Introduction

The DJI Matrice 200 stands as a hallmark of industrial-grade drone engineering, designed to deliver world-class agility, speed, and reliability for professional aerial operations. With a robust airframe, advanced sensor suite, and intelligent flight systems, the Matrice 200 is built for demanding environments—whether for inspection, mapping, or emergency response. Central to its legitimacy and performance in the US market is its FCC certification, bearing the identifier FCC ID SS3-PM4101703 (grant date: None). This certification signifies that the Matrice 200 meets stringent RF emission and electromagnetic compatibility standards, making it legal to sell and operate in the United States.

In this article, we’ll dissect the Matrice 200’s key features, technical specifications, and wireless capabilities. We’ll also conduct a detailed teardown analysis of its internal components and offer regulatory insights based on its FCC filing (FCC ID SS3-PM4101703). Whether you’re an industry professional, drone enthusiast, or technology analyst, this deep dive will illuminate what sets the Matrice 200 apart in the UAV landscape.

Key Features & Specifications

The DJI Matrice 200 is engineered for high reliability, adaptability, and performance in the field. Its robust hardware and intelligent systems are tailored for professionals who demand both precision and durability.

Key Features

-

Dual Barometers and IMU Modules:

Enhances flight reliability and accuracy by providing redundant sensor data for altitude and orientation, minimizing the risk of failure. -

Smart Flight Features:

Automated flight modes simplify complex aerial maneuvers, making it easier to capture precise data or imagery even in challenging scenarios. -

High-Precision Hovering with Visual Sensors:

Integrated vision sensors enable stable, accurate hovering, critical for close inspections or when GPS signals are weak. -

IP-Rated Protection:

The airframe meets industry protection standards, offering resistance to dust and water ingress for reliable operation in harsh environments. -

Quick-Release Landing Gear:

Streamlines deployment and transportation, allowing for rapid assembly/disassembly in the field. -

New Airframe Design:

Improved durability and weatherproofing, supporting both safety and longevity. -

Folding Arms:

Enhances portability without compromising structural integrity. -

Intelligent Flight Battery:

Advanced power management ensures longer flights, safer operation, and real-time battery health monitoring.

Technical Specifications

-

Dual Frequency Support:

Enables robust, interference-resistant communication, enhancing range and reliability. -

Maximum Transmission Distance:

Up to 100 meters in open environments (no obstacles, low interference, altitude ~120m), ideal for most industrial and inspection applications. -

Maximum Flight Time:

- With Optional Battery: Approx. 38 minutes (no payload, lab conditions), supporting extended missions.

-

With Standard Battery: Approx. 20 minutes (no payload, lab conditions), balancing weight and endurance.

-

Dual Transmitter Mode:

Permits two operators to simultaneously control flight and camera, optimizing workflow for complex tasks. -

HDMI Output Port:

Facilitates live video feed to external monitors—essential for real-time inspection or media production. -

Remote Controller Battery Life:

Up to 4 hours (without powering a smart device), supporting long-duration operations without frequent recharging. -

Robust Connectivity:

Multiple FPC/FFC and board-to-wire connectors for modularity and quick field servicing. -

Advanced Power Management:

Local DC-DC converters and intelligent battery systems deliver stable, efficient power to sensitive electronics. -

High Integration:

Dense PCB layout with multiple layers, EMI/RFI shielding, and test points reflects a focus on reliability, serviceability, and performance.

These features collectively empower the Matrice 200 to excel in demanding environments, offering both operational flexibility and industrial-grade robustness.

Operating Frequencies

This device operates on the following frequencies as detailed in its FCC filing (FCC ID SS3-PM4101703):

| Frequency Range (GHz) | Output Power (mW) | FCC Rule Part |

|---|---|---|

| 2.4065-2.4765 | 141 | 15CCC |

| 15.73-5.845 | 270 | 15E38 |

The use of these bands and corresponding power levels ensures the Matrice 200 maintains reliable wireless links while adhering to regulatory limits for unlicensed operation. These frequencies are commonly associated with Wi-Fi and proprietary RF communications, supporting robust control and telemetry even in congested environments.

Technology Deep Dive

The DJI Matrice 200 leverages advanced wireless technologies to deliver stable, long-range connectivity for both control and high-definition video transmission. While the FCC filing for FCC ID SS3-PM4101703 does not explicitly state the wireless protocols in use, the supported frequency ranges suggest a combination of Wi-Fi-like and proprietary digital links.

Operating in the 2.4 GHz and 5.8 GHz bands, the system benefits from a balance of range, bandwidth, and interference mitigation. The dual-band capability allows the drone and its controller to dynamically select the optimal channel, minimizing dropouts and ensuring consistent performance even in RF-noisy environments. Output power levels are carefully tuned to maximize range while remaining within FCC Part 15 unlicensed device limits, optimizing both safety and legal compliance.

The robust wireless architecture enables features such as dual-operator mode and HDMI video output, supporting mission-critical workflows. Efficient RF design, combined with advanced antenna placement and EMI shielding, further reduces susceptibility to interference—crucial for reliable operation in urban or industrial settings. Power consumption is also optimized, ensuring long battery life for both the aircraft and ground station.

