Introduction

The DJI Ronin-MX is a professional-grade camera stabilization gimbal designed to meet the demanding needs of filmmakers and content creators. Engineered for both ground and aerial cinematography, it enables seamless, stabilized footage whether mounted on a vehicle, jib, wirecam, or DJI’s Matrice 600 aerial platform. With its robust brushless stabilization, intelligent power management, and versatile connectivity, the Ronin-MX stands out as a workhorse for dynamic, high-mobility shooting scenarios.

A crucial milestone in the Ronin-MX’s journey to market is its FCC certification under FCC ID SS3-RM101604. While the grant date is not specified, this certification signifies that the device meets stringent U.S. standards for radio frequency (RF) emissions and electromagnetic compatibility. For filmmaking professionals, this means the Ronin-MX is legal to sell and operate in the U.S., ensuring both regulatory peace of mind and reliable wireless performance on set.

In this in-depth analysis, we’ll dissect the Ronin-MX’s key features, technical specifications, wireless capabilities, and regulatory credentials. We’ll also take you inside the device with a component-level teardown, revealing the engineering decisions that make this gimbal a staple in the professional toolkit.

Key Features & Specifications

The DJI Ronin-MX is purpose-built for versatility, stability, and seamless integration into modern filmmaking workflows. Its feature set and technical specifications reflect DJI’s commitment to performance, reliability, and user flexibility.

Key Features

- Multiple Accessory Ports

-

CAN, USB, P-TAP, Lightbridge, GCU: These ports allow for advanced accessory integration, data transfer, power distribution, and real-time video transmission. This flexibility makes the Ronin-MX compatible with a wide range of third-party and DJI components, expanding creative possibilities.

-

Flexible Mounting Options

-

Supports DJI Matrice 600, vehicles, jibs, and wirecam rigs: The Ronin-MX is engineered for adaptability, enabling handheld, vehicle-mounted, and aerial operation. Its modularity means it can handle diverse shooting environments—from car chases to drone flights—without compromising stabilization.

-

Remote Control (2.4 GHz)

-

Included remote for wireless operation: The integrated remote, operating in the 2.4 GHz band, allows for precise gimbal control over long distances, crucial for coordinated multi-operator shoots.

-

Wide Camera Compatibility

-

Accommodates a broad range of camera bodies: The gimbal’s adjustable mounting system ensures support for various camera sizes, making it suitable for everything from DSLRs to compact cinema cameras.

-

Bluetooth Connectivity & DJI Assistant App

-

Seamless configuration and tuning: Bluetooth support enables quick setup and fine-tuning via the DJI Assistant App, streamlining workflow and allowing on-the-fly adjustments.

-

DJI Intelligent Battery

-

Advanced power management and safety: The 1580 mAh, 14.4 V LiPo battery features built-in protection and delivers up to three hours of runtime. The battery system’s smart circuitry ensures safe charging, discharging, and real-time monitoring.

-

Brushless Gimbal Stabilization with IMU Feedback

- Precision stabilization: Utilizing a brushless motor system and integrated IMU (Inertial Measurement Unit), the Ronin-MX actively corrects for angular disturbances, reducing vibration to less than 0.02˚ of translated movement. This results in buttery-smooth footage even in high-action scenarios.

Technical Specifications

- Battery

- Capacity: 1580 mAh

- Voltage: 14.4 V (LiPo)

- Maximum Runtime: Up to 3 hours

- Charging/Discharging Environment Relative Humidity: <80%

-

Operating Temperature: 14° to 104°F (-10° to 40°C)

-

Camera Mounting

- Maximum Camera Depth from Center of Gravity on Base Plate: 120 mm

-

Wide camera compatibility ensures versatility for different production needs.

-

Connectivity

- Bluetooth: Present (enables app-based configuration)

-

Multiple accessory and data ports for integration with auxiliary equipment.

-

Stabilization Performance

- Angular Vibration Reduction: <0.02˚

-

High-precision motor control for professional-grade stabilization.

-

Environmental Tolerance

- Operating Environment: 14° to 104°F (-10° to 40°C)

- Relative Humidity: <80% for safe charging/discharging

These specifications underscore the Ronin-MX’s focus on reliability, flexibility, and professional-grade performance, making it an ideal solution for dynamic, on-the-move filmmaking.

Operating Frequencies

The Ronin-MX, under FCC ID SS3-RM101604, operates on the following frequencies as detailed in its FCC filings:

| Frequency Range (GHz) | Output Power (mW) | FCC Rule Part |

|---|---|---|

| 2.473 | 10.8 | 15CCC2.1 |

| 12.402–2.48 | 1 | 15CCC2.22.415 |

These frequencies encompass the widely used 2.4 GHz ISM band—common for remote control and Bluetooth communications—ensuring robust wireless performance and regulatory compliance for both control and configuration functions.

