Introduction

The DJI Agras T25 (Model: 3WWDZ-20B) represents a leap forward in agricultural drone technology, engineered for precision, efficiency, and rugged reliability in demanding field environments. As a professional-grade UAV, the Agras T25 is purpose-built for crop spraying, spreading, and advanced field data collection, empowering modern farms with automation and data-driven insights.

A key milestone for the Agras T25’s entry into the US market is its successful FCC certification under FCC ID SS3-T50A2303. This designation is not just a regulatory formality—it confirms that the device meets stringent US requirements for radio frequency (RF) emissions, electromagnetic compatibility, and safety, making it legal for sale and operation domestically. The FCC process also provides a window into the drone’s technical architecture and wireless capabilities, offering transparency for both regulatory bodies and tech professionals.

In this comprehensive analysis, we’ll dive deep into the Agras T25’s standout features, technical specifications, and the advanced technology that sets it apart. We’ll also examine internal component photographs for a teardown-level look at its engineering, and decode what its FCC filing reveals about its RF performance and regulatory compliance. Whether you’re a drone engineer, agritech specialist, or tech enthusiast, this article will provide authoritative insights into the Agras T25’s design, capabilities, and place in the agricultural drone ecosystem.

Key Features & Specifications

The DJI Agras T25 is meticulously engineered to address the complex needs of modern agriculture, combining robust hardware, intelligent automation, and sophisticated data collection. Below, we break down its main features and technical specifications, highlighting the real-world benefits for professional users.

Key Features

-

Operation Resumption:

The drone can automatically resume tasks where they left off after interruptions, minimizing downtime and ensuring consistent coverage. -

Upgradable Spraying System:

The spraying system supports upgrades with two additional sprinklers, allowing for increased application rates and broader coverage per flight. -

Ultra HD FPV Camera with Tiltable Gimbal:

A high-definition, tiltable gimbal-mounted camera enables real-time field monitoring, precise imaging, and offline field reconstruction, critical for mapping and analytics. -

Advanced Spraying Technology:

- Magnetic Drive Impeller Pump: Ensures efficient, reliable fluid transfer with minimal maintenance.

- Dual Atomized Sprinkler: Achieves fine, uniform droplet distribution for maximum coverage and absorption.

-

Anti-Drip Centrifugal Valve & Solenoid Valve: Prevents unwanted leaks and supports precise on-off spraying control, reducing chemical waste.

-

System Data Protection:

Integrated safeguards ensure operational data integrity and secure mission records, vital for compliance and traceability. -

Modular Spraying & Spreading System:

The drone’s integrated spraying system can be rapidly converted to a spreading configuration, supporting a payload of up to 25 kg. This flexibility enables multi-purpose use—spreading seeds, fertilizer, or granular pesticides. -

Empty Tank Function:

Intelligent detection and notification of empty tanks minimize the risk of incomplete or inconsistent application.

Technical Specifications

- Transmitter Power (EIRP):

- 2.4 GHz: <33 dBm (FCC), <20 dBm (CE/SRRC/MIC)

- 5.8 GHz: <33 dBm (FCC), <23 dBm (SRRC), <14 dBm (CE)

- Operating Frequency:

- 2.4000–2.4835 GHz

- 5.725–5.850 GHz

- Forward Phased Array Radar:

- Power Consumption: 23 W

- Operating Frequency: 24.05–24.25 GHz (compliant with NCC/FCC/MIC/KC/CE)

- Model: RD241608RF

- Rear Phased Array Radar:

- Transmitter Power (EIRP): <20 dBm (NCC/MIC/KC/CE/FCC)

- Operating Voltage: DC 15 V

- Operating Temperature: 0° to 45°C (32° to 113°F)

- Wireless Connectivity:

- Wi-Fi: 2.4000–2.4835 GHz, 5.725–5.850 GHz

- Bluetooth: Present (details not specified)

- Camera:

- Ultra HD FPV camera with tiltable gimbal for automated HD image collection

- Battery:

- Only official DJI flight batteries recommended for optimal safety and performance

These features and specifications ensure the Agras T25 stands out for its precision application, data-driven field management, and operational reliability. The high power output and multi-band operation enable robust wireless connectivity over large agricultural plots, while advanced radar and camera systems support both autonomous navigation and detailed field analysis.

Operating Frequencies

The DJI Agras T25 operates across a range of frequencies, as certified in its FCC filing under FCC ID SS3-T50A2303. These allocations are essential for understanding its communication capabilities, range, and regulatory compliance.

| Frequency Range (GHz) | Output Power (mW) | FCC Rule Part |

|---|---|---|

| 2.4035–2.47112 | 79.4 | 15CCC |

| 12.4055–2.4712 | 81.5 | 15CCC |

| 15.7305–5.8445 | 751.6 | 15ECC |

| 22.4075–2.4675 | 737.9 | 15CCC |

| 25.7285–5.84812 | 87.9 | 15ECC |

| 32.4125–2.4625 | 731.1 | 15CCC |

| 35.7355–5.8395 | 751.6 | 15ECC |

| 42.4225–2.4525 | 549.5 | 15CCC |

| 45.7455–5.8295 | 527.2 | 15ECC |

| 55.7275–5.8472 | 88.7 | 15ECC |

The use of both 2.4 GHz and 5.8 GHz bands supports strong, interference-resistant communication links typical for drone control, telemetry, and video transmission. Output power levels are tuned for compliance with FCC Part 15, ensuring both effective range and adherence to legal limits.

