Introduction

The Agras T40, developed by SZ DJI TECHNOLOGY CO., LTD. (Model: 3WWDZ-40A), represents a significant leap in agricultural drone technology, designed to meet the demanding needs of modern farming. Engineered for high-efficiency aerial spraying and spreading, the Agras T40 is tailored for agricultural professionals and operators seeking precision, automation, and robust performance in the field.

A pivotal milestone in its journey to market is its FCC certification under FCC ID SS3-T40A2112. This regulatory approval not only certifies that the Agras T40 complies with stringent U.S. RF emissions and electromagnetic interference standards, but also ensures its legality for sale and operation within the United States. For operators, this translates to peace of mind regarding regulatory compliance and device reliability.

In this article, we’ll dissect the Agras T40’s standout features, technical specifications, wireless technologies, and internal components—backed by expert teardown analysis. We’ll also explore the implications of its FCC certification and provide key regulatory insights. Whether you’re an agritech professional, drone engineer, or tech enthusiast, read on for a comprehensive look at this advanced agricultural UAV.

Key Features & Specifications

The Agras T40 is purpose-built to address the challenges of large-scale agriculture, combining intelligent automation, high payload capacity, and advanced sensing into a single robust platform. Below are its defining features and core specifications, with practical insights on their significance:

Key Features

-

Operation Resumption:

Automatically resumes interrupted spraying or spreading missions, minimizing downtime and enhancing field coverage efficiency. -

Fully Autonomous 3D Continuous Obstacle Avoidance:

Utilizes spatial intelligent sensing with binocular vision and phased array digital radar for real-time, 360° environmental awareness—enabling safe, autonomous navigation even in complex terrains. -

Prescription Map Generation for Variable Rate Fertilization:

Integrates with DJI Agras Cloud and P4 Multispectral to generate field-specific prescription maps, optimizing input usage and improving crop yields through targeted application. -

12MP Ultra HD FPV Camera with Tiltable Gimbal:

Delivers high-definition live field imagery for precise navigation, field mapping, and in-flight monitoring, enhancing operator situational awareness. -

Spreading Payload up to 50 kg:

Supports significant payloads for granular spreading, making it suitable for large-scale operations and reducing the number of required sorties. -

System Data Protection:

Incorporates robust data management and redundancy features to secure mission data and ensure operational integrity. -

Dual Atomized Centrifugal Sprinklers:

Ensures uniform droplet distribution and adjustable flow rates, promoting efficient and consistent application of agrochemicals. -

Integrated Spraying System Convertible to Spreading Configuration:

Offers flexibility to switch between spraying and spreading modes, maximizing versatility and return on investment.

