Introduction

The DJI AGRAS T10 stands at the forefront of agricultural drone technology, designed to revolutionize aerial spraying operations for modern farms. As a robust and intelligent UAV, the AGRAS T10 brings precision, safety, and efficiency to crop management, offering features tailored for large-scale and specialty agriculture. Its advanced radar systems, high-performance spraying capabilities, and intelligent operation planning cater to the demanding needs of agricultural professionals and operators.

A key milestone in its deployment is the FCC certification under FCC ID SS3-RD2424R. This certification ensures the AGRAS T10 meets stringent U.S. standards for radio frequency (RF) emissions and electromagnetic compatibility, making it legal for sale and use within the United States. This article provides a comprehensive analysis of the DJI AGRAS T10, delving into its standout features, technical specifications, wireless technologies, and a detailed teardown of its internal components—offering an expert perspective for those evaluating this advanced agricultural drone.

Key Features & Specifications

The AGRAS T10 by DJI is engineered with a suite of features that elevate operational reliability, safety, and efficiency in agricultural spraying. Here’s a breakdown of its core capabilities and technical details:

Key Features

- Automatic Bubbles Discharge Function

Prevents air bubbles in the spraying system, ensuring consistent and accurate pesticide or fertilizer application. - Dual Battery Support for Remote Controller

Supports both built-in and external batteries, maximizing field operation time and reducing downtime. - Smart Controller Enterprise with OcuSync Enterprise Transmission

Offers robust, low-latency video and control links, supporting stable operation even at extended ranges. - Centimeter-Level Positioning with Onboard D-RTK

Delivers ultra-precise navigation for repeatable routes and accurate spraying, vital for targeted applications and resource efficiency. - Forward and Backward FPV Cameras & Bright Spotlights

Dual FPV cameras and integrated spotlights enhance situational awareness and operational safety during both day and night missions. - Dual-Layer Protection for Core Components

Ensures critical electronics are shielded from dust, moisture, and electromagnetic interference, increasing reliability in harsh field environments. - Terrain Following, Obstacle Sensing, and Circumventing

Advanced radar and sensor systems enable autonomous terrain adaptation, obstacle detection, and avoidance, reducing risks and maximizing coverage. - Intelligent Operation Planning in DJI Agras App

Streamlines mission setup, route planning, and execution, enhancing productivity for operators with varying levels of drone expertise.

Technical Specifications

- Hovering Time:

- Up to 19 minutes (16 kg takeoff weight, 29000 mAh battery)

- 8.7 minutes (26 kg takeoff weight, 29000 mAh battery)

- Nozzle Options:

- Standard: XR11001VS

- Optional: XR110015VS, XR11002VS

- Remote Controller Charging Environment:

- 5° to 40°C (41° to 104°F)

- Radar System:

- Upward Radar Power Consumption: 4 W

- Upward Radar Safety Limit Distance: 2 m

- General Safety Limit Distance: 2.5 m

- Charging Hub Input Voltage:

- 17.3–26.2 V (Intelligent Battery Charging Hub)

- Wireless Capabilities:

- Wi-Fi:

- Wi-Fi Direct, Wi-Fi Display

- IEEE 802.11a/g/n/ac

- 2×2 MIMO support

- Frequency bands: 2.4000–2.4835 GHz, 5.150–5.250 GHz, 5.725–5.850 GHz

- Bluetooth:

- Bluetooth 4.2

- Cameras:

- Resolution: 1280×720, 15–30 fps

- Battery System:

- 29000 mAh, 51.8 V DJI-approved flight battery (BAX501-29000mAh-51.8V)

These capabilities translate into tangible benefits for agricultural professionals: improved spraying accuracy, reduced chemical usage, operational flexibility in challenging terrains, and minimized risks through advanced safety systems.

Technology Deep Dive

The AGRAS T10’s wireless architecture leverages advanced Wi-Fi and Bluetooth technologies to ensure seamless connectivity, robust command and control, and high-quality video transmission. With support for Wi-Fi Direct, Wi-Fi Display, and 802.11a/g/n/ac standards, coupled with 2×2 MIMO, the drone achieves both high data throughput and strong resistance to interference—a necessity in rural or industrial environments where spectrum congestion and long-range requirements are common.

Bluetooth 4.2 provides reliable short-range communication for device pairing and auxiliary controls, minimizing power consumption while maintaining stable links. The array of supported Wi-Fi bands (2.4 GHz and 5 GHz ranges) allows the AGRAS T10 to dynamically adapt to environmental conditions and regulatory constraints, optimizing for range or bandwidth as needed.

The inclusion of phased array antennas and sophisticated RF front-ends (as seen in internal component analysis) further enhances signal quality, enabling features like real-time HD video streaming and precise telemetry. This technological backbone is critical for safe, autonomous operations and supports the intelligent functions—such as terrain following and obstacle avoidance—that set the AGRAS T10 apart in the agricultural UAV market.

In-Depth Internal Component Analysis / Teardown

A close look at the AGRAS T10’s internal hardware reveals DJI’s commitment to engineering excellence, integrating advanced RF, processing, and sensor technologies tailored for demanding agricultural applications. Below, each component photograph is analyzed for its unique contribution to the system.