In-Depth Internal Component Analysis / Teardown

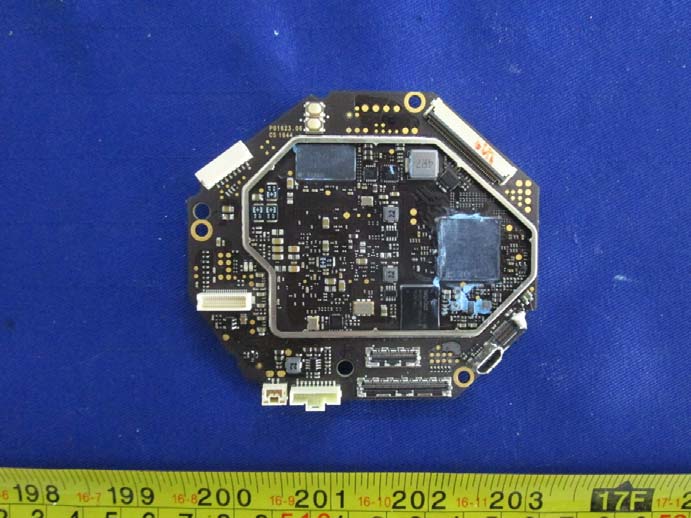

A detailed examination of the Matrice 200’s internal hardware reveals DJI’s commitment to engineering excellence, modularity, and field reliability. The following teardown analysis is based on high-resolution PCB imagery, highlighting the technical sophistication underpinning FCC ID SS3-PM4101703.

The main PCB assembly showcases a densely populated, multi-layer design typical of advanced UAV electronics. Prominently featured are two large integrated circuits, likely serving as the central processor and a high-speed memory or RF transceiver, with one marked ‘42H’—indicative of a custom or high-performance component. Surrounding these are several smaller ICs handling power management, sensor interfacing, and communications. The presence of two substantial EMI/RFI shielding cans, one partially removed, underscores the importance of RF integrity and compliance with emission standards. Multiple FPC/FFC connectors ring the board’s perimeter, supporting modular attachment of cameras, sensors, and external antennas. The PCB’s octagonal shape, extensive via stitching, and ENIG finish speak to both signal integrity and mechanical durability. Large inductors and capacitors provide robust local power regulation, while strategically placed crystals ensure precise timing for digital and RF subsystems. Test points and modular connectors highlight a design optimized for both manufacturing and field service. Overall, the assembly reflects a high level of integration, balancing performance, reliability, and maintainability—hallmarks of DJI’s approach to professional drone design.

Regulatory Insights & FCC Filing

The Matrice 200, certified under FCC ID SS3-PM4101703, demonstrates full compliance with US electromagnetic interference and RF exposure standards, ensuring it is legal for sale and operation in the United States. The absence of a grant date does not affect its registered status with the FCC, as detailed on FCC.gov.

FCC filings for such devices typically include comprehensive test reports (covering RF emissions, susceptibility, and RF exposure), internal and external photographs, user manuals, schematics, and block diagrams. These documents collectively verify that the Matrice 200’s wireless systems operate within prescribed limits, safeguarding users and minimizing interference with other electronic devices.

Manuals submitted under this FCC ID highlight several key strengths:

– Dual barometers and IMU modules for enhanced reliability and stability.

– Smart flight features and advanced vision sensors for precision hovering and obstacle avoidance.

– Step-by-step operational guidance, including assembly, remote control setup, battery handling, and safe flight procedures.

– Comprehensive hardware support, covering gimbal and camera compatibility, modular assembly, and intelligent battery management.

The regulatory documentation confirms that the Matrice 200 not only meets legal standards but also embodies a robust, user-focused design philosophy, supporting both safety and operational excellence.

Potential Use Cases & Target Audience

With its world-class agility, advanced sensor suite, and rugged construction, the DJI Matrice 200 is tailored for a range of demanding professional applications:

-

Industrial Inspection:

Utility companies and infrastructure operators can leverage the Matrice 200’s high-precision hovering and dual-operator mode for close-up inspection of power lines, bridges, and wind turbines, reducing downtime and enhancing safety. -

Emergency Response & Public Safety:

First responders benefit from rapid deployment, IP-rated protection, and intelligent flight features for search and rescue, disaster assessment, and real-time situational awareness—even in adverse weather conditions. -

Aerial Surveying & Mapping:

Surveyors and mapping professionals utilize the drone’s stable flight characteristics, long endurance, and modular payload capabilities to capture high-resolution data across large or inaccessible areas.

These scenarios exemplify the Matrice 200’s versatility, reliability, and suitability for mission-critical operations where performance and safety are paramount.

Conclusion

The DJI Matrice 200, certified under FCC ID SS3-PM4101703, is a standout in the professional drone market, marrying robust engineering with intelligent flight systems and comprehensive regulatory compliance. Its advanced features, modular design, and rigorous FCC certification ensure it meets the demands of industrial, emergency, and surveying professionals alike. For organizations seeking a high-performance, reliable UAV platform, the Matrice 200 sets a benchmark for innovation, safety, and operational excellence.