Technical Specifications

- Model: 3WWDZ-40A

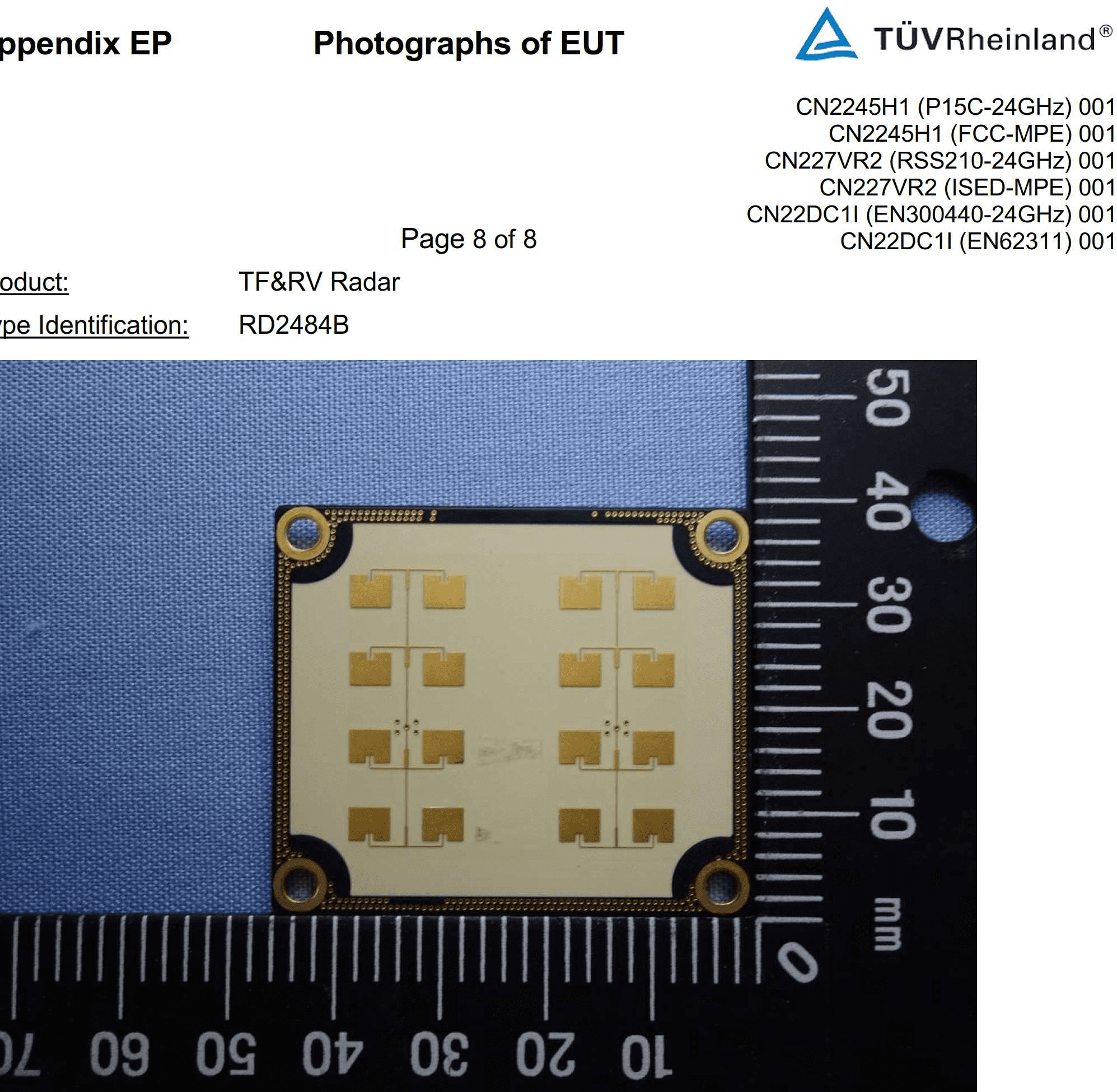

- Phased Array Downward Rear Radar Model: RD2484B

- Intelligent Flight Battery: 30,000 mAh, 52.22 V

- Operating Temperature (Radar): 0° to 45° C (32° to 113° F)

- Flight Parameters Operating Frequency: 2.400–2.4835 GHz, 5.725–5.850 GHz

- Dimensions (Arms Unfolded, Blades Folded): 1580 mm × 1930 mm × 820 mm

- Phased Array Downward Rear Radar Operating Voltage: DC 15 V

Additional Extracted Specifications

- Wireless Connectivity:

- Wi-Fi: 2.400–2.4835 GHz, 5.725–5.850 GHz

-

Bluetooth: Present (details not specified)

-

Camera:

-

12MP ultra HD FPV camera with tiltable gimbal

-

Battery:

- 30,000 mAh, 52.22 V intelligent flight battery

Practical Implications

-

High Payload & Versatility:

Large capacity and convertible systems allow operators to quickly adapt to different agricultural tasks, maximizing productivity per flight. -

Advanced Sensing & Automation:

Autonomous obstacle avoidance and prescription map integration empower precision agriculture, reducing human error and resource waste. -

Robust Build & Environmental Resistance:

High-quality connectors, modular design, and environmental sealing (IPX6K) ensure longevity and reliability in harsh field conditions.

Operating Frequencies

The Agras T40 (FCC ID SS3-T40A2112) operates across a range of frequencies and power levels, supporting its advanced wireless functionality and regulatory compliance. The table below summarizes the primary RF parameters:

| Frequency Range (GHz) | Output Power (mW) | FCC Rule Part |

|---|---|---|

| 2.4035–2.4735 | 69.5 | 15CCC |

| 12.4055–2.4745 | 68.5 | 15CCC |

| 15.7305–5.8445 | 553.4 | 15ECC |

| 22.4055–2.4755 | 628.1 | 15CCC |

| 25.7285–5.8465 | 61.7 | 15ECC |

| 32.4105–2.4715 | 599.8 | 15CCC |

| 35.7355–5.8395 | 660.7 | 15ECC |

| 42.4205–2.4625 | 498.9 | 15CCC |

| 45.7455–5.8295 | 588.8 | 15ECC |

| 55.7275–5.8445 | 61.7 | 15ECC |

These frequencies and power levels are essential for understanding the device’s wireless reach, reliability, and adherence to FCC Part 15 regulations for unlicensed operation.