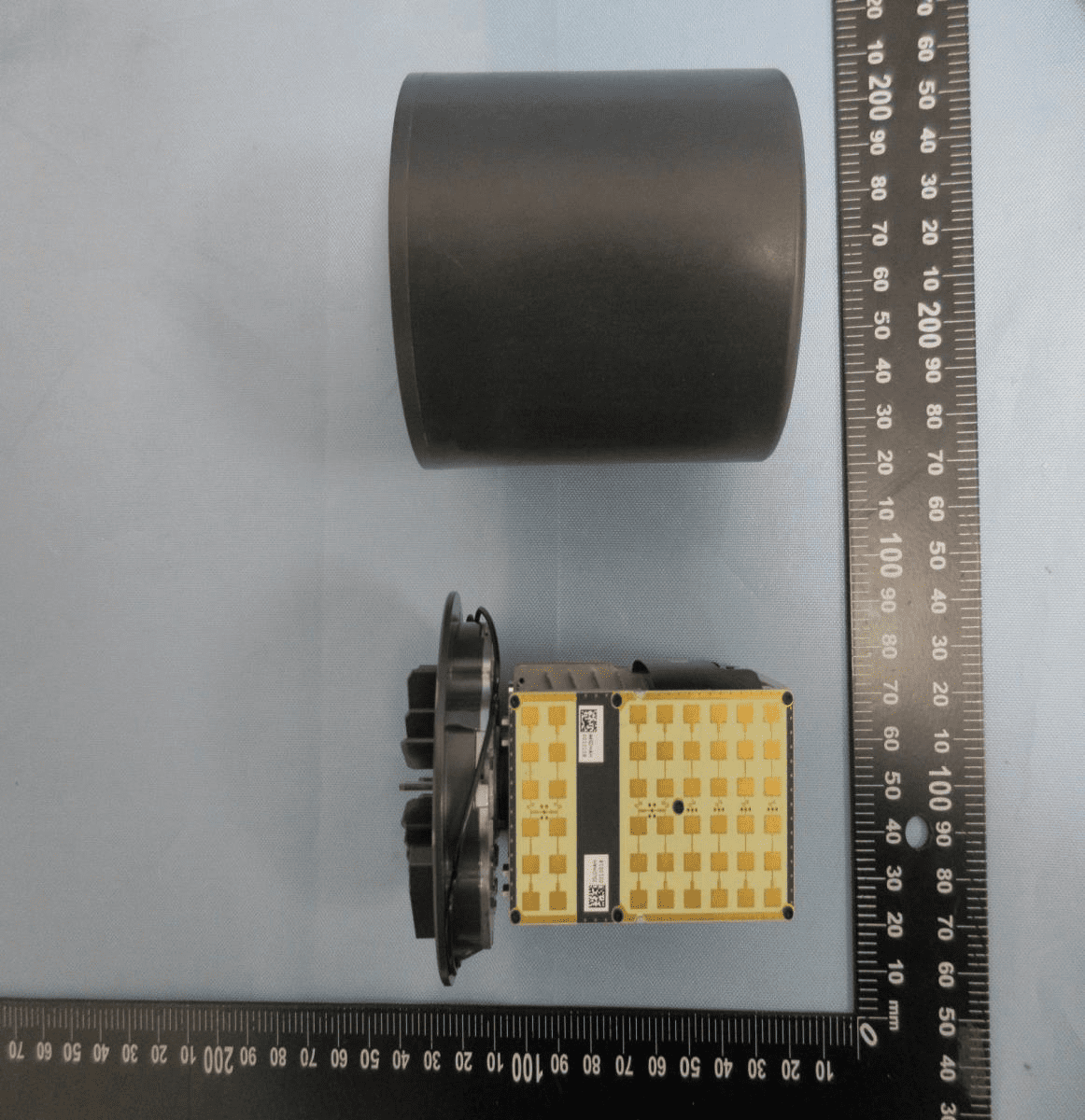

Radar Sensor Module with PCB Antenna Array

Dominating this module is a precision-engineered PCB, characterized by a grid of gold-plated pads forming a sophisticated patch antenna array. This design, typical of high-frequency radar front-ends, is optimized for obstacle avoidance and terrain-following functions. The absence of exposed ICs and the presence of robust enclosure shielding indicate a focus on both RF performance and environmental protection, ensuring reliable operation in the field. The array likely operates in the 24 GHz or 60 GHz band, delivering real-time spatial awareness essential for autonomous flight and precise spraying missions.

