Introduction

The DJI Mavic 3E and Mavic 3T, engineered by SZ DJI TECHNOLOGY CO., LTD., represent the pinnacle of enterprise-grade drone technology. Designed for demanding professional applications such as security, patrol inspection, and high-precision mapping, these drones combine powerful imaging systems, robust safety features, and advanced wireless connectivity. With their recent FCC certification under the identifier SS3-M3E2206, the Mavic 3E/3T models are fully authorized for sale and operation in the United States, confirming compliance with stringent radio frequency emission and electromagnetic compatibility standards.

FCC ID SS3-M3E2206 not only ensures the Mavic 3E/3T meet legal and safety requirements, but also underscores their sophisticated engineering—every wireless subsystem, sensor, and component has been rigorously tested to meet regulatory benchmarks. In this article, we’ll delve into the Mavic 3E/3T’s key features, technical specifications, wireless capabilities, and internal hardware. We’ll also explore regulatory insights from the FCC filing and highlight practical use cases that showcase why these drones are trusted by professionals worldwide.

Key Features & Specifications

Standout Features

The DJI Mavic 3E/3T are purpose-built for enterprise users, integrating cutting-edge technology to maximize versatility, safety, and performance:

- Omnidirectional Vision Systems: Equipped with upward, downward, and horizontal sensors, these drones deliver full 360-degree environmental awareness, enabling advanced obstacle detection and avoidance for safe indoor and outdoor flight.

- Multi-Camera Payloads:

- Mavic 3E: Features a powerful 4/3″ CMOS wide camera (20 MP effective pixels) for high-resolution imaging.

- Mavic 3T: Integrates a thermal camera (uncooled VOx microbolometer) and a 1/2″ CMOS wide camera (48 MP), plus a 12 MP tele camera, providing unmatched versatility for inspection and search missions.

- Built-in Microphone and Speaker: Facilitates two-way audio, critical for search and rescue, site management, or law enforcement operations.

- Three-Axis Gimbal Stabilization: Ensures smooth, blur-free footage and precise imaging, essential for mapping and documentation.

- O3 Enterprise (OCUSYNC) Transmission: Delivers ultra-reliable, low-latency video and command links up to 15 km, even in challenging RF environments.

- DJI AirSense: Proactively detects nearby manned aircraft, enhancing operational safety.

- Remote Controller: Features integrated O3 Enterprise transmission and advanced GNSS support (GPS, Galileo, GLONASS), with a robust 3-hour operating time.

Technical Specifications

Flight and Imaging Capabilities:

– Takeoff Weight (with propellers):

– Mavic 3E: 915 g

– Mavic 3T: 920 g

– Max Horizontal Speed:

– 21 m/s (Sport)

– 19 m/s (Sport, EU)

– 15 m/s (Normal)

– 5 m/s (Cine)

– Gimbal Angular Vibration Range: ±0.007°

– Gimbal Controllable Tilt: -90° to +35°

– Infrared Temperature Measurement Accuracy (M3T): ±2°C or ±2% (whichever is larger)

Wireless and Connectivity:

– Wi-Fi Standards: 802.11 a/b/g/n/ac/ax

– Wi-Fi Frequency Bands:

– 2.400–2.4835 GHz

– 5.150–5.250 GHz

– 5.725–5.850 GHz

– Bluetooth: Bluetooth 5.1

Camera Systems:

– Mavic 3E Wide Camera: 4/3″ CMOS, 20 MP

– Mavic 3T Thermal Camera: Uncooled VOx Microbolometer

– Mavic 3T Wide Camera: 1/2″ CMOS, 48 MP

– Mavic 3E/3T Tele Camera: 1/2″ CMOS, 12 MP

Battery and Endurance:

– Intelligent Flight Battery Capacity: 5000 mAh

– Max Hover Time (no wind):

– Mavic 3E: 39 min

– Mavic 3T: 38 min

– Max Flight Time (no wind):

– Mavic 3E: 45 min

– Mavic 3T: 44 min

Remote Controller:

– GNSS Support: GPS, Galileo, GLONASS

– Operating Time: 3 hours

These specifications empower the Mavic 3E/3T to deliver extended flight times, ultra-stable imaging, and outstanding wireless range—key requirements for enterprise and industrial operations.