Technology Deep Dive

The Agras T40 leverages a suite of advanced wireless technologies, including Wi-Fi and Bluetooth, to enable robust communication, remote control, and real-time data exchange. Operating primarily in the 2.4 GHz and 5.8 GHz ISM bands, the drone ensures reliable connectivity for flight control, telemetry, video transmission, and integration with base stations or mobile devices.

The use of dual-band Wi-Fi enhances both range and data throughput, critical for transmitting high-definition FPV camera feeds and real-time sensor data. Bluetooth support, while less detailed in documentation, likely facilitates device pairing and short-range configuration tasks.

The specified frequency ranges and output power levels indicate a strong emphasis on maximizing communication reliability while minimizing interference with other RF devices—a necessity in densely populated or electromagnetically noisy environments typical of large agricultural fields. The design balances high output power for extended range with compliance to FCC regulations, ensuring safe and legal operation.

Test report summaries and internal documentation further highlight the drone’s sophisticated RF engineering, including robust EMC performance and careful antenna design, which are vital for maintaining stable flight and data links even under challenging environmental conditions.

In-Depth Internal Component Analysis / Teardown

Expert analysis of the Agras T40’s internal component photographs reveals a meticulous approach to electronic design, thermal management, and modularity. Each subsystem is engineered for reliability, performance, and ease of maintenance—hallmarks of DJI’s design philosophy.

The photograph displays a partially disassembled electronic module, revealing two densely populated PCBs—one inside a plastic enclosure and the other removed for inspection. The boards are layered with extensive EMI shielding and thermal pads, signaling high-frequency and high-power operation. Large ICs, likely including the main processor and RF transceivers, are protected beneath metal shields, ensuring both signal integrity and EMI suppression. Visible gold-plated RF test points and connectors suggest provisions for external antennas, supporting Wi-Fi, Bluetooth, or proprietary wireless links. Robust FPC/FFC connectors indicate modular interconnectivity with other drone subsystems, while the presence of supercapacitors and power management circuitry underscores the system’s ability to handle significant current loads. The design demonstrates a clear separation of analog/RF and digital domains, with careful attention to grounding and thermal dissipation. Overall, this assembly exemplifies high-reliability electronics, optimized for the demands of UAV flight control and communication.

This view focuses on a section of the drone’s power distribution or motor control PCB, densely populated with robust connectors and wiring harnesses. Thick orange wires, likely carrying high current to motors or batteries, connect via automotive-grade, environmentally sealed connectors—demonstrating attention to both electrical and environmental reliability. Multicolored cables facilitate signal and sensor connections, while locking mechanisms on connectors enhance vibration resistance, critical for aerial platforms. The PCB’s multi-layer construction and heavy copper pours enable efficient power distribution across the system. The modular connector layout allows for straightforward maintenance and replacement of wiring harnesses or PCB sections, supporting long-term durability in harsh agricultural environments. This infrastructure is fundamental to the Agras T40’s ability to deliver consistent power and control to its high-output propulsion and payload systems.

Inside this enclosure, a sophisticated PCB assembly is dominated by a large metal shield, beneath which reside the main processor and RF transceivers. Blue thermal interface pads on the shield and enclosure facilitate efficient heat transfer, a necessity for high-performance computing and wireless operations. Multiple coaxial connectors near the shielded area suggest direct routing of RF signals to external antennas, supporting the drone’s advanced wireless communication and navigation capabilities. The board’s multi-layer construction and high-density layout enable high-speed data handling, while robust edge connectors provide modular integration with other subsystems. Localized power regulation components ensure stable operation of sensitive electronics. The overall build quality, with a focus on thermal and EMI management, reflects a design tailored for reliable, high-throughput processing and communication in demanding UAV applications.

This internal module showcases a compact, high-density PCB housed within a protective enclosure, with blue thermal pads strategically placed over key components for optimal heat dissipation. Several logic and analog ICs are visible, supporting a blend of processing, power management, and sensor interfacing functions. A prominent edge connector enables high-speed communication with other subsystems, while dense via patterns and differential pair routing suggest support for high-speed data transfer and robust signal integrity. Onboard capacitors and inductors facilitate local DC-DC conversion and filtering, stabilizing power delivery to sensitive circuits. The enclosure itself serves as both a thermal and EMI shield, illustrating DJI’s commitment to reliable operation in electrically and thermally demanding environments. This module likely plays a critical role in flight control, navigation, or payload management.