Technology Deep Dive

The Agras T25 leverages a suite of wireless technologies to enable its advanced functionality. The primary communication channels utilize both the 2.4 GHz and 5.8 GHz ISM bands, which are industry standards for Wi-Fi and proprietary drone control links. This dual-band capability enhances connectivity, allowing the drone to maintain robust links even in environments with potential RF interference, such as areas with high Wi-Fi congestion or overlapping agricultural operations.

Bluetooth is also present, likely facilitating short-range device pairing, diagnostics, or auxiliary control. The integration of phased array radar systems—operating in the 24 GHz band—provides the drone with precise obstacle detection and navigation capabilities, supporting autonomous flight and complex field maneuvers.

The specified output power and multi-band operation translate to extended operational range, high data throughput (for real-time HD video and telemetry), and reliable command/control in challenging environments. The use of phased array radar not only improves safety (360-degree obstacle sensing) but also enhances the drone’s ability to operate in diverse weather and lighting conditions.

From the internal documentation and test reports, it’s evident that careful attention has been paid to EMI control, signal integrity, and system robustness. The separation of RF, power, and digital domains on the PCB level further minimizes interference, ensuring stable performance even during high-power operations like spraying or spreading. Overall, the Agras T25’s technology stack is tailored for professional, mission-critical agricultural use.

In-Depth Internal Component Analysis / Teardown

High-Reliability Sensor or Interface Module

A compact black PCB module, approximately 35mm x 18mm, exemplifies DJI’s focus on modularity and field serviceability. The board features a robust multi-pin connector at its center, optimized for secure, vibration-resistant connections—ideal for the harsh operating environment of agricultural drones. Gold-plated mounting holes offer both mechanical stability and electrical grounding, reflecting a design geared for reliability. Although no major ICs or RF components are visible on this side, the wide traces indicate low-speed or power signals, likely serving as an interface for sensors or peripheral systems. The inclusion of a QR code label underscores DJI’s emphasis on traceability and quality control. This module’s construction suggests it plays a critical role as a sensor interface or passive breakout, seamlessly integrating with the Agras T25’s broader system architecture to ensure dependable operation under demanding field conditions.

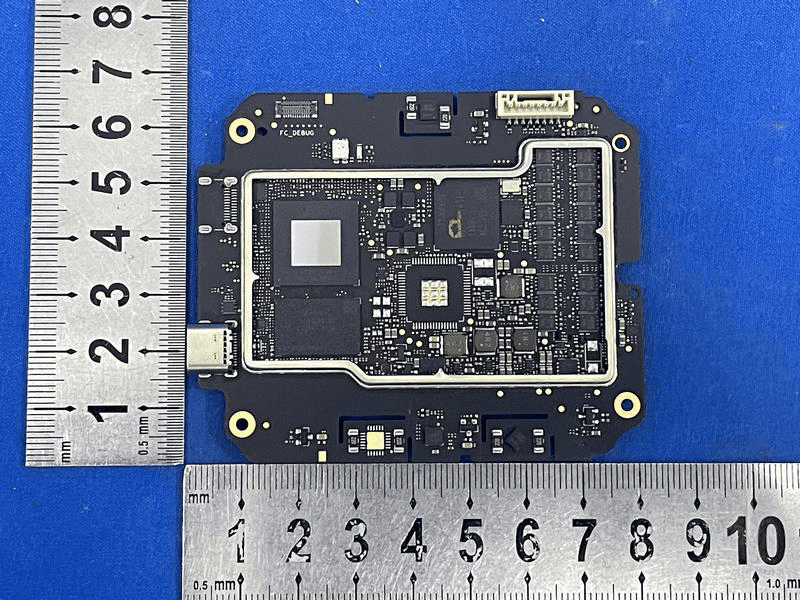

Advanced Flight Controller or Communications PCB

A densely populated, high-density PCB showcases the sophistication behind the Agras T25’s flight control or communications subsystem. Central to the board is a large BGA-packaged SoC or MCU—responsible for real-time flight control, sensor data fusion, or high-speed wireless communication. Adjacent memory chips facilitate rapid data access and storage, while a suite of smaller ICs manage power delivery and analog interfacing. The presence of a white coaxial connector hints at external antenna support for RF-intensive functions such as telemetry or HD video transmission. Meticulous PCB layout, with via-in-pad structures, stitched ground planes, and a shield frame (for EMI minimization), highlights DJI’s commitment to signal integrity and electromagnetic resilience. The integrated switching regulators and bulk capacitors ensure efficient, stable power for mission-critical avionics. Modular connectors along the edges further indicate ease of integration with other drone subsystems, enabling the seamless orchestration of flight, sensing, and communications demanded by advanced agricultural operations.