Operating Frequencies

The DJI Mavic 3E/3T (FCC ID SS3-M3E2206) operates across a wide spectrum of frequencies, as detailed in its FCC documentation. These frequencies support robust wireless communications for command, control, and video transmission, ensuring both range and reliability in demanding environments.

| Frequency Range (GHz) | Output Power (mW) | FCC Rule Part |

|---|---|---|

| 2.4035-2.4695 | 73.5 | 15CCC1.12.4035 |

| 2.4525 | 392.6 | 15CCC1.72.4225 |

| 2.4525 | 392.6 | 15CCC3.75.156 |

| 2.4625 | 502.3 | 15CCC1.62.4125 |

| 2.4625 | 502.3 | 15CCC3.62.4225 |

| 2.4675 | 400.9 | 15CCC1.52.4075 |

| 2.4675 | 400.9 | 15CCC3.52.4082 |

| 2.4685 | 69.7 | 15CCC1.32.4055 |

| 2.4685 | 69.7 | 15CCC3.32.4075 |

| 2.4695 | 73.5 | 15CCC3.12.40512 |

| 2.47112 | 69.7 | 15CCC1.22.40512 |

| 2.47112 | 69.7 | 15CCC3.22.4055 |

| 2.4712 | 69.5 | 15CCC1.42.4082 |

| 2.4712 | 69.5 | 15CCC3.42.4125 |

| 5.245 | 56.1 | 15ECC |

| 5.8295 | 415 | 15ECC |

| 5.8395 | 326.6 | 15ECC |

| 5.8445 | 46.5/328.1 | 15ECC |

| 5.8472 | 49.4 | 15ECC |

| 5.84812 | 50.8 | 15ECC |

| 5.161-5.24 | 53.5 | 15ECC |

| 5.17-5.23 | 52 | 15ECC |

| … | … | … |

These allocations enable the drone to utilize both 2.4 GHz and 5 GHz bands for Wi-Fi and proprietary OcuSync transmission, enhancing resistance to interference and maximizing operational flexibility.

Technology Deep Dive

The DJI Mavic 3E/3T leverages a sophisticated wireless architecture, integrating Wi-Fi 6 (802.11ax), Bluetooth 5.1, and DJI’s proprietary O3 Enterprise (OcuSync) transmission. The use of dual-band (2.4 GHz and 5 GHz) wireless not only boosts range and data throughput but also enables dynamic channel selection to mitigate interference from crowded RF environments—a critical advantage for operations in urban or industrial areas.

Bluetooth 5.1 provides low-energy, short-range communication, likely used for device pairing, proximity-based features, or accessory integration. The high output power levels registered in the 2.4 GHz and 5.8 GHz bands support long-range, low-latency video streaming and command/control links, essential for real-time situational awareness and mission-critical reliability.

The absence of cellular technology (as reflected by the equipment class) channels all communication through robust, license-free ISM bands. This design choice ensures compliance with global standards while delivering the flexibility and performance enterprise users demand. Test reports confirm that the radio modules meet FCC limits for emissions and power, safeguarding both operational safety and regulatory conformity.

In-Depth Internal Component Analysis / Teardown

A close examination of the Mavic 3E/3T’s internal hardware reveals meticulous engineering, with each subsystem optimized for performance, reliability, and serviceability.

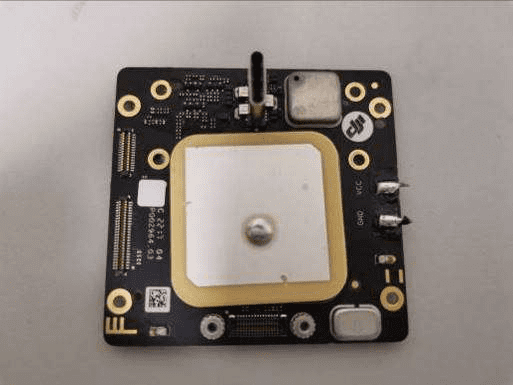

The first component photograph provides a detailed look at the drone’s GNSS receiver module. Dominating the PCB is a large ceramic patch antenna, centrally positioned for optimal satellite signal reception across GPS, GLONASS, and BeiDou bands. The surrounding gold-plated vias and ENIG finish ensure excellent signal integrity and reliability, while the prominent metal shield can houses the sensitive RF front-end, protecting against electromagnetic interference. The presence of a crystal oscillator and robust power filtering capacitors highlights the focus on stable, precise satellite tracking—crucial for the drone’s autonomous flight and navigation. Multiple fine-pitch FPC connectors interface this module with the main flight controller, reflecting a modular, service-friendly design. This GNSS module is a cornerstone of the Mavic 3E/3T’s navigation accuracy and operational safety.