Technology Deep Dive

The Ronin-MX leverages a combination of advanced wireless technologies to deliver seamless user experiences in demanding production environments. Its primary RF operations are centered in the 2.4 GHz ISM band, supporting both remote gimbal control and Bluetooth-based configuration via the DJI Assistant App.

Operating in this frequency range offers several advantages:

– Performance & Range: The 2.4 GHz band provides a reliable balance between range and interference resistance, making it ideal for both direct remote control and wireless device pairing in on-location shoots.

– Interference Considerations: As the 2.4 GHz spectrum is shared with Wi-Fi and other consumer devices, DJI’s engineering incorporates robust error correction and frequency agility to mitigate interference—crucial in crowded RF environments.

– Power Consumption: The Ronin-MX’s wireless modules are designed for low-power operation, contributing to the device’s impressive three-hour battery life, even during continuous control and configuration sessions.

While the FCC equipment class for this device is listed as “None,” the test reports confirm compliance with all relevant Part 15 rules, ensuring safe, interference-free operation alongside other wireless equipment commonly found on professional sets.

In-Depth Internal Component Analysis / Teardown

Main Gimbal Control PCB: Precision Motor Management

The circular main PCB showcases DJI’s expertise in high-density, real-time motor control. At its heart, a large TQFP/LQFP IC likely serves as the main microcontroller or a dedicated motor driver, orchestrating the gimbal’s stabilization algorithms. Flanking this are several SOIC-8 or QFN-8 ICs, likely forming a three-phase motor drive circuit—essential for precise brushless motor actuation. The board’s robust power management is evident from large ceramic capacitors and inductors, ensuring clean voltage rails for sensitive control electronics. Differential signal routing and extensive ground pours minimize noise, critical for accurate stabilization. The board’s circular, multilayer design is mechanically and electrically optimized for integration within the gimbal, reflecting a sophisticated approach to both signal integrity and space efficiency.

Arm Section Control Board: Modular Motor & Sensor Interface

Inside the Ronin-MX’s arm section, the circular PCB is engineered for modularity and durability. A prominent SOIC-8 IC, likely a MOSFET or motor driver, works alongside SOT-23 packages—possibly voltage regulators or signal transistors—to deliver precise motor control and sensor interfacing. The board features multiple connectors, including a white JST-style connector for sensor data and a larger multi-pin interface for power or motor phases. Large ceramic capacitors ensure local power decoupling, while the robust mounting and strain relief reflect DJI’s focus on reliability under mechanical stress. The absence of RF components reinforces this board’s dedicated role in distributed motor and sensor control, ensuring smooth, coordinated gimbal movement.

Cylindrical Module PCB: CAN Bus & Distributed Control

The exposed PCB within the cylindrical module demonstrates DJI’s commitment to distributed, networked control. CANL and CANH labeling identify a CAN bus transceiver, enabling robust, low-latency communication between gimbal subsystems. Multiple JST-style connectors provide power and data pathways, while local capacitors and possible inductors maintain signal integrity and power stability. The compact, multilayer layout fits precisely within the cylindrical housing, emphasizing modularity and serviceability. Clear labeling and test points support streamlined manufacturing and maintenance, while the absence of RF components signals a strict focus on control and communication functions.

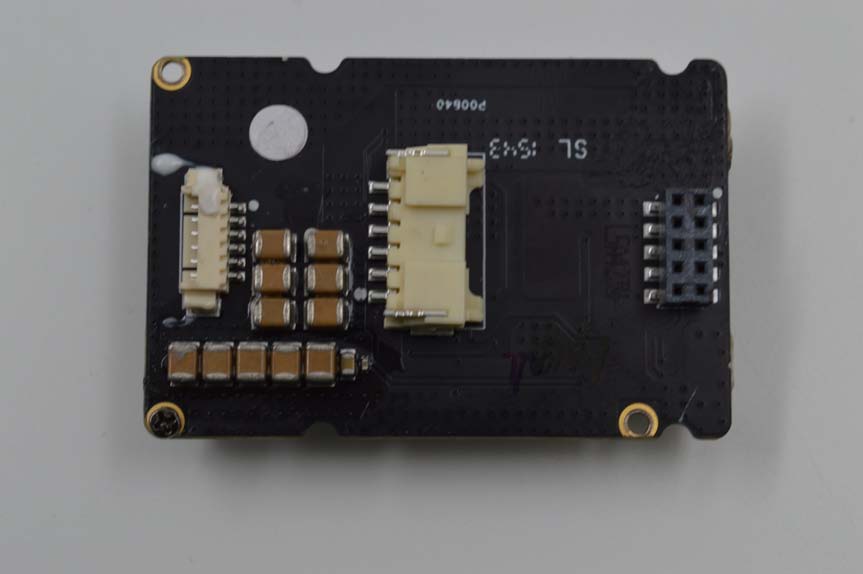

Secondary PCB Face: Interconnection & Power Distribution

This PCB face is designed for connectivity rather than processing, featuring multiple large connectors for ribbon cables and modular interfaces. The array of SMD capacitors and clear ground pours indicate a focus on power distribution and signal breakout, supporting the Ronin-MX’s modular architecture. The lack of major ICs suggests this is a secondary side or daughterboard, handling robust interconnection between the main controller, power domains, and peripheral modules. The clean soldering and organized layout ensure both reliability and ease of assembly, hallmarks of DJI’s professional build standards.