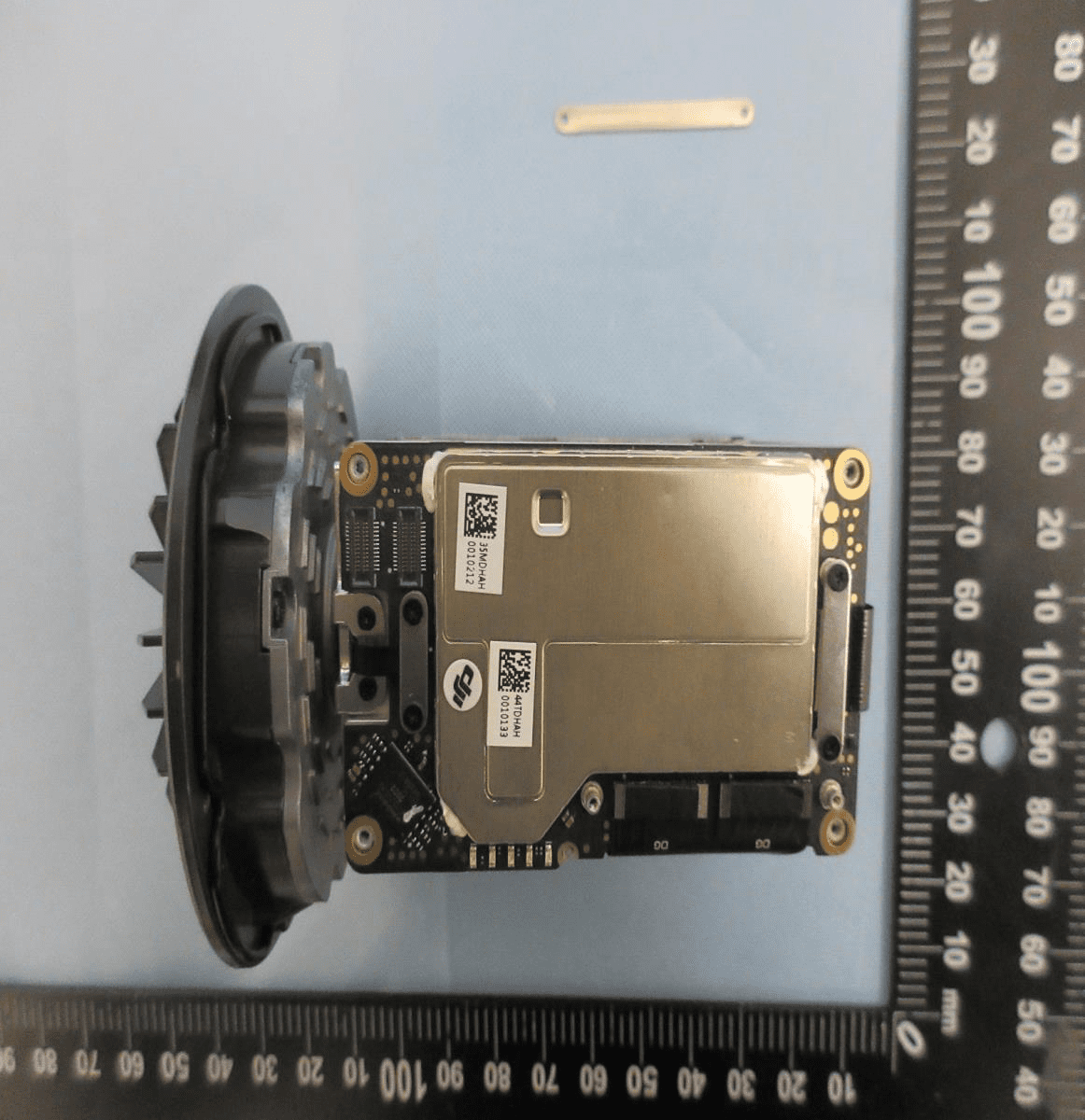

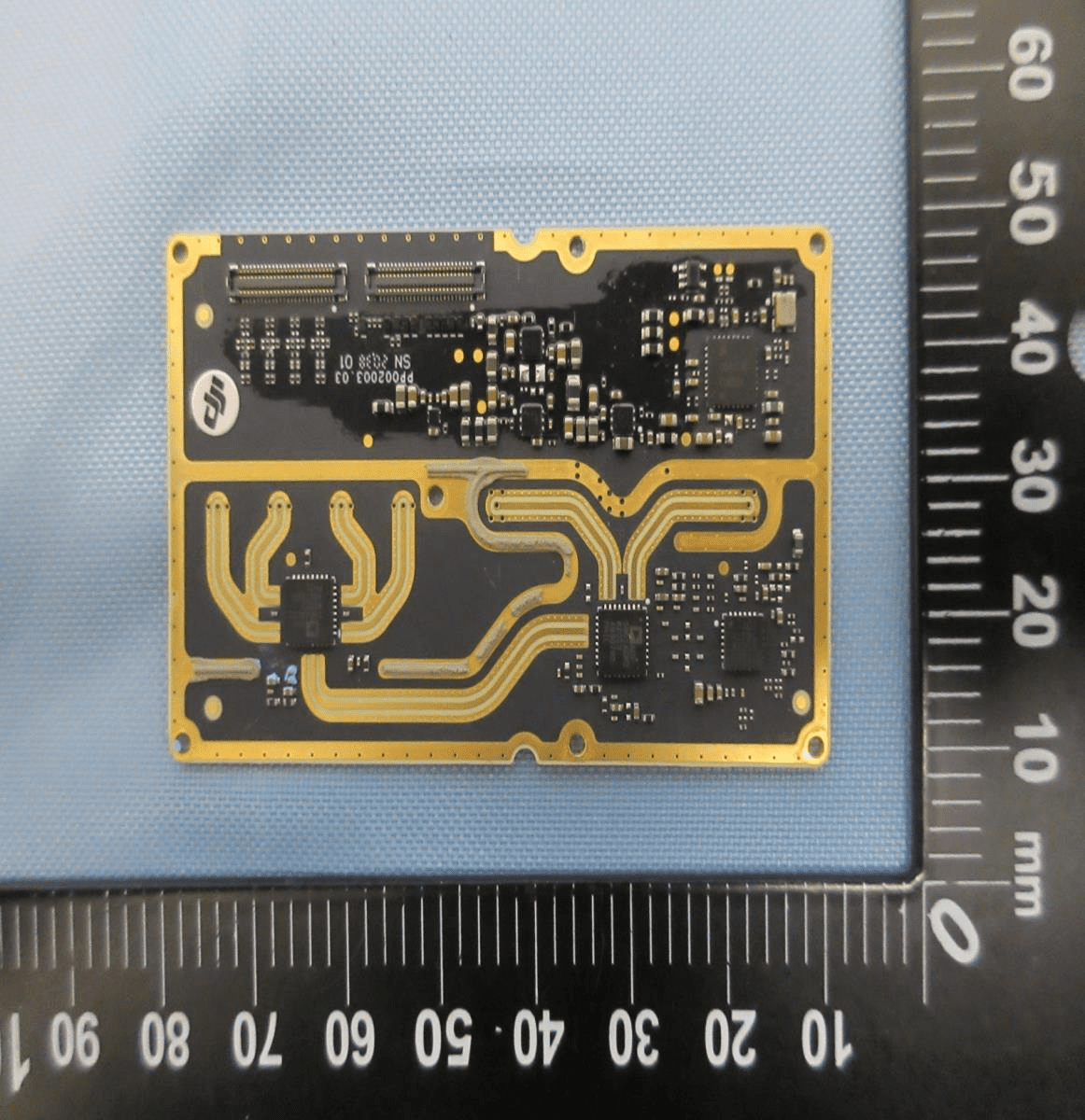

Main Flight Controller and Communication Module

This densely populated, multi-layer PCB is the nerve center of the AGRAS T10, featuring substantial EMI/RFI shielding over critical components. Beneath these shields reside the main processors, RF transceivers, and memory, orchestrating flight control, navigation, and wireless communication. High-density connectors facilitate integration with subsystems, while the mechanical structure suggests effective thermal management. The meticulous grounding and signal integrity strategies highlight DJI’s attention to reliable, interference-free operation—vital for safety-critical drone missions.