The next image reveals a compact sensor or indicator module, exemplifying DJI’s approach to miniaturization and integration. The small, high-quality PCB is connected via a flexible cable, allowing installation in tight spaces—potentially near the gimbal or obstacle sensing array. A single prominent IC, likely a sensor or LED driver, dominates the board, with minimal supporting components, indicating low power consumption and a specialized function. The lack of RF elements or heavy shielding suggests this board is dedicated to sensory input or status output rather than communication. Its modular, gold-plated design ensures reliable connectivity and straightforward replacement, supporting the drone’s advanced perception systems or user interface features.

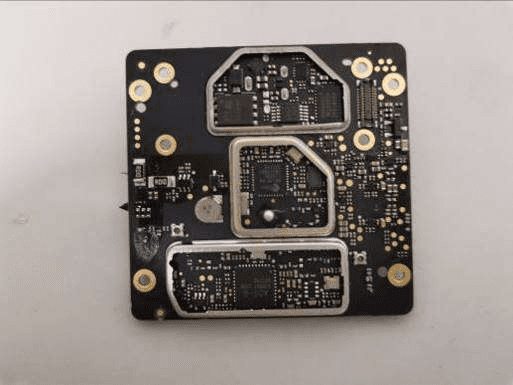

A densely populated PCB is showcased in the following image, most likely responsible for core processing or memory functions. At its center are two large BGA-packaged ICs, indicative of a main processor (such as a flight control SoC or image processor) paired with high-density memory. The multi-layer black PCB, with extensive via placement and robust grounding, is engineered for high-speed data handling and EMI suppression. Multiple power regulation components and test points reflect careful management of sensitive analog and digital subsystems. The gold-fingered connector suggests this board interfaces with major system modules, ensuring high-bandwidth data and power transfer. This board is central to the Mavic 3E/3T’s ability to process high-resolution imagery, execute real-time flight algorithms, and manage complex mission profiles.