This precision-fabricated PCB antenna array is a cornerstone of the Agras T40’s radar system, specifically the RD2484B phased array radar module. The gold-plated 2×4 patch antenna elements are meticulously arranged for optimal performance at 24 GHz, enabling millimeter-wave radar sensing essential for 3D obstacle avoidance and terrain following. The board’s high-frequency laminate minimizes dielectric losses, while symmetric layout ensures consistent beamforming and spatial resolution. Four mounting holes provide mechanical stability and grounding, facilitating accurate alignment within the drone’s sensor suite. The absence of active components on this side highlights its role as a passive radiating structure, with RF feedlines likely located on the reverse. This antenna array exemplifies high-precision RF engineering, directly enabling the drone’s autonomous navigation and environmental sensing capabilities.

A high-density PCB is presented with thermal pads covering key ICs, indicating a focus on both heat dissipation and EMI containment. The central processor, likely responsible for flight control or sensor fusion, sits beneath the largest thermal pad, while a shielded section houses sensitive RF or high-speed digital circuitry. Multiple large inductors and capacitors provide robust onboard power regulation, supporting stable operation of digital, analog, and RF subsystems. Edge connectors and gold-plated mounting holes enable secure integration and grounding within the enclosure. The presence of crystals and test points facilitates precise timing and diagnostics. The modular design, combined with the enclosure’s dual role as a shield and heat sink, exemplifies DJI’s approach to building resilient, high-performance drone electronics for challenging agricultural environments.

[INTERNAL_IMAGE: Photos-internal-1-5687173_page002_merged003_18fragments.png “High-density control PCB with advanced thermal and EMI design.”]

Regulatory Insights & FCC Filing

The FCC ID SS3-T40A2112 certification is a testament to the Agras T40’s compliance with U.S. electromagnetic interference and RF exposure standards. This approval, recorded by the FCC (Federal Communications Commission), is a prerequisite for legal sale, importation, and operation of the device within the United States.

FCC filings for the Agras T40 provide a wealth of technical documentation—including test reports for RF emissions and exposure, electromagnetic compatibility assessments, internal and external photographs, user manuals, block diagrams, and schematics. These documents collectively verify that the device meets all relevant safety and performance criteria enforced by U.S. regulators.

From the user manual and regulatory documentation, it’s clear that the Agras T40 is engineered as an advanced agricultural drone, prioritizing efficiency, precision, and operational safety. The inclusion of features such as autonomous 3D obstacle avoidance, high-resolution field imaging, and robust environmental sealing further underscores its compliance with both technical and practical standards for professional use. The FCC certification process validates not only the device’s RF characteristics but also its overall suitability for demanding agricultural applications.

Potential Use Cases & Target Audience

The Agras T40 is tailored for agricultural professionals and enterprises seeking to modernize and optimize their field operations. Its advanced capabilities support a variety of real-world applications:

-

Large-Scale Crop Spraying:

Operators managing expansive farms can deploy the Agras T40 to autonomously apply pesticides, herbicides, or fertilizers with precision. The drone’s prescription map integration enables variable-rate application, reducing chemical usage and enhancing crop health. -

Granular Spreading for Variable Rate Fertilization:

Leveraging its 50 kg payload and convertible spreading system, the T40 is ideal for distributing seeds or granular fertilizers efficiently. Integration with multispectral mapping tools ensures targeted delivery based on real-time field data. -

Safe Operations in Challenging Environments:

Thanks to its fully autonomous 3D obstacle avoidance system and robust IPX6K-rated construction, the Agras T40 excels in environments with complex terrain or unpredictable weather. This makes it suitable for operators who require reliable performance and minimal downtime, even in adverse conditions.

These scenarios highlight the Agras T40’s versatility, intelligence, and ruggedness—qualities essential for driving productivity and sustainability in modern agriculture.

Conclusion

The Agras T40 by SZ DJI TECHNOLOGY CO., LTD. stands at the forefront of agricultural drone technology, combining autonomous intelligence, robust wireless connectivity, and modular hardware design to address the evolving needs of professional operators. Its FCC certification under FCC ID SS3-T40A2112 affirms its compliance with U.S. regulatory standards, ensuring both safety and legal operability. With advanced features like 3D obstacle avoidance, high payload capacity, and precision mapping, the Agras T40 is poised to play a pivotal role in the future of precision agriculture—delivering efficiency, reliability, and innovation to the field.