Main PCB with extensive EMI shielding, connectors, and thermal management features.

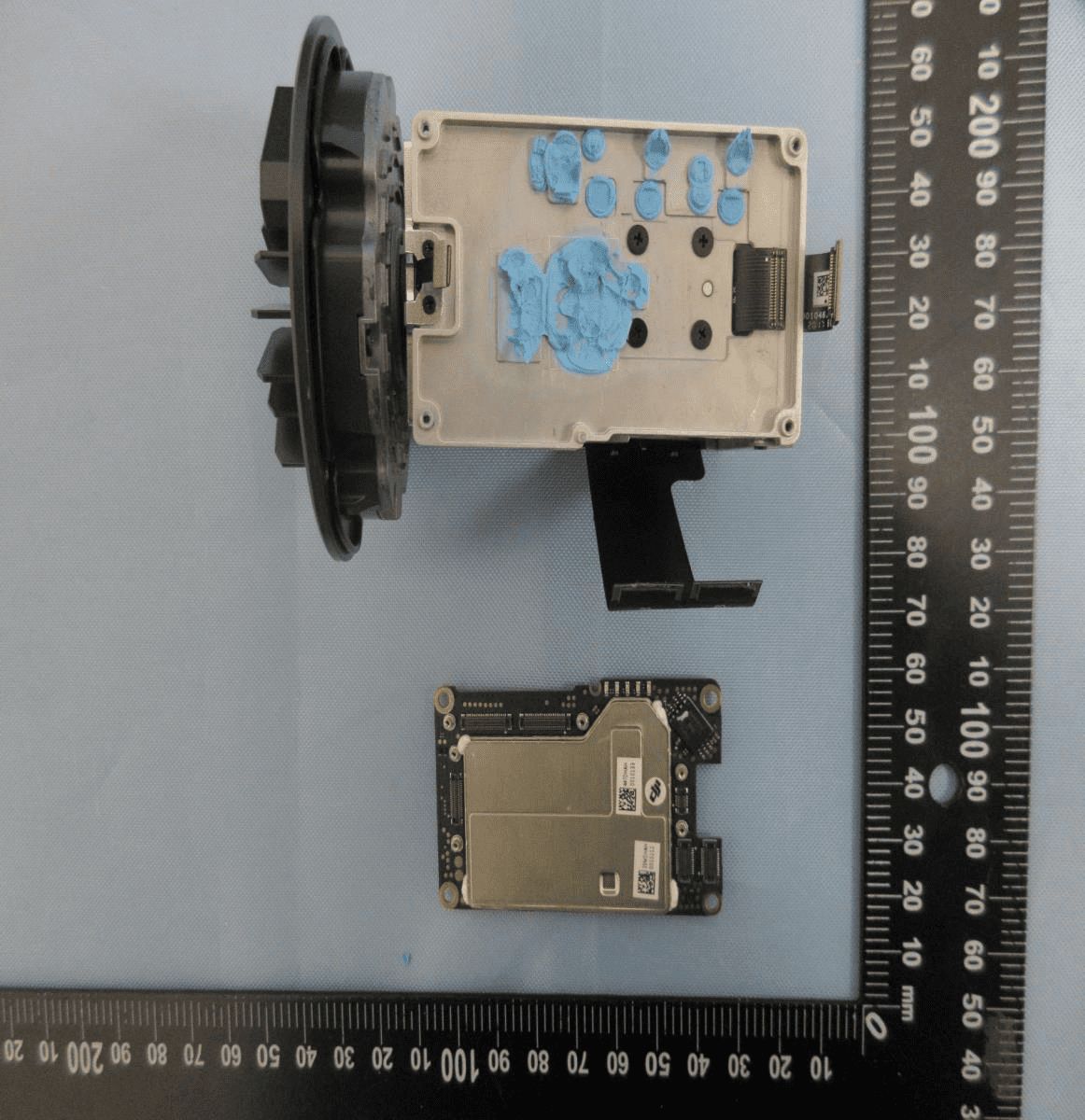

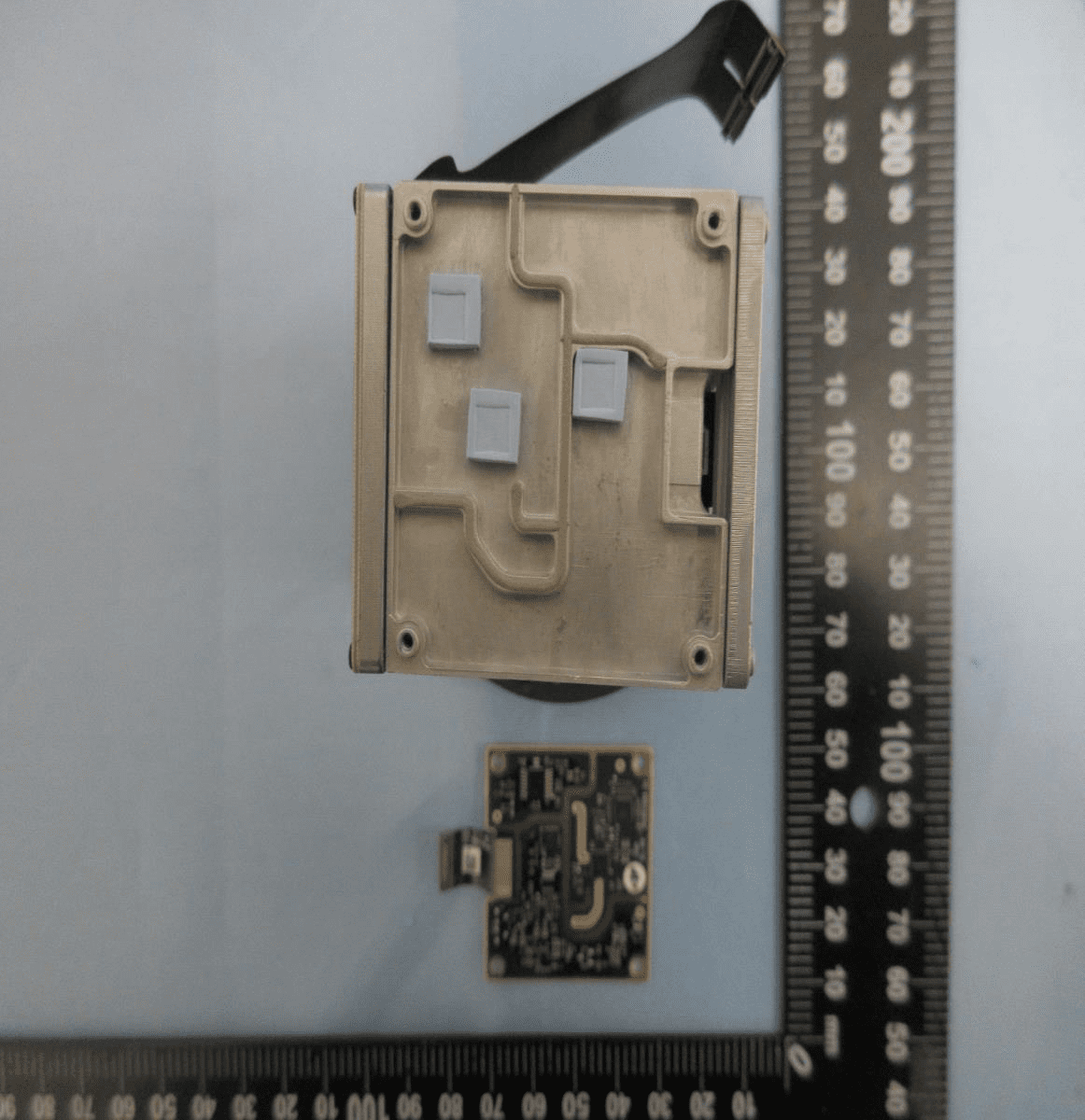

Shielded Processing and RF Module

This compact assembly integrates a PCB and metal housing, with a large soldered shield protecting sensitive digital and RF circuitry. Blue thermal interface material underscores the need for efficient heat dissipation, indicating high-power processing or RF tasks. The flex cable connector and modular design support vibration resistance and serviceability, while the overall build reflects DJI’s emphasis on electromagnetic compatibility and robust field operation—key for reliable flight control and communication.