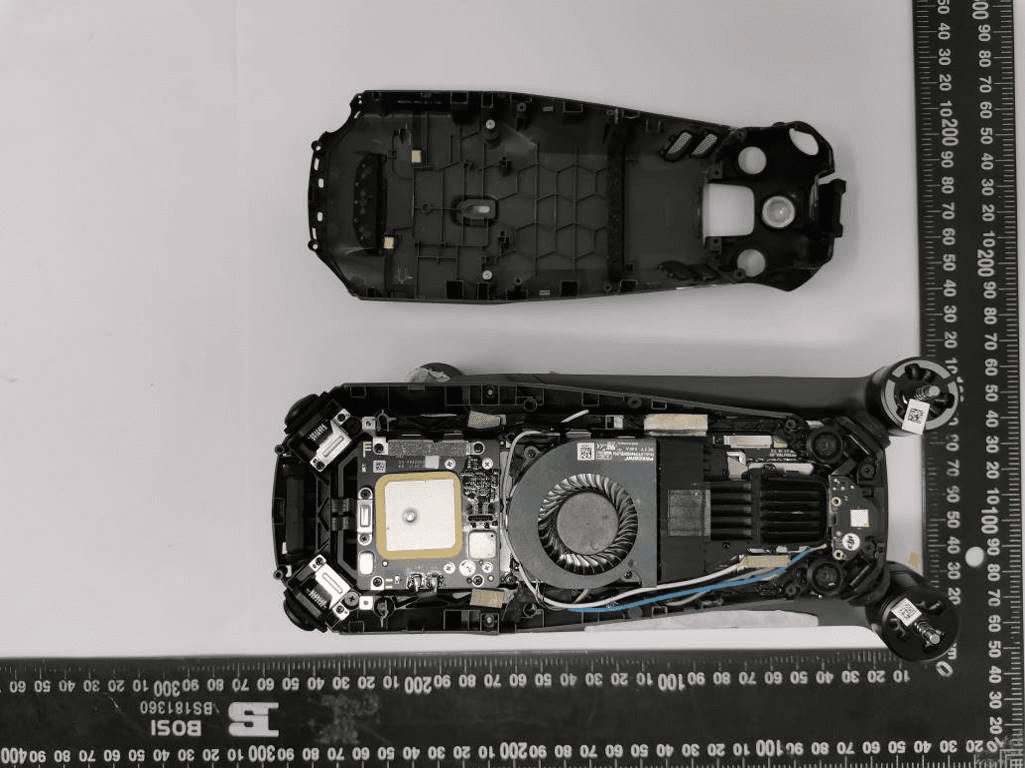

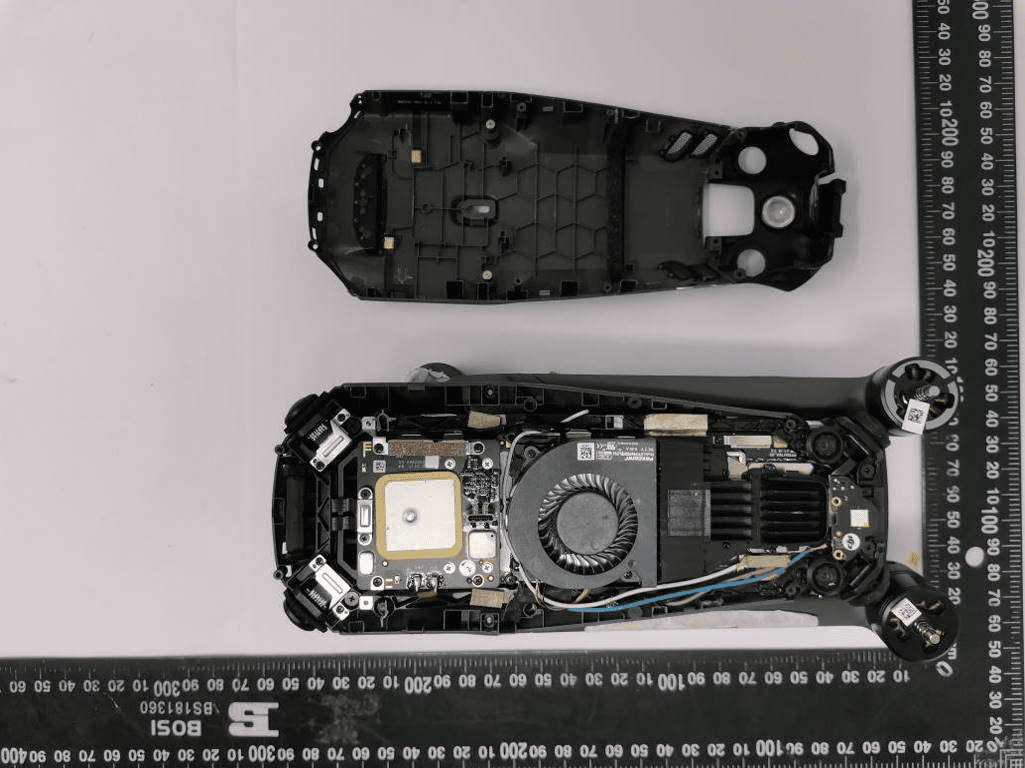

Another internal photograph uncovers the drone’s main PCB, cooling system, and internal structure. The left side features a prominent GNSS patch antenna for precise positioning, while the central region is dominated by a substantial heatsink and fan assembly—evidence of significant computational power and heat generation, likely from an advanced SoC. Multiple FPC connectors and wire harnesses facilitate connections to cameras, sensors, and propulsion systems. The use of multilayer PCB technology, extensive EMI shielding, and active cooling exemplifies DJI’s commitment to reliability and performance under demanding workloads. This section integrates the drone’s power distribution, flight control, and communication subsystems, forming the backbone of the aircraft’s intelligent operation.