Power & Communication Node: CAN, SWD, and Power Management

This circular PCB serves as a power and communication hub within the Ronin-MX system. Small SOT-23 ICs—likely MOSFETs or power management chips—are arranged near connectors labeled for 12V, 3.3V, CAN bus, and SWD programming/debug lines. The board’s design facilitates both power delivery and fast, reliable communication across the gimbal’s distributed architecture. The use of multiple ground planes, test points, and robust connector mounting ensures durability and ease of maintenance. The absence of major processors or RF elements confirms this board’s specialized role as a node for power and data distribution.

Main System PCB: Modular Control & Potential RF Integration

A key system PCB reveals a dense arrangement of QFP and QFN ICs, likely including the main MCU and motor driver chips required for real-time stabilization. Supporting components such as op-amps, voltage regulators, and logic shifters are distributed across clearly defined analog and digital sections. The board’s gold ENIG finish and via-in-pad construction highlight an emphasis on durability and signal integrity. Of particular note is the presence of a thin orange coaxial cable—potentially an RF antenna feed for 2.4 GHz wireless control or telemetry—showcasing the integration of wireless capabilities within the main system board. The modular connector layout supports easy assembly and repair, aligning with the needs of field technicians and professional users.

Regulatory Insights & FCC Filing

The FCC ID SS3-RM101604 is the official certification for the DJI Ronin-MX, confirming that the device meets U.S. FCC Part 15 standards for electromagnetic interference (EMI) and radiofrequency (RF) emissions. Although the grant date is listed as “None,” the registration through FCC.gov means the Ronin-MX is legal for sale and operation in the United States, providing assurance to both resellers and end users regarding compliance.

FCC filings for such devices typically include:

– Test Reports: Detailed measurements of RF output, EMI, and EMC performance.

– User Manuals: Comprehensive guides for safe operation, assembly, and maintenance.

– Internal & External Photographs: Documentation of the device’s construction for regulatory review.

– Schematics and Block Diagrams: Technical blueprints outlining circuit operation and RF pathways.

From the User Manual (User-Manual-2982266.pdf), key insights include step-by-step instructions for assembly, balancing, and configuration, as well as critical safety advisories to ensure reliable and secure operation in various environments. The manual emphasizes the importance of proper power management, correct installation of accessories, and adherence to recommended operating conditions—reflecting DJI’s focus on both user experience and compliance with regulatory standards.

Potential Use Cases & Target Audience

Designed for filmmaking professionals, the Ronin-MX’s advanced stabilization and flexible mounting options unlock a range of creative possibilities:

-

Dynamic Vehicle Rigs: Mounted on cars, motorcycles, or even wirecams, the Ronin-MX delivers rock-steady shots during high-speed chases or complex tracking sequences, enhancing production value for commercials, music videos, and feature films.

-

Aerial Cinematography: When paired with the DJI Matrice 600 drone, the Ronin-MX provides stabilized, 360-degree continuous rotation and HD video downlink capabilities, enabling breathtaking aerial shots for documentaries, action films, and live broadcasts.

-

Versatile Studio & Field Work: Whether used handheld, on a jib, or as part of a custom rig, the gimbal’s wide camera compatibility and intelligent battery system ensure extended, uninterrupted shooting—ideal for event coverage, sports, and independent filmmaking.

These scenarios illustrate the Ronin-MX’s role as a multipurpose stabilization platform, trusted by professionals who demand reliability, precision, and adaptability in the field.

Conclusion

The DJI Ronin-MX, certified under FCC ID SS3-RM101604, exemplifies the intersection of robust engineering, regulatory compliance, and professional usability. Its advanced stabilization, modular architecture, and wireless capabilities make it a go-to solution for filmmakers seeking uncompromising performance across ground and aerial platforms. The detailed internal analysis reveals a meticulous design approach that prioritizes reliability, serviceability, and integration with modern production workflows. As wireless standards and filmmaking demands continue to evolve, the Ronin-MX stands as a testament to DJI’s leadership in the pro gimbal market—delivering both technical excellence and peace of mind through FCC-certified compliance.