Shielded PCB module with thermal management for RF and processing circuits.

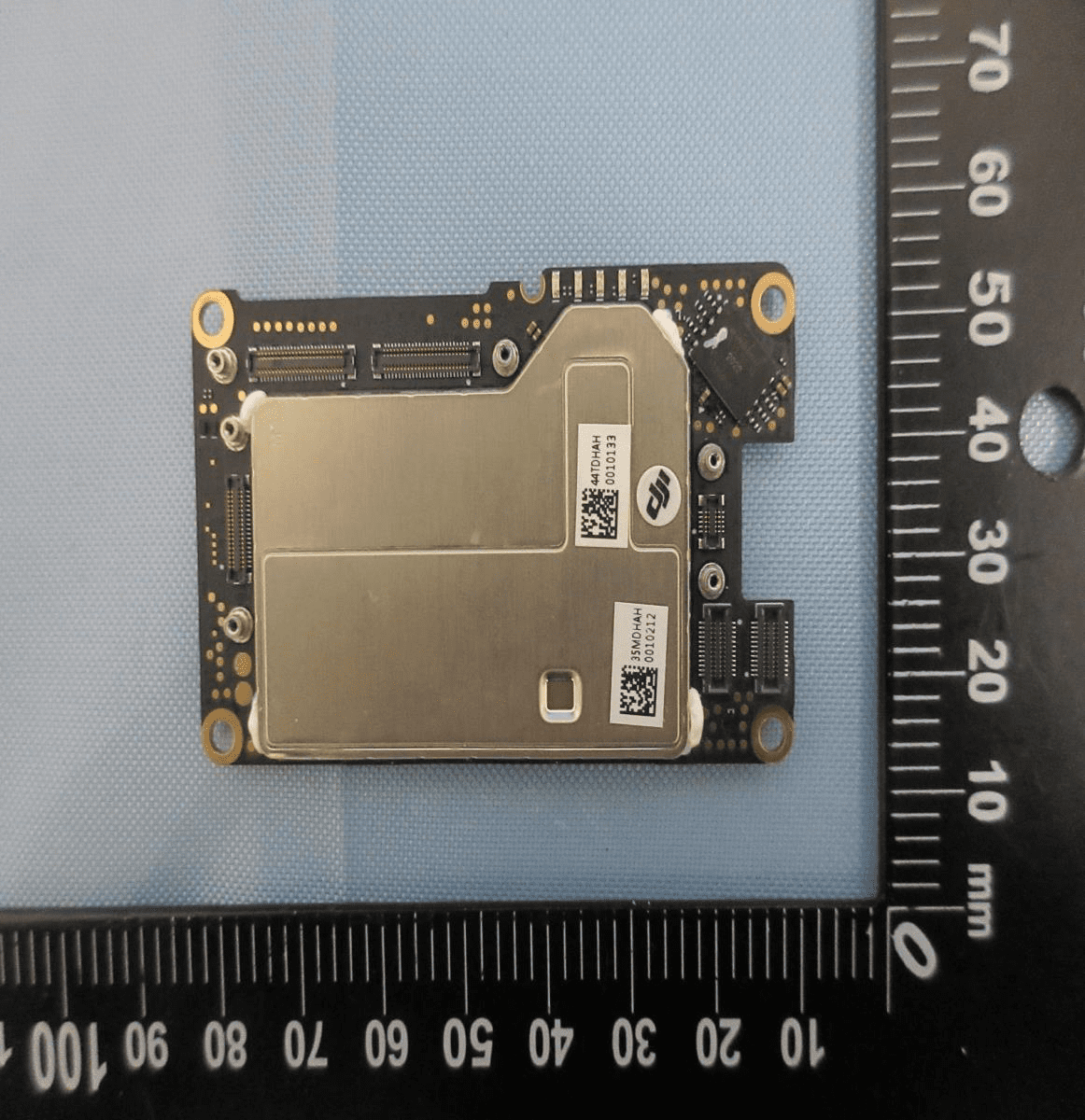

High-Density PCB with Integrated Shielding

A large shield can dominates this PCB, safeguarding a likely array of processors, RF transceivers, and memory. Multiple board-to-board connectors enable modularity, supporting rapid assembly and field servicing. The carefully segregated analog, digital, and RF sections, along with distributed power regulation, signal DJI’s focus on minimizing electromagnetic interference and maximizing operational reliability—attributes crucial for autonomous agricultural drones.