Power Distribution and Main Controller Board

This substantial black PCB, measuring roughly 13cm x 6cm, is engineered to manage the Agras T25’s significant power and control requirements. Prominent on the board are large inductors, capacitors, and a likely switching regulator IC, forming a high-efficiency DC-DC converter capable of powering motors or other high-current subsystems. Dual robust board-to-board connectors facilitate reliable interconnection with other critical modules, while a smaller FPC/FFC connector supports flexible integration with sensors or displays. The organized layout, clear separation of power and signal domains, and multiple ground vias reflect a thoughtful approach to both electrical performance and EMI suppression. High-value electrolytic capacitors and test points signal a design optimized for long-term reliability and ease of diagnostics. This board’s architecture ensures that the Agras T25 can deliver stable, regulated power across all operational scenarios, underpinning the drone’s ability to execute demanding agricultural tasks with precision and safety.

Integrated RF and Digital Communications Module

A compact, ENIG-finished PCB—measuring approximately 8.5cm x 3.5cm—highlights the Agras T25’s advanced RF engineering. The upper left quadrant features a meticulously designed meandered PCB trace antenna, optimized for 2.4 GHz or 5.8 GHz operation, enabling robust wireless links for control, telemetry, or video data. Multiple medium-sized ICs, likely including a microcontroller and RF front-end chips, are strategically placed to minimize signal loss and interference. The dense layout, numerous ground vias, and separation of RF and digital domains demonstrate careful attention to signal integrity and EMI suppression. Several crystals and oscillators provide precise timing for both data processing and RF transmission. The absence of large power components suggests this board is optimized for low-power, high-reliability communication. Its integration within the Agras T25 ensures seamless connectivity, supporting the drone’s mission-critical wireless functions and reinforcing DJI’s reputation for engineering excellence in the UAV sector.

Regulatory Insights & FCC Filing

The FCC ID SS3-T50A2303 certification is a testament to the Agras T25’s compliance with US electromagnetic emissions standards, a prerequisite for legal sale and operation in the United States. This certification, registered with the FCC, confirms that the device’s wireless transmissions, from control links to radar systems, remain within federally mandated limits for both output power and spectral purity.

FCC filings for the Agras T25 include user manuals, technical test reports, internal and external photos, and detailed documentation on RF exposure and device schematics. These materials provide transparency into the drone’s engineering, manufacturing quality, and adherence to safety and interference requirements.

Key insights from the documentation reveal that the Agras T25 is designed for efficient, large-scale agricultural operations, featuring robust safety systems like omnidirectional obstacle sensing, precise field mapping, and modular payload options. The internal documentation underscores the drone’s emphasis on operational safety, data integrity, and adaptability—attributes essential for compliance with both regulatory and industry standards. Through its FCC certification, the Agras T25 demonstrates not only technical excellence but also a commitment to responsible, legal operation in complex RF environments.

Potential Use Cases & Target Audience

With its advanced feature set and robust engineering, the DJI Agras T25 is ideally suited for a range of professional agricultural applications:

-

Large-Scale Crop Spraying:

Operators managing extensive farmland can leverage the T25’s high payload capacity, upgradable spraying system, and intelligent resumption features for efficient, thorough pesticide or fertilizer application—even across complex terrains or interrupted missions. -

Precision Field Mapping & Data Collection:

Agronomists and agricultural consultants benefit from the ultra HD FPV camera and offline reconstruction capabilities, enabling detailed crop health analysis, yield estimation, and targeted treatment planning. -

Specialized Spreading Operations:

The drone’s rapid conversion to a spreading configuration supports tasks such as seeding, granular fertilizer distribution, or pest control, making it a versatile tool for mixed-crop or specialty farming operations.

These scenarios underscore the Agras T25’s appeal to commercial farmers, agricultural service providers, and research institutions seeking to modernize operations, maximize yield, and ensure regulatory compliance through advanced UAV technology.

Conclusion

The DJI Agras T25 (Model: 3WWDZ-20B) stands at the forefront of agricultural drone innovation, combining high-capacity spraying and spreading, advanced sensor integration, and robust wireless connectivity. Its FCC certification under FCC ID SS3-T50A2303 guarantees not only legal compliance but also adherence to best practices in RF emissions and electromagnetic compatibility. With its modular design, precision engineering, and comprehensive safety features, the Agras T25 is poised to empower the next generation of data-driven, efficient, and sustainable farming. For professionals seeking a reliable, high-performance agricultural UAV, the Agras T25 offers a compelling blend of technological sophistication and operational practicality.