals a dedicated control board with a micro USB connector, pin headers, and test points. This board likely manages user interactions, firmware updates, and debugging functionalities, supporting straightforward maintenance and configuration.

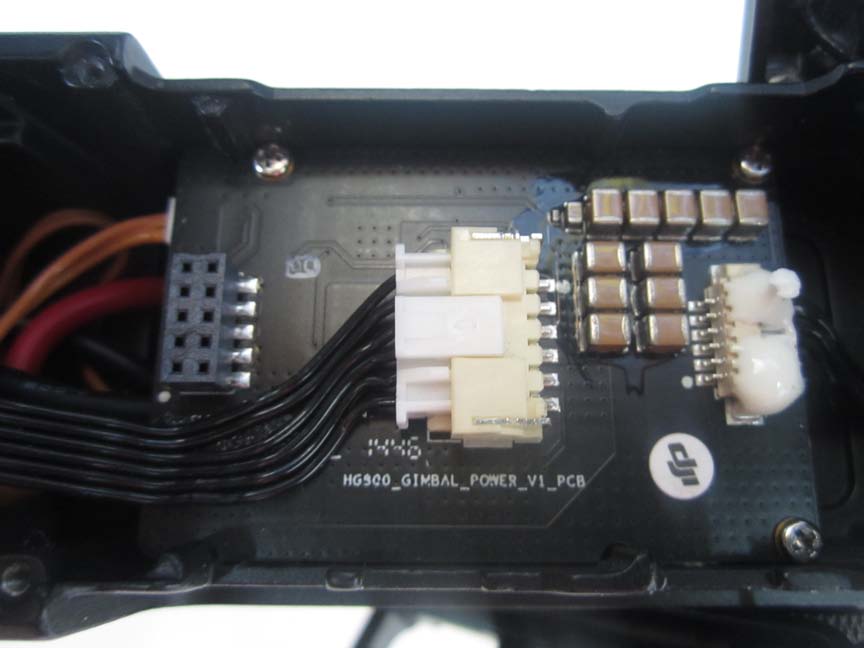

A dedicated power distribution PCB labeled ‘HG900_GIMBAL_POWER_V1_PCB’ incorporates large capacitors for power stabilization, ensuring reliable energy delivery to the gimbal’s motors under varying load conditions.

The power management circuitry prominently features a Wurth Elektronik inductor, underscoring DJI’s commitment to high-quality components capable of handling substantial currents, vital for rapid stabilization responses during dynamic filming scenarios.

An additional PCB emphasizes advanced processing capabilities, likely housing a central microcontroller or SoC essential for stabilization algorithms, sensor data processing, and real-time motor adjustments.

The remote control unit features an integrated whip antenna connected via coaxial cable, ensuring stable RF communication essential for responsive remote operation.

Another PCB includes a voltage regulator and shielded RF components, highlighting DJI’s attention to stable power delivery and interference mitigation.

A PCB trace antenna within a shielded area further demonstrates DJI’s careful design to optimize RF performance and minimize external interference.

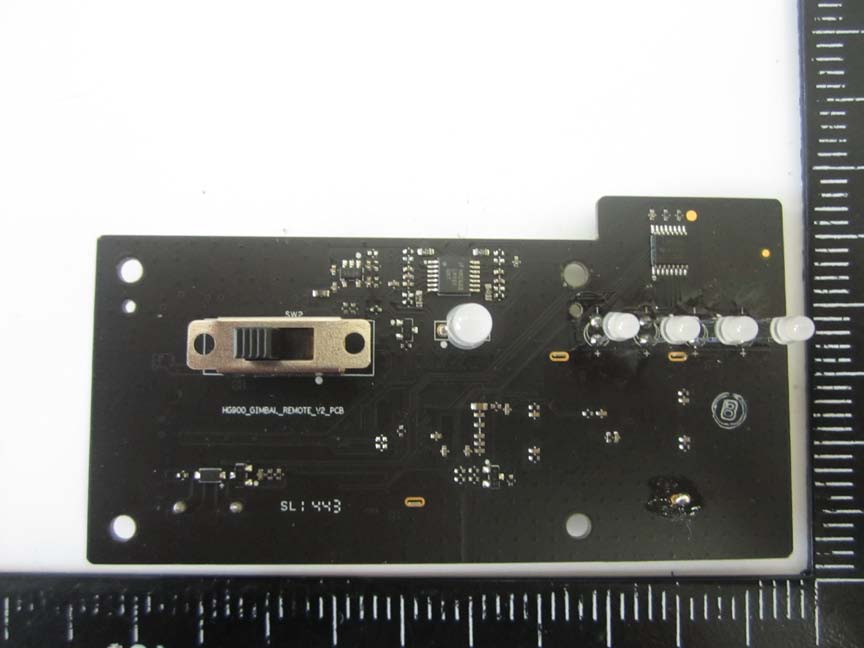

Lastly, a straightforward control PCB with status LEDs and switches indicates user interaction functionalities, providing clear device status feedback and operational control.

Regulatory Insights & FCC Filing

The FCC ID SS3-HG800TX15 confirms Ronin-M’s compliance with US EMI standards, ensuring safe and legal usage. FCC filings typically include comprehensive test reports on RF exposure, electromagnetic compatibility (EMC), internal/external photographs, user manuals, schematics, and block diagrams. According to the provided user manuals, DJI emphasizes critical maintenance procedures, advanced calibration options, and troubleshooting methods (e.g., Auto Tune Stability, SmoothTrack adjustments), underscoring the Ronin-M’s sophisticated yet user-friendly operational design.

Potential Use Cases & Target Audience

Given its advanced stabilization technology—independent IMU, encoder-equipped motors, and powerful 32-bit DSP—the Ronin-M proves ideal for professional filmmakers capturing dynamic scenes, such as action sequences, documentaries, and live events. It’s equally suitable for independent creators and content producers requiring cinematic footage quality for narrative films, commercials, or music videos. Its versatile operation modes (underslung, upright, briefcase) cater to diverse filming scenarios, ranging from low-angle shots in tight spaces to seamless transitions between camera positions during continuous takes.

Conclusion

DJI’s Ronin-M (FCC ID SS3-HG800TX15) stands as a testament to cutting-edge gimbal stabilization technology, combining sophisticated internal electronics, robust wireless communication capabilities, and regulatory compliance assurance. Its meticulous internal design, advanced processing power, and versatile operational modes solidify its position as an essential tool for filmmakers seeking professional-grade stabilization.