Densely populated PCB with major EMI shield and modular connectors.

Communication Module with Integrated Trace Antenna

This PCB features several medium-sized ICs, likely including microcontrollers and RF front-end chips, complemented by a finely engineered trace antenna—probably for Wi-Fi or Bluetooth. The gold-plated traces and controlled-impedance routing reflect a design optimized for high-speed data and robust wireless links. Board-to-board connectors facilitate integration with other drone subsystems, while the absence of shielding on this side points to PCB-level EMI mitigation and a focus on manufacturability and reliability.

PCB with integrated trace antenna and high-density ICs for wireless communication.

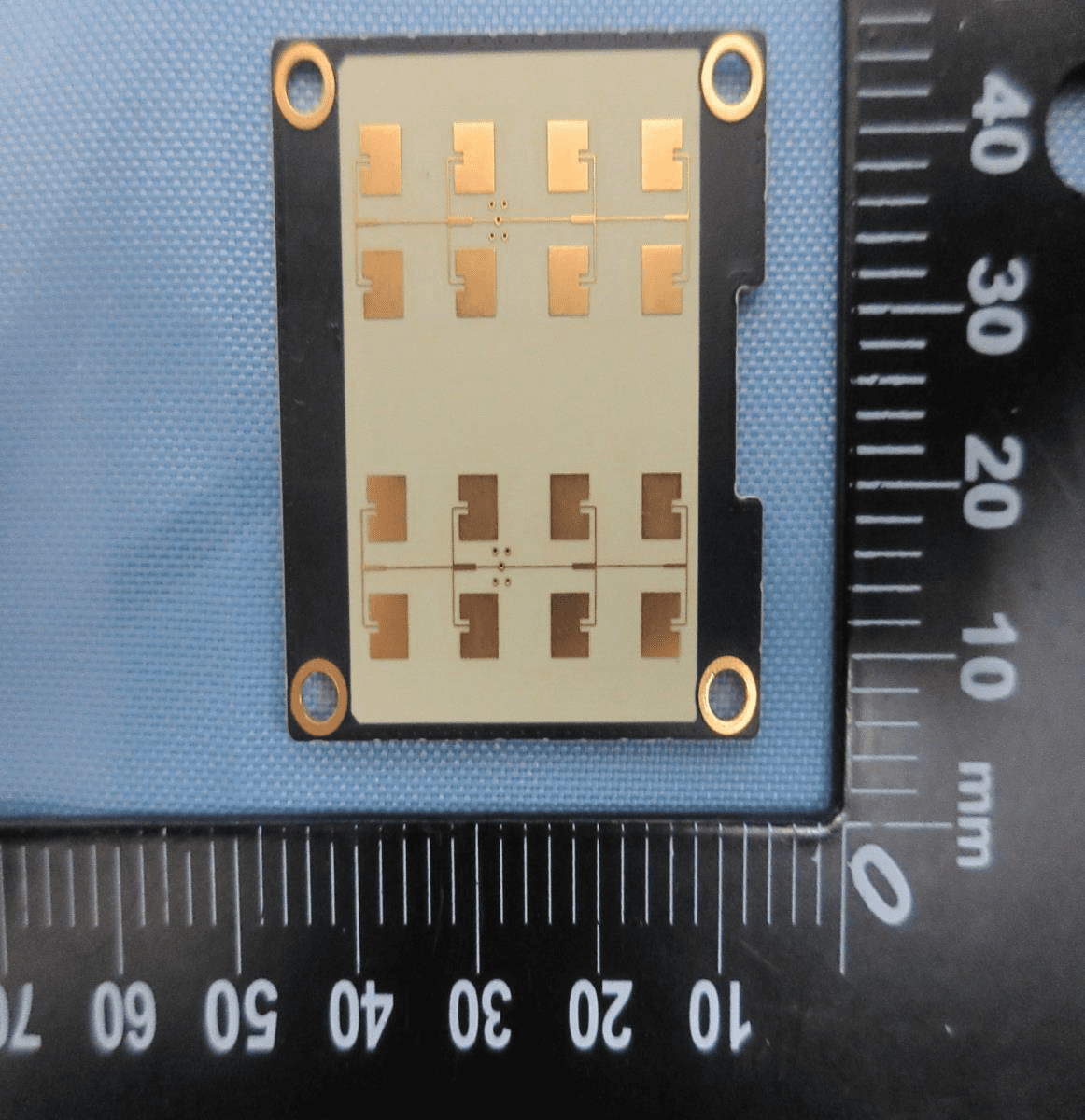

Planar Microstrip Antenna Array

This dedicated antenna PCB, fabricated on high-frequency laminate, showcases eight precise microstrip patches suitable for MIMO or beamforming applications. The array supports robust telemetry, control, or video downlink—critical for maintaining link quality in complex environments. The gold-plated traces and symmetrical layout exemplify meticulous RF engineering, and the presence of mounting holes ensures secure integration within the drone’s structure.

8-element microstrip antenna array for MIMO or directional RF links.