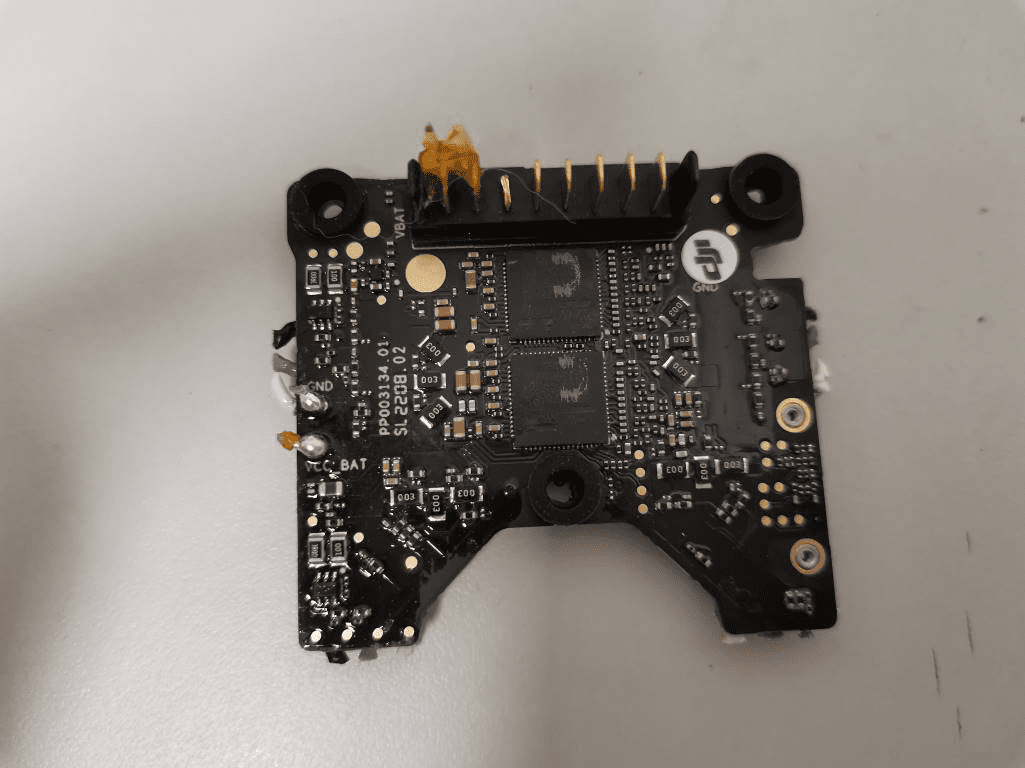

A further close-up highlights a sophisticated, multi-layer PCB with several shielded ICs. The central chip, likely a microcontroller or DSP, orchestrates real-time sensor fusion or flight control logic. The surrounding shielded areas protect RF transceivers and power management circuits, ensuring clean signal routing and robust operation in electromagnetically noisy environments. The dense layout of passives, crystals, and test points supports both manufacturing quality and future maintenance. This board likely manages critical subsystems, such as sensor aggregation, system health monitoring, or communication, reinforcing the drone’s mission-critical reliability.

The final image provides a comprehensive view of the main PCB and associated electronics after the drone’s top cover is removed. The upper left houses a GNSS module with an integrated ceramic antenna, while the rest of the board is populated with power management ICs, motor controllers, and RF modules—most under robust shielding or heatsinks. Multiple FPC connectors, coaxial cables, and thick power traces are visible, reflecting the high current and data demands of the propulsion and communication systems. The active cooling solution is particularly noteworthy, highlighting the high-performance nature of the onboard processing. The overall design balances compactness, modularity, and serviceability, supporting advanced features such as real-time video streaming, obstacle avoidance, and autonomous navigation.

Regulatory Insights & FCC Filing

Certification under FCC ID SS3-M3E2206 is a testament to the Mavic 3E/3T’s compliance with U.S. electromagnetic interference and RF exposure standards, making it fully legal for sale and operation in the United States. Registered with the FCC, the drone’s filing includes critical documentation such as RF test results, electromagnetic compatibility reports, internal and external photographs, user manuals, and technical block diagrams.

These filings confirm that the Mavic 3E/3T meets or exceeds all regulatory limits for radio emissions, power output, and safety. The user manual highlights advanced features such as omnidirectional vision, infrared sensing, automatic obstacle avoidance, and Return to Home functionality. Internal documentation details the sophisticated integration of wireless modules, antennas, and shielding strategies that underpin the drone’s robust and interference-resistant operation. Such comprehensive FCC evaluation not only assures users of compliance but also reflects the high standard of engineering applied throughout the device.

Potential Use Cases & Target Audience

With its advanced imaging, robust wireless connectivity, and enterprise-grade safety features, the DJI Mavic 3E/3T is tailored for a range of demanding professional scenarios:

- Security & Law Enforcement: Rapid aerial surveillance, perimeter monitoring, and incident response benefit from the drone’s omnidirectional vision, thermal imaging (Mavic 3T), and real-time video transmission. The built-in microphone and speaker enable direct communication during critical operations.

- Infrastructure Inspection & Mapping: Surveyors and engineers leverage the high-resolution cameras, precise GNSS, and extended flight time for detailed mapping, 3D modeling, and inspection of hard-to-reach assets such as power lines, solar farms, or bridges.

- Search & Rescue: The combination of thermal imaging, long-range OcuSync transmission, and DJI AirSense for aircraft detection enhances situational awareness and safety during emergency missions. The automatic Return to Home and beacon features ensure the drone’s recovery even in challenging conditions.

These scenarios demonstrate the Mavic 3E/3T’s value for professionals who require reliability, safety, and actionable data from their aerial platform.

Conclusion

The DJI Mavic 3E and Mavic 3T, under FCC ID SS3-M3E2206, set a high bar for enterprise drones—offering advanced imaging, omnidirectional sensing, and reliable long-range wireless connectivity in a compact, robust package. Their FCC certification not only confirms regulatory compliance but also attests to the meticulous engineering and safety built into every subsystem. For professionals in security, mapping, inspection, or emergency response, the Mavic 3E/3T deliver unmatched operational capability and peace of mind, cementing their status as industry-leading tools for the most demanding aerial missions.