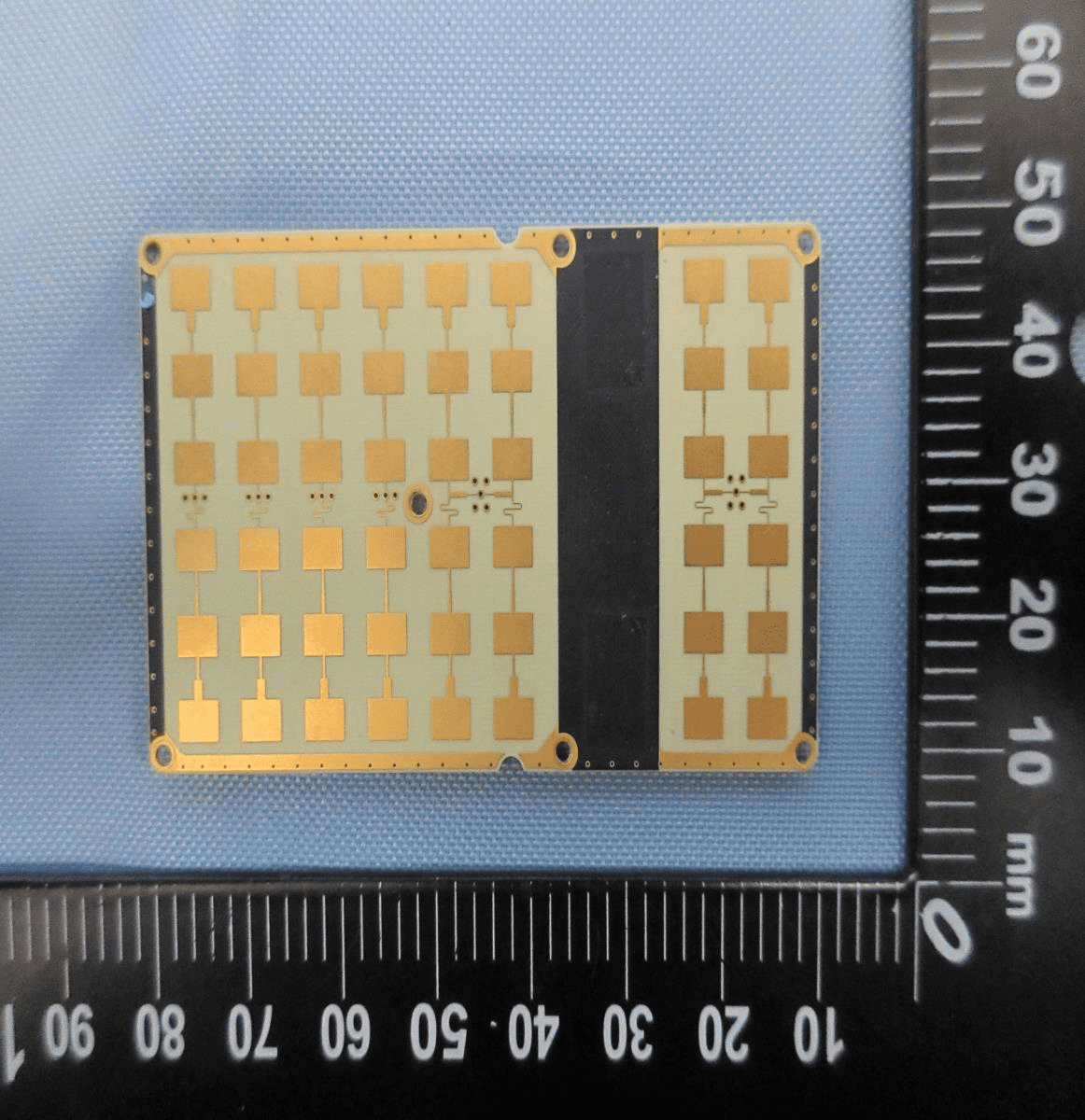

Large Phased Array Antenna Board

Here, a larger PCB reveals a dense grid of gold-plated patch antennas, likely serving as the backbone for high-frequency telemetry, radar, or positioning functions. The careful microstrip feed network and precise via placement enable advanced features like beamforming or spatial diversity, enhancing range and reliability. This passive array, with no visible active components, is a testament to DJI’s investment in cutting-edge wireless technology for agricultural drone operations.

Phased array PCB with gold-plated patch antennas for advanced RF applications.

Shielded Processing Module with Flex Connectivity

This module comprises a compact PCB with several ICs, robust onboard power regulation, and a flex cable connector for seamless integration. The substantial metal enclosure, combined with thermal pads, provides both EMI shielding and efficient heat dissipation. This design is ideal for high-vibration, high-power environments, ensuring the AGRAS T10’s control or sensor systems remain stable and reliable during intensive field operations.

Shielded PCB with flex connector and thermal pads for robust sensor or control tasks.

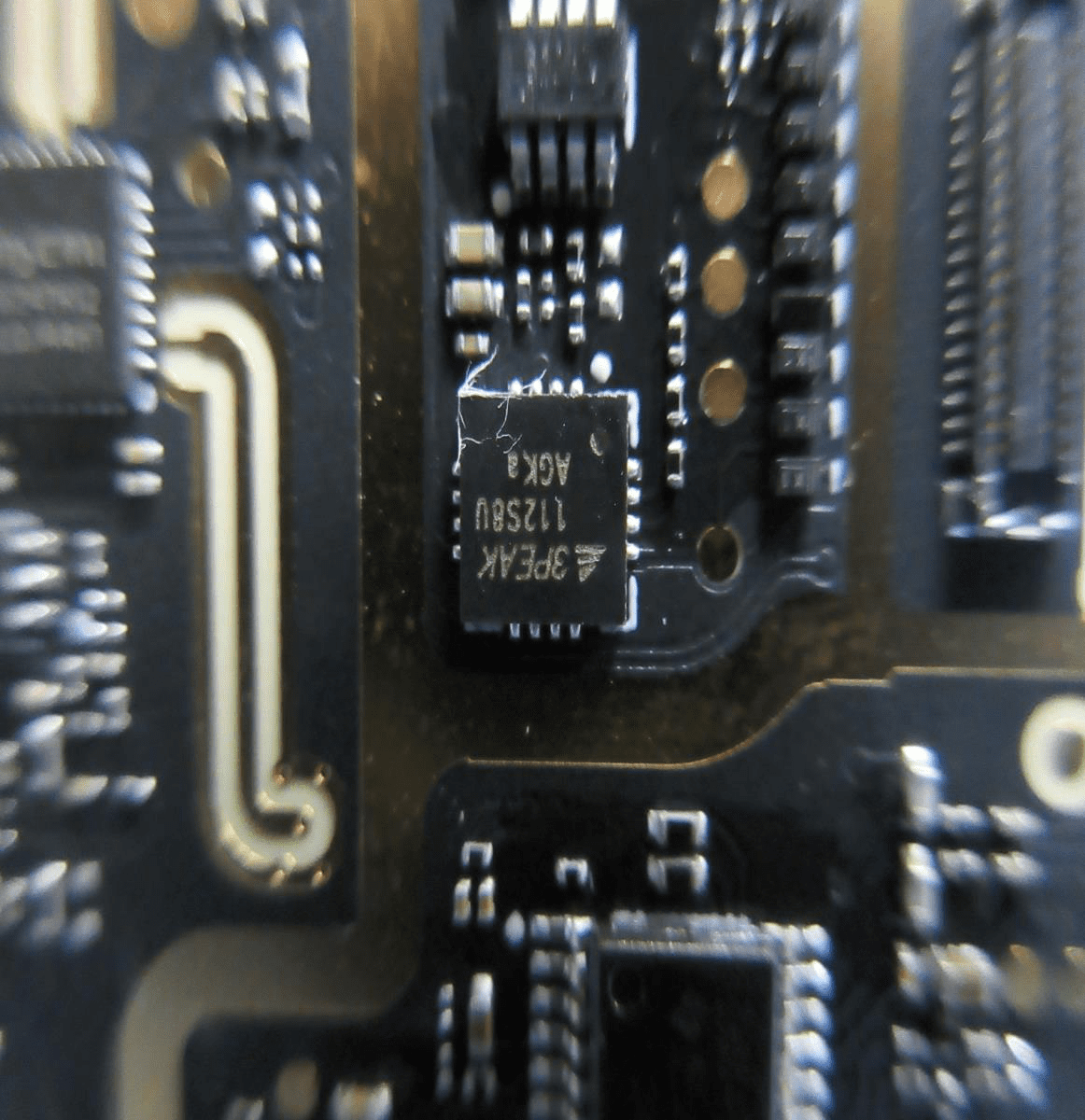

Precision Analog Signal Processing Section

A close-up of a high-density PCB section reveals a prominent 3PEAK analog IC, likely an operational amplifier, surrounded by carefully placed passives and test points. This area is dedicated to precision analog signal conditioning, vital for sensor inputs or feedback systems. The meticulous layout, dense via stitching, and multi-layer design ensure exceptional noise immunity and reliability—attributes essential for accurate control and feedback in the AGRAS T10’s demanding operating environment.

Analog signal processing section with 3PEAK op-amp and dense passive layout.

Regulatory Insights & FCC Filing

The FCC ID SS3-RD2424R certification for the DJI AGRAS T10 is a critical indicator of its compliance with U.S. electromagnetic interference (EMI) and RF emission standards. This certification, registered with the FCC, legally authorizes the device for sale and operation in the United States—ensuring it does not cause harmful interference with other wireless equipment.

FCC filings for the AGRAS T10 typically include comprehensive test reports (covering RF exposure, EMI, EMC), internal and external photographs, user manuals, and technical schematics. These documents confirm the drone’s adherence to safety and performance benchmarks, providing transparency for regulators and users alike.

Insights from the user manual and internal documentation reveal that the AGRAS T10 introduces a novel folding structure, quick-release spray tank and battery system, and advanced radar modules for terrain adaptation and obstacle avoidance. The robust design, with dual-layer protection for core components, reflects a focus on durability and reliability in harsh agricultural environments. Test reports further validate the device’s compliance with stringent RF and EMC requirements, underpinning its reputation for safe and dependable operation.

Potential Use Cases & Target Audience

The DJI AGRAS T10 is purpose-built for agricultural professionals and drone operators seeking to optimize spraying operations with precision and efficiency. Here are key scenarios where the AGRAS T10 excels:

- Large-Scale Crop Spraying:

Operators managing extensive farmland can leverage the AGRAS T10’s intelligent planning, high payload capacity, and centimeter-level D-RTK positioning for consistent and accurate pesticide or fertilizer application—reducing chemical use and operational costs. - Specialty Crop Management:

For vineyards, orchards, or high-value specialty crops, the drone’s advanced radar, obstacle avoidance, and terrain-following capabilities ensure safe and precise spraying in challenging, uneven terrains or around obstacles, minimizing drift and maximizing coverage. - Magnetic Interference-Prone Environments:

The AGRAS T10’s strong resistance to magnetic interference and robust wireless links make it ideal for use near power lines, metal structures, or in areas with high electromagnetic activity, maintaining flight stability and operational safety.

These use cases highlight the AGRAS T10’s adaptability and value for a broad spectrum of agricultural professionals aiming to modernize their crop protection strategies.

Conclusion

The DJI AGRAS T10 (Model: 3WWDZ-10A), certified under FCC ID SS3-RD2424R, stands as a benchmark for innovation and reliability in agricultural drone technology. Its combination of intelligent planning, advanced radar and positioning systems, robust wireless architecture, and meticulously engineered internal components make it a formidable tool for modern farming operations. The FCC certification not only ensures regulatory compliance and safe operation but also underscores DJI’s commitment to quality and performance. For agricultural professionals seeking to elevate productivity and precision, the AGRAS T10 is a compelling investment in the future of